Académique Documents

Professionnel Documents

Culture Documents

Coagulation: Waters Requiring Treatment

Transféré par

Ngoni MukukuDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Coagulation: Waters Requiring Treatment

Transféré par

Ngoni MukukuDroits d'auteur :

Formats disponibles

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng.

, NUST

28/09/2006

3.1

Chapter 3 COAGULATION Treatment processes

Waters requiring treatment Surface waters: streams, rivers, lakes and limited treatment for groundwater Guidelines for the selection of a treatment processes reliability appropriate technology, availability of equipment, construction materials and chemicals economic viability pilot testing water quality of raw and treated water standards/ guidelines to be satisfied availability of skilled and unskilled manpower to design and operate the plant Process Fig. 3.1 summarises the treatment processes for surface waters in their sequence and some stages can be omitted (the dashed arrows). Groundwater is generally of high quality and does not require treatment. In exceptional case, treatment may be necessary and the stages of treatment for groundwater are shown in Fig.3.2.

Screening

Pre-settlement

Settlement

Coagulation

Distribution Tertiary treatment

Flocculation

Disinfection

Filtration

Fig. 3.1

Schematic illustration of treatments stages for surface waters

1

Chapter 5 Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.2

Pre-settlement It is the first stage in water treatment for highly turbid waters and besides the settlement of solids there is a great reduction in bacteria. It also attenuates sudden fluctuations in river water quality. Prolonged storage should be discarded because it result in growth of algae and this will increase the treatment costs.

Fig. 3. 2:

Schematic illustration of groundwater treatment

(a) Disinfection and fluoridation (b) Iron and manganese removal (c) Precipitation softening

Sedimentation alone will not be effective for small suspended particles less than 50m. Coagulation and flocculation will result in bigger particles with higher settling velocities, which can settle down due to gravity in sedimentation tanks. Suspension Dispersion of solid particles in liquid Colloids Small particle 1 to 200x10-9m and are called stable if they do not join together and hence form stable suspension. Colloids do not join together because: 2

Chapter 5

Fig.2

Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.3

molecular arrangement within crystals loss of atoms due to abrasion of surfaces they are small and therefore have a large surface to volume ration because of the large surface area, colloidal particles accumulate a net negative charge at the surface-water interface and hence colloidal particles are negatively charged in water the net negative electrical charges at the particle surface result in preferential adsorption of ions. The first layer of cations (+ve) is attracted to the negatively charged surface to form the Stern layer and will travel with it (Fig. 3.3, 3.4 and 3.5). The Stern layer produces a rapid drop in potential. The net charge (+ve) is strong at the bound layer (Stern layer) and decreases exponentially with distance from the colloid (Fig. 3.3). the surface charge will contribute to stability and there will be no coalescence due to the repelling by the like charge.

Fig.3.3

Guoy-Stern colloidal model

Source: Water Supply, Terence McGee

Floc Collection of colloidal particles held together and has density closer to water Coagulation A process of making conditions favourable for colloidal particles to join together to form flocs. It is a process directed towards destabilisation of the colloidal particles. Flocculation The growth of flocs

3

Chapter 5 Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.4

Fig.3.4:

Charge system in colloidal suspension

Source: Environmental Engineering, Peavy (1998)

Coagulation

When two colloids come in close proximity, thee are two forces acting on them: electrostatic potential Van der Waals force Electrostatic potential created by counter ions surrounding each colloid. It is a repelling force and hence colloids will repel each other. Van der Waals force It supports contact and is an attraction force. It is inversely proportional to the 6th power of the distance between particles. It decreases exponentially with distance (Fig. 3.5). It decreases more rapidly than the electrostatic potential (Fig. 3.5). It is more attractive force at close distances and repulsive at greater distances It become attractive only after passing through a maximum net repulsive force called the energy barrier at some distance between the colloids. Once the forces become attractive, contact between the particles takes place. A means of overcoming the energy barrier must be available before agglomeration of particles can occur. Some of the means of overcoming this energy barrier are outlined hereafter:

4

Chapter 5 Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.5

Brownian movement random movement of smaller colloids because of molecular bombardment may produce enough momentum for particles to overcome the energy barrier for the colloidal particles to collide. Mechanical agitation mechanical agitation of the water may impart enough momentum to larger particle to move them across the energy barrier

The above processes are too slow to be efficient in water treatment and therefore other means of agglomeration must be used. Generally this is accomplished by chemical coagulation with aluminium sulphate (Al2(SO4)3 and ferric chloride (FeCl3).

