Académique Documents

Professionnel Documents

Culture Documents

Process Equip & Symbols

Transféré par

bethnfgDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Process Equip & Symbols

Transféré par

bethnfgDroits d'auteur :

Formats disponibles

PROCESS EQUIPMENTS AND SYMBOLS Introduction Equipments are devices that provide power, process and store materials.

Equipments in piping systems depend on the specific industries using them. Specialized equipment can be found in petroleum, petrochemical, pulp and paper, food processing, brewing and power plants. It is important that new versions of equipment are used in designs and vendors equipment drawing for location and orientation of nuzzles and connections for instrumentations and utilities must be consulted. Common equipments include pumps, tanks, vessels, heat exchangers, etc. Many of the following equipments will be found in some plants of different industry types. Equipment Types Pumps: A pump draws in liquid from one side (suction) and releases it under pressure through another side (discharge). Pumps are the workhorses of process plants and centrifugal pumps are the most popular because they make up about 90% of pumps in process piping. Horizontal and vertical design models of pumps are available. Compressors: Compressors draw in gas or vapor from one side (suction) and releases it under pressure through another side (discharge). The gas or vapor is compressed and discharged at the higher pressure. Fans and blowers: Fans are used to induce air draft through a room while blowers are used to induce air draft through other equipment. Blowers are more powerful than fans. Tanks and Vessels: Tanks are storage devices for fluids with internal pressure under 15 psig. They come in different shapes (cylindrical, spherical, rectangular, square, etc.) and sizes and may be horizontal, horizontal or inclined. Vessels are special container used in processing materials usually at elevated temperatures and pressures (above 15 psig). Processes such as distillation, cooking, chemical reactions, separation and accumulation occur inside a vessel. Tanks and vessels often have attachments such as nuzzles, manhole, saddle, caps, etc. The shell is the wall of the tank. The caps form the end or head. The nozzle is a short pipe with a flange that provide piping interface. The saddle may be a steel or concrete support that carries the tank. A steel saddle is anchored to a concrete pad or foundation. The manhole is an opening (18 or more) that provides access into the tank for maintenance Heat exchangers: These are devices that allow the transfer of heat from the fluid in one set of pipes to the fluid in another set of pipe. The two fluids do not mix in the process. Kilns: Kilns are long slightly inclined large diameter vessels used to dry materials. They usually rotate during operations and are common in pulp and paper plants and cement factories. Towers: These are vertical vessels used to distill various products from crude oil. As the material rises in the column, different products are extracted due to varying temperatures and pressures in the column sections. They are also called columns. Condensers: A condenser is vessel that converts gas to liquid. The gas enters the vessel on one side and comes out on the other side as a liquid. Heaters: Heaters are also called furnaces. They are used to heat up materials during processing. The material like crude oil is transported through the heater in a series of tubes. Heaters are common in petrochemical plants. Reactors: These are used to contain catalysts that enhance chemical reactions or remove un-required materials from feeds. They usually operate under high pressures and temperatures. Design models may be vertical, horizontal or spherical. Boiler: A heater that is fired by oil, natural gas or wood. It converts water into steam. Reboiler: A heater that is used to keep the temperature of circulating fluid at its boiling point. It replenishes the temperature of a feedstock. The kettle-type reboiler design is similar to the shell-tube type heat exchanger.

Mixer: A vessel with a propeller used to mix liquids. It is also called an agitator. The propeller may be attached or removable from the vessel. Clarifiers: A clarifier is an open tank that receives wastewater and effluents. Slugs are removed from the bottom that tapers toward the center but clarified liquid is obtained from the top over weir. Cyclone: A cyclone is a separation device with a stormy motion inside during operation. Materials enter at the base at an angle the heavier ones fall to the bottom and the lighter ones exit at the top. It is common in the pulp and paper industries. Evaporator: A device that removes water from liquid chemical compound by steam heating. The processed liquid becomes more concentrated. It is common in the pulp and paper industries. Filter: A rotating vessel used to separate solids from liquids. Refiner: A high-speed grinding equipment used mainly in the food processing industries to convert coarse ANSI Equipment Symbols Below are listed some symbols of chemical apparatus and instrumentation normally used in a P&ID, according to ANSI.

Fig. 2a: Some ANSI equipment symbols

Fig. 2b: Some ANSI equipment symbols ISO Equipment Symbols Below are listed some symbols of chemical apparatus and instrumentation normally used in a P&ID, according to DIN 30600 and ISO 14617.

