Académique Documents

Professionnel Documents

Culture Documents

Nutritive Value of Dried and Heat Processed Mola Fish (Amblypharyngodon Mola) Products

Transféré par

jakiulbauTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nutritive Value of Dried and Heat Processed Mola Fish (Amblypharyngodon Mola) Products

Transféré par

jakiulbauDroits d'auteur :

Formats disponibles

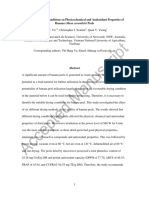

International Journal of Natural Sciences (2012), 2(2):43-48

pISSN : 2221-1012 eISSN : 2221-1020

___________________________________________________________________________ Nutritive value of dried and heat processed mola fish (Amblypharyngodon mola) products

Islam MJ 1*, Hossain MS2 and Mian S3

Department of Fisheries Technology and Resource Utilization, 2Department of Aquaculture, 3Department of Fisheries Biology and Genetics, Faculty of Fisheries, Sylhet Agricultural University, Sylhet-3100, Bangladesh. [Received: April 29, Accepted: June 20, 2012]

1

www.ijns.net

ABSTRACT

Sensory characteristics, nutritive and food qualities of traditional, rotary and solar tunnel dried mola (Amblypharyngodon mola) products were investigated. Nutritional analyses of fresh mola fish at various steps of heat processing (cooking) were also studied. Organoleptically, the colour of traditional dried mola products was slight brownish with emission of faint off odour. On the other hand, the colour of dried mola fish produced in rotary and solar tunnel dryer was showed characteristic shiny colour and whitish to slight brownish respectively. For traditional dried mola products texture was somewhat soft, whereas it was firm and flexible with characteristic fresh fishlike odour for rotary dryer and solar tunnel dryer. Traditionally dried products were not satisfactory and found to be infested. On the contrary, rotary and solar tunnel dried mola products were excellent having no insect infestation or broken pieces. The dried mola products showed different nutritional contents significantly (p<0.05) higher than others. The percent of moisture content of dried mola products obtained from different drying procedures was in the range of 12.80 to 26.60 %, protein content varied from 50.03 to 62.53%; lipid content also varied considerably from 12.16 to 18.36% and ash content varied from 5.93 to 12.19%. The Total Volatile Base Nitrogen (TVB-N) values varied from 10.64 to 20.36 mg/100g. Considerable loss of protein occurred during cooking of mola with or without vegetables compared to fresh mola. Considering the nutritional value, colour, odour and texture of the dried products rotary dryer gave good and significant (p<0.05) result. Key Words: Drying, sensory, composition, mola and textures

INTRODUCTION

In tropical countries like Bangladesh drying of the fish and fishery products is an important method of fish preservation for most traditional fishing communities. Traditionally sun drying is performed mainly by artisanal and local processors who have serious lack of knowledge on processing, sanitation and public health. The physical and organoleptic qualities of most of the traditional sun dried products available in the market are not satisfactory for human consumption [10, 11, 13, 14]. There are frequent complaints from the consumers about the quality of the products available in the market. The dry fishes are often infested by blow fly (Chrysomya sp.) and their larvae (maggot) during drying phase especially in the cloudy and rainy days; and by beetle (Necrobia sp.) and mites in the store causing considerable amount of weight loss of the finished product every year. Quality loss through spoilage and insect attack on dried fish has been estimated to 1035% in the coastal areas [7]. To protect the products from the infestation of insects, the processors, wholesalers and retailers often use various harmful insecticides and fungicides indiscriminately. Use of insecticides like DDT, Nogos, Rubral etc. to avoid insect infestation was reported during a market survey conducted by BFRI [5]. Sun dried fish contaminated with insecticides like DDT can act as a

