Académique Documents

Professionnel Documents

Culture Documents

IOSR Journals

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IOSR Journals

Droits d'auteur :

Formats disponibles

IOSR Journal of Applied Physics (IOSRJAP)

ISSN 2278-4861 Volume 1, Issue 6 (Sep-Oct. 2012), PP 36-41

www.iosrjournals.org

www.iosrjournals.org 36 | Page

Room Temperature Synthesis of Zinc Zno and Azo Thin Films by

Successive Ionic Layer Adsorption and Reaction Method and Its

Structural and Optical Characterization

1

Ayodeji Oladiran Awodugba,

2

Ayooye Abigael Olawoyin

1,2,

Department of Pure and Applied Physics, Ladoke Akintola University of Technology, P.M.B. 4000,

Ogbomoso , Nigeria

Abstract: ZnO and Al-doped ZnO (AZO) thin films were grown by Successive Ionic Layer Adsorption and

Reaction (SILAR) method on a glass substrate from sodium zincate solution. Doping was achieved with

controlled introduction of aluminum chloride. The technique involved multiple dipping of the substrate in an

aqueous solution of sodium zincate kept at room temperature and a hot water bath kept at 95

o

C in which ZnO

and AZO thin films were synthesized at 0.125M and 0.25M of sodium zincate (Na

2

ZnO

2

) where 100 and 200

dippings were performed for each. The thickness of the layers were determined using Metler PB303 digital

balance and a Radicon 10 mini- diffractometer (XRD) for the structural characterization while optical

characterization was achieved with the use of a Jenway 6405 UV-Vis Spectrophotometer. The results revealed

(002) peaks for ZnO thin films and (112) peaks for AZO thin films. Also the transmittances of the ZnO films

were higher than those of AZO while AZO films have higher absorbance than those of ZnO films. The energy

band gap of both ZnO and AZO were both found to be between 3.71eV and 3.80eV, the values which are slightly

higher than most reported values in literature.

Keywords - Absorbance, AZO, Energy bandgap, SILAR, Thin Films, XRD, ZnO

I. Introduction

ZnO is a wide band gap (~3.3eV) group II-VI thin film semiconductor with a large exciton binding

energy (60meV) which exhibits good piezoelectric, photo electric and optical properties and various usages such

as anti-reflective coatings, gas sensors, transparent electrodes in solar cells [1] and whose study goes far back

many decades and has enjoyed substantial interest in the research community partly because of its large exciton

binding energy which could lead to lasing action based on exciton recombination even above room temperature.

Researchers renewed interest is fueled by availability of high quality substrates and reports of p-type conduction

and ferromagnetic behavior when doped with transition metals [2] .However, pure ZnO thin films lack stability

in terms of thermal edging in air or corrosive environments [3]. Doping with III (p-type) ions such as Aluminum

(Al), Gallium (Ga), Boron (B), etc is used to enhance their structural, optical and electrical properties. Doping is

particularly done to get high transparency, stability and high conductivity. P-type doping using Aluminum was

particularly suitable for this purpose.

The field is also fueled by theoretical predictions and perhaps experimental confirmation of

ferromagnetism at room temperature for potential spintronics applications. [2] (Ozgur et al 2005). ZnO as group

II-VI thin films has a tendency to grow with strong preferential orientation of various kinds of substrates

including glass [4], sapphire [5] and diamond [6]. In order to reduce the strains and dislocation density in

epitaxial ZnO and related films, closely lattice-matched substrates are favoured for growth. Sapphire substrates

are commonly used for ZnO heteroepitaxial growth. Single crystal ZnO films have been grown on sapphire with

a high degree of surface flatness which is essential for device fabrication. Glass was used as a preferred

substrate in this research because of its high availability and low costs.

Researchers have used different physical and chemical techniques to grow both ZnO and in AZO.

Amongst them are sputtering (dc sputtering , rf magnetron sputtering and reactive sputtering which is one of the

most popular growth techniques for early ZnO investigations as compared to sol-gel [7] and chemical vapour

deposition [8]. However, the conventional physical techniques generally produce good quality transparent films

but are very expensive and are difficult to carry out in the industrial level. Chemical deposition techniques on

the other hand, are relatively low cost processes and can be easily scaled up for industrial applications [9].

Among the chemical techniques, chemical bath deposition (CBD) is one of the simplest methods of depositing

semiconductors and ceramic films [10]. It occurs due to substrate maintained in contact with dilute chemical

bath by which film formation of substrate takes place when ionic product (IP) exceeds solubility product (SP)

seems more appropriate than others such as spray pryolysis which is a high temperature process and also with a

disadvantage with inconveniency in availability of choice of suitable precursor solution and its high temperature

Room Temperature Synthesis Of Zinc Zno And Azo Thin Films By Successive Ionic Layer Adsorption

www.iosrjournals.org 37 | Page

requirement. CBD often suffers from reproductibility, perhaps more than most chemical processes, a for ZnO

films grown from alkaline solution onto glass. It requires a pre-deposition of ZnO on the substrate from other

techniques known as seed layer [11] which brought about its modification known as Successive Ionic Layer

Adsorption and Reaction method SILAR by [12].