Fig. 3.5:

Force fields between colloids of like charge

Source: Environmental Engineering, Peavy (1998)

Mechanisms of coagulation ionic layer compression adsorption and charge neutralisation sweep coagulation inter-particle bridging 5

Chapter 5 Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.6

Ionic layer compression A higher negative charge concentration compresses layers composed of +ve ions towards the surface of colloid and if this layer is sufficiently compressed, then Van der Waals force will become predominant producing a net attractive force and removing the energy barrier. Adsorption and charge neutralisation It is through the use of aluminium sulphate and ionisation of the aluminium sulphate in water produces sulphate anions and aluminium cations:

Al 2 (S 0 4 )3 S 0 2 + Al 3+ 4

Al 3+ react immediately with water to form a variety of aquometallic ions and hydrogen, a process called hydrolysis

Hydrolysis Al 3+ + H 2 O AlOH 2+ + H + Al 3+ + 2 H 2 O Al (OH 2 ) + 2 H +

+

7Al3+ +17H2O Al7 (OH ) +17H + 17

4+

Al3+ + 3H2O Al(OH)3 + 3H +

aquometallic ions

the aquometallic ions become part of the ionic cloud surrounding the colloid i.e. large, insoluble positively charged particles they are adsorbed onto the surface of the colloid where they neutralise the surface of the charge once the surface charge has been neutralised, the ionic cloud dissipates and the electrostatic potential disappears and contact occurs overdosing with a coagulant can result in restabilising the suspension.

Sweep coagulation From the above equations, the last product formed in the hydrolysis of Al (SO4)3 is aluminium hydroxide (Al (OH)3.

The aluminium hydroxide forms gelatinous flocs that are heavier than water and settle by gravity. The colloids may become entrapped in a floc as it is formed or may become enmeshed by its sticky surface as the flocs settle. The process by which colloids are swept from the suspension in this manner is known as sweep coagulation. 6

Chapter 5

Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.7

Inter-particle bridging Synthetic polymers may be used in addition to the stated coagulants. Such polymers are linear or branched and have a surface which is highly reactive. They have adsorption forces and the colloids may get attached to these surfaces to form polymer-colloid, and the several polymer-colloids may become enmeshed and grow into bigger particles, which can settle (Fig. 3.6). Also synthetic polymers may carry a negative, positive charge or can be neutral, metallic polymers from aluminium and ferric iron carry positive charge. Hence the negative synthetic polymers will help in the attraction of colloids.

Fig. 3.6

Inter-particle bridging by polymers

Source: Environmental Engineering, Peavy (1998)

Conditions for optimum formulation of flocs, the pH should be between 6-8. an optimum dosage of coagulant is required and is determined by the jar test too high or too low dosages are ineffective 7

Chapter 5 Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.8

acid is formed when alum reacts with water, so it is necessary to maintain the desired pH range. To achieve a satisfactory final pH, its usually necessary to add an alkali and rapid mixing will be important. hydrated lime is often added for pH correction on cost grounds