potential carcinogenic agent and could create a wide spectrum of health hazard. In an attempt to reduce post-catch losses and to overcome the limitations of outdoor sun drying, solar dryer may be used as an alternative to sun drying to produce quality dried products. The available information on solar drying suggests that it is effective in controlling blow fly larvae infestation and other contaminants with higher drying rate over the traditional sun drying for producing high quality product with longer shelf life. Solar dryer consumes no fuel for operation; requires less maintenance and there is no pilferage by animals and birds and it is non-polluting [12]. A Hohenheim type solar tunnel dryer constructed with locally available materials was found very suitable for drying of Silver Jew fish at temperature of 35 to 52C for 5 days without showing any infestation, oxidative rancidity, spoilage and contamination [3,4] . Solar dryer may be considered as one of the best scientific tools within the reach of poor fishermen living in remote fishing villages for drying their daily catch. But the solar drying technology has some limitations also. Such as solar drying is not effective in bad/cloudy weather conditions particularly during the rainy season which results in spoilage of fishes. It needs to operate the solar dryer very early in the morning to get the fish dried by the evening. Failure to operate it in the early morning results in the elongation of the drying

*Corresponding author E-mail: jakiulbau@yahoo.com

43

Int J Nat Sci (2012), 2(2):43-48

Islam et al.

process. From this point of view this study aimed to investigate selection of an effective drying device to produce dried mola and also to choose the best cooking methods for mola fish comparing the nutritive values of various processed mola products.

analysis of moisture, crude protein, lipid and ash were performed according to the methods given in AOAC [1] with certain modifications. Statistical analysis Statistical analysis was performed by using MSSTATC programme. The mean values were compared by following the DMRT (Duncan Multiple Range Test) at 5% level of probability for interpretation of results [9]. Determination of Total Volatile Base Nitrogen (TVB-N) Total volatile base nitrogen (TVB-N) was determined according to the standard method described by EC [8] with some modifications. Processing technique of mola fish curry with vegetables and spices At first, fresh mola fishes were simply gutted by using knives and the entire viscera were removed. After gutting, the raw materials were washed again with tap water to remove blood, slime and other undesirable substances. Fishes were then washed with salt water and again washed with plain water. Some vegetables like potato, bean, brinjal, coriander leaf etc and spice like turmeric powder, red chili powder, coriander powder, salt and oil were added and cooked for about half an hour.

MATERIALS AND METHODS

Materials Fresh mola fish samples were collected from a local market adjacent to Sylhet Agricultural University (SAU) Campus, Sylhet and were transported to the Faculty of Fisheries, SAU, Sylhet using an insulated ice box. The samples were divided into two groups; one group of about 500 gm of fresh samples of mola were used for drying in solar tunnel and rotary dryer and another group of sample was used for cooking to evaluate the quality change by determining organoleptic and biochemical aspects. Traditionally dried mola samples were also collected from the same market. Whole samples obtained from both dried and cooked fish were ground in an electric blender to produce a homogenous mixture before being sampled for analysis. Methods Production of dried fish in solar tunnel and rotary dryer The raw materials were washed with tap water to remove dirt and other undesirable substances attached with the fish body. After gutting, the entire viscera were removed using knives and washed again with tap water to remove blood, slime and other undesirable substances. The fishes were then dried in rotary dryer and solar tunnel dryer. In case of rotary dryer, drying time was in the range of 12-24 hours while it was about 10-12 hours in case of solar tunnel dryer. After drying, the different processed products were packed in polyethylene bag using sealer to prevent moisture absorption. Organoleptic quality assessment A large number of schemes have been proposed for sensory evaluation for various types of fish and fishery products. The evaluation methods used in this study were based on the one that is currently used in various institution of the world. Representative whole sample of dried products were taken on a tray to assess the characteristics such as colour, odour, texture, broken pieces and insect infestation by panel of experts of four (4) members constituted in the department of Fisheries Technology and Resource Utilization, Faculty of Fisheries, SAU. Proximate composition analysis Whole samples obtained from both dried and cooked fish were ground in an electric blender to produce a homogenous mixture before being sampled for biochemical analysis. Proximate composition