The advantages of this method are its simplicity of working principal and low cost of apparatus. It is

this renewed interest in ZnO which forms the basis of this research.

II. Materials And Method

Deposition of ZnO and AZO thin films was carried out from 0.125M and 0.25M sodium zincate

(Na

2

ZnO

2

) solution and hot water bath. The sodium zincate bath was prepared by adding sodium hydroxide

(NaOH) in zinc sulphate solution (ZnSO

4

.7H

2

O). Aluminum doping of the sodium zincate was carried out by

adding anhydrous aluminum chloride (AlCl

3

) at 7 at % doping concentration.

A pre-cleaned microscopic glass slide substrate which was first washed with detergent and rinsed in

clean water severally and subsequently rinsed again in distilled water and kept in neat petri-dishes to avoid

further contamination was used. Film deposition was carried out by alternatively dipping the pre-cleaned

microscopic glass substrate in sodium zincate bath which is kept near room temperature for two seconds and in

hot water bath maintained at 95

o

C for another two seconds.100 and 200 dippings were performed each for the

experiment.

The measurement of film thickness was carried out using gravimetry technique. The method involves

measuring the weight change of the doped ZnO film formed on the substrate due to film deposition (M) together

with the theoretical density of ZnO.

Structural characterization and phase identification was carried out using X-Ray diffractometer with

CuK radiation in a Radicon MD-10 mini diffractometer while the optical characterization was done using a

Metler PB 303 UV-VIS spectrophotometer.

III. Result And Discussions

(a) Film thickness

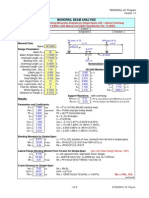

Table 1. Mass of ZnO and AZO deposited on substrate.

From Table 1 and for both 0.125 M and 0.25 M baths, film thicknesses were found to depend in this

case on the number of dippings, thus the film thickness can be controlled.

(b) Structural Characterization

Figs. 1and 2 shows the X-ray diffraction (XRD) pattern of ZnO and AZO thin films of

0.125M, 100 dippings deposited from sodium zincate bath. XRD spectra for other configurations are

not shown. The material was scanned in the range 20

o

-70

o

. The figures show the plot of pulses against

2, where is the angle of incidence of X-ray beam. The ZnO films crystallize in the orthorombic

phase with the prominent orientation along (002) plane at 29.34

o

parallel with the substrate while the

predominant orientation for AZO is along (102) plane at 19.27

o

.

The grain size, D, was estimated using the Scherrers formula:

cos

k

D =

(1)

Where k is the shape factor with value in the neighborhood of 0.94 and is the full-width at half-

maximum (FWHM).

The dislocation density which represents the amount of defects in the film was determined from the

2

D

1

=

[14].

Concentration No of dippings Mass of ZnO (g) Mass of AZO (g)

0.125 M 100

200

0.113

0.114

0.116

0.117

0.25M 100

200

0.114

0.115

0.117

0.118

Room Temperature Synthesis Of Zinc Zno And Azo Thin Films By Successive Ionic Layer Adsorption

www.iosrjournals.org 38 | Page

Figure 1: XRD pattern of undoped ZnO film at 0.125M, 100 dippings

Also, the lattice parameters a and c were calculated by using the well-known analytical method

[13], the Zn-O bond length L [14] for ZnO was calculated using:

|

|

.

|

\

|

|

.

|

\

|

+ =

2

2

2

2

1

3

c u

a

L

(2)

Where u the parameter in the wurtzite structure is given by:

25 . 0

3

2

2

+ =

c

a

u

(3)

and related to a/c ratio.

The parameters a, c, a/c and L are listed in Table 2

Table 2. The structural parameters of ZnO thin films for ZnO and AZO

a () c () a/c L () D(nm)

2 -4

) ( 10

nm

ZnO 5.884 9.886 0.595 3.623 31.0 10.41

AZO 4.308 7.289 0.591 3.433 28.0 12.78

Ref.[14] - - - - 31.9 9.80

The large values of D, the grain size is an indication of better crystallization of the films or

both ZnO and AZO comparable to the best value of 31.9 reported by [14].

(c) Optical Characterization

(c)(i) Transmittance

The graphs above have been arranged in order of their decreasing transmittance, with 0.25M bath of

100 dippings of AZO having the highest transmittance, ranging from 0.6126-0.8922 at wavelengths between

338 1100 nm, 0.25M bath with 200 dippings of AZO having a transmittance values between 0.6001- 0.8257 at

wavelengths between 471 1100 nm. The bath containing 0.125M with 100 dippings of AZO has transmittance

values between 0.5748 - 0.7555 at wavelengths between 359 1100 nm while the bath with 0.25M and 100

dippings of ZnO has transmittance values between 0.7416 - 0.9128 at wavelength of 419 1100 nm.0.25M bath

with 200 dippings of ZnO had a higher transmittance than ZnO of the same molarities and equal number of

dippings with ZnO transmittance between 0.7012 - 0.8878 at wavelengths of 357-1100 nm and ZnO

transmittance values between 0.7031 - 0.8796 at a wavelength between 391-1100 nm.

It can be further deduced from the results gotten that the incorporation of Al in the ZnO has increased

the transmittance but it should likewise be noted that ZnO has a lower transmittance wavelength than AZO.

