Académique Documents

Professionnel Documents

Culture Documents

MV Capbank

Transféré par

Rey ArthurDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MV Capbank

Transféré par

Rey ArthurDroits d'auteur :

Formats disponibles

CEB STANDARD 031 : 1996

Specification for

MEDIUM VOLTAGE POWER CAPACITOR BANKS AND ACCESSORIES

CEYLON ELECTRICITY BOARD SRI LANKA

Specification for

MEDIUM VOLTAGE POWER CAPACITOR BANKS AND ACCESSORIES

CEB Standard 031 : 1996

CEYLON ELECTRICITY BOARD

No. 50, Sir Chittampalam A. Gardiner Mawatha, Colombo 2. Sri Lanka

Telephone: 24471-8

Telex : 21368 CE

Facsimile: 94-1-449572

CEB STANDARD 031 : 1996

CONTENTS

Page

1.Scope 2.System Parameters 3.Service Conditions 4.Applicable Standards 5.Basic Features 6.Additional Requirements 7.Capitalization of Losses 8.Quality Control 9.Information to be Supplied with the Offer 10.Technical Literature & Working Drawings 11.Inspection & Testing 12.Annexure

2 2 2 3 3 11 12 12 12 13 13 15

CEB STANDARD 031 : 1996

SPECIFICATION FOR MEDIUM VOLTAGE POWER CAPACITOR BANKS AND ACCESSORIES 1.0 SCOPE This Specification covers the design, manufacture and testing of Power Capacitor Banks and Accessories of the following types for use in the 12 KV and 36 kV overhead lines to improve the power factor of the Medium Voltage Distribution system . i) ii) 2.0 Fixed Type Power Capacitor Bank and Accessories Switching Type Power Capacitor Bank and Accessories

SYSTEM PARAMETERS a) b) c) d) e) Nominal Voltage System Highest Voltage System Frequency System Fault Level Method of Earthing 11 kV 12 kV 50 Hz 13.1 kA Effectively earthed 33 kV 36 kV 50 Hz 13.1 kA Non effectively earthed

3.0

SERVICE CONDITIONS a) Annual average ambient temperature b) c) d) e) f) Maximum ambient temperature Maximum Relative Humidity Environmental Operational Altitude Isokeraunic (Thunder day) Level -

Humid -

30 deg. C 40 deg. C 90% tropical climate with Condition polluted atmosphere. From M.S.L. to 1000 m above M.S.L. 90 days.

CEB STANDARD 031 : 1996

4.0

APPLICABLE STANDARDS The equipment and components supplied shall be in accordance with the latest editions of the standards specified below and amendments thereof. a) b) c) c) f) g) h) IEC IEC IEC IEC IEC IEC BS 871-1 (1987) 56 289 672 (1987) (1988) (1980) Shunt capacitors for a.c. power systems having a rated voltage above 660V. High-voltage Breakers Reactors Ceramic and materials glass electrical insulating alternatingcurrent Circuit-

71-1,2 &3 (1976) 60-1 (1982) 729 (1986)

Insulation Co-ordination. High-voltage test techniques. Hot dip galvanized coatings on iron and steel articles.

5.0

BASIC FEATURES The three phase Power Capacitor Banks shall be of the two types stipulated in Clause 1.0 - Scope for use in the medium voltage overhead feeders and shall be suitable for continuous operation under the climatic conditions stipulated in Clause 3.0 -Service conditions above. The design shall also ensure that the Capacitor Banks, including their connections, are adequately rated so that they are not damaged if their terminals are short circuited. The Fixed Type Power Capacitor Banks shall have capacitor banks and accessories mounted on a bracket which shall be suitable for mounting on a concrete pole support of the existing feeders. The Switching Type Power Capacitor Banks shall have capacitor banks, accessories and the switchgear with automatic switching facilities, suitable for mounting on two concrete pole supports, ie. an additional concrete pole to be erected close to the existing

CEB STANDARD 031 : 1996

feeder pole support. Earthing facilities shall be provided on the steel structure/mounting brackets for effectively bonding the power capacitor tank and relevant accessories to the structure/ bracket as well as for the earthing lead. A detail drawing of mounting arrangements shall be furnished with the offer. The Bidder shall provide a detailed description of the construction features, manufacturing process, the internal arrangement of elements and the protective devices. 5.1 Fixed Type Capacitor Banks and Accessories

The Fixed Type Power Capacitor Banks shall consist of the following; i) ii) iii) iv) v) 5.1.2 Naturally cooled static type shunt Power Capacitors - Three/six Nos. Mounting Bracket to accommodate six Nos. of Power Capacitors Earth Electrodes - Four Nos 95mm?, Black PVC Insulator Stranded Copper Earth Conductor of length thirty meters And necessary connecting Leads & Connectors.

Manufacture

The basic unit of the Power Capacitor Bank shall consist of three Numbers of single phase power capacitors, each of rating 100/150 kVAr, assembled to form a Star connection to provide a basic unit of rating 300/450 kVAr respectively. The rating required is indicated in the schedule of prices. When the Bank consists of 6 Nos of Power Capacitors (two basic units assembled in parallel) the unit rating shall be 600/900 kVAr respectively and the star point (neutral) shall be kept unearthed. Provision shall be made to earth the capacitors and the mounting bracket.