RESULTS AND DISCUSSION

Organoleptic and Nutritional Quality Analysis Organoleptic quality assessment of traditional, solar and rotary dried mola products The organoleptic parameters such as colour, odour, texture, insect infestation, presence of broken pieces and overall quality of traditional, rotary and solar tunnel dried mola products were examined and recorded (Table 1). Organoleptically, the colour of traditional dried mola products were slight brownish with emission of slight off odour and the texture found somewhat soft. The overall quality of the product obtained from traditionally dried was not up to the mark of acceptable limit. The colour of dried mola fish produced in rotary dryer showed characteristic shiny colour. Texture was firm and flexible with characteristic fresh fish like odour. No insect infestation or broken pieces were found around the products and the overall quality of rotary dried mola fish products was found excellent. On the other hand, the colour of solar tunnel dried mola was whitish to slight brownish. Texture was firm and flexible with characteristic odour. Any insect infestation and broken pieces around the products was not observed. The overall quality of solar tunnel dried mola fish products was also excellent. From the above observation, it can be said

44

Int J Nat Sci (2012), 2(2):43-48

Islam et al.

that during the production of traditional sun dried products, proper care was not taken in various processing steps.

Specially, improper washing and long time exposure in the open air for drying leads to loss of color. Storage in abused condition probably caused the oxidation of lipid in the muscle and leads to development of sour rancid odour. Improper storage also allows the infestation which results in loss of texture and breaking the dried fish muscle. Proximate composition of dried mola fish products Proximate composition such as moisture, crude protein, lipid and ash contents of traditional, rotary and solar tunnel dried products were studied and are

presented in Table 2. A significant difference (p<0.05) was found among different dried mola products. The moisture content of dried mola products was in the range of 12.80 to 26.60 % with the lowest value obtained from solar tunnel dried mola and the highest value from traditional dried mola. The moisture content of dried mola products produced in rotary dryer under room condition was 16.23%, whereas the moisture content was 18.13% in those products produced in rotary dryer under direct sun light. These values are much lower than that of traditional dried products which contains 26.60% moisture. Moisture content of traditional dried mola products was high because in most cases traditional dried products were stored without any packaging materials. As a result, moisture uptake from the environment takes place giving rise to the chance of the growth of microorganisms, loss of nutrients and

Table 1. Organoleptic characteristics of traditional, rotary and solar tunnel dried mola fish products Dryer Used Colour Odour Texture Insect infestation Broken piece Overall Quality

Traditional

Slight brownish in colour Whitish colour like as fresh fish

Slight off odour

Texture somewhat soft Firm and flexible texture

Infested by insect No infestation

Present

Poor

Rotary dryer

Characteristic odour like as fresh fish

Absent

Excellent

Solar tunnel dryer

Whitish and slightly brownish

Good fishy odour

Firm and flexible texture

No infestation

Absent

Excellent

Table 2. Proximate composition of traditional, rotary and solar tunnel dried mola products Solar dryer with white polythene 12.800.15e 62.530.74a *(71.270.73b) 18.360.21a *(21.030.23a) 7.520.01b *(8.710.01c) Solar dryer with black polythene 15.870.13d 61.190.88b *(73.060.63a) 16.120.24b *(19.160.33b) 5.930.03d *(8.080.03d)

Composition Moisture Protein *(Dry) Lipid *(Dry) Ash *(Dry)

Sun dried (Traditional) 26.60 0.37a 50.030.52d *(67.090.42c) 12.160.11c *(16.900.26d) 12.190.12a *(15.110.10a)

Rotary dryer in room 16.230.18c 60.430.83b *(72.130.75ab) 16.380.13b *(19.550.10b) 6.960.04c *(8.320.03d)

Rotary dryer in direct sunlight 18.130.39b 57.600.46c *(71.580.52b) 16.450.34b *(18.890.21c) 7.780.03b *(9.500.05b)

LS 0.01 0.01 *(0.05) 0.01 *(0.05) 0.01 *(0.01)

LSD

1.12 1.01 (0.98) 0.57 (0.55) 0.32 (0.24)

*Values within parenthesis are on dry matter basis

45

Int J Nat Sci (2012), 2(2):43-48

Islam et al.