Disadvantage of lime low solubility i.e. needs constant agitation blocks pipes As an alternative sodium carbonate (washing soda) is used or sodium hydroxide (caustic soda). But caustic soda is more expensive and dangerous Coagulant aids Poly-ectrolytes (polymers); They make flocs larger, tougher and denser. They have longer molecules with charged site which link small flocs together (inter-particle bridging). There are three groups: cationic, anionic and non ionic (ampholytic). Activated silica It is prepared from sodium silicate and it has the following benefits: increases the rate of coagulation and flocculation reduces coagulant dosage broaden pH range for effective coagulation produces large and tougher floc particles increases removal of both colour and colloidal particles Purified clays May be added to water with low turbidity to add weight to the flocs and reduce coagulant requirement e.g. bentonite clay. Jar test Selection of an appropriate coagulant is through experiments and taking into consideration costs, sludge management and the Jar test is mostly used. Overdosing may lead to filter clogging. The required dose cannot be calculated because water chemistry is too complex. The right dose is found by comparing the effects of different doses of coagulant on water, and choosing the lowest dose that gives a satisfactory result (Jar test). If too low a dose is used, little treatment is achieved and money is wasted, and a high residual goes into supply. If too much is dosed, the turbidity removal is below the optimum. This result in the filters clogging quickly and a high residual goes into supply and this is a health hazard. Procedure normally six jars are used one for control (Fig. 3.7) the other five jars are dosed with different doses of aluminium sulphate initial turbidity, pH and alkalinity of sample should be known one minute flash mix at 200 rpm 8

Chapter 5 Coagulation

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.9

this is followed by 10 to 30 min flocculation period at between 20 to 70 rpm (i.e. water is being allowed to settle). the time of appearance of the flocs, the size of floc and the turbidities of the treated water should be noted the jar with the minimum dose but with the lowest final turbidity gives the optimum dose e.g. beaker 3 in Table 3.1 gives the optimum dose of 5ml of aluminium sulphate solution. a jar test is performed every shit Jar test results to determine optimum dosage 2 2 6 3 5 2 4 8 2 5 15 4 6 25 9

Tabl1 3.1:

Beaker 1 Dose, ml 1 Final turbidity (NTU) 17

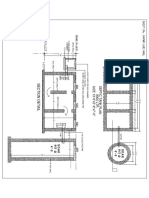

Fig.3.7:

Schematic illustration of a jar-test equipment

Chemo-feeders This is the equipment used to introduce the coagulant in the chamber. coagulant can be dosed by: gravity dosing pumps 9

Chapter 5 Coagulation

The

cmutsvangwa: Water Quality & Treatment: Dept. of Civil & Water Eng., NUST

28/09/2006

3.10

In small plants, and when the power requirements or degree of complexity of the plat are to be kept to a minimum, the coagulant can be dosed by gravity. The tank in which the coagulant is mixed and stored should be at a high level to allow the prepared solution to flow under gravity through a flow controller. A float valve can also be used in gravity systems to maintain head constant.

References 1. Peavy H. S., Rowe D. R., and Tchobanoglous G., (1985), Environmental Engineering, McGraw Hill, New York, USA 2. Terrence McGhee Water supply

10

Chapter 5 Coagulation

Vous aimerez peut-être aussi

- Particle Deposition and Aggregation: Measurement, Modelling and SimulationD'EverandParticle Deposition and Aggregation: Measurement, Modelling and SimulationPas encore d'évaluation

- Introduction to Applied Colloid and Surface ChemistryD'EverandIntroduction to Applied Colloid and Surface ChemistryPas encore d'évaluation

- Coagulation and FiltrationDocument49 pagesCoagulation and Filtrationmuhammednumaan235Pas encore d'évaluation

- Coagulation and FlocculationDocument36 pagesCoagulation and Flocculationyovanny familianPas encore d'évaluation

- Lecture 10 &11 Water TreatmentDocument33 pagesLecture 10 &11 Water Treatmentanantlakhotiya.11Pas encore d'évaluation

- Chapter 5Document9 pagesChapter 5selambante shiferawPas encore d'évaluation

- Electrochemical Water Softening: Principle and ApplicationDocument14 pagesElectrochemical Water Softening: Principle and ApplicationThao DophuongPas encore d'évaluation

- PPW730 - Chapter 6 Summary - Noor Mohammed AnterDocument12 pagesPPW730 - Chapter 6 Summary - Noor Mohammed AnterNoor AnterPas encore d'évaluation

