Académique Documents

Professionnel Documents

Culture Documents

4 Page Fact Sheet III

Transféré par

rentarenergyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4 Page Fact Sheet III

Transféré par

rentarenergyDroits d'auteur :

Formats disponibles

The Science of the Rentar Fuel Catalyst

Exhaust emissions are unburned and wasted fuel. When fuel is passed thru the Rentar Fuel Catalysts patented combination of metallic and rare earth elements prior to combustion, several parallel reactions occur which modifies the fuel molecules as well as releases a small amount of Hydrogen Gas. This pre-combustion treatment of the fuel results in a more complete burn. One of the reactions is the changes in the proportion of saturated straight chain aliphatic paraffins to unsaturated ring compound aromatics which leads to dehydrogenation of the saturated hydrocarbon chain resulting in the release of a small quantity of hydrogen gas. The hydrogen gas, with a flame speed faster than that of fuel, improves the combustion process and reduces NOx as a result of burning at a cooler temperature. A second reaction is a polarization or separation of clustered fuel molecules resulting in more surface area of the fuel molecules being exposed to oxygen at the point of combustion. Additional reactions result in a hydrocarbon mixture with a lower vapor density, (improved atomization), an increased cetane number, shorter ignition delays, a turbulent fuel flow all of which leads to fuel that burns more efficiently. The Rentar Fuel Catalyst uses combinations of rare earth elements and metals in various formulations depending on the applications and the 17 different Rentar Fuel Catalyst models. Such elements may include Zirconium, Cerium, Rhodium, Platinum, Palladium and Iridium. These same elements are used today in the cracking process at Oil Refineries. Platinum is currently $1600 per ounce and Zirconium hit a high of $10,000 per ounce in 2009. Many such elements come from China who has now restricted the amounts exported to create a more expensive market. The process which Rentar has 27 patents on allows the kinetic energy of the fuel to be transformed into increased useful mechanical energy. This results in better engine efficiency which leads to better fuel economy, increased engine power and reduced emissions, increased horsepower/torque and a cleaner operating engine with less maintenance required and an extended engine life.

Authored by: Robert E. Yelin, PH.D,

Dr. Yelin has a doctorate in Chemistry. Dr. Yelin has 30 years experience as project engineer, division director and principal with national and international environmental engineering consulting firms. Dr. Yelin is a past President and Present Board Member of a Multi-Disciplinary Environmental/Engineering Firm that was partially owned by General Motors. Dr. Yelin also organized an environmental services group for Honeywell Corporation. At present he is a VP for a major multi-disciplinary environmental services company leading their alternative energy initiative. Dr. Yelin is widely published. Dr. Yelin has been head of the Rentar Science Team for more than 12 years.

Rentar Environmental Solutions, Inc. * Email: Info@Rentar.com * Telephone: (561) 333-3411 * Website: www.Rentar.com

**

The Global Leader in Pre-combustion Technology

Rentars patented technology (27 domestic and international patents) has been verified by EPA and CARB recognized laboratories. Some noteworthy examples are Southwest Research Institute; the U.S. Armys Aberdeen Proving Ground, Virginia Tech University Olson Ecco-logic Emissions Laboratory and internationally by government recognized facilities in Italy, Venezuela and England.

On-road vehicles have achieved a 2% to 5% reduction in fuel consumption, up to 58.2% Particulate Matter, Greenhouse Gas and Soot reductions. Off-road vehicles achieve a 3% to 7% reduction in fuel consumption, with up to 51.6% Particulate Matter, Greenhouse Gas and Soot reduction. Furnaces / Boilers achieve a 7% to 30% fuel reduction with up to 50% Particulate Matter, Greenhouse Gas and Soot reductions.

The Rentar Fuel Catalyst is a cost effective means of managing fuel consumption and emission reduction. The cost of the Rentar Fuel Catalyst is typically recovered through fuel savings within 3 to 12 months. (ROI)

Fortune 500 companies and government agencies better manage their fuel consumption and emission control using the Rentar Fuel Catalyst. Applications include On-road, Off-road, Stationary Engines, Agriculture, Furnace/Boiler, Cell Towers, Commercial Marine, Power Generation and Railroad Locomotives

Some notable users of the Rentar Fuel Catalyst are the State of Delaware, the City of New York, Occidental Chemical, Exxon Mobils Monterey Mines, Toyota Motor Car Carriers, CEMEX Materials, Covanta Energy, Rogers Group and more than 250 furnaces in school districts throughout the Northeastern U.S.