5.1.3

Mounting Brackets

CEB STANDARD 031 : 1996

The mounting bracket shall be made of Galvanized Steel and shall be suitably designed to carry upto six Nos. of Power Capacitors of rating either 100 or kVAr and for mounting on a single concrete pole by clamping to the vertical surface of the pole of section 400mm x 300mm. Through bolting shall not be acceptable. 5.1.4 Minimum Technical Requirements - Fixed Type Capacitor Banks & Accessories 11kV 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Rated Voltage kVAr output at rated voltage Tolerance on kVAr No. of Units/Bank Rating of Single Units kVAr Mode of connection of Bank (floating neutral) Frequency Hz No. of phases of Bank Location Type of Fuses Type of Bank 3 Outdoor 50 3 Outdoor 3/6 100/150 Star 50 12 300/450/600/900 0 to + 10% 3/6 36 33kV

External expulsion type unit fuses Open type

5.2

Switching Type Capacitor Banks and Accessories The Switching Type Power Capacitor Banks shall consist of the following ;

CEB STANDARD 031 : 1996

i)

Naturally cooled static type shunt Power Capacitors 100/150 kVAr with external fuses - Nine Nos. The rating required is indicated in the schedule of prices. Three Phase Medium Voltage (MV) Switch with automatic switching facilities for switching the capacitor bank - One No Current Limiting Reactors - Three Nos. MV Current Transformer - One No. MV Voltage Transformer with fuse protection - One No. Mounting Platform for the above equipment Four Nos.of Earth Electrodes 95mm?, Black PVC Insulated Stranded Copper Earth Conductor of length forty meters And necessary connecting leads & Connectors.

ii) iii) iv) v) vi) vii) viii) ix) 5.2.1

Manufacture

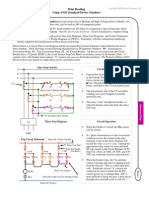

The above mentioned items shall be assembled on a platform as indicated in the schematic drawing attached. The platform shall be suitable for mounting on two or four concrete pole supports as shown in Drawing No. DS&S/95/7699 and the control cubicle shall be suitable for mounting on the same concrete pole support. Three nos. of the above Capacitors shall be assembled to form a star connection to provide a basic unit of rating 400/450 kVAr, connected permanently to the feeder. The remaining six Nos. shall be assembled to form a double star of rating 600/900 kVAr connected in parallel to the permanently connected unit mentioned above through the current limiting reactors and MV Switch. The star points (neutral) shall be kept unearthed. The MV Current Transformer (CT) and Voltage Transformer (VT) shall be connected to one of the phase conductors to sense the feeder current and voltage respectively.

The single phase Power Factor Relay connected to the secondary of the CT and VT shall automatically control the operation of the MV Switch through auxiliary relays at present low and high power factors of the feeders. An adjustable time delay facility of 2 to 5 minutes before switching in the capacitor bank and 0.5 to 1 minute before switching off the capacitor bank shall be introduced to prevent

CEB STANDARD 031 : 1996

too frequent switching operations due to load variation in the feeder as well as power failure. The capacitor bank switching in power factor shall be adjustable from 0.8 to 0.9 lagging (for making adjustment to suit the find requirements), and switching off power factor shall be 0.99 lagging. Provision shall be made to switch off the Capacitor Banks automatically during the control (LV) and feeder (MV) power failure periods. 5.2.2 Sensing Relays and Control Equipment

All necessary sensing relays and control equipment such as indicated below shall be provided. They shall be tropicalize and durable for use in a tropical climate. a) b) c) d) e) f) g) h) 5.2.3 Single Phase Power Factor Relay. Time Delay Switching Equipment. Auxiliary Relays Feeder Power (MV) Failure Sensing Relay. Control Power (LV) Failure Sensing Relay/Indicator. Automatic/Remote/Local Control Switch Necessary Control Wiring Any other

Control Cubicle

The Sensing Relays and Control Equipment stipulated in Clause 5.2.2 above (other than the MV Switch) shall be housed in control cubicle (with locking facility). It shall be made of steel and galvanized. The control cubicle shall be designed to protect the sensing relays and control equipment from the tropical climatic conditions in Sri Lanka. The necessary thermal insulation and ventilation shall be provided. 5.2.4 Mounting Brackets

The power capacitor bank mounting platform shall be suitably designed to be mounted on two concrete poles of cross section 400mm X 300mm by clamping to the tapered surface. Through bolting shall not be acceptable.

CEB STANDARD 031 : 1996

The mounting brackets shall be made of galvanized steel and they shall be of light weight and strong enough to carry the weight of the power capacitors, Current limiting Reactors and the MV Switch as stipulated in Clause 5.2 above. 5.2.5 Technical Requirements - Switching Type Capacitor Banks & Accessories 11kV a. b. c. d. e. f. g. h. i. j. k. Rated Voltage kVAr output at rated voltage Tolerance on kVAr No. of Units/Bank Rating of Single Units kVAr Mode of connection of Bank Frequency Hz No. of phases of Bank Location Type of Fuses Type of Bank 3 12 900 36 1350 0 to + 10% 9 100 Star Neutral) 50 3 Outdoor Internal/External Open type fuses 9 150 (floating 50 33kV

5.3 a)

Capacitor Units The capacitor unit shall be of self contained outdoor type of two bushing and dead tank construction and shall conform to the Minimum Technical Requirements stipulated in Clause 5.4. The bushing shall be glazed porcelain having a minimum creepage distance and protected creepage distance as stipulated in Clause 5.4 - Technical Requirement

b)

CEB STANDARD 031 : 1996

Requirements of Power Capacitor units and shall be effectively sealed to case. c) The case shall be of stainless steel type with a coating of suitable Primer and a coat of Epoxy base light grey Enamel applied in accordance with the relevant standard specified. The case shall be strong enough to withstand the system fault current specified without explosion. The dielectric of the unit shall be pure Polypropylene Film and the electrode shall be soft annealed aluminium foil. Capacitor units shall have the required number of capacitor elements each of which is protected by an internal fuse. In the case of a blown internal fuse the lost reactive power shall not be more than 2% of the reactive power of the capacitor unit. Capacitor elements shall have extended foil type construction where, one edge of the foil is extended suitably beyond dielectric layers. Each capacitor unit l be fitted with a permanently connected discharge resister. This shall be designed so that when the Capacitor Banks are disconnected from the supply, the residual voltage across the terminals of the banks is reduced from the crest value of the rated voltage to 50V or less within 300 seconds. The power leads shall be connected to the extended portion of Aluminium Foil by soldering/crimping or any other suitable method, eliminating conventional tabs in order to make a strong and positive electrical contact. The other edge of the foil shall be folded suitably to form a corona ring in order to minimise partial discharges. The impregnant shall be introduced into the capacitor tanks by means of a sealed vacuum system and it shall be environmentally safe and bio-degradable and shall not be of the polychlorinated biphenyl type Condenser Oil. The method of handling and disposal of the capacitor insulating fluid shall be indicated. j) Capacitors shall be suitable for continuous operation provided that none of the following limitations are exceeded. a) b) c) 110% of nameplate kVAr. 110% of rated voltage RMS including harmonics but, excluding transients. 140% rated current RMS including harmonics.

d) e)

f) g)

h)

i)

CEB STANDARD 031 : 1996

k)

Momentary transient and power frequency voltages shall be in accordance with IEC Standard specified and the partial discharge voltage shall also be not less than that specified in the relevant IEC Standard. Capacitors shall be thermally stable in accordance with the definition and operating conditions outlined in the IEC and the Radio Influence Voltage shall be kept to a minimum not exceeding 250v. Technical Requirements - Capacitor Units a. b. Rated Voltage Basic Insulation Level i. ii. c. Lightning impulse withstand voltage Power frequency withstand voltage (wet) 70kV 28kV 170kV 70kV 12kV 36kV

l)

5.4

Insulator Bushing Creepage distance i. ii) Total (min.) Protected (min.) 300mm 105mm 100/150 Single Two 0.15 900mm 315mm 100/150 Single Two 0.15

d) e) f) g) h. i. j. k. l. m.

Rated kVAr No. of Phases No. of Bushings Loss Mxx. W/kVAr Discharge Device Discharge Time (max.) Type of dielectric Type of electrode Type of elements Impregnant

Built in discharge Resistors 300 sec. 300 sec. Polypropylene (all PP) Aluminium Foil Extended foil type Non-PCB, Non-Toxic,

CEB STANDARD 031 : 1996

Biodegradable n. 5.5 Fuse Protection Internal/External fuse type

Current Transformer 12kV and 36kV

The Current Transformer shall be conform to the IEC 185 having transformation ratio 400200/5.5 suitable for out door installation in tropical climate as stipulated in Clause 3.0. The Rated Voltage, Basic Insulation Level and Creepage Distance shall be the same specified in Clause 5.4 Technical Requirements for Power Capacitor units. 5.6 Voltage Transformer 12kV and 36kV

The Voltage Transformer shall conform to the IEC 186, suitable for out door installation in tropical climate as stipulated in Clause 3.0. The Rated Voltage, Basic Insulation Level and Creepage Distance shall be the same specified in Clause 5.4 Technical Requirements for Power Capacitor Units. 5.7 Current Limiting Reactors 12kV and 36kV

The capacity of Reactors provided with the switching type capacitor banks shall be suitable to limit the inrush current to a low level for the safe operation of the switchgear and equipment. The Reactor shall be of air core type conforming to IEC 289 (1988) Reactors, suitable for out door installation in tropical climate as stipulated in Clause 3.0. The Rated Voltage, Basic Insulation Level and Creepage Distance shall be the same specified in Clause 5.4 Technical Requirements for Power Capacitor units. The calculation for proper selection of Current limiting reactors for the respective capacitor banks shall be furnished. 5.8 Medium Voltage Switch 12kV and 36kV

The MV Switch shall be of three phase Outdoor type complete with operating mechanism. It shall be Oil/Vacuum/SF6 type, conforming to the System Parameters and the Service Conditions specified in Clause 2.0 and 3.0 and suitable for switching the Capacitor Bank in and out of the feeder. The Rated Voltage, Basic Insulation Level and Creepage Distance shall be the same specified in Clause 5.4. Technical Requirement for Power Capacitor. It shall be suitable for mounting on the platform specified in Clause 5.2.1. The control voltage of the operating mechanism and closing & tripping coil voltage shall be 230V AC. The operating mechanism shall be so designed that the Switch is free to open immediately when the tripping circuit is energised without any additional external power to

CEB STANDARD 031 : 1996

the operating mechanism. Energy needed for tipping shall be made to open the Switch when there is a failure of control voltage LV supply. 5.8.1 Operating Mechanism

The operating mechanism shall be re-charged automatically for further operations as soon as the Switch has completed the closing operation. The design of closing mechanism shall be that the Switch cannot be operated inadvertently due to external shock forces resulting from short circuit Switch Operations or any other cause. The three poles of the Switch shall make and break the circuits simultaneously. In the event of any phases failing to complete a closing operation, provision shall be made for automatic tripping of all phases of the Switch. In the event of the mechanism failing to latch in the closed position, the Switch shall be arranged to open at normal speed. A mechanically operated indicator shall be provided on the operating mechanism to indicate whether the switch is closed or open. A mechanically operated re-settable operating counter shall also be provided. 5.8.2 Temperature Rise

Each current carrying component of the equipment supplied shall be capable of continuous operation at the specified ratings without exceeding the maximum temperature rise stated in the appropriate IEC recommendations.

5.9 5.9.1

Earth Electrodes and Leads Earth Electrode

Earth rods shall be 16mm diameter X 2.4m long copper clad steel with drive heads to permit hammer installation. Four numbers of earth rods shall be supplied with each unit. The bonding between the copper and steel shall be such that there will be no corrosion and will not peal off when driven into earth. The thickness of copper shall be adequate enough to protect the steel rod from corrosion during its life span. 5.9.2 Earth Leads

Earth leads shall be of 95mm? Black PVC Insulated Stranded Copper Earth Conductor and suitable bolted type connectors for effectively bonding the copper earth conductor with the earth electrodes shall also be provided with each earth electrode.

CEB STANDARD 031 : 1996

5.10

Galvanizing

Except where specified to the contrary all iron and steel parts such as mounting and support brackets, bolts and nuts, washers etc. shall be galvanized after the process such as sawing, shearing, drilling, punching, filling, bending and machining are completed. Galvanizing shall be carried out using the hot-dip process to comply with the standard BS 729 specified. 6.0 ADDITIONAL REQUIREMENTS 6.1 Nameplate Marking

Each power capacitor shall be provided with a permanent nameplate which includes the following information. 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) 11) 6.2 Tools Name of manufacturer Serial number Manufacturer's type, model, style, or catalog number Year of manufacture Rated reactive power Rated voltage, rms Number of phases Rated frequency BIL Statement as to whether insulating liquid in the capacitor is or is not flammable. (If flammable, amount in gallons shall be shown). Statement that capacitor contains an internal discharge device.

Any special tools if required for installation and maintenance shall be supplied with the equipment.

CEB STANDARD 031 : 1996

7.0

CAPITALIZATION OF LOSSES The power loss of capacitor shall not exceed 0.15 Watt/kVAr. All capacitor losses shall be capitalised and added to the cost of the capacitor bank in evaluating the offer. The losses shall be capitalized for a period of 8 Years. For the purpose of comparing the offers following values will be adopted when capitalizing the loss. US $ 2.0 for loss in Watt per kVAr Interest and sinking fund Charges - 10%

8.0

QUALITY CONTROL Quality Assurance System conforming to ISO 9001 shall be followed in the manufacture of Power Capacitors and Accessories and the Bidders shall furnish documentary evidence with the offer to prove this.

9.0

INFORMATION TO BE SUPPLIED WITH THE OFFER a) b) c) d) Manufacturers catalogues (indicating type and model number) of all equipment (including the sensing relays and control equipment) offered shall be furnished. Bidders shall recommend maintenance requirements for the Capacitor Banks and shall state the interval between scheduled maintenance works. Bidders shall state the method by which capacitor units can be removed and replaced. The following Certificate of Type Test for Power Capacitors from an independent testing authority shall be provided with the offer and shall be in accordance with the relevant standards and this specification. i) ii) iii) iv) e) f) Tests for output/capacitance Thermal stability tests Tangent of dielectric loss angle at elevated temperature Capacitor discharge tests

List of Purchasers for the same make and similar model for the last five years and performance certificates from the user utilities. Schedule of Particulars - Annexure 1

CEB STANDARD 031 : 1996

Failure to furnish the above details will result in the offer being rejected. 10.0 TECHNICAL LITERATURE AND WORKING DRAWINGS 10.1 10.2 The Supplier shall provide to the Purchaser the Layout Drawings of the equipment and the Wiring Diagrams and obtain his approval prior to manufacture. The Tenderer shall furnish the following with the equipment. i) ii) iii) iv) v) vi) 11.0 Equipment Layout drawings and foundation details. Full technical literature of all items of the equipment. Installation instructions of all items in detail. Full wiring drawings of the equipment. Instruction for commissioning the equipment and details of commissioning Tests to be carried out. Operation and maintenance instructions.

INSPECTION AND TESTING 11.1 Inspection and Testing

The selected tenderer shall make arrangements for inspection by an Engineer appointed by the Purchaser and also make arrangements to carry out in his presence necessary simulation and conventional tests of the materials and items offered. All tests shall be made prior to despatch in the presence of the representative of the purchaser and the test results in quadruplicate shall be supplied to the purchaser for approval. No material shall be despatched without prior approval of the test certificate by the purchaser. Copies of the type tests already performed on similar type of equipment shall be enclosed with the Bid to judge the merits of the equipment offered by the Bidder. 11.2 Tests on Capacitors

11.2.1 Type Tests on Capacitors Type Tests shall be carried out on one unit of each rating provided that, where batch production occurs, all batches of the same rating shall be manufactured from the same

CEB STANDARD 031 : 1996

stock of materials. If more than one stock of materials is used for each rating, one unit, manufactured from each stock of materials, shall be tested for this rating. The following Type Tests shall be carried out in accordance with the IEC specified. a) b) c) d) Tests for output/capacitance Thermal stability tests Tangent of dielectric loss angle at elevated temperature Capacitor discharge tests

11.2.2 Routine Tests on Capacitors The following Routine tests as per IEC 871 shall be carried out on all capacitor units and shall comprise of: a) b) c) d) e) f) Visual Examination Sealing Test Voltage Test between terminals Test for efficacy of discharge device Measurement of tangent of loss angle. Discharge device test

11.2.3 Acceptance Tests on Capacitors The following Acceptance Tests in accordance with the relevant IEC 871 shall be carried out in samples selected at random at the time of inspection. a) b) c) d) e)

f)

Visual Examination Sealing Test Voltage Test between terminals Test for efficacy of discharge device Measurement of tangent of loss angle

Galvanizing Test on Steel Hardware Components

12.0

ANNEXURE

CEB STANDARD 031 : 1996

A-

Guaranteed Technical Particulars for Power Capacitor Bank.

Medium Voltage 12kV/36kV Capacitor Bank Switching Type B) C) Connection Drawing. Typical Double Concrete Pole Platform Mounted Construction

CEB STANDARD 031 : 1996

Annexure - 1 GUARANTEED TECHNICAL PARTICULARS FOR POWER CAPACITOR BANK (The Bidders Shall furnish these particulars for each type offered) 1) 2) 3) 4) 5) 6) Manufacturer's Name Maker's type designation Standard followed Purpose Location (outdoor/indoor) Capacitor Bank : 6.1 6.2 6.3 6.4 6.5 Rated output MVAR Rated voltage kV. -

Rated current Amp. Rated frequency Hz. (i) (ii) Rated capacitance per phase, micro-farad Tolerance on rated capacitance

6.6 6.7 6.8 6.9 6.10 6.11 6.12 6.13 6.14

Rated reactance per phase, Ohms No. of phase Type of connection No. of units per Bank Power frequency withstand voltage, kV (RMS) Impulse withstand voltage, kV (Peak) Type of mounting structure Galvanizing thickness mm. Height of life conductor from the ground level mm.

CEB STANDARD 031 : 1996

6.15 7.

Approx. overall dimension and weight

Capacitor Unit 7.1 7.2 7.3 7.4 7.5 Rated output KVAr. Rated voltage Rated current A. Rated frequency Hz. (a) (b) 7.6 7.7 7.8 7.9 7.10 Phase No. of bushing terminals Type of fuse Losses as per IEC (W/kVAr) Insulation Level a) b) 7.11 Power frequency withstand voltage kV (RMS) Impulse withstand voltage kV (peak) Rated capacitance microfarad Tolerance on rated capacitance % kV. -

Permissible overloads 7.11.1 Voltage including harmonics 7.11.2 Current including harmonics 7.11.3 Output -

7.12 7.13 8.

Type of dielectric and type of impregnant Type of foil material

Discharge device to discharge capacitor bank to 50V or less in 300 sec after disconnection from supply 8.1 8.2 Directly connected., internal discharge resistor Other discharge device

CEB STANDARD 031 : 1996

9. 10. 11. 12. 13. 14. 15

Type of construction of elements Insulation level of bushing used No. of bushing/unit Type of bushing Upper limit of temp. category Material of container Medium Voltage Switch Item (a) (b) (c) Description Rated voltage Rated current Impulse withstand Voltage(1.2/50 s)kV peak Rated power frequency Withstand Voltage (wet) Rated short-circuit breaking current Rated short- circuit making current Control mechanism operating Voltage Closing Coil operating Voltage Tripping Coil operating voltage

Units kV A kV

Details

(d) (e) (f) (g) (h) (i) (j) (k) (l) (m) (n)

kv kA kA V V V Nos.

Minimum number of auxiliary contacts normally open normally closed Nos. Minimum Electrical clearance between phases Minimum Creepage distance minimum Protected distance Gas monitoring (for SF6 type only)

mm mm mm -

CEB STANDARD 031 : 1996

Vous aimerez peut-être aussi

- VCB SpecificationsDocument17 pagesVCB SpecificationsHarsh GuptaPas encore d'évaluation

- Earthing Protection SpecificationDocument5 pagesEarthing Protection SpecificationNi RePas encore d'évaluation

- Section 26 24 13-LV Power Distribution Boards PDFDocument15 pagesSection 26 24 13-LV Power Distribution Boards PDFmasoodaePas encore d'évaluation

- Ring Main UnitDocument7 pagesRing Main UnitWaleed Abd El-HamiedPas encore d'évaluation

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedPas encore d'évaluation

- Specification For TransformersDocument25 pagesSpecification For Transformerswaleed.liaquat.kkPas encore d'évaluation

- System Substation BatteryDocument15 pagesSystem Substation BatteryCarlos Martinez100% (1)

- Figure 1 - Motor Control CabinetDocument6 pagesFigure 1 - Motor Control CabinetJosé Vicente González VivasPas encore d'évaluation

- 37SDMS02Document5 pages37SDMS02Mohamed Ahmed MansourPas encore d'évaluation

- Capacitor BankDocument9 pagesCapacitor BankBala M100% (1)

- 6 400KV CB PirDocument36 pages6 400KV CB PirRAPRATSINPas encore d'évaluation

- Abb 11kv Vd4 VCB CatalogueDocument10 pagesAbb 11kv Vd4 VCB CataloguePithoon UngnaparatPas encore d'évaluation

- Guidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFDocument89 pagesGuidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFSwaroop Biswas100% (1)

- Inspection of Electric EquipmentDocument26 pagesInspection of Electric Equipmentkalyan ReddyPas encore d'évaluation

- Cable PullingDocument3 pagesCable PullingvipinrajPas encore d'évaluation

- Substation Maintenance Inspection ListDocument327 pagesSubstation Maintenance Inspection Listjohndavsg8022Pas encore d'évaluation

- Substation Filter BankSpecsDocument7 pagesSubstation Filter BankSpecsTudor BostanPas encore d'évaluation

- S TR CIVIL OHL (Rev.0 2018) 1648785693296Document33 pagesS TR CIVIL OHL (Rev.0 2018) 1648785693296Vimala PonnusamyPas encore d'évaluation

- Nuisance TrippingDocument6 pagesNuisance TrippingSeindahNyaPas encore d'évaluation

- Specification of 11kv SF6 Insulated Ring Main UnitsDocument8 pagesSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANPas encore d'évaluation

- ANSI Standard Device Number - Kilowatt ClassroomDocument7 pagesANSI Standard Device Number - Kilowatt ClassroomLimbagaPas encore d'évaluation

- KA Cable Laying, Testing and Commissioning: Description Unit Qty Total Price (RS.) SL NoDocument8 pagesKA Cable Laying, Testing and Commissioning: Description Unit Qty Total Price (RS.) SL NoLakshika AshaniPas encore d'évaluation

- Lighting Philosphy NTPCDocument8 pagesLighting Philosphy NTPCHarpreet SinghPas encore d'évaluation

- 11 KV Switch Board - Specification DetailsDocument18 pages11 KV Switch Board - Specification DetailsssbPas encore d'évaluation

- Schedule of Charges and Procedure PDFDocument58 pagesSchedule of Charges and Procedure PDFabhi...Pas encore d'évaluation

- Package SubstationDocument9 pagesPackage SubstationuddinnadeemPas encore d'évaluation

- Specification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqDocument10 pagesSpecification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqyildirimonlinePas encore d'évaluation

- Vacuum Circuit BreakerDocument12 pagesVacuum Circuit Breakerherovhung12100% (1)

- Wiring Specification ManualDocument17 pagesWiring Specification ManualHadrien FaryalaPas encore d'évaluation

- 6.3MVA Distribution TransformerDocument6 pages6.3MVA Distribution TransformerAnonymous KFOfMbNAPas encore d'évaluation

- Pilot Cable Specs FewaDocument13 pagesPilot Cable Specs Fewabharat_22nandulaPas encore d'évaluation

- Auto Recloser Solid Type 11KVDocument6 pagesAuto Recloser Solid Type 11KVNajeeb MaghnagPas encore d'évaluation

- 12.es-10 Capcitor BankDocument5 pages12.es-10 Capcitor BankDEADMANPas encore d'évaluation

- Breaker Manual PDFDocument52 pagesBreaker Manual PDFNiraj YadavPas encore d'évaluation

- Type of Drawout PDFDocument58 pagesType of Drawout PDFrantaroPas encore d'évaluation

- Overhead SwitchesDocument24 pagesOverhead SwitchesAnthony LagradaPas encore d'évaluation

- Auxiliary Transformer DatasheetDocument3 pagesAuxiliary Transformer DatasheetRigoberto UrrutiaPas encore d'évaluation

- Tech - Spec. LA For WBSEDCL Sept.07, ArresterDocument6 pagesTech - Spec. LA For WBSEDCL Sept.07, ArresterThanh NguyenPas encore d'évaluation

- 18Document15 pages18edgardPas encore d'évaluation

- SEWA-E-D-003 33 KV CableDocument37 pagesSEWA-E-D-003 33 KV Cablezaheer2931100% (1)

- SubstationsDocument34 pagesSubstationsBeen Carlo De JasminPas encore d'évaluation

- Distribution Feeder PrinciplesDocument9 pagesDistribution Feeder Principlesanoopeluvathingal100Pas encore d'évaluation

- Technial Specification of Panel .Wiring, SwitchgearDocument19 pagesTechnial Specification of Panel .Wiring, SwitchgearkiroPas encore d'évaluation

- Electrical Safety Standards For LV-MV-HV Part-1)Document12 pagesElectrical Safety Standards For LV-MV-HV Part-1)Suresh UmadiPas encore d'évaluation

- High Voltage Components PresentationsDocument28 pagesHigh Voltage Components Presentationschristian fruto100% (1)

- System Operation Memorandum T-08Document12 pagesSystem Operation Memorandum T-08xabproject100% (1)

- Main Components of Electrical Substation: Incoming LineDocument10 pagesMain Components of Electrical Substation: Incoming LineShiv Kumar Verma100% (1)

- P-90-82 F - CT's 33 To 132 KVDocument13 pagesP-90-82 F - CT's 33 To 132 KVHasnain AwanPas encore d'évaluation

- Power Cable ScheduleDocument40 pagesPower Cable ScheduleAnupam0103Pas encore d'évaluation

- All Electrical InterviewDocument20 pagesAll Electrical InterviewramprakashpatelPas encore d'évaluation

- 33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARDocument9 pages33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARSatyajit RaiPas encore d'évaluation

- 220-132kV Power and Control Cable Schedule - Dhalkebar With CommentDocument53 pages220-132kV Power and Control Cable Schedule - Dhalkebar With CommentmanishPas encore d'évaluation

- Minimum Electrical ClearanceDocument5 pagesMinimum Electrical ClearancemkbpgcilPas encore d'évaluation

- D-07 11kv SwitchgearDocument12 pagesD-07 11kv SwitchgearShri Anvesha D100% (1)

- Knowledge is "Real Power": Introduction to Power QualityD'EverandKnowledge is "Real Power": Introduction to Power QualityPas encore d'évaluation

- S&C Custom Metal-Enclosed Switchgear: (Select Values From Table On Page 2.)Document29 pagesS&C Custom Metal-Enclosed Switchgear: (Select Values From Table On Page 2.)Luis CabimasPas encore d'évaluation

- 18 11KV VCBs PDFDocument37 pages18 11KV VCBs PDFSharafat AliPas encore d'évaluation

- 50SDMS01Document11 pages50SDMS01amazonia1954Pas encore d'évaluation

- Annexure - A Part-I (Technical Bid)Document19 pagesAnnexure - A Part-I (Technical Bid)Prachi DongrePas encore d'évaluation

- HB 03025Document28 pagesHB 03025Rey ArthurPas encore d'évaluation

- Introduction To Power SystemsDocument60 pagesIntroduction To Power Systemsworldcreators2_79758Pas encore d'évaluation

- Short Circuit CalculationDocument1 pageShort Circuit CalculationRey ArthurPas encore d'évaluation

- AG Learn More BrochureDocument12 pagesAG Learn More Brochuregyanendra_vatsa4380Pas encore d'évaluation

- Road-Lighting Electrical Plan EstimateDocument2 pagesRoad-Lighting Electrical Plan EstimateRey Arthur100% (1)

- 1 Reactive Power Compensation PDFDocument97 pages1 Reactive Power Compensation PDFSorin ChirilaPas encore d'évaluation

- IIEE Response To HB4325Document10 pagesIIEE Response To HB4325Rey ArthurPas encore d'évaluation

- Voltage Drop Calculation SampleDocument1 pageVoltage Drop Calculation SampleRey ArthurPas encore d'évaluation

- Graphic 1Document1 pageGraphic 1Rey ArthurPas encore d'évaluation

- Marine MotorsDocument13 pagesMarine MotorsRey ArthurPas encore d'évaluation

- PLCDocument1 pagePLCRey ArthurPas encore d'évaluation

- Graphic 9952-001Document1 pageGraphic 9952-001Rey ArthurPas encore d'évaluation

- SampleDocument1 pageSampleRey ArthurPas encore d'évaluation

- Incident Investigation Self Guided Working Package PDFDocument30 pagesIncident Investigation Self Guided Working Package PDFRey ArthurPas encore d'évaluation

- Power System Protective Relaying: Basic Concepts, Industrial-Grade Devices, and Communication MechanismsDocument35 pagesPower System Protective Relaying: Basic Concepts, Industrial-Grade Devices, and Communication MechanismsAnonymous hWRGcOe4X100% (1)

- OMRON PLC-Based Process Control Engineering GuideDocument228 pagesOMRON PLC-Based Process Control Engineering GuideMichael Parohinog GregasPas encore d'évaluation

- DSB Maritime Earthing GuidelinesDocument36 pagesDSB Maritime Earthing GuidelinesMakiberPas encore d'évaluation

- 01$GC Cable-Install Manual PowerControl Cables-7 14Document102 pages01$GC Cable-Install Manual PowerControl Cables-7 14galdreyPas encore d'évaluation

- Fault Management in Electrical Distribution SystemsDocument41 pagesFault Management in Electrical Distribution Systemsrian0201Pas encore d'évaluation

- Trafobox InstallationDocument4 pagesTrafobox InstallationRey ArthurPas encore d'évaluation

- Molded-Case Circuit Breakers & EnclosuresDocument136 pagesMolded-Case Circuit Breakers & EnclosuresKandan KarunaiPas encore d'évaluation

- Fuses or Molded Case Circuit BreakersDocument10 pagesFuses or Molded Case Circuit BreakersRey ArthurPas encore d'évaluation

- StudytransformersDocument55 pagesStudytransformersManuel Alejandro Echeverry LopezPas encore d'évaluation

- 1800 GreenleeDocument14 pages1800 Greenleejcauble73Pas encore d'évaluation

- MVC 9068Document52 pagesMVC 9068Rey ArthurPas encore d'évaluation

- Cement SpecificationsDocument2 pagesCement SpecificationsUsman Umar TabassumPas encore d'évaluation

- MVC 9078Document32 pagesMVC 9078Rey Arthur100% (1)

- Sgim 9068BDocument52 pagesSgim 9068BRey ArthurPas encore d'évaluation

- 17 9 - WESM-MSDM-010 PEM Board Approved 30 May 2014 Clean BDocument215 pages17 9 - WESM-MSDM-010 PEM Board Approved 30 May 2014 Clean BRey ArthurPas encore d'évaluation

- Amen PDFDocument1 pageAmen PDFRey ArthurPas encore d'évaluation

- A Look at The Power Rating of ResistorsDocument2 pagesA Look at The Power Rating of ResistorsTigrilloPas encore d'évaluation

- High Voltage Circuit BreakersDocument42 pagesHigh Voltage Circuit BreakersItalo MartinangeliPas encore d'évaluation

- PSR PPSXDocument19 pagesPSR PPSXpmahesh268Pas encore d'évaluation

- Booklet Pindad Elektrik A5 Eng - Compressed PDFDocument18 pagesBooklet Pindad Elektrik A5 Eng - Compressed PDFIjal LubisPas encore d'évaluation

- E34-1 Battery Charging and Dishcharging BoardDocument23 pagesE34-1 Battery Charging and Dishcharging BoardGanesa MurthyPas encore d'évaluation

- Matlab-Simulink Model of AC Grid With Non-LinearDocument5 pagesMatlab-Simulink Model of AC Grid With Non-LinearSalman HarasisPas encore d'évaluation

- PP Lab Reports - Steam Power PlantDocument5 pagesPP Lab Reports - Steam Power PlantMuhammad Waleed TariqPas encore d'évaluation

- CMF 300 ManualDocument2 pagesCMF 300 ManualCristhian Monasterio HuertasPas encore d'évaluation

- Diesel Diesel Diesel Diesel Generator Generator Generator Generator Data Data Data Data Sheet Sheet Sheet SheetDocument5 pagesDiesel Diesel Diesel Diesel Generator Generator Generator Generator Data Data Data Data Sheet Sheet Sheet SheetRaymond Komala AgusPas encore d'évaluation

- PT7Document2 pagesPT7Anonymous j5apk2AumPas encore d'évaluation

- Mobile SubstationsDocument7 pagesMobile SubstationsAnonymous EVFw59Pas encore d'évaluation

- Annual PlanDocument38 pagesAnnual PlanAbdul Rashid QureshiPas encore d'évaluation

- Illustrated Guide To Electrical Building Services 3rd EditionDocument85 pagesIllustrated Guide To Electrical Building Services 3rd EditionMihaela AntonPas encore d'évaluation

- Corporate Exposure 2021 (Pendalaman 23 Feb 2021)Document58 pagesCorporate Exposure 2021 (Pendalaman 23 Feb 2021)Audy ErrybowoPas encore d'évaluation

- Electrical Load Calculation For Three-Storey BuildingDocument20 pagesElectrical Load Calculation For Three-Storey BuildingMoe Thant OoPas encore d'évaluation

- Iwokazpy Fo - QR Forj.K Fuxe Fyfevsm: Purvanchal Vidyut Vitaran Nigam LTDDocument2 pagesIwokazpy Fo - QR Forj.K Fuxe Fyfevsm: Purvanchal Vidyut Vitaran Nigam LTDAvinash palPas encore d'évaluation

- Test Single Phase MotorDocument2 pagesTest Single Phase MotorquangPas encore d'évaluation

- Generator Type Ecp 3-1L/4: HZ V kVA KW kVA KW DSRDocument5 pagesGenerator Type Ecp 3-1L/4: HZ V kVA KW kVA KW DSRFaridh AmroullohPas encore d'évaluation

- CNCPG SeminarDocument29 pagesCNCPG SeminarHemant PatilPas encore d'évaluation

- Caracteristicas Tecnicas Breakers IndustrialesDocument2 pagesCaracteristicas Tecnicas Breakers IndustrialesLuis GilPas encore d'évaluation

- Gravitational Water Vortex PP (Project Proposal)Document21 pagesGravitational Water Vortex PP (Project Proposal)Haider AliPas encore d'évaluation

- Heat Balance DiagramDocument10 pagesHeat Balance DiagramJitendra Bhatia100% (3)

- 53D - Abvolt - Digital Micro-Ohm MeterDocument6 pages53D - Abvolt - Digital Micro-Ohm Meterilesh shahPas encore d'évaluation

- Absorption 7 Series Service Instruction ENDocument56 pagesAbsorption 7 Series Service Instruction ENPolishLovePolicePas encore d'évaluation

- Generator ProtectionDocument34 pagesGenerator ProtectionNaveed RabbaniPas encore d'évaluation

- Electrical TransformersDocument10 pagesElectrical TransformersSindhu ManchukondaPas encore d'évaluation

- Abb Ref615 Relay Ansi Broch 1mac105890-Db EnfDocument4 pagesAbb Ref615 Relay Ansi Broch 1mac105890-Db Enfadamshoe34Pas encore d'évaluation

- CL-NG-6460-002-022Checklist For NER Rev00Document2 pagesCL-NG-6460-002-022Checklist For NER Rev00WajahatPas encore d'évaluation

- Excitation Loss Module: SpecificationDocument2 pagesExcitation Loss Module: SpecificationKenNaPas encore d'évaluation

- Renewable Energy Sources AssignmentDocument11 pagesRenewable Energy Sources Assignment18TUIT016 BALAKRISHNAN .PPas encore d'évaluation