short shelf life of the product. Generally bacteria, yeast and mold do not grow with moisture content below 18, 20 and 16% respectively [13]. So, for a better shelf life of the product a moisture content of less than 16% is considered ideal for dried fish [12, 13]. Protein content varied from 50.03 to 62.5% with highest value in dried fish produced in solar dryer with white polythene and lower value obtained from

of 16.90% obtained from traditional dried mola products. No significant (p<0.05) difference between the products obtained from solar dryer with black polythene and rotary dryer in room. Ash content varied from 5.93 to 12.19 % with highest value obtained from traditional sun dried products and lowest value from the solar dried product with black polythene. No significant

Table 3. Proximate composition of mola fish at various steps of processing and cooking

Sample Fresh muscle of mola Whole mola After salt wash muscle Fried mola Boiled mola Mola Cooked with vegetables Gut content LS LSD(0.05) Moisture% 82.871.09a 75.790.88e 81.030.87ab 76.550.76d 80.180.85b Protein% *(Dry ) 13.830.34b *(72.390.85a) 15.400.24a *(69.500.88c) 10.980.22d *(71.661.02ab) 13.540.33b *(59.490.56d) 11.890.31c *(70.520.64bc) 13.230.12b *(59.220.88d) 12.300.19c *(52.250.45e) 0.01 *(0.01) 0.54 *(1.115) Lipid% *(Dry ) 3.850.03c *(19.690.44d) 5.480.02d *(25.360.34c) 3.490.03d *(19.950.45d) 8.220.04a *(36.110.34b) 3.560.01d *(21.110.45d) 8.050.04b *(36.030.34b) 8.190.04a *(42.850.54a) 0.01 *(0.01) 0.124 *(0.343) Ash% *(Dry ) 1.430.005bc *(7.940.12b) 1.600.006a *(7.250.13c) 1.520.007ab *(8.380.11a) 1.000.005d *(4.390.03e) 1.410.007c *(8.360.05a) 1.060.005d *(4.740.03d) 1.080.005d *(4.560.04de) *(0.05) *(0.01) 0.094 *(0.183)

77.770.66c

79.230.98bc 0.01 1.437

*Values within parenthesis are on dry matter basis

traditional dried product. Protein content in both rotary and solar dried fish produced under different conditions was more or less similar. There were a significant (p<0.05) difference found among sun dried (Traditional), solar dried and rotary dryer dried mola fish except products from rotary dryer in room and solar dryer with black polythene. Protein content varied from 67.09 to 73.06 % with highest value obtained from solar dried mola with black polythene and lowest value obtained from traditional sun dried product on dry weight basis. There were no significant (p<0.05) differences among the protein content of the products obtained from solar dryer and rotary dryer in room. Lipid values were found significant among dried products from different drying methods. Lipid content also varied considerably with highest value of 18.36% obtained from dried mola fish produced in solar dried with white polythene and lowest value of 12.16% obtained from traditional dried mola products. There was no significant (p<0.05) difference between the lipid contents of the products obtained from solar and rotary dryers under different conditions. On dry weight basis, highest lipid content of 21.03% was obtained from the product produced in solar dryer with white polythene and lowest value

(p<0.05) difference between the products obtained from solar dried with black polythene and rotary dryer in direct sunlight. There was also little difference between the ash content of mola products obtained from both solar and rotary dryer under various conditions. The lowest protein content of the traditional sun dried product was due to some loss of water soluble protein and lipid during different stages of processing and subsequent storage. On the other hand the highest ash content of traditional sun dried mola products was due to contamination of sand, filth and dust during different processing stages and subsequent storage. The most significant (p<0.05) variation in chemical composition of mola fish products were the higher moisture content in traditional dried mola compared to those of rotary and solar tunnel dried mola. It was evident from the study that there was an inverse relationship between fat content and protein content of dried mola fish products. However, result of the present study is in agreement with [2] who reported that the solar dried fishes contain high percentage of protein and fat over the traditional sun dried products.

46

Int J Nat Sci (2012), 2(2):43-48

Islam et al.