- WT Chapter 4Document21 pagesWT Chapter 4tedy yidegPas encore d'évaluation

- Water Treatment SystemDocument36 pagesWater Treatment Systempavank8Pas encore d'évaluation

- 2018 تقييم معالجة المياه المغناطيسية على مقياس تشكيل الكالسيوم في أغشية التناضح العكسيDocument6 pages2018 تقييم معالجة المياه المغناطيسية على مقياس تشكيل الكالسيوم في أغشية التناضح العكسيMUHAMMED ALSUVAİDPas encore d'évaluation

- Lecture 3 - Coagulation and FlocculationDocument93 pagesLecture 3 - Coagulation and FlocculationChuah Chong YangPas encore d'évaluation

- Pre Treatment PresentationDocument183 pagesPre Treatment PresentationHamza RaoPas encore d'évaluation

- Lecture 5. Coagulation and FlocculationDocument72 pagesLecture 5. Coagulation and FlocculationFatima Al-Doski100% (1)

- Clarification of WaterDocument41 pagesClarification of WaterpicefeatiPas encore d'évaluation

- Super PlasticizerDocument7 pagesSuper PlasticizerReshmita PallaPas encore d'évaluation

- Chapter 1 2Document38 pagesChapter 1 2Hady JawadPas encore d'évaluation

- Water Treatment System - ReferenceDocument115 pagesWater Treatment System - Referencemuhammednumaan235Pas encore d'évaluation

- Super-Absorbant Polymers PDFDocument13 pagesSuper-Absorbant Polymers PDFGayathri SelvarajPas encore d'évaluation

- 10-Coagulation and PrecipitationDocument34 pages10-Coagulation and PrecipitationAnu NPas encore d'évaluation

- SedimentationDocument9 pagesSedimentationسراء حيدر كاظمPas encore d'évaluation

- Coagulation FlocculationDocument59 pagesCoagulation FlocculationAl Patrick Dela CalzadaPas encore d'évaluation

- A Quantitative Comparison Between Chemical Dosing and ElectrocoagulationDocument16 pagesA Quantitative Comparison Between Chemical Dosing and Electrocoagulationlusi.meliyanaPas encore d'évaluation

- Jawaban Soal Liquid Dielectric Santos EdunDocument8 pagesJawaban Soal Liquid Dielectric Santos EdunLuthfi Arif Fadillah100% (1)

- 04-Coagulation & Flocculation, Dec. 07, 2017Document22 pages04-Coagulation & Flocculation, Dec. 07, 2017jantskiePas encore d'évaluation

- Scaling Assessment, Inhibition and Monitoring of Geothermal WellsDocument13 pagesScaling Assessment, Inhibition and Monitoring of Geothermal WellsmuryaspPas encore d'évaluation

- Waste Water TreatmentDocument90 pagesWaste Water TreatmentAnonymous 90mJSn2xPas encore d'évaluation

- ملزمة صحية 4 ثالث مدنيDocument10 pagesملزمة صحية 4 ثالث مدنيAbdulaziz hazemPas encore d'évaluation

- Engineered Systems For Water PurificationDocument3 pagesEngineered Systems For Water PurificationColdWinterKid50% (2)

- Desalter OperationDocument11 pagesDesalter OperationBhumika Chawla80% (5)

- Sludge Conditioning: Mechanisms To Condition The SludgeDocument9 pagesSludge Conditioning: Mechanisms To Condition The Sludgeashoori79Pas encore d'évaluation

- Zeta Potential - An Introduction in 30 MinutesDocument6 pagesZeta Potential - An Introduction in 30 MinutesFA AyPas encore d'évaluation

- Lecture 3 Coagulation and Flocculation PDFDocument53 pagesLecture 3 Coagulation and Flocculation PDFMichael MedinaPas encore d'évaluation

- Ion Exchanger Lab ReportDocument36 pagesIon Exchanger Lab Reporthinman714Pas encore d'évaluation