Double pipe

U shaped tubes

Spiral

Fixed straight tubes

Plate & frame

Fig. 3: Heat exchangers

a) Fan

b) Axial fan

c) Radial fan

Fig. 4 Fans

a) Tray column

b) Packing column

c) Half pipe mixer

d) Jacketed mixer (autoclave)

Fig. 5 Columns and mixers

a) Furnace

b) Cooling Tower Fig. 6: Furnace and coolers

c) Cooler

a) Pump

b) Vacuum pump or compressor Fig. 7: Pumps and compressors

Covered gas vent

Viewing glass

Dust trap Fig. 8: Miscellaneous symbols

Steam trap

Vous aimerez peut-être aussi

- Heat Transfer Assignment 1Document13 pagesHeat Transfer Assignment 1Abhinav mothaPas encore d'évaluation

- Malak Walid Ayyad Imi Equipment: 1. ValvesDocument5 pagesMalak Walid Ayyad Imi Equipment: 1. ValvesMustafa AyyadPas encore d'évaluation

- Test of A Tubular CondenserDocument9 pagesTest of A Tubular CondenserDevin Bea0% (1)

- Heat Exchangers V1 16-10-2019Document72 pagesHeat Exchangers V1 16-10-2019Bal krishna srivastava100% (1)

- 2 TECH TD Heat Exchanger Applications in Chemical IndustryDocument3 pages2 TECH TD Heat Exchanger Applications in Chemical IndustryHua Tien DungPas encore d'évaluation

- Heat Exchanger.Document10 pagesHeat Exchanger.RajarajeswariPas encore d'évaluation

- HX PresentationDocument14 pagesHX PresentationPriyankaPas encore d'évaluation

- Unit 3 Fractionation & Distillation EquipmentDocument15 pagesUnit 3 Fractionation & Distillation EquipmentKha Mn100% (1)

- Heat ExchangerDocument5 pagesHeat ExchangerMurtaza NaeemPas encore d'évaluation

- Heat Exchangers and It'S Classification, Temperature Disruibution in Heat ExangersDocument15 pagesHeat Exchangers and It'S Classification, Temperature Disruibution in Heat Exangersdhyan shahPas encore d'évaluation

- Absorption Equipment: Water/Lithium Bromide Absorption Technology Components and TerminologyDocument11 pagesAbsorption Equipment: Water/Lithium Bromide Absorption Technology Components and TerminologyMir Aqueel AliPas encore d'évaluation

- Utility Assignment: Reboiler Arranged By: I Made Vidya Prawira Satrio 21030117190076 Awindya Candrasmurti 21030117190176Document7 pagesUtility Assignment: Reboiler Arranged By: I Made Vidya Prawira Satrio 21030117190076 Awindya Candrasmurti 21030117190176I Made Vidya Prawira SatrioPas encore d'évaluation

- Shell and Tube Heat ExchangerDocument4 pagesShell and Tube Heat Exchangerru4angelPas encore d'évaluation

- CondenserDocument2 pagesCondenserAgustinus PrassetoPas encore d'évaluation

- Power Engineering MicroprojectDocument14 pagesPower Engineering MicroprojectROHANPas encore d'évaluation

- Heat Exchangers Classification Based On ApplicationDocument21 pagesHeat Exchangers Classification Based On ApplicationBadr AlwleedPas encore d'évaluation

- Hvac TrainingDocument33 pagesHvac TrainingABHILASH THAKREPas encore d'évaluation

- Types of Compressor:: 1) Reciprocating CompressorsDocument4 pagesTypes of Compressor:: 1) Reciprocating CompressorsAnthropophobe NyctophilePas encore d'évaluation

- Shell and Tube Heat Exchanger: Wall ThicknessDocument10 pagesShell and Tube Heat Exchanger: Wall ThicknessZeke KazamiPas encore d'évaluation

- IntroductionDocument11 pagesIntroductionAhmed KhalidPas encore d'évaluation

- Heat Exchanger TypesDocument7 pagesHeat Exchanger TypesMarwan ShamsPas encore d'évaluation

- A Piece of Equipment Built For Efficient Heat Transfer From One Medium To AnotherDocument19 pagesA Piece of Equipment Built For Efficient Heat Transfer From One Medium To AnotherKirti SuryawanshiPas encore d'évaluation

- Heat ExchangersDocument2 pagesHeat Exchangerscarleston thurgoodPas encore d'évaluation

- Utilities Used in Textile Industry: University of Karachi Chemical EngineeringDocument27 pagesUtilities Used in Textile Industry: University of Karachi Chemical EngineeringAneesha PandaPas encore d'évaluation