Food Quality Analysis Food quality of traditional, rotary and solar tunnel dried products was analyzed by determining Total Volatile Base Nitrogen (TVB-N). TVB-N values of dried products prepared under different conditions are presented in Fig. 1 and Table 4. TVB-N values varied from 10.64 to 20.36 mg/100g with highest value obtained from traditional sun dried and lowest value from the products obtained in rotary dryer in room conditions. TVB-N values of the dried products prepared using solar or rotary dryer were more or less similar ranged from 10.64 to 15.68 mg/100g. The highest TVB-N values of traditional dried products are probably associated with some bacterial actions during processing and subsequent storage. However, TVB-N values of all the samples were found lower than the recommended value of 100-200 mg/100g for variety of salted and dried products [6]. It is likely to expect low TVB-N values in dried products because most of the volatile bases are lost due to heat during drying. Proximate composition of mola during various processing and cooking steps is shown in Table 3. The analysed moisture contents of different mola products ranges between 75.79 % to 82.87% whereas it was 82.87%, 75.79%, 81.03%, 76.55%, 80.18%, 77.77% and 79.23% in fresh muscle of whole mola, whole mola, after salt wash muscle, fried mola, boiled mola, cooked mola with vegetables and gut content respectively . In case of moisture content there were no significant (p<0.05) difference between fresh muscle of whole mola and after salt wash muscle; boiled mola and after salt wash muscle, cooked mola with vegetables and gut content. The analysed protein contents of fresh muscle of whole mola, whole mola, after salt wash muscle, fried mola, boiled mola, cooked mola with vegetables and gut content was 13.83%, 15.40%, 10.98%, 13.54%, 11.89%, 13.23%, 12.30% respectively. The highest crude protein content (15.40%) was found in whole mola and the lowest (10.98%) was found in after salt wash muscle. No significant differences were found among the fresh muscle of whole mola, fried mola and cooked mola with vegetables. To get more precise results dry matter basis analysis were also conducted. In case of dry matter analysis highest value of protein content was found in fresh muscle of mola (72.39%) and lowest amount of protein content were found in gut content (52.25%). No significant difference was found except cooked vegetables and gut content. The result from after salt wash muscle indicates loss of protein from muscle. This was due to washout of sarcoplasmic and salt soluble protein.

Table 4. TVB-N value of Traditional, Rotary and Solar Tunnel Dried mola Products

Dried Sample Name *RR *RS Mola *SD *SD(B) *TD TVB-N value (mg/100g) 10.64 13.80 15.68 14.82 20.36

* RR-Rotary Dryer in Room condition; *RS-Rotary Dryer under Sunlight; *SD- Solar Tunnel Dryer; *SDB-Solar Tunnel Dryer using Black polyethylene; *TD- Traditional dried.

The analysed lipid contents of different fish feeds varied considerably among the different processed mola fish under different conditions. The value of crude lipid was recorded as 3.85% in fresh muscle of whole mola, 5.48% in whole mola, and 3.49% in after salt wash muscle, 8.22% in fried mola, 3.56% in boiled mola, 8.05% in cooked mola with vegetables and 8.19% in gut content (Table 3). The values obtained from whole mola, after salt wash muscle and boiled mola show no significant difeerences. Whereas fresh muscle of mola and fried mola show a statistically significant different values. The highest lipid value was found in fried mola (8.22%) and lowest value in after salt wash muscles (3.49%). Dry matter basis results show that insignificant relation were found among fresh muscle of mola, after salt wash muscle and boiled mola. Values from whole mola, fried & cooked mola with vegetables and gut content showed significant (p<0.05) results.

25

T V B -N v a l u e (m g /1 0 0 g )

20.36 15.68 14.82 10.64 13.8

Sun dried (Traditional) Solar with white polythene Solar with black polythene Rotary in room Rotary direct sunlight

20 15 10 5 0 Types of Products based on drying process

Figure 1. TVB-N values of different dried mola fish products

The analysed ash contents were found as fresh muscle of whole mola(1.43%), whole mola(1.60%), after salt wash muscle, fried mola (1.52%),fried mola (1.00%), boiled mola(1.41%), cooked mola with vegetables (1.06%) and gut content (1.08). A significant difference for ash content were found in whole mola, boiled mola and cooked with vegetables (Table 3).