Room Temperature Synthesis Of Zinc Zno And Azo Thin Films By Successive Ionic Layer Adsorption

www.iosrjournals.org 39 | Page

Figure 2: Transmittance of 0.125M 100 dippings ZnO

Figure 3: Transmittance of 0.125M 100 dippings AZO

(c)(ii) Absorbance

Figure 4: Absorbance for 0.125M, 100 dipping of ZnO

Figure 5: Absorbance for 0.125M, 100 dipping of AZO

The graphs above were arranged in order of decreasing absorbance. The absorbance values were

calculated with wavelengths in the range of 287 1100 nm. The results show that zinc oxide of 0.25M with 200

dippings has the highest absorbance between 0.863 - 0.114, followed by zinc oxide of 0.25M with 100 dippings

having values between 0.706 - 0.038. Zinc oxide with 0.125M at 100 dippings has absorbance values between

0.734 - 0.050, followed by Aluminum-doped zinc oxide with 0.125M of 100 dippings having values between

0.724 - 0.081. For the 0.25M bath with 200 dippings, aluminum doped zinc oxide have values between 0.657 -

Room Temperature Synthesis Of Zinc Zno And Azo Thin Films By Successive Ionic Layer Adsorption

www.iosrjournals.org 40 | Page

0.054, and aluminum doped zinc oxide in bath of 0.25M and 100 dippings have absorbance values between

0.642 - 0.054.

(c)(iii) Energy Band Gap

The energy band gap of the films were determined from the plot of the square of the product of

coefficient absorbance and energy of photon E(h ) against energy of photon E(h ) given rise to Figs. 13 18.

Figure 6: Energy bandgap of 0.125M, 100 dippings ZnO thin film.

Figure 7: Energy band gap of 0.125M, 100 dippings AZO thin film.

The energy band gap for both Zinc oxide ZnO and Aluminum doped Zinc oxide AZO were found to be

in the range between 3.75 - 3.80 eV.

IV. Conclusions

Aluminum was successfully incorporated into ZnO thin films via SILAR method at 7atm% and the

effect was observed from the increase in transmittance of doped ZnO to undoped ZnO thin films. Obviously

from Table 1, increase in molarity can lead to increase in thickness of deposited film on the substrate. Also, the

band gap gotten slightly differs from the ones reported in literatures. This slight deviation may be due partly to

the method and substrate used and the temperature of deposition, the ambient room temperature in this work.

Work is on-going to study the effects of these three factors on the optical and electrical characteristics of ZnO

thin films, both doped and undoped. Also, the effect of annealing on the structural and optical characteristics is

being investigated.

IV. Acknowledgement

The authors would like to sincerely appreciate Mr Ayoola C.T of Science Laboratory technology

department of Ladoke Akintola University of Technology, Ogbomoso and also Dr Pascal T.O. of Center for

Energy Research & Development (CERD) Obafemi Awolowo University, Ile-Ife for their immense

contributions and valuable suggestions throughout the work and Engineering Materials Development Institute

(EMDI) Akure for the provision of some of the research facilities.

Room Temperature Synthesis Of Zinc Zno And Azo Thin Films By Successive Ionic Layer Adsorption

www.iosrjournals.org 41 | Page

References

[1]. Studenikin SA, Golego N and Cocivera M, Fabrication of green and orange photoluminescence, undoped ZnO films using Spray

pyrolysis.

[2]. J.Appl. Phys. 84(4) 1998 2287-2294.

[3]. Ozgur, U., Ya. I., Alivov, C., Liu, A., Teke, M.A., Reshchikov, S., Dogan, Avrutin, V. Cho. S.J. and Morkoc, H. A

comprehensive review of ZnO materials and devices, Journal of applied Physics 98, 2005, 041301.

[4]. Jimenez-Gonzalez, A. E. Modification of ZnO Thin Films by Ni, Cu, and Cd doping, Journal of Solid-State Chemistry 28 (1997),

176-180.

[5]. T.Yamamoto, T.Shiosaki, and A.Kawabata, Characterization of ZnO piezoelectric films prepared by rf planar-magnetron sputtering,

J.Appl. Phys.51, 3113 (1980).

[6]. T.Mitsuyu, S.Ono, and K.Wasa, Structures and SAW properties of rf-sputtered single-crystal films of ZnO on sapphire, J.Appl.

Phys. 51,2464 (1980).

[7]. A.Hachigo, H.Nakahata, K.Higaki, S.Fujii, and S.Shikata, Heteroepitaxial growth of ZnO films on diamond (111) plane by

magnetron sputtering, Appl. Phys. Lett.65, 2556 (1994).

[8]. Harish Bahadur, Ram Kishore, K.N. Sood, Rashmi. D.K Suri, M. Kar, A. Basu, R.K Sharma, and Sudhir Chandra, Preparation and

Characterization of ZnO Thin films of silicon substrate using Sol-gel process, Physics of Semiconductor Devices (IWPSD-2003),

Mondal, X., Kanta, K.P and Mitra, P. Preparation of Al-doped ZnO (AZO) Thin Film by SILAR, Jounal of Physical Sciences,

Vol.12, 2008, 221-229.

[9]. Tiku S.K, C.K Lan and K.M Lakin , Chemical vapour deposition of ZnO epitaxial films on sapphire, Applied physics letter 36,

1980, 318-320.

[10]. Michael Kokotov, Ariel Biller, and Gary Hodes, Reproducible Chemical Bath Deposition of ZnO by a One-Step Method: The

Importance of Contaminants in Nucleation.

[11]. J. Chem. Mater.2008, 20 4542-4544.

[12]. Hodes, G., Chemical Solution Deposition of Semiconductor Films (Marcel Dekker; New York 2003).

[13]. Nicolau, Y. F. and Menard, J.C. , Growth of ZnS, CdS and ZnO Thin films by SILAR,

[14]. J. Cryst. Growth, 92 (1988) 128-132.

[15]. G.B. Williamson, R.C. Smallman, Philos. Mag. (1956) 1, 34 S. Ilican, Y. Caglar, and M. Caglar Preparation and Characterization of

ZnO thin films deposited by sol-gel spin coating coating method.

[16]. Journal of Optoelectronics and Advanced Materials Vol. 10, No 10 (2008) 2578-2583

Vous aimerez peut-être aussi

- AISI 4140 Alloy Steel (UNS G41400) : Topics CoveredDocument3 pagesAISI 4140 Alloy Steel (UNS G41400) : Topics Covereda.mohamedlathifPas encore d'évaluation

- Transparent Conducting Zno:Al Films Via CCVD For Amorphous Silicon Solar CellsDocument4 pagesTransparent Conducting Zno:Al Films Via CCVD For Amorphous Silicon Solar CellsEidelsayedPas encore d'évaluation

- Mughal Et Al. - 2017 - Structural and Optical Properties of Group III Doped Hydrothermal ZnO Thin Films - Journal of Electronic MaterialsDocument5 pagesMughal Et Al. - 2017 - Structural and Optical Properties of Group III Doped Hydrothermal ZnO Thin Films - Journal of Electronic MaterialsAsadPas encore d'évaluation

- Highly Oriented 1-D Zno Nanorod Arrays On Zinc Foil: Direct Growth From Substrate, Optical Properties and Photocatalytic ActivitiesDocument5 pagesHighly Oriented 1-D Zno Nanorod Arrays On Zinc Foil: Direct Growth From Substrate, Optical Properties and Photocatalytic ActivitiesAleandra Rasyid AzuraPas encore d'évaluation

- Macromolecular SympposiaDocument4 pagesMacromolecular Sympposiasunny1288Pas encore d'évaluation

- Shinde 2005Document7 pagesShinde 2005Annisa TurrahmahPas encore d'évaluation

- Structural, Morphological, Photo-Properties of Hetrojunction Zno Nanostructure Films Deposited On N-Si (100) by PLDDocument12 pagesStructural, Morphological, Photo-Properties of Hetrojunction Zno Nanostructure Films Deposited On N-Si (100) by PLDInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Zno Thin Films Prepared by A Single Step Sol - Gel Process: Shane O'Brien, L.H.K. Koh, Gabriel M. CreanDocument5 pagesZno Thin Films Prepared by A Single Step Sol - Gel Process: Shane O'Brien, L.H.K. Koh, Gabriel M. Creanumut bayPas encore d'évaluation

- Meziane - Et - Al - ApplPhysA2017 - Li Concentration Dependence of Structural Properties and Optical PDFDocument6 pagesMeziane - Et - Al - ApplPhysA2017 - Li Concentration Dependence of Structural Properties and Optical PDFNektaria LouisePas encore d'évaluation

- JApplPhys 93 3837 PDFDocument7 pagesJApplPhys 93 3837 PDFEidelsayedPas encore d'évaluation

- Solar Energy Materials & Solar Cells: Jin Zhang, Wenxiu QueDocument6 pagesSolar Energy Materials & Solar Cells: Jin Zhang, Wenxiu QueAzhar AbbasPas encore d'évaluation

- Comparative Studies of Al-Doped Zno and Ga-Doped Zno Transparent Conducting Oxide Thin FilmsDocument6 pagesComparative Studies of Al-Doped Zno and Ga-Doped Zno Transparent Conducting Oxide Thin FilmsMurtaza SieamPas encore d'évaluation

- Effect of ZN Concentration On Structural and Optical Proprieties of Zno Thin Films Deposited by Spray PyrolysisDocument14 pagesEffect of ZN Concentration On Structural and Optical Proprieties of Zno Thin Films Deposited by Spray Pyrolysisjournalaeij100% (1)

- Sol Gel Spin Coated Zno Thin Films For Biosensing ApplicationsDocument3 pagesSol Gel Spin Coated Zno Thin Films For Biosensing ApplicationserpublicationPas encore d'évaluation

- Electrical and Optical Properties of Al-Doped Zno Thin Films by Sol-Gel ProcessDocument6 pagesElectrical and Optical Properties of Al-Doped Zno Thin Films by Sol-Gel ProcessMurtaza SieamPas encore d'évaluation

- Study of Structural and Optical Properties of Zinc Oxide Rods Grown On Glasses by Chemical Spray PyrolysisDocument8 pagesStudy of Structural and Optical Properties of Zinc Oxide Rods Grown On Glasses by Chemical Spray PyrolysismanisjcPas encore d'évaluation