- FFBL Intern Ship ReportDocument20 pagesFFBL Intern Ship ReportHamza RaoPas encore d'évaluation

- Heat Exchangers, Strainers and SeperatorsDocument12 pagesHeat Exchangers, Strainers and SeperatorsJaveed A. Khan100% (1)

- Pertemuan 12: Heat Exchanger Heat ExchangerDocument4 pagesPertemuan 12: Heat Exchanger Heat ExchangerAmelya SariPas encore d'évaluation

- Main Project DocumentationDocument62 pagesMain Project Documentationnitin_micPas encore d'évaluation

- Application and Function of EquipmentsDocument5 pagesApplication and Function of EquipmentsPE9001 AarthiPas encore d'évaluation

- HVAC - Assignment 1a - AAKDocument4 pagesHVAC - Assignment 1a - AAKAleena Amin KhuwajaPas encore d'évaluation

- Experiment No. 8 Heat ExchangerDocument26 pagesExperiment No. 8 Heat ExchangerAli Requiso Mahmud100% (1)

- System ComponentsDocument35 pagesSystem ComponentsCharan Reddy AbbadiPas encore d'évaluation

- Ite Note On Process PlantDocument14 pagesIte Note On Process PlantSam Wang Chern PengPas encore d'évaluation

- Types of Heat ExchangersDocument13 pagesTypes of Heat ExchangersAbhijit NathPas encore d'évaluation

- Heat ExchangersDocument56 pagesHeat ExchangersGeeva Prasanth APas encore d'évaluation

- Heat ExchangerDocument7 pagesHeat ExchangerShayne Aira AnggongPas encore d'évaluation

- Introduction To Heat ExchangerDocument15 pagesIntroduction To Heat ExchangernsfvhsfPas encore d'évaluation

- Part - 2Document11 pagesPart - 2ROHIT KESHRIPas encore d'évaluation

- Technical English 2.Document32 pagesTechnical English 2.Jhostin AntonioPas encore d'évaluation

- What Are The Types of Heat ExchangersDocument9 pagesWhat Are The Types of Heat Exchangersjr gajelesPas encore d'évaluation

- PHT Lec 1Document32 pagesPHT Lec 1M.Attique Ur RehmanPas encore d'évaluation

- Heat ExchangersDocument8 pagesHeat Exchangerskats2404Pas encore d'évaluation

- Chemical Engineering: Govt - Polytechnic Mankenda (Agra)Document47 pagesChemical Engineering: Govt - Polytechnic Mankenda (Agra)Shekhar YaduvanshiPas encore d'évaluation

- Conceptual Diagram of A Plate and Frame Heat Exchanger02Document9 pagesConceptual Diagram of A Plate and Frame Heat Exchanger02sai thesisPas encore d'évaluation

- Types of Heat Exchangers - Classification of Heat ExchangersDocument3 pagesTypes of Heat Exchangers - Classification of Heat ExchangersMuhammet Ahmet SarıkayaPas encore d'évaluation

- Heat Exchanger PresentationDocument66 pagesHeat Exchanger PresentationMahmoud100% (1)

- Shell and Tube Heat ExchangerDocument4 pagesShell and Tube Heat Exchangerasim zeeshanPas encore d'évaluation

- The Applications of Heat Exchangers Refrigeration SystemsDocument38 pagesThe Applications of Heat Exchangers Refrigeration SystemsBasem RajabPas encore d'évaluation

- Heat ExchangerDocument11 pagesHeat ExchangerHuda ShahPas encore d'évaluation

- Lesson 4 - Industrial Steam v3Document85 pagesLesson 4 - Industrial Steam v3JHON LHOYD CORPUZPas encore d'évaluation

- CondenserDocument12 pagesCondenserPrabir Kumar Pati100% (1)

- HVAC1Document107 pagesHVAC1deesing100% (1)

- ProjectDocument24 pagesProjectSantosh Kumar HottaPas encore d'évaluation

- Introduction (1) &DisH.EDocument12 pagesIntroduction (1) &DisH.ESarah RabayaPas encore d'évaluation

- Shell and Tube Heat Exchanger - WikipediaDocument5 pagesShell and Tube Heat Exchanger - Wikipediabinok19Pas encore d'évaluation

- Different Type of ChillersDocument7 pagesDifferent Type of ChillersMAGDY KAMEL100% (3)

- What Is A Heat ExchangerDocument4 pagesWhat Is A Heat ExchangermarviPas encore d'évaluation