47

Int J Nat Sci (2012), 2(2):43-48

Islam et al.

The highest ash value was found in whole mola (1.60%) and lowest value in fried mola (1.00%). Analytical results from dry matter indicated significant difference among fresh muscle of mola, whole mola and after salt treatment where values obtained from fried mola and gut content; boiled mola and after salt treatment showed no significant differences. The whole mola contained much amount of ash and show a little loss and fried mola with huge loss of minerals content.

8. European Communities (EC) 1995. Determination of the concentration of volatile nitrogenous bases (TVBN) in fish and fish products: A reference procedure. Official Journal of the European Communities. Commission decision, p. 15. 9. Gomez, K. A. and Gomez, A. A. 1984. Statistical procedures for Agricultural Research. Second edition. Intl. Rice. Res. Inst. A. Willey Int. sci. pub.pp.28-192. 10. Kamruzzaman, A. K. M. 1992. Qualitative evaluation of some commercially dried fish products of Bangladesh. M.S Thesis, Department of Fisheries Technology, Bangladesh Agricultural University, Mymensingh, Bangladesh. p. 37. 11. Khan, M. A. A. 1992. Study on dry fish (Marine) with special reference to insect infestation, use of health hazard insecticides and control effect of pirimiphos methyl. A thesis in the Institute of Marine Sciences, University of Chittagong. 12. Kumar, S., Bhattacharya, S. C., Leo, M. A. and Pham, H. L. 1998. Opportunities in Renewable energy Business in South-East Asia: the case of solar photovoltaics and solar drying. Institutional co-operation for solar energy in the Makong riparian countries. Hanoi, Vietnam. 13. Reza, M. S., Bapary, M. A. J., Azimuddin, K. M., Nurullah, M. and Kamal, M. 2005. Studies on the Traditional Drying Activities of Commercially Important Marine Fishes of Bangladesh. Pakistan Journal of Biological Sciences, 8 (9): 1303-1310. 14. Saha, S. C. 1999. Studies on production, marketing and nutritional aspects of traditional dried products of Bangladesh. M.S. Thesis, Department of Fisheries Technology, Bangladesh Agricultural University, Mymensingh, Bangladesh, p. 62.

REFERENCES

1. Ahmed, A. T. A., Mustafa, G. and Rahman, H. N. 1979. Solar drying of silver jewfish, Johnius argentatus (Houttuyn) in polythene tent dryer. Bangladesh J. Biol. Sci., 8 (1): 23-30.

2. AOAC (Association of Official Analytical Chemist). (2000). W. Horwitz (Editor), Official Methods of Analysis. Association of Official Analytical Chemist, 13th edition, Washington, D.C. 3. Bala, B. K. and Hossain, M. D. 1998. Experimental Investigation of solar drying of fish using tunnel dryer. WREC, Elsevier Science Ltd., pp. 2049-2052. 4. Bala, B. K. and Mondol, M. R. A. 2001. Experimental Investigation of solar drying of fish using tunnel dryer. Drying Technology, 19(2):1-10. 5. BFRI (Bangladesh Fisheries Research Institute).1998. Research progress report for 1994-1997, p. 73. 6. Connell, J. J. 1995. Quality deterioration and extrinsic quality defects in raw material. In: Control of Fish Quality, Fishing News Books Ltd. Surrey, England. 7. Doe, P. E., Ahmed, M., Muslemuddin, M. and Sachithananthan, K. 1977. A polythene tent dryer for improved sun drying of fish. Food Technology in Australia., 29:437-441.