- Arif Wahya Handoko - The Crystalline Structure, Conductivity and Optical Properties of Co-Doped ZnO Thin FilmsDocument5 pagesArif Wahya Handoko - The Crystalline Structure, Conductivity and Optical Properties of Co-Doped ZnO Thin FilmsGutama Ade WardanaPas encore d'évaluation

- Accepted ManuscriptDocument22 pagesAccepted ManuscriptLoubna MentarPas encore d'évaluation

- Oxygen Deficiency 4Document8 pagesOxygen Deficiency 4Halil EşginPas encore d'évaluation

- Photocatalytic Oxidation of Paracetamol and Chloramphenicol by Zno NanowiresDocument5 pagesPhotocatalytic Oxidation of Paracetamol and Chloramphenicol by Zno NanowiresWella Fitria HareraPas encore d'évaluation

- Buffer1 s2.0 S0272884213003519 Main PDFDocument7 pagesBuffer1 s2.0 S0272884213003519 Main PDFeid elsayedPas encore d'évaluation

- Al-Zno Paper JoamDocument7 pagesAl-Zno Paper JoamYasir KhanPas encore d'évaluation

- Influence of Substrate Temperature On Structural, Electrical and Optical Properties of Zno:Al Thin FilmsDocument11 pagesInfluence of Substrate Temperature On Structural, Electrical and Optical Properties of Zno:Al Thin FilmsMuhammad Sahlan RidwanPas encore d'évaluation

- 2012aluminum-Doped Zinc Oxide Formed by Atomic Layer Deposition For Use As Anodes in Organic Light Emitting DiodesDocument7 pages2012aluminum-Doped Zinc Oxide Formed by Atomic Layer Deposition For Use As Anodes in Organic Light Emitting DiodesKanchanee NIYOMPas encore d'évaluation

- Properties of Thin Films: TeammatesDocument8 pagesProperties of Thin Films: TeammatesSuhil IrshadPas encore d'évaluation

- Current Transport Studies of N-Zno/P-Si Hetero-Nanostructures Grown by Pulsed Laser DepositionDocument9 pagesCurrent Transport Studies of N-Zno/P-Si Hetero-Nanostructures Grown by Pulsed Laser DepositionInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- ZnMgO by Sol-Gel Thin Films PDFDocument9 pagesZnMgO by Sol-Gel Thin Films PDFMorari VadimPas encore d'évaluation

- Yusof2020 Merged OrganizedDocument9 pagesYusof2020 Merged Organized069 Sharathkumar V G EEPas encore d'évaluation

- Spectral Investigations of Chemical Bath Deposited Zinc Oxide Thin Films - Ammonia Gas SensorDocument9 pagesSpectral Investigations of Chemical Bath Deposited Zinc Oxide Thin Films - Ammonia Gas SensorAditya GannamarajuPas encore d'évaluation

- Determination of Optical Constants and Thickness of Nanostructured Zno Film by Spin Coating TechniqueDocument8 pagesDetermination of Optical Constants and Thickness of Nanostructured Zno Film by Spin Coating TechniqueDeym GómezPas encore d'évaluation

- MPM144 13 SakharovDocument6 pagesMPM144 13 SakharovВадим АрыковPas encore d'évaluation

- Synthesis, Characterization, and Photocatalytic Properties of Zno/ (La, SR) Coo Composite Nanorod ArraysDocument6 pagesSynthesis, Characterization, and Photocatalytic Properties of Zno/ (La, SR) Coo Composite Nanorod Arraysvadlapatlaradhika_914Pas encore d'évaluation

- Thesis Zinc Oxide Thin FilmsDocument8 pagesThesis Zinc Oxide Thin FilmsKatie Robinson100% (2)

- High Transparency of Zno:In Coated Glass SubstratesDocument6 pagesHigh Transparency of Zno:In Coated Glass SubstratesСара ОрхидеяPas encore d'évaluation

- FtoDocument5 pagesFtoHeruKristiantoPas encore d'évaluation

- JApplPhys 85 2595 PDFDocument8 pagesJApplPhys 85 2595 PDFEidelsayedPas encore d'évaluation

- Heliyon: Md. Irfan Khan, Tasratur Reaj Neha, Md. Muktadir BillahDocument8 pagesHeliyon: Md. Irfan Khan, Tasratur Reaj Neha, Md. Muktadir BillahMurtaza SieamPas encore d'évaluation

- Synthesis and Characterization of Zno Thin Film Grown by Electron Beam EvaporationDocument7 pagesSynthesis and Characterization of Zno Thin Film Grown by Electron Beam EvaporationTomas JeffersonPas encore d'évaluation

- Fabrication and Properties of Zinc Oxide Thin FilmDocument6 pagesFabrication and Properties of Zinc Oxide Thin FilmLalu SuhaimiPas encore d'évaluation

- Goudarzi 2008Document5 pagesGoudarzi 2008Annisa TurrahmahPas encore d'évaluation

- The Optical and Structural Properties of Undoped Zno and Co-Doped Zno:Al:Cd Thin Films, and Their Electrical Characteristics As PhotodiodeDocument12 pagesThe Optical and Structural Properties of Undoped Zno and Co-Doped Zno:Al:Cd Thin Films, and Their Electrical Characteristics As Photodiodemehmet kayaPas encore d'évaluation