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AD'EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&APas encore d'évaluation

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewD'EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewPas encore d'évaluation

- Barrett Beyond Psychometrics 2003 AugmentedDocument34 pagesBarrett Beyond Psychometrics 2003 AugmentedRoy Umaña CarrilloPas encore d'évaluation

- Homeopatija I KancerDocument1 pageHomeopatija I KancermafkoPas encore d'évaluation

- Ethical Conflicts in Psychology PDF DownloadDocument2 pagesEthical Conflicts in Psychology PDF DownloadAvory0% (2)

- KMKT Pra PSPM ANS SCHEMEDocument16 pagesKMKT Pra PSPM ANS SCHEMEElda AldaPas encore d'évaluation

- Data Network Unit 6 - UCDocument15 pagesData Network Unit 6 - UCANISHA DONDEPas encore d'évaluation

- A Case On Marketing Strategy of Xiaomi IndiaDocument39 pagesA Case On Marketing Strategy of Xiaomi IndiaSoumyajeet Rout0% (1)

- Reflection in Sexually Transmitted DiseaseDocument1 pageReflection in Sexually Transmitted Diseasewenna janePas encore d'évaluation

- Drager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementDocument24 pagesDrager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementAmirPas encore d'évaluation

- Iec Codes PDFDocument257 pagesIec Codes PDFAkhil AnumandlaPas encore d'évaluation

- 1 PBDocument7 pages1 PBIndah Purnama TaraPas encore d'évaluation

- All India Civil Services Coaching Centre, Chennai - 28Document4 pagesAll India Civil Services Coaching Centre, Chennai - 28prakashPas encore d'évaluation

- Enrile v. SalazarDocument26 pagesEnrile v. SalazarMaria Aerial AbawagPas encore d'évaluation

- Microfinance Ass 1Document15 pagesMicrofinance Ass 1Willard MusengeyiPas encore d'évaluation

- Toshiba MotorsDocument16 pagesToshiba MotorsSergio Cabrera100% (1)

- Inventions Over The Last 100 YearsDocument3 pagesInventions Over The Last 100 YearsHombreMorado GamerYTPas encore d'évaluation

- Hw10 SolutionsDocument4 pagesHw10 Solutionsbernandaz123Pas encore d'évaluation

- Microwave EngineeringDocument2 pagesMicrowave Engineeringசுந்தர் சின்னையா0% (9)

- Spectacle Blinds - Closed Blinds Open Blinds (Ring Spacer)Document2 pagesSpectacle Blinds - Closed Blinds Open Blinds (Ring Spacer)Widiyanto WiwidPas encore d'évaluation

- Project ProposalDocument4 pagesProject Proposaljiaclaire2998100% (1)

- Operating Instructions: HTL-PHP Air Torque PumpDocument38 pagesOperating Instructions: HTL-PHP Air Torque PumpvankarpPas encore d'évaluation

- SecurityFund PPT 1.1Document13 pagesSecurityFund PPT 1.1Fmunoz MunozPas encore d'évaluation

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocument36 pagesPrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- Aribah Ahmed CertificateDocument2 pagesAribah Ahmed CertificateBahadur AliPas encore d'évaluation

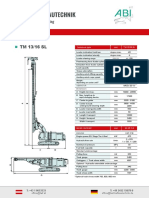

- ABI TM 13 16 SL - EngDocument1 pageABI TM 13 16 SL - EngJuan Carlos Benitez MartinezPas encore d'évaluation

- Consent Form: Republic of The Philippines Province of - Municipality ofDocument1 pageConsent Form: Republic of The Philippines Province of - Municipality ofLucette Legaspi EstrellaPas encore d'évaluation

- Analytics Designer - Comment Deletion - SAP CommunityDocument6 pagesAnalytics Designer - Comment Deletion - SAP CommunityARPITA BISWASPas encore d'évaluation

- Low Voltage Switchgear Specification: 1. ScopeDocument6 pagesLow Voltage Switchgear Specification: 1. ScopejendrikoPas encore d'évaluation

- Existentialism in LiteratureDocument2 pagesExistentialism in LiteratureGirlhappy Romy100% (1)

- Functional Programming in Swift by Eidhof Chris, Kugler Florian, Swierstra Wouter.Document212 pagesFunctional Programming in Swift by Eidhof Chris, Kugler Florian, Swierstra Wouter.angloesamPas encore d'évaluation

- IOT Questions and Answers - SolutionDocument8 pagesIOT Questions and Answers - SolutionOmar CheikhrouhouPas encore d'évaluation