Académique Documents

Professionnel Documents

Culture Documents

CMI700US

Transféré par

同道文档中心Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CMI700US

Transféré par

同道文档中心Droits d'auteur :

Formats disponibles

CMI700 Series

Control your plating/coating process with the most

advanced bench-top system that we have ever designed

Ergonomic design, a large backlit LCD display, and Oxford from several feet away and from virtually any angle.

Instruments technology and experience have been brought The CMI700 provides high tech solutions for non-destructive

together to produce the CMI700 Series. This easy-to-use coating/plating thickness measurement for both non-

microprocessor driven instrument delivers precise measure- magnetic coatings over magnetic substrates, non-conductive

ments at the touch of a button. Specially designed to coatings over conductive substrates, and electroplated nickel

handle the needs of platers, coaters, and quality profession- over magnetic substrates.

als, the CMI700 was built to withstand even the most

Like all our instruments, it’s backed by the Oxford

hostile work environments.

Instruments Group. We guarantee superior service before

The CMI700 combines ease-of-use with high inspections and after your order.

productivity and accuracy with a display that is clearly visible

● Platers: Zn, Cd, Ni, Cu etc

● Coaters: Paint, Powder and Anodize

● Quality: Ideal for incoming inspection of

coated or plated parts

CMI700 Series coating thickness measurement system CMI700 Series Specifications

Magnetic Induction: Conforms to

methods ASTM B499 & B530, DIN 50981,

ISO 2178 and BS 5411 Parts 9 & 11

Eddy Current: Conforms to methods

ASTM B244 & B259, DIN 50984, ISO 2360

and BS 5411 Part 3

Cancel Memory: 8000 bytes, non volatile

Clear Accuracy: ± 1% ± 0.1 µm referred to

reference standards

Backspace

Outputs: Parallel printer port and RS232

Enter

serial port

Numeric Pad

Unit Conversions: Select from mils, µm,

Go µin, mm, in., or % as units for display

Weight: 6 Lbs. (2.79 kg)

Hand Rest Dimensions: (W) 11.5" (29.21 cm)

(D) 10.5" (26.67 cm)

Measure

(H) 5.5" (13.97 cm)

Calibrate

Display: Large LCD 480(H) x 320(V) pixels,

Setup backlit, wide angle view

Menu Softkeys

Statistics: Mean, high and low, standard

Backlit Screen deviation, % deviation and CPK

Charts: Histogram, trend, x-Bar and r

Eddy Current Mode Range Magnetic Mode Range

Non-Conductive on 0-40.0 mils (0-1000 µm) Non-Magnetic on 0-50.0 mils (0-1250 µm) Call Sales Support for more information

Conductive Magnetic Steel regarding the CMI700 Series.

Zinc on Steel 0-1.50 mils (0-37.5 µm) CMI700 Series instruments comply with

ISO/IEC Guide 25 requirements.

Cadmium on Steel 0-1.50 mils (0-37.5 µm) Electroplated Nickel 0-5.00 mils (0-125 µm)

on Non-Magnetic Multiple Security Levels

Copper on Steel 0-1.50 mils (0-37.5 µm) CE Mark

Nickel on Steel 0-3.00 mils (0-75.0 µm)

(electroplated)

Probe Samples and Information The Oxford Instruments Support team

will help you select the

probe that will measure

your application. Factors

involved in probe

selection are type of

coating, thickness of

This publication is the copyright of Oxford Instruments

coating, size of part, Analytical Limited and provides outline information only which

(unless agreed by the company in writing) may not be used,

and shape of part. applied or reproduced for any purpose or form part of any order

or contract or be regarded as a representation relating to the

Probes are required with all CMI700 Series Optional probe products or services concerned.

systems. Despite their size and simple appearance, guides provide Oxford Instruments’ policy is one of continued improvement.

The company reserves the right to alter without notice the speci-

probes are high precision electromechanical precision fication, design or conditions of supply of any product or service.

Oxford Instruments acknowledges all trademarks and registra-

assemblies that play a critical role in your ability control. tions.

to measure parts accurately.

Probe Guide (optional)

USA

Chicago, Illinois

Tel: +1 800 678 1117

Fax: +1 847 439 4425 Email: sales@oicm.com

www.oicm.com OIA/52/A/0202

© Oxford Instruments Analytical Limited, 2002. All rights reserved.

Vous aimerez peut-être aussi

- Special Offer Manual CMM SMART Capps ThomeDocument17 pagesSpecial Offer Manual CMM SMART Capps ThomeMohammad NorooziPas encore d'évaluation

- High Efficiency Video Coding: Coding Tools and SpecificationD'EverandHigh Efficiency Video Coding: Coding Tools and SpecificationPas encore d'évaluation

- CMI200USDocument2 pagesCMI200US同道文档中心Pas encore d'évaluation

- Versatile Performance: Color LCD MonitorDocument2 pagesVersatile Performance: Color LCD MonitorHugh RaltonPas encore d'évaluation

- Samsung SMART Signage: HighlightsDocument2 pagesSamsung SMART Signage: HighlightsTarek SleemPas encore d'évaluation

- B7ec PDFDocument13 pagesB7ec PDFEl KojackPas encore d'évaluation

- Acx 391 AkbDocument2 pagesAcx 391 AkbmobiFlip.de100% (1)

- TAS-Z1 Brochure EN 20220906 v1.1Document4 pagesTAS-Z1 Brochure EN 20220906 v1.1Arief Rahman HakimPas encore d'évaluation

- Qnix 8500 Data SheetDocument10 pagesQnix 8500 Data SheetMustafa BahtiyarPas encore d'évaluation

- LG IT Diagnostic Monitor 21HK512D ShareDocument2 pagesLG IT Diagnostic Monitor 21HK512D Sharedanang setiawanPas encore d'évaluation

- Pipescan HD: Mapping The UnseenDocument4 pagesPipescan HD: Mapping The UnseenArmando MendietaPas encore d'évaluation

- FL SONOWALL 70 en Rev 1 2017-04-27Document6 pagesFL SONOWALL 70 en Rev 1 2017-04-27VICENTE CHAPARROPas encore d'évaluation

- Xenon 1900g: General Duty ScannersDocument2 pagesXenon 1900g: General Duty ScannersSopo KowePas encore d'évaluation

- 2.-Kelch Broschure Tool Presetter Englisch V01 04-2015Document36 pages2.-Kelch Broschure Tool Presetter Englisch V01 04-2015parsha nayakPas encore d'évaluation

- F22s TSUMU18ERDocument43 pagesF22s TSUMU18ERdan_tiganucPas encore d'évaluation

- Vinyl Cutter Cutting Plotter Roll Vinyl Cutter Graphtec CE6000Document2 pagesVinyl Cutter Cutting Plotter Roll Vinyl Cutter Graphtec CE6000Stuart PongPas encore d'évaluation

- Smart Signage QB24R, QB24R-T 201228 WEBDocument5 pagesSmart Signage QB24R, QB24R-T 201228 WEBJuan José MejíaPas encore d'évaluation

- AOPEN Digital Mosaic 22MDocument2 pagesAOPEN Digital Mosaic 22MMarisagarcia2014Pas encore d'évaluation

- Barco UniSee-800 NitsDocument2 pagesBarco UniSee-800 NitsBullzeye StrategyPas encore d'évaluation

- Di Lev7 Digital Level - Jual Waterpass Digital Level Horizon Di Lev7 - Tlp.082217294199Document2 pagesDi Lev7 Digital Level - Jual Waterpass Digital Level Horizon Di Lev7 - Tlp.082217294199Tantan Teknik IndonesiaPas encore d'évaluation

- ThinkVision T24i 20 61F7MAR1LADocument2 pagesThinkVision T24i 20 61F7MAR1LACarlos MonterreyPas encore d'évaluation

- Tramo2 PDFDocument2 pagesTramo2 PDFAhmed MyfacePas encore d'évaluation

- LBT-1042O - Caltron 10 Inch LCD Open Frame Monitor and Industrial Touch Screen MonitorsDocument1 pageLBT-1042O - Caltron 10 Inch LCD Open Frame Monitor and Industrial Touch Screen MonitorsCaltron Industries, Inc.Pas encore d'évaluation

- OverView KVD5521 - SpecificationsDocument3 pagesOverView KVD5521 - SpecificationsMohran HakimPas encore d'évaluation

- Roughness Tester CatalogueDocument12 pagesRoughness Tester Cataloguerohit singhPas encore d'évaluation

- Leica Cs20-Cs35 DsDocument2 pagesLeica Cs20-Cs35 DsJelena TerzicPas encore d'évaluation

- Service Manual: Torinitron Color Graphic DisplayDocument87 pagesService Manual: Torinitron Color Graphic DisplayHristo IvanovPas encore d'évaluation

- CG70Document2 pagesCG70Jawwad AhmedPas encore d'évaluation

- CG70Document2 pagesCG70Jawwad AhmedPas encore d'évaluation

- Hitec - Katalog CMM 2018 ENDocument4 pagesHitec - Katalog CMM 2018 END.T.Pas encore d'évaluation

- Co2 Sensor EMCDocument4 pagesCo2 Sensor EMCsnfulPas encore d'évaluation

- Your Chance To Change: by MacsaDocument2 pagesYour Chance To Change: by MacsaLeonard PeñaPas encore d'évaluation

- Smart Signage QB13R, QB13R-T Series Datasheet 200131 Online WebDocument4 pagesSmart Signage QB13R, QB13R-T Series Datasheet 200131 Online Webasubarkah22Pas encore d'évaluation

- Catalog Dahua-Display - Control V1.0 EN 202003 (32P) PDFDocument31 pagesCatalog Dahua-Display - Control V1.0 EN 202003 (32P) PDFHelmy HtssPas encore d'évaluation

- DHL460UCH-ES: 46'' FHD Video Wall Display Unit (Ultra Narrow Bezel 3.5mm)Document2 pagesDHL460UCH-ES: 46'' FHD Video Wall Display Unit (Ultra Narrow Bezel 3.5mm)Paola ZorrillaPas encore d'évaluation

- Helios Preisser 2021Document290 pagesHelios Preisser 2021Valentin IonescuPas encore d'évaluation

- p24q10 OverviewDocument2 pagesp24q10 OverviewyohzqxexgezbrclnquPas encore d'évaluation

- LipiLMP6800Series 04052021Document2 pagesLipiLMP6800Series 04052021OkgfrPas encore d'évaluation

- D. Odometro Nu-Metrics 1Document2 pagesD. Odometro Nu-Metrics 1Marco Antonio Quispe BerrocalPas encore d'évaluation

- Taylor Hobson CCI MP BrochureDocument4 pagesTaylor Hobson CCI MP Brochuresm_carvalhoPas encore d'évaluation

- A Series Plus DuoDocument2 pagesA Series Plus Duonguyencuong2212Pas encore d'évaluation

- Linx 8900-8910 0319 MDocument2 pagesLinx 8900-8910 0319 Mmit.vikasmalwalPas encore d'évaluation

- Solartron 7828 Insertion Density Transmitter: The Complete Density SolutionDocument4 pagesSolartron 7828 Insertion Density Transmitter: The Complete Density SolutionBrigido SalazarPas encore d'évaluation

- Dell - S Series - S2340LM - SpecSheet - UK PDFDocument1 pageDell - S Series - S2340LM - SpecSheet - UK PDFRochdi BouzaienPas encore d'évaluation

- 1412 - C32V1Q FlyerDocument2 pages1412 - C32V1Q FlyerselapPas encore d'évaluation

- Dahua Video Wall Spec LS550UCM-EF - 2019.10.11Document2 pagesDahua Video Wall Spec LS550UCM-EF - 2019.10.11exitlag free1Pas encore d'évaluation

- Leica Captivate CS20 DS 1119 enDocument2 pagesLeica Captivate CS20 DS 1119 enwadhahPas encore d'évaluation

- DS-2CE19U1T-AIT3ZF: 8 MP Outdoor Varifocal Bullet CameraDocument2 pagesDS-2CE19U1T-AIT3ZF: 8 MP Outdoor Varifocal Bullet Camerab01eru84Pas encore d'évaluation

- 615 Indicator: DescriptionDocument4 pages615 Indicator: DescriptionrobinPas encore d'évaluation

- 1202g General Duty Scanner - HoneywellDocument4 pages1202g General Duty Scanner - HoneywellGasser EltananiPas encore d'évaluation

- Barco-RGB Laser ODL-721 - en - 1710164597.3761673Document3 pagesBarco-RGB Laser ODL-721 - en - 1710164597.3761673paulopspPas encore d'évaluation

- Qc20-w Technical Brochure Luck PTSCDocument8 pagesQc20-w Technical Brochure Luck PTSCAnansitthichok MuangPas encore d'évaluation

- Diatest 9Document86 pagesDiatest 9tungPas encore d'évaluation

- Sony BRC x400Document8 pagesSony BRC x400Teodor DanPas encore d'évaluation

- Blue Core Laser Projector: LX810STDDocument2 pagesBlue Core Laser Projector: LX810STDMuthu MukeshPas encore d'évaluation

- Agilent Tech., DSO8104 Oscilloscope 1GHz Serive Manual PDFDocument162 pagesAgilent Tech., DSO8104 Oscilloscope 1GHz Serive Manual PDFLulu Sweet ThingPas encore d'évaluation

- Service Manual: DSC-H5Document51 pagesService Manual: DSC-H5DanielPas encore d'évaluation

- CMD Series 20231205 v2Document4 pagesCMD Series 20231205 v2Wiro HamjenPas encore d'évaluation

- 4daqsc208-209 212-213 230Document2 pages4daqsc208-209 212-213 230Tzouralas TheodorosPas encore d'évaluation

- M-Almite Sealer (E)Document2 pagesM-Almite Sealer (E)同道文档中心Pas encore d'évaluation

- Gartner Market Research PrimerDocument97 pagesGartner Market Research PrimerSurya Kiran RaiPas encore d'évaluation

- Conferences 2001Document7 pagesConferences 2001同道文档中心Pas encore d'évaluation

- Miranol C2M AADocument2 pagesMiranol C2M AA同道文档中心100% (1)

- Corfin Ind Leadfree ProbsDocument39 pagesCorfin Ind Leadfree Probs同道文档中心Pas encore d'évaluation

- Orion Aplus: Advanced Conductivity MetersDocument54 pagesOrion Aplus: Advanced Conductivity Meters同道文档中心75% (8)

- CMI100USDocument2 pagesCMI100US同道文档中心Pas encore d'évaluation

- Case 1Document4 pagesCase 1同道文档中心Pas encore d'évaluation

- Case 5Document3 pagesCase 5同道文档中心Pas encore d'évaluation

- CBM Connector: Bridging The Gap Between Failure Prediction and Asset ManagementDocument16 pagesCBM Connector: Bridging The Gap Between Failure Prediction and Asset Management同道文档中心Pas encore d'évaluation

- Evaluating Cortec Vpci-126 Blue Film With Requirements Listed On Performance Specification Mil-Prf-22019DDocument5 pagesEvaluating Cortec Vpci-126 Blue Film With Requirements Listed On Performance Specification Mil-Prf-22019D同道文档中心100% (2)

- Asia News 6Document4 pagesAsia News 6同道文档中心100% (1)

- Alkaline Cleaning GuideDocument3 pagesAlkaline Cleaning Guide同道文档中心100% (3)

- Long-Term Performance of Cadmium AlternativesDocument8 pagesLong-Term Performance of Cadmium Alternatives同道文档中心100% (2)

- 6000 Thickness Testing SystemDocument6 pages6000 Thickness Testing System同道文档中心100% (1)

- Abs MTG 204&abs 0604Document1 pageAbs MTG 204&abs 0604同道文档中心100% (1)

- CE Analytics: Your Surface Analysis and Materials Properties ResourceDocument5 pagesCE Analytics: Your Surface Analysis and Materials Properties Resource同道文档中心100% (1)

- 5.0 Adobe Acrobat: New Feature HighlightsDocument7 pages5.0 Adobe Acrobat: New Feature Highlights同道文档中心100% (2)

- Repositioning Taiwan's Industry: A Service-Added Manufacturing IndustryDocument26 pagesRepositioning Taiwan's Industry: A Service-Added Manufacturing Industry同道文档中心Pas encore d'évaluation

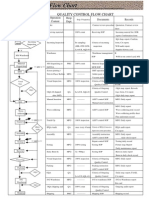

- Quality Control Flow ChartDocument1 pageQuality Control Flow Chart同道文档中心100% (17)

- How Vci WorkDocument21 pagesHow Vci Work同道文档中心100% (1)

- Department of Defense Test Method Standard: Dod Preferred Methods For Acceptance of ProductDocument33 pagesDepartment of Defense Test Method Standard: Dod Preferred Methods For Acceptance of ProductVladimir AquinoPas encore d'évaluation

- BF2207 Exercise 6 - Dorchester LimitedDocument2 pagesBF2207 Exercise 6 - Dorchester LimitedEvelyn TeoPas encore d'évaluation

- HP Training Diagnostics 75 Usage and AdministrationDocument2 pagesHP Training Diagnostics 75 Usage and AdministrationraviskskskPas encore d'évaluation

- Rhea Huddleston For Supervisor - 17467 - DR2Document1 pageRhea Huddleston For Supervisor - 17467 - DR2Zach EdwardsPas encore d'évaluation

- Pecson Vs CADocument3 pagesPecson Vs CASophiaFrancescaEspinosaPas encore d'évaluation

- Precision Probability Index (Elf)Document20 pagesPrecision Probability Index (Elf)EdsonnSPBrPas encore d'évaluation

- Metrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233ADocument3 pagesMetrologic Colombia S.A.S. Medellín Medellín Colombia: Oferta Economica CO20233AJulian MoraPas encore d'évaluation

- Sample Rubrics MakingDocument4 pagesSample Rubrics MakingKerstmis “Scale” NataliaPas encore d'évaluation

- SIConitDocument2 pagesSIConitJosuePas encore d'évaluation

- AttitudeDocument24 pagesAttitudeisratazimPas encore d'évaluation

- SQA Plan TemplateDocument105 pagesSQA Plan Templatestudent1291Pas encore d'évaluation

- FEDocument20 pagesFEKenadid Ahmed OsmanPas encore d'évaluation

- COA DBM JOINT CIRCULAR NO 2 s2022 DATED NOVEMBER 10 2022Document2 pagesCOA DBM JOINT CIRCULAR NO 2 s2022 DATED NOVEMBER 10 2022John Christian ReyesPas encore d'évaluation

- Allama Iqbal Open University, Islamabad Warning: (Department of Secondary Teacher Education)Document2 pagesAllama Iqbal Open University, Islamabad Warning: (Department of Secondary Teacher Education)Tehmina HanifPas encore d'évaluation

- PV1800VPM SEREIS (1-5KW) : Pure Sine Wave High Frequency Solar Inverter With MPPT InsideDocument4 pagesPV1800VPM SEREIS (1-5KW) : Pure Sine Wave High Frequency Solar Inverter With MPPT InsideHuber CallataPas encore d'évaluation

- 24th SFCON Parallel Sessions Schedule (For Souvenir Program)Document1 page24th SFCON Parallel Sessions Schedule (For Souvenir Program)genesistorres286Pas encore d'évaluation

- 150 67-Eg1Document104 pages150 67-Eg1rikoPas encore d'évaluation

- Chapter 9 CompensationDocument24 pagesChapter 9 CompensationSophie CheungPas encore d'évaluation

- a27272636 s dndjdjdjd ansjdns sc7727272726 wuqyqqyyqwywyywwy2ywywyw6 4 u ssbsbx d d dbxnxjdjdjdnsjsjsjallospspsksnsnd s sscalop sksnsks scslcoapa ri8887773737372 d djdjwnzks sclalososplsakosskkszmdn d ebwjw2i2737721osjxnx n ksjdjdiwi27273uwzva sclakopsisos scaloopsnx_01_eDocument762 pagesa27272636 s dndjdjdjd ansjdns sc7727272726 wuqyqqyyqwywyywwy2ywywyw6 4 u ssbsbx d d dbxnxjdjdjdnsjsjsjallospspsksnsnd s sscalop sksnsks scslcoapa ri8887773737372 d djdjwnzks sclalososplsakosskkszmdn d ebwjw2i2737721osjxnx n ksjdjdiwi27273uwzva sclakopsisos scaloopsnx_01_eRed DiggerPas encore d'évaluation

- CIVPRO - Case Compilation No. 2Document95 pagesCIVPRO - Case Compilation No. 2Darla GreyPas encore d'évaluation

- Defining The Audiovisual IndustryDocument20 pagesDefining The Audiovisual IndustryAyoub Ait MahmoudPas encore d'évaluation

- PDF of Proposed Museum ProjectDocument145 pagesPDF of Proposed Museum ProjectHarshita ParnamiPas encore d'évaluation

- 1-Page TimeBoxing Planner v2.0Document2 pages1-Page TimeBoxing Planner v2.0ash.webstarPas encore d'évaluation

- Region VIII Schools Division of Tacloban City DLC V Sto. Niño Extension, Tacloban CityDocument3 pagesRegion VIII Schools Division of Tacloban City DLC V Sto. Niño Extension, Tacloban CityRikka EspedillaPas encore d'évaluation

- The Influence of The Transformational LeaderDocument9 pagesThe Influence of The Transformational Leaderkenmuira100% (1)

- Difference Between Art. 128 and 129 of The Labor CodeDocument3 pagesDifference Between Art. 128 and 129 of The Labor CodeKarl0% (1)

- Simple Usecases of PI B2B - SFTP and PGPDocument35 pagesSimple Usecases of PI B2B - SFTP and PGPPiedone640% (1)

- Emailing Prime - Brochure - DigitalDocument32 pagesEmailing Prime - Brochure - DigitalCASA VALLIPas encore d'évaluation

- CM760 E-Brochure HemobasculaDocument6 pagesCM760 E-Brochure Hemobasculajordigs50Pas encore d'évaluation

- ALP Final Test KeyDocument3 pagesALP Final Test KeyPetro Nela50% (2)

- GSP Product Info 092711Document19 pagesGSP Product Info 092711Joao SilvaPas encore d'évaluation

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansD'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetD'EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)D'EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Pas encore d'évaluation

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeD'EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeÉvaluation : 4.5 sur 5 étoiles4.5/5 (59)

- Environmental Impact Assessment: Theory and PracticeD'EverandEnvironmental Impact Assessment: Theory and PracticeÉvaluation : 5 sur 5 étoiles5/5 (5)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsD'EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsÉvaluation : 4 sur 5 étoiles4/5 (16)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyD'EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Principles of Forensic Engineering Applied to Industrial AccidentsD'EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsPas encore d'évaluation

- Troubleshooting and Repair of Diesel EnginesD'EverandTroubleshooting and Repair of Diesel EnginesÉvaluation : 1.5 sur 5 étoiles1.5/5 (2)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownD'EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- The History of the Theory of Structures: From Arch Analysis to Computational MechanicsD'EverandThe History of the Theory of Structures: From Arch Analysis to Computational MechanicsPas encore d'évaluation

- Introduction To Civil EngineeringD'EverandIntroduction To Civil EngineeringÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Rock Fracture and Blasting: Theory and ApplicationsD'EverandRock Fracture and Blasting: Theory and ApplicationsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)