C N A T T l 6 .6 .0 3 ma: f@R naE eg S l i s o O T C : e 8 05 10 3 E ii o e trn ry o t n . m : ln uo c We St ht:w wrnae eg s l i s o b i t / w . trn ryo t n . m/ e p/ e uo c

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Trouble Shooting EngineDocument34 pagesTrouble Shooting EngineDesta Andri MuryonoPas encore d'évaluation

- How Does A Refrigerator WorkDocument5 pagesHow Does A Refrigerator WorkAlfis0% (1)

- Sunward SWE08B Operator's ManualDocument96 pagesSunward SWE08B Operator's ManualIisakki50% (2)

- Technical-Vocational and Livelihood: (Automotive Servicing NC I)Document35 pagesTechnical-Vocational and Livelihood: (Automotive Servicing NC I)Carina Tan100% (2)

- List I (16 5 2011)Document585 pagesList I (16 5 2011)Ayaz Mani50% (2)

- ZeTo RulesDocument30 pagesZeTo RulesRamli Disa100% (5)

- Yale School Bus Report 12 Page SummaryDocument12 pagesYale School Bus Report 12 Page SummaryrentarenergyPas encore d'évaluation

- 18 - USNS WatsonDocument1 page18 - USNS WatsonrentarenergyPas encore d'évaluation

- Toyota Study by Olson EngineeringDocument6 pagesToyota Study by Olson EngineeringrentarenergyPas encore d'évaluation

- School BusDocument13 pagesSchool BusrentarenergyPas encore d'évaluation

- 16 - State TransportaionDocument5 pages16 - State TransportaionrentarenergyPas encore d'évaluation

- Nashoba Regional School Dist StudyDocument3 pagesNashoba Regional School Dist StudyrentarenergyPas encore d'évaluation

- RentarEnergySolutions - UnilaskaDocument1 pageRentarEnergySolutions - UnilaskarentarenergyPas encore d'évaluation

- New York City, NY Transit, NY StateDocument10 pagesNew York City, NY Transit, NY StaterentarenergyPas encore d'évaluation

- 15 - State TestingDocument5 pages15 - State TestingrentarenergyPas encore d'évaluation

- 11 - Mass. School FurnaceDocument3 pages11 - Mass. School FurnacerentarenergyPas encore d'évaluation

- 14 - Delaware StateDocument1 page14 - Delaware StaterentarenergyPas encore d'évaluation

- 4 Page Fact Sheet IIIDocument4 pages4 Page Fact Sheet IIIrentarenergyPas encore d'évaluation

- Bio HGHDocument19 pagesBio HGHapi-240332064Pas encore d'évaluation

- TDS - Mastertop 1330Document2 pagesTDS - Mastertop 1330Venkata RaoPas encore d'évaluation

- FuelsDocument22 pagesFuelsADITYA GAURPas encore d'évaluation

- MScSYChem18 19Document40 pagesMScSYChem18 19kumarPas encore d'évaluation

- Nucleic Acids BrochureDocument2 pagesNucleic Acids BrochureCring-cring NavarroPas encore d'évaluation

- Is 10204 PDFDocument4 pagesIs 10204 PDFDimple EntertainmentPas encore d'évaluation

- 1 Auxilliary Equipment - US PricingDocument132 pages1 Auxilliary Equipment - US PricingOscar EspitiaPas encore d'évaluation

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesPas encore d'évaluation

- Dotaverine HCLDocument5 pagesDotaverine HCLalbertsmasudoPas encore d'évaluation

- Spontaneous Combustion ConversionDocument68 pagesSpontaneous Combustion ConversionRizwan Ullah BaigPas encore d'évaluation

- Titrimetric Methods of AnalysisDocument28 pagesTitrimetric Methods of AnalysisPraveen Kumar Avvaru100% (2)

- Removal of Hardness 1Document35 pagesRemoval of Hardness 1KISHAN PATELPas encore d'évaluation

- Quality Assurance Plan Product Name: Stone Ware PipesDocument3 pagesQuality Assurance Plan Product Name: Stone Ware PipesAnonymous ciKyr0tPas encore d'évaluation

- Sansico Top Access Floor Trap - S3Document20 pagesSansico Top Access Floor Trap - S3Biggie ColdAngelPas encore d'évaluation

- 02 Heubach No 00181 ZPA RZ Epoxy Dispersion WDocument2 pages02 Heubach No 00181 ZPA RZ Epoxy Dispersion WnanoPas encore d'évaluation

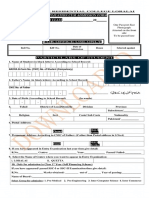

- Admission Form All 2019 1Document8 pagesAdmission Form All 2019 1Riz WanPas encore d'évaluation

- Gas TransportDocument19 pagesGas TransportJesus GutierrezPas encore d'évaluation

- NAK80 MaterialDocument3 pagesNAK80 MaterialRicky Indra DjunawanPas encore d'évaluation

- Properties of WaterDocument3 pagesProperties of WaterLupis HernándezPas encore d'évaluation

- Chemical, Physical, and Baking Properties of Apple FiberDocument4 pagesChemical, Physical, and Baking Properties of Apple FiberHector FloresPas encore d'évaluation

- Packed bed axial thermal conductivityDocument7 pagesPacked bed axial thermal conductivityAdriano HenriquePas encore d'évaluation

- Ceilcote 242 Flakeline coating specification for concreteDocument2 pagesCeilcote 242 Flakeline coating specification for concretenoto.sugiartoPas encore d'évaluation

- Chem 2 Course OutlineDocument15 pagesChem 2 Course Outlineapi-607966786Pas encore d'évaluation