- Advanced Cooling Tower TreatmentDocument6 pagesAdvanced Cooling Tower TreatmentFawaaz KhurwolahPas encore d'évaluation

- Desalination: Kristen S. Brastad, Zhen HeDocument6 pagesDesalination: Kristen S. Brastad, Zhen HeThao DophuongPas encore d'évaluation

- Coagulation and FlocculationDocument41 pagesCoagulation and FlocculationaquibzafarPas encore d'évaluation

- 10 Study of The Electrocoagulation Process..Document7 pages10 Study of The Electrocoagulation Process..Martin FernandezPas encore d'évaluation

- Water Treatment Part 2 Coagulation PDFDocument7 pagesWater Treatment Part 2 Coagulation PDFDr-Manoj GargPas encore d'évaluation

- Subramani - Numerical Analysis On Horizontal Jet FlocculatesDocument6 pagesSubramani - Numerical Analysis On Horizontal Jet Flocculatesalang_businessPas encore d'évaluation

- Coagulation & Flocculation in Water TreatmentDocument131 pagesCoagulation & Flocculation in Water TreatmentAli HassenPas encore d'évaluation

- Coagulation/ Floccuation For Wastewater Treatment: I N Dustrial Wa Ste & Ma N Agement Con T RolDocument39 pagesCoagulation/ Floccuation For Wastewater Treatment: I N Dustrial Wa Ste & Ma N Agement Con T RolKyle Dela CruzPas encore d'évaluation

- Tugas - TTT - A - Nabila Isnaini Putri - 1910953012Document6 pagesTugas - TTT - A - Nabila Isnaini Putri - 1910953012Fajar AsheqafPas encore d'évaluation

- Coagulación Floculación PresentaciónDocument66 pagesCoagulación Floculación PresentaciónRicardo Castillo VegaPas encore d'évaluation

- Introduction To Water Clarification: Questions & AnswersDocument16 pagesIntroduction To Water Clarification: Questions & AnswersElvin EndozoPas encore d'évaluation

- Micro Silica and Placement PropertiesDocument11 pagesMicro Silica and Placement PropertiesChris BothaPas encore d'évaluation

- Growth and Structure of Flocs Following Ele - 2016 - Separation and PurificationDocument7 pagesGrowth and Structure of Flocs Following Ele - 2016 - Separation and PurificationBrett Gonzalez CardenasPas encore d'évaluation

- Coagulation and Flocculation For StudentsDocument21 pagesCoagulation and Flocculation For Studentsm saadullah khanPas encore d'évaluation

- Q 1 - Principle, Procedure, Advantage, Limitation and Application of Magnetic Particle Test?Document10 pagesQ 1 - Principle, Procedure, Advantage, Limitation and Application of Magnetic Particle Test?Alpesh PanchalPas encore d'évaluation

- CoagulationDocument104 pagesCoagulationAnnisa IstiqomahPas encore d'évaluation

- Michaels Bolger Settling Rates and Sediment Volumes of Flocculated Kaolin Suspensions PDFDocument10 pagesMichaels Bolger Settling Rates and Sediment Volumes of Flocculated Kaolin Suspensions PDFpixulinoPas encore d'évaluation

- Mohd Nasrullah Et Al., (2020) Crecimiento Del FlocDocument11 pagesMohd Nasrullah Et Al., (2020) Crecimiento Del FlocAndrea Carolina Cubillos OnatePas encore d'évaluation

- Charging and Discharging of Single Colloidal Particles at Oil/water InterfacesDocument7 pagesCharging and Discharging of Single Colloidal Particles at Oil/water InterfacesAmirPas encore d'évaluation

- DarshitDocument18 pagesDarshitDevashish JoshiPas encore d'évaluation

- Chapter 4Document38 pagesChapter 4Anonymous T7vjZG4otPas encore d'évaluation

- Lecture 6 (AHVE)Document24 pagesLecture 6 (AHVE)SAJEEDPas encore d'évaluation

- Cohesive Sediments in Open Channels: Erosion, Transport and DepositionD'EverandCohesive Sediments in Open Channels: Erosion, Transport and DepositionPas encore d'évaluation

- Deep Marine Systems: Processes, Deposits, Environments, Tectonics and SedimentationD'EverandDeep Marine Systems: Processes, Deposits, Environments, Tectonics and SedimentationPas encore d'évaluation

- General Strategies For Global BrandsDocument10 pagesGeneral Strategies For Global BrandsSteffen KurniawanPas encore d'évaluation

- Sample Project PlanDocument21 pagesSample Project PlanNgoni MukukuPas encore d'évaluation

- 01 Teach Yourself Complete Afrikaans (2010)Document370 pages01 Teach Yourself Complete Afrikaans (2010)Ngoni Mukuku100% (7)

- Chapter 4 Accruals and PrepaymentsDocument12 pagesChapter 4 Accruals and PrepaymentsNgoni MukukuPas encore d'évaluation

- Use of DiscreteDocument8 pagesUse of DiscreteamancivilPas encore d'évaluation

- Chapter 3 Double Entry BookkeepingDocument16 pagesChapter 3 Double Entry BookkeepingNgoni Mukuku100% (2)

- 1effect of Fly AshDocument2 pages1effect of Fly AshNgoni MukukuPas encore d'évaluation

- Brave Brands AccountingDocument6 pagesBrave Brands AccountingNgoni MukukuPas encore d'évaluation

- Externality AssignmentDocument8 pagesExternality AssignmentNgoni MukukuPas encore d'évaluation

- Chapter 2 Accounting Concepts and Principles PDFDocument12 pagesChapter 2 Accounting Concepts and Principles PDFAnonymous F9lLWExNPas encore d'évaluation

- IPMZ Higher Dip Assignment Booklet April 2013Document15 pagesIPMZ Higher Dip Assignment Booklet April 2013Ngoni MukukuPas encore d'évaluation

- By Doug Batchelor Gift of Tongues by Hal Steenson: An Amazing FactDocument11 pagesBy Doug Batchelor Gift of Tongues by Hal Steenson: An Amazing FactNgoni MukukuPas encore d'évaluation

- Commodity MarketingDocument21 pagesCommodity MarketingNgoni MukukuPas encore d'évaluation

- Famous Honda BusinessDocument20 pagesFamous Honda BusinessNgoni MukukuPas encore d'évaluation

- Developing A Global Marketing Vision Through Marketing ResearchDocument3 pagesDeveloping A Global Marketing Vision Through Marketing ResearchNgoni MukukuPas encore d'évaluation

- Scope and Challenge of International MarketingDocument6 pagesScope and Challenge of International MarketingNgoni MukukuPas encore d'évaluation

- Agricultural PoliciesDocument8 pagesAgricultural PoliciesNgoni MukukuPas encore d'évaluation

- The Entrepreneurial ProcessDocument13 pagesThe Entrepreneurial ProcessNgoni Mukuku100% (1)

- Marketing Mix 1 4psDocument21 pagesMarketing Mix 1 4psNgoni MukukuPas encore d'évaluation

- Chapter 9 Agribusiness ConsolidationDocument3 pagesChapter 9 Agribusiness ConsolidationNgoni MukukuPas encore d'évaluation

- Civil Technology - Topic 4Document14 pagesCivil Technology - Topic 4Zyla Balandra SorillaPas encore d'évaluation

- Water Supply Code of Australia WSA 03 - 2011-3.1: Melbourne Retail Water Agencies EditionDocument74 pagesWater Supply Code of Australia WSA 03 - 2011-3.1: Melbourne Retail Water Agencies EditionSol RogowskiPas encore d'évaluation

- Master Plan To GW Recharge 2020 - 2Document197 pagesMaster Plan To GW Recharge 2020 - 2Wrd Arunachal PradeshPas encore d'évaluation