48

Vous aimerez peut-être aussi

- Controlled Atmosphere Storage of Fruit and VegetablesD'EverandControlled Atmosphere Storage of Fruit and VegetablesPas encore d'évaluation

- Foods: Ffects of Various Drying Methods OnDocument11 pagesFoods: Ffects of Various Drying Methods OnGreat Idea Business Solutions CorporationPas encore d'évaluation

- Aquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaD'EverandAquaponics Systems, Fish. Volume 6: Sistemas de acuaponíaPas encore d'évaluation

- Quality Assessment of Rotating and Solar Tunnel Dried Marine Fish ProductDocument8 pagesQuality Assessment of Rotating and Solar Tunnel Dried Marine Fish ProductashisbhuniyaPas encore d'évaluation

- Effects of Drying Methods On Proximate CompositionDocument4 pagesEffects of Drying Methods On Proximate CompositionSamuelPas encore d'évaluation

- Microbial Quality of Nile Perch Lates Niloticus AnDocument6 pagesMicrobial Quality of Nile Perch Lates Niloticus AnSakina AliPas encore d'évaluation

- 123Document6 pages123necboowatonPas encore d'évaluation

- Evaluation of Bioactives Using SeaweedDocument13 pagesEvaluation of Bioactives Using Seaweedhimani dewanganPas encore d'évaluation

- PRODUCT STANDARDIZATION Edited Version PDFDocument30 pagesPRODUCT STANDARDIZATION Edited Version PDFClarrice HalladorPas encore d'évaluation

- Synopsis of The Proposed Research Project For National SDcence and TechnologyDocument3 pagesSynopsis of The Proposed Research Project For National SDcence and TechnologyRaisul IslamPas encore d'évaluation

- Chukwu PDFDocument3 pagesChukwu PDFhansenPas encore d'évaluation

- Ebenezer Seminar 2Document12 pagesEbenezer Seminar 2kennedy NkitikporPas encore d'évaluation

- Title Proposal 2.1Document5 pagesTitle Proposal 2.1Christian HerrasPas encore d'évaluation

- Agriculture, Livestock FisheriesDocument8 pagesAgriculture, Livestock FisheriesGreat Idea Business Solutions CorporationPas encore d'évaluation

- Microbiological Analysis of Three of Smoked Fish Obtained From The Ondo State, NigeriaDocument5 pagesMicrobiological Analysis of Three of Smoked Fish Obtained From The Ondo State, NigeriaWae-WAEPas encore d'évaluation

- 1.1 Background of StudyDocument7 pages1.1 Background of Studyflorjuliette4Pas encore d'évaluation

- 0362-028x-72 7 1419 PDFDocument8 pages0362-028x-72 7 1419 PDFnofriadyPas encore d'évaluation

- Implementation of Food Safety On Frozen ShrimpDocument7 pagesImplementation of Food Safety On Frozen Shrimp12CH1-13 ĐỖ HOÀNG PHÚCPas encore d'évaluation

- Evaluation of The Anti Genotoxicity and Growth Performance Impacts of Green Algae On M CephalusDocument12 pagesEvaluation of The Anti Genotoxicity and Growth Performance Impacts of Green Algae On M CephalusJuan FranciaPas encore d'évaluation

- Utilization of Marine By-ProductDocument7 pagesUtilization of Marine By-ProductBalaji Prasanna KumarPas encore d'évaluation

- 2016 1 RJAVFS RasulDocument7 pages2016 1 RJAVFS Rasul020ANNISA NUR MAHARANIPas encore d'évaluation

- 12 1 19 3251Document7 pages12 1 19 3251Salami SegunPas encore d'évaluation

- Dry Fermented Seafood: Properties, Nutritional Values, Microbial Safety of Selected Starter Culture. NameDocument35 pagesDry Fermented Seafood: Properties, Nutritional Values, Microbial Safety of Selected Starter Culture. NamefidelisPas encore d'évaluation

- IOSR JournalsDocument4 pagesIOSR JournalsInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- Effect of Dragon Fruit Peel Powder On Quality and Acceptability of Fish Nuggets Stored in A Solar Cooler (5 1 °C)Document13 pagesEffect of Dragon Fruit Peel Powder On Quality and Acceptability of Fish Nuggets Stored in A Solar Cooler (5 1 °C)Ashley CarandangPas encore d'évaluation

- Politowicz 2017Document13 pagesPolitowicz 2017farhanms80Pas encore d'évaluation

- PDF PirolisisDocument7 pagesPDF Pirolisisfera maileniPas encore d'évaluation

- Amitