Académique Documents

Professionnel Documents

Culture Documents

Shell and Tube Heat Exchanger Spreadsheet

Transféré par

Hernan Cardenas FrancoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Shell and Tube Heat Exchanger Spreadsheet

Transféré par

Hernan Cardenas FrancoDroits d'auteur :

Formats disponibles

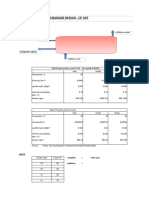

Shell and Tube Heat Exchanger Design Spreadsheet

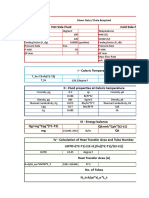

Project Item No. Light Base Oil Feed Exchanger E-101 Service Light Base Oil Feed Exchanger Project No. STBE for Establishment By

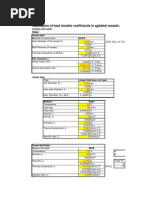

Step 1. Input flows, conditions and properties data for shellside and tubeside. Tube Used Lube Oil 14,925.1 68 163.4 54.765 92.989 0.605 861,007 0.095 0.004 1426.38 Uncorrected MTD Corrected MTD Side Fluid Name Flow (M), lb/h o Temp. in, F o Temp. out, F 3 r, lb/ft m, cP cp, Btu/lboF Q, Btu/h k, Btu/hftoF R, ft2hoF/Btu cpm/k 143.6 108.3

o o

Step 4. Start configuring the exchanger. Begin with the total transfer coefficients to this point (i.e., not including shellside Shell Light Base Oil 4,854.5 392 150.8 51.3158 8.767 0.613 717,769 0.1098 0.004 118.44 F F Step 5. Select tube arrangement and estimate shell diameter

Reset tubes/pass (Step 3), then no. of passes =

Av. Density Av. Viscosity Av. Heat Capacity Heat Exchanged Av. Thermal Conductivity Fouling Resistance Prandtl No.

Step 2. Input tubing OD, BWG and length (can be trial and error).

Tube OD BWG Tube ID, d = Tube Length, L = Flow area per tube, at = Effective transfer area per tube =

0.7500 16 0.620 8 0.302 1.571

in. in. ft. in.2 2 ft

Equivalent Diameter, de (see table) =

Step 3. Estimate the number of tubes per tube pass.

Tubes/pass = lb/h per tube = Av. velocity, fps = Tubeside Reynolds No., NRe = Tubeside Friction Factor, f = DP per pass, psi = Nusselt number, Nr = Inside Film Coefficient, hi =

129 116 0.28 13 0.219 0.02 9.09 168

Check: % difference, Ucalc. vs Uassum. =

Step 6. Check tubeside velocity and DP, shellside DP. If too adjust tube length, number of tubes per pass, number of pa required.

baffle spacing. Remember to reset shell diameter from tub

ger Design Spreadsheet

STBE for Establishment SETH Date/Time

7-Nov-12 12:07

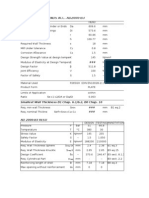

Step 4. Start configuring the exchanger. Begin with the total calculated transfer coefficients to this point (i.e., not including shellside h): Ustart = 72 On that basis, assumed Uo = Then the required transfer A = Number of tubes required = Reset tubes/pass (Step 3), then no. of passes = Total tube count = Tubeside DP (incl. returns) = Actual effective transfer area, A = 20 398 253 2 258 0.036 405

BWG/Tube Wall Thicknesses 8 0.165 9 0.148 0.017 10 0.134 0.014 11 12 13 14 15 16 0.120 0.109 0.095 0.083 0.072 0.065 0.014 0.011 0.014 0.012 0.011 0.007

2 o

Btu/hft2oF Btu/hft F ft2

psi ft2

MTD Correction Factors R = ( T1 - T2 ) / ( t2 - t1 ) = 2.528 0.294 2.719 2.761 1.762 0.161 0.754

Step 5. Select tube arrangement and estimate shell diameter

Tube Pitch Pattern

1 Sqr 21 5 18 0.182 0.9476 26,631 240 0.00421 0.027 8.1 55 31.2 35.9% 41.6

in. S = ( t2 - t1 ) / ( T1 - t1 ) = in. in. ft2 in. lb/hft2 18.20 ( 1 - S ) / ( 1 - RS ) = 2-S(R+1-(R +1)

2

Shell ID from Tube Count Tables Select Baffle Spacing Number of Baffles = Flow Area across Bundle, as = Equivalent Diameter, de (see table) = Mass Velocity, Gs = Shellside Reynolds No., NRe = Shellside Friction Factor = Shellside DP = Outside Transfer Factor, jh = Outside Film Coefficient, ho = Calculated Uo = Check: % difference, Ucalc. vs Uassum. = Uclean =

( R2 + 1 ) =

)=

2 - S ( R + 1 + ( R2 + 1 ) ) = psi FT =

Step 6. Check tubeside velocity and DP, shellside DP. If too high or too low, adjust tube length, number of tubes per pass, number of passes, and/or shell baffle spacing. Remember to reset shell diameter from tube count tables, as required.

Vous aimerez peut-être aussi

- Shell and Tube Heat ExchangerDocument19 pagesShell and Tube Heat Exchangerhuangjl33% (3)

- Heat ExchangerDocument53 pagesHeat ExchangerNurulHidayahPas encore d'évaluation

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelPas encore d'évaluation

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINPas encore d'évaluation

- Perhitungan Dan Disain HeaterDocument19 pagesPerhitungan Dan Disain HeatersehonoPas encore d'évaluation

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocument2 pagesDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Pas encore d'évaluation

- Air Cooled ExchangerDocument4 pagesAir Cooled Exchangermayurjannu100% (1)

- Thermal Design of Heat ExchangerDocument9 pagesThermal Design of Heat ExchangerNaqqash SajidPas encore d'évaluation

- Diameter of Tank Baffle and Coil DimensionsDocument4 pagesDiameter of Tank Baffle and Coil DimensionsTarmana Antt50% (2)

- Asme Tubesheet (Heater 10m2)Document23 pagesAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Evaporator heat transfer and surface area calculationDocument4 pagesEvaporator heat transfer and surface area calculationDaniyal HashmiPas encore d'évaluation

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 pagesDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaPas encore d'évaluation

- FLUE GAS ANALYSIS AND HEAT EXCHANGER SIZINGDocument3 pagesFLUE GAS ANALYSIS AND HEAT EXCHANGER SIZINGRajendraPas encore d'évaluation

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- Tube Sheet CalculationDocument3 pagesTube Sheet CalculationAbhay UpadhyayPas encore d'évaluation

- Heat Exchanger DesignDocument48 pagesHeat Exchanger DesignJose SotoPas encore d'évaluation

- TEMA Shell & Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell & Bundle Entrance and Exit Areasnagtummala100% (3)

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelPas encore d'évaluation

- Sizing Heating Coil Insulated Fuel TankDocument2 pagesSizing Heating Coil Insulated Fuel Tankypatels50% (2)

- Heat Exchanger Calculation Version 2Document2 pagesHeat Exchanger Calculation Version 2huangjlPas encore d'évaluation

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhPas encore d'évaluation

- Shell and Tube Heat Exchanger1Document19 pagesShell and Tube Heat Exchanger1Lily NurdianaPas encore d'évaluation

- Vessel Weight CheckDocument8 pagesVessel Weight ChecknileshPas encore d'évaluation

- Steam Coil CalculationDocument10 pagesSteam Coil CalculationRefqi Kemal Habib100% (2)

- Calculation Overall Heat TransferDocument4 pagesCalculation Overall Heat TransferDavid LambertPas encore d'évaluation

- Air Cooler-Example 8-2Document3 pagesAir Cooler-Example 8-2citramuaraPas encore d'évaluation

- Design of a Double Pipe Heat Exchanger CalculationsDocument2 pagesDesign of a Double Pipe Heat Exchanger CalculationsSaqib RaoufPas encore d'évaluation

- Heat Exchanger Design CalculationsDocument8 pagesHeat Exchanger Design Calculationskikokiko KarimPas encore d'évaluation

- Heat Loss From An Insulated Pipe: ParametersDocument4 pagesHeat Loss From An Insulated Pipe: ParametersMohan BabuPas encore d'évaluation

- Heat Exchanger DesignDocument20 pagesHeat Exchanger Designpav270875% (4)

- Heating Coil CalculationDocument1 pageHeating Coil Calculationyatin888100% (1)

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Document1 pageTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456Pas encore d'évaluation

- Method of Heat Exchanger Sizing (Kern Method)Document11 pagesMethod of Heat Exchanger Sizing (Kern Method)Hani Kirmani80% (5)

- Internal CoilDocument2 pagesInternal CoilwhngomjPas encore d'évaluation

- Ejemplo Tubesheet Asme UHXDocument14 pagesEjemplo Tubesheet Asme UHXPedro Montes MarinPas encore d'évaluation

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemPas encore d'évaluation

- Shell & Tube - Heat-Exchanger - DesignDocument6 pagesShell & Tube - Heat-Exchanger - DesignVirendra Bhagat100% (2)

- Film Temp Calculation For Thermic Fluid ApplicationDocument2 pagesFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuPas encore d'évaluation

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertPas encore d'évaluation

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVAPas encore d'évaluation

- Tubular Heat Exchanger Rating Sheet: Start 2 o 2 oDocument1 pageTubular Heat Exchanger Rating Sheet: Start 2 o 2 oSIVAPas encore d'évaluation

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- 432 ProjectDocument19 pages432 ProjectSahil PalPas encore d'évaluation

- Tappi 0502-17 Papermaker FormulaDocument19 pagesTappi 0502-17 Papermaker FormulaMulyadi Moel85% (20)

- Heat Exchanger DesignDocument22 pagesHeat Exchanger DesignRupack HalderPas encore d'évaluation

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Información Diseño de Intercambiadores Shell and TubeDocument16 pagesInformación Diseño de Intercambiadores Shell and Tubejenny pereaPas encore d'évaluation

- Sludge ThickenerDocument15 pagesSludge ThickenerDavid LambertPas encore d'évaluation

- CE 432 Wastewater treatment plant design optimizationDocument19 pagesCE 432 Wastewater treatment plant design optimizationjnmanivannanPas encore d'évaluation

- Half Pipe CalculationDocument3 pagesHalf Pipe CalculationCaptainTonies0% (1)

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MPas encore d'évaluation

- Designing a shell-and-tube heat exchangerDocument8 pagesDesigning a shell-and-tube heat exchangerLorna AhlaamiPas encore d'évaluation

- Hex-301 0209Document29 pagesHex-301 0209qilaqrsPas encore d'évaluation

- Discharge CoefficientDocument11 pagesDischarge Coefficientsisai12u2420% (2)

- 7D162B Pressure Drop For Double Pipe Heat Exchanger SiDocument4 pages7D162B Pressure Drop For Double Pipe Heat Exchanger SiparagmhamunkarPas encore d'évaluation

- Design of EquipmentDocument14 pagesDesign of EquipmentNaeem KhanPas encore d'évaluation

- 7.flash DistilerDocument35 pages7.flash DistilerNa-na OktaviaPas encore d'évaluation

- Extraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)Document17 pagesExtraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)weeseongPas encore d'évaluation

- Steel Slit Shear Walls With An Efficient GeometryDocument13 pagesSteel Slit Shear Walls With An Efficient GeometryTY ZPas encore d'évaluation

- HFC R32 SuperheatDocument5 pagesHFC R32 SuperheatWeka FajarPas encore d'évaluation

- Manual de PLT NeilDocument172 pagesManual de PLT Neilfergot2010Pas encore d'évaluation

- Fluorescence Quenching of Albumin. A Spectrofluorimetric ExperimentDocument3 pagesFluorescence Quenching of Albumin. A Spectrofluorimetric Experimentsujay85Pas encore d'évaluation

- ConductorsDocument19 pagesConductorsNavdeep KaurPas encore d'évaluation

- Assigment Individual ECV5407 PDFDocument4 pagesAssigment Individual ECV5407 PDFsaimaPas encore d'évaluation

- Periodic TrendsDocument31 pagesPeriodic TrendsAndrew Bondad100% (1)

- EPA Corrosion ManualDocument141 pagesEPA Corrosion Manualnert100% (1)

- Latihan Soal GasDocument1 pageLatihan Soal GasnajmahsPas encore d'évaluation

- Lightening ArresterDocument13 pagesLightening Arresterrohanlagad10Pas encore d'évaluation

- Standardization of HCL Solution PDFDocument12 pagesStandardization of HCL Solution PDFMohamed MahmoudPas encore d'évaluation

- Tablas, Figuras, ASTM-G Marroquin 9mayo23Document62 pagesTablas, Figuras, ASTM-G Marroquin 9mayo23MEGALOMANIACPas encore d'évaluation

- Pipe Stress Calculations012340913294Document13 pagesPipe Stress Calculations012340913294H VPas encore d'évaluation

- Nanoindentation Testers NHT2 From CSM Instruments: Quote, RFQ, Price and BuyDocument3 pagesNanoindentation Testers NHT2 From CSM Instruments: Quote, RFQ, Price and BuyNathawat PleumsamranPas encore d'évaluation

- BASF Specialty Monomers 1Document16 pagesBASF Specialty Monomers 1Victor LopezPas encore d'évaluation

- Laser Parameters PDFDocument20 pagesLaser Parameters PDFayyappa laserPas encore d'évaluation

- Physics Chapter 11 Human Eye & Colourful World AssignmentDocument2 pagesPhysics Chapter 11 Human Eye & Colourful World AssignmentAashna BarnabasPas encore d'évaluation

- ISO 29541-2010 Solid Mineral Fuels - Determination Total Carbon Hydrogen NitrogDocument18 pagesISO 29541-2010 Solid Mineral Fuels - Determination Total Carbon Hydrogen NitrogWinnjone YinPas encore d'évaluation

- Purging Gas 304HDocument7 pagesPurging Gas 304HketasriPas encore d'évaluation

- Sheet - 01 - Real GasDocument41 pagesSheet - 01 - Real GasSushant VermaPas encore d'évaluation

- REVIEWER FOR ChE COMPRE 07082018Document352 pagesREVIEWER FOR ChE COMPRE 07082018Ahe BeongPas encore d'évaluation

- Condensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsDocument9 pagesCondensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsLutfiah Nur HidayatiPas encore d'évaluation

- Efficient H2S Scavenger Glyoxal Outperforms TriazineDocument8 pagesEfficient H2S Scavenger Glyoxal Outperforms TriazineMo OsPas encore d'évaluation

- Heterogeneous and Homogeneous MixtureDocument4 pagesHeterogeneous and Homogeneous MixtureThe Digital Library100% (1)

- Chapter 16 Halogen DerivativesDocument11 pagesChapter 16 Halogen DerivativesSabina SabaPas encore d'évaluation

- CHE202.2 SPRING 2023 Course OutlineDocument11 pagesCHE202.2 SPRING 2023 Course OutlineZahra NasreenPas encore d'évaluation

- Gas StateDocument38 pagesGas StatesavisuPas encore d'évaluation

- Austenitic Cast Iron Welding Detailsfrequently Aske-WPS OfficeDocument17 pagesAustenitic Cast Iron Welding Detailsfrequently Aske-WPS Officearjun prajapatiPas encore d'évaluation

- Gas Circulation - Cement Plant PDFDocument127 pagesGas Circulation - Cement Plant PDFKenny RuizPas encore d'évaluation

- Local Treatment of Electron Correlation-Svein SaeboDocument24 pagesLocal Treatment of Electron Correlation-Svein SaeboAndré RojasPas encore d'évaluation