- Water Society and SustainabilityDocument9 pagesWater Society and SustainabilityAlok SharmaPas encore d'évaluation

- Colwood Creek Microhydro Proposal (2021)Document18 pagesColwood Creek Microhydro Proposal (2021)Jessica TruongPas encore d'évaluation

- Manual of Septic Tank PracticeDocument106 pagesManual of Septic Tank PracticeFitri ArdhianPas encore d'évaluation

- Ken Betwa ReportDocument161 pagesKen Betwa ReportNazakat Hussain100% (1)

- KMC Bricks Sewer QuotationDocument1 pageKMC Bricks Sewer QuotationKalyan GainePas encore d'évaluation

- Septic Tank DetailDocument1 pageSeptic Tank DetailVishnu PrajapatiPas encore d'évaluation

- 4 Turbinat HidraulikeDocument24 pages4 Turbinat HidraulikeAltin Dorri33% (3)

- MonjardinDocument58 pagesMonjardinCesar MalenabPas encore d'évaluation

- Orden de Cumplimiento de EPA Contra ALV DevelopmentDocument14 pagesOrden de Cumplimiento de EPA Contra ALV DevelopmentEl Nuevo DíaPas encore d'évaluation

- Calc FormulaDocument1 pageCalc FormulaVaibhav PathakPas encore d'évaluation

- Open Ended Lab: Environmental Engineering-I LabDocument9 pagesOpen Ended Lab: Environmental Engineering-I LabSaroosh ul Musatafa CheemaPas encore d'évaluation

- Site Selection For Drinking-Water Pumping Boreholes Using A Fuzzy Spatial Decision Support System in The Korinthia Prefecture, SE GreeceDocument14 pagesSite Selection For Drinking-Water Pumping Boreholes Using A Fuzzy Spatial Decision Support System in The Korinthia Prefecture, SE GreeceAndreas AntonakosPas encore d'évaluation

- Chapter 1Document51 pagesChapter 1KHA120096 StudentPas encore d'évaluation

- Nalanda Non Residential Specifications Part II ServicesDocument325 pagesNalanda Non Residential Specifications Part II ServicesJothimanikkam SomasundaramPas encore d'évaluation

- Blaser Handling and Care 14.214 CH enDocument4 pagesBlaser Handling and Care 14.214 CH enApriadi HartantoPas encore d'évaluation

- Civil Rainwater HarvestingDocument19 pagesCivil Rainwater HarvestingBabaji SharmaPas encore d'évaluation

- Saes S 010Document19 pagesSaes S 010Cherukunnon Jubu100% (1)

- Community Water and Sanitation: Agency Act, 1998Document6 pagesCommunity Water and Sanitation: Agency Act, 1998Bayari E EricPas encore d'évaluation

- Infrastructure Charges Notice CalculatorDocument1 pageInfrastructure Charges Notice Calculatorabdullah amanullahPas encore d'évaluation

- Buildings Models & Government StrcturesDocument334 pagesBuildings Models & Government StrcturesMuthu Praveen Sarwan100% (1)

- Chapter 4Document41 pagesChapter 4Encik ComotPas encore d'évaluation

- The Otji-Toilet: Different Designs - One SystemDocument6 pagesThe Otji-Toilet: Different Designs - One Systempaula888Pas encore d'évaluation

- Reservoir, It's Purposes, Classification of ReservoirDocument19 pagesReservoir, It's Purposes, Classification of ReservoirFaizan PathanPas encore d'évaluation

- Hatchery Design and ConstructionDocument43 pagesHatchery Design and ConstructionHannah Crystal Agravante-Tampus Capacio-jurolan100% (5)

- Review of KWDT II Final ReportDocument63 pagesReview of KWDT II Final ReportN. SasidharPas encore d'évaluation

- Plumbing Analysis LoakanDocument2 pagesPlumbing Analysis LoakanCaryll BuenaluzPas encore d'évaluation

- 3MDocument46 pages3Mgonzales030189Pas encore d'évaluation