- Preparation of Al Doped Nio Thin Films by Spray Pyrolysis Technique For Co Gas SensingDocument6 pagesPreparation of Al Doped Nio Thin Films by Spray Pyrolysis Technique For Co Gas SensingSoufianeBenhamidaPas encore d'évaluation

- Structural and Optical Characterization of Cu DopeDocument5 pagesStructural and Optical Characterization of Cu DopeSyahrul MuchlisPas encore d'évaluation

- In Doped ZnO - by SprayPyrolDocument4 pagesIn Doped ZnO - by SprayPyrolRodrigoLeandro Nima-MazaPas encore d'évaluation

- Optimizing The Nanostructural Characteristics of Chemical Bath - Yuwono Et Al 2013Document7 pagesOptimizing The Nanostructural Characteristics of Chemical Bath - Yuwono Et Al 2013Riza Agung NugrahaPas encore d'évaluation

- 3 Temp AzsDocument5 pages3 Temp AzsFikrisalsabilahmahmudPas encore d'évaluation

- Surface Passivation and Antire Ection Behavior of Ald Tio 2 On N-Type Silicon For Solar CellsDocument9 pagesSurface Passivation and Antire Ection Behavior of Ald Tio 2 On N-Type Silicon For Solar CellsHazal ÇetinPas encore d'évaluation

- Electrical, Optical and Structural Properties of Transparent Conducting Al Doped Zno (Azo) Deposited by Sol-Gel Spin CoatingDocument8 pagesElectrical, Optical and Structural Properties of Transparent Conducting Al Doped Zno (Azo) Deposited by Sol-Gel Spin CoatingMainul HossainPas encore d'évaluation

- 24 Characteristicsof SN O2 FThin Films Depositedby Ultrasonic Spray Pyrolysis Effectof Water Contentin Solutionand Substrate TemperatureDocument7 pages24 Characteristicsof SN O2 FThin Films Depositedby Ultrasonic Spray Pyrolysis Effectof Water Contentin Solutionand Substrate TemperatureMariane AzevedoPas encore d'évaluation

- Properties of N-Type SnO2 Semiconductor Prepared by Spray Ultrasonic Technique For Photovoltaic ApplicationsDocument4 pagesProperties of N-Type SnO2 Semiconductor Prepared by Spray Ultrasonic Technique For Photovoltaic ApplicationsMarouane KhPas encore d'évaluation

- Thesis On Doped ZnoDocument6 pagesThesis On Doped Znoameliarichardsonsouthbend100% (1)

- 7Document9 pages7GopalaKrishnan MPas encore d'évaluation

- Nanomaterials 12 00195Document11 pagesNanomaterials 12 00195Htein Aung WinPas encore d'évaluation

- Ijaiem 2014 03 02 001Document7 pagesIjaiem 2014 03 02 001International Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Spray Pyrolysis ThesisDocument4 pagesSpray Pyrolysis ThesisAngie Miller100% (2)

- Physical Properties of Ga ZN O Thin Film Prepared by Spray Pyrolysis: Dependence On Annealing TemperatureDocument9 pagesPhysical Properties of Ga ZN O Thin Film Prepared by Spray Pyrolysis: Dependence On Annealing TemperatureInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Enhancement of Electrical Properties On Zno: Al Thin Film Due To Hydrogen Annealing and Sio Coating in Damp-Heat EnvironmentDocument4 pagesEnhancement of Electrical Properties On Zno: Al Thin Film Due To Hydrogen Annealing and Sio Coating in Damp-Heat Environmenthazbi2011Pas encore d'évaluation

- Metals 10 00437Document10 pagesMetals 10 00437069 Sharathkumar V G EEPas encore d'évaluation

- Effects of Growth Interruption of ZnO Buffer Layers On The Structural andDocument5 pagesEffects of Growth Interruption of ZnO Buffer Layers On The Structural andSara MAROUFPas encore d'évaluation

- Microwave Assisted Synthesis of Zno Nano-Sheets and Their Application in Uv-DetectorDocument4 pagesMicrowave Assisted Synthesis of Zno Nano-Sheets and Their Application in Uv-DetectorqeqwrwersrdfsdfPas encore d'évaluation

- Functional Polymer Coatings: Principles, Methods, and ApplicationsD'EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsÉvaluation : 1 sur 5 étoiles1/5 (1)

- Study The Changes in Al-Ahwaz Marshal Using Principal Component Analysis and Classification TechniqueDocument9 pagesStudy The Changes in Al-Ahwaz Marshal Using Principal Component Analysis and Classification TechniqueInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Philosophical Analysis of The Theories of Punishment in The Context of Nigerian Educational SystemDocument6 pagesPhilosophical Analysis of The Theories of Punishment in The Context of Nigerian Educational SystemInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Students' Perceptions of Grammar Teaching and Learning in English Language Classrooms in LibyaDocument6 pagesStudents' Perceptions of Grammar Teaching and Learning in English Language Classrooms in LibyaInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Necessary Evils of Private Tuition: A Case StudyDocument6 pagesNecessary Evils of Private Tuition: A Case StudyInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Project Based Learning Tools Development On Salt Hydrolysis Materials Through Scientific ApproachDocument5 pagesProject Based Learning Tools Development On Salt Hydrolysis Materials Through Scientific ApproachInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- The Effect of Instructional Methods and Locus of Control On Students' Speaking Ability (An Experimental Study in State Senior High School 01, Cibinong Bogor, West Java)Document11 pagesThe Effect of Instructional Methods and Locus of Control On Students' Speaking Ability (An Experimental Study in State Senior High School 01, Cibinong Bogor, West Java)International Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Effects of Formative Assessment On Mathematics Test Anxiety and Performance of Senior Secondary School Students in Jos, NigeriaDocument10 pagesEffects of Formative Assessment On Mathematics Test Anxiety and Performance of Senior Secondary School Students in Jos, NigeriaInternational Organization of Scientific Research (IOSR)100% (1)

- Enhancing Pupils' Knowledge of Mathematical Concepts Through Game and PoemDocument7 pagesEnhancing Pupils' Knowledge of Mathematical Concepts Through Game and PoemInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Development of Dacum As Identification Technique On Job Competence Based-Curriculum in High Vocational EducationDocument5 pagesDevelopment of Dacum As Identification Technique On Job Competence Based-Curriculum in High Vocational EducationInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Geohydrological Study of Weathered Basement Aquifers in Oban Massif and Environs Southeastern Nigeria: Using Remote Sensing and Geographic Information System TechniquesDocument14 pagesGeohydrological Study of Weathered Basement Aquifers in Oban Massif and Environs Southeastern Nigeria: Using Remote Sensing and Geographic Information System TechniquesInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Youth Entrepreneurship: Opportunities and Challenges in IndiaDocument5 pagesYouth Entrepreneurship: Opportunities and Challenges in IndiaInternational Organization of Scientific Research (IOSR)100% (1)

- Need of Non - Technical Content in Engineering EducationDocument3 pagesNeed of Non - Technical Content in Engineering EducationInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Child Mortality Among Teenage Mothers in OJU MetropolisDocument6 pagesChild Mortality Among Teenage Mothers in OJU MetropolisInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Comparison of Psychological Variables Within Different Positions of Players of The State Junior Boys Ball Badminton Players of ManipurDocument4 pagesComparison of Psychological Variables Within Different Positions of Players of The State Junior Boys Ball Badminton Players of ManipurInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Lipoproteins and Lipid Peroxidation in Thyroid DisordersDocument6 pagesLipoproteins and Lipid Peroxidation in Thyroid DisordersInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Comparison of Selected Anthropometric and Physical Fitness Variables Between Offencive and Defencive Players of Kho-KhoDocument2 pagesComparison of Selected Anthropometric and Physical Fitness Variables Between Offencive and Defencive Players of Kho-KhoInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Microencapsulation For Textile FinishingDocument4 pagesMicroencapsulation For Textile FinishingInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Study of Effect of Rotor Speed, Combing-Roll Speed and Type of Recycled Waste On Rotor Yarn Quality Using Response Surface MethodologyDocument9 pagesStudy of Effect of Rotor Speed, Combing-Roll Speed and Type of Recycled Waste On Rotor Yarn Quality Using Response Surface MethodologyInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Core Components of The Metabolic Syndrome in Nonalcohlic Fatty Liver DiseaseDocument5 pagesCore Components of The Metabolic Syndrome in Nonalcohlic Fatty Liver DiseaseInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Comparison of Explosive Strength Between Football and Volley Ball Players of Jamboni BlockDocument2 pagesComparison of Explosive Strength Between Football and Volley Ball Players of Jamboni BlockInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Advancing Statistical Education Using Technology and Mobile DevicesDocument9 pagesAdvancing Statistical Education Using Technology and Mobile DevicesInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Comparative Effect of Daily Administration of Allium Sativum and Allium Cepa Extracts On Alloxan Induced Diabetic RatsDocument6 pagesComparative Effect of Daily Administration of Allium Sativum and Allium Cepa Extracts On Alloxan Induced Diabetic RatsInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Application of Xylanase Produced by Bacillus Megaterium in Saccharification, Juice Clarification and Oil Extraction From Jatropha Seed KernelDocument8 pagesApplication of Xylanase Produced by Bacillus Megaterium in Saccharification, Juice Clarification and Oil Extraction From Jatropha Seed KernelInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Auxin Induced Germination and Plantlet Regeneration Via Rhizome Section Culture in Spiranthes Sinensis (Pers.) Ames: A Vulnerable Medicinal Orchid of Kashmir HimalayaDocument4 pagesAuxin Induced Germination and Plantlet Regeneration Via Rhizome Section Culture in Spiranthes Sinensis (Pers.) Ames: A Vulnerable Medicinal Orchid of Kashmir HimalayaInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- A Review On Refrigerants, and Effects On Global Warming For Making Green EnvironmentDocument4 pagesA Review On Refrigerants, and Effects On Global Warming For Making Green EnvironmentInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Investigation of Wear Loss in Aluminium Silicon Carbide Mica Hybrid Metal Matrix CompositeDocument5 pagesInvestigation of Wear Loss in Aluminium Silicon Carbide Mica Hybrid Metal Matrix CompositeInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Factors Affecting Success of Construction ProjectDocument10 pagesFactors Affecting Success of Construction ProjectInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Research Analysis On Sustainability Opportunities and Challenges of Bio-Fuels Industry in IndiaDocument7 pagesResearch Analysis On Sustainability Opportunities and Challenges of Bio-Fuels Industry in IndiaInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Parametric Optimization of Single Cylinder Diesel Engine For Specific Fuel Consumption Using Palm Seed Oil As A BlendDocument6 pagesParametric Optimization of Single Cylinder Diesel Engine For Specific Fuel Consumption Using Palm Seed Oil As A BlendInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Effect of Al2O3 NanoparticlesDocument11 pagesEffect of Al2O3 NanoparticlesmirelamanteamirelaPas encore d'évaluation

- Critical State Soil Mechnics - Part2Document65 pagesCritical State Soil Mechnics - Part2Nur PriyantoPas encore d'évaluation

- Stress-Based Uniaxial Fatigue Analysis Using Methods Described in FKM-GuidelineDocument40 pagesStress-Based Uniaxial Fatigue Analysis Using Methods Described in FKM-GuidelineclevercogPas encore d'évaluation

- Quikport - ResultsDocument34 pagesQuikport - Resultsjohnsmith1980Pas encore d'évaluation

- Fabrication and Characterization of Organic Field-Effect TransistorsDocument11 pagesFabrication and Characterization of Organic Field-Effect TransistorsEbru CoşkunPas encore d'évaluation

- ME213 Mechanics of Materials Formula SheetDocument3 pagesME213 Mechanics of Materials Formula SheetAishwaryShuklaPas encore d'évaluation

- Measurement of Tool WearDocument4 pagesMeasurement of Tool WearSourav KayalPas encore d'évaluation

- Automization and Powder AndersonDocument25 pagesAutomization and Powder AndersonRashed KaiserPas encore d'évaluation

- Ternary Phase DiagramDocument34 pagesTernary Phase DiagramCindy PancaPas encore d'évaluation

- Lesson 3 SoADocument5 pagesLesson 3 SoAJaneccaPas encore d'évaluation

- Theory and Application of Time Temperature ParametersDocument19 pagesTheory and Application of Time Temperature ParametersAnonymous KzJcjGCJbPas encore d'évaluation

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15Pas encore d'évaluation

- SJ Ansys Day 4 Report 10 2DDocument15 pagesSJ Ansys Day 4 Report 10 2DOM SHAHPas encore d'évaluation

- 3 D Printing Material Information SheetDocument2 pages3 D Printing Material Information SheetNirav DesaiPas encore d'évaluation

- Bycicle Frame Static AnalysisDocument21 pagesBycicle Frame Static Analysisteuku arriessa sukhairiPas encore d'évaluation

- Analysis of A Reinforced Concrete BuildingDocument119 pagesAnalysis of A Reinforced Concrete Buildinghooty_OWLPas encore d'évaluation

- Composite Structures Full Notes Part 2 PDFDocument19 pagesComposite Structures Full Notes Part 2 PDFsvnPas encore d'évaluation

- NEW SYLLABUS in Strength of MaterialsDocument14 pagesNEW SYLLABUS in Strength of MaterialsJohn Henry TampoyPas encore d'évaluation

- EN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyDocument13 pagesEN380 Naval Materials Science and Engineering Course Notes, U.S. Naval AcademyMahmoudPas encore d'évaluation

- Tig Dressing PDFDocument12 pagesTig Dressing PDFSergio MuñozPas encore d'évaluation

- HS 800 SpecsDocument8 pagesHS 800 Specspradeep yadavPas encore d'évaluation

- MonorailDocument3 pagesMonorailHelard AlvarezPas encore d'évaluation

- Ncma Tek: Design of Concrete Masonry Noncomposite (Cavity) Walls TEK 16-4ADocument4 pagesNcma Tek: Design of Concrete Masonry Noncomposite (Cavity) Walls TEK 16-4AmurdicksPas encore d'évaluation

- Lab 2 - Shear Force and Bending Moment DiagramDocument8 pagesLab 2 - Shear Force and Bending Moment Diagramaiman azhar100% (1)

- Author's Accepted ManuscriptDocument32 pagesAuthor's Accepted ManuscriptManish PatilPas encore d'évaluation

- Impact Testing: of TextilesDocument9 pagesImpact Testing: of Textilesരജീഷ് വി എംPas encore d'évaluation

- EBBEF2p-A Computer Code For Analyzing Beams On Elastic FoundationsDocument18 pagesEBBEF2p-A Computer Code For Analyzing Beams On Elastic FoundationshoojztePas encore d'évaluation

- Current Design Procedures For Steel-Lined Pressure TunnelsDocument12 pagesCurrent Design Procedures For Steel-Lined Pressure TunnelsEngr. Mohammad AdilPas encore d'évaluation

- Asphalt Techno Road Engineering Ebook FrEdDocument61 pagesAsphalt Techno Road Engineering Ebook FrEdvynaPas encore d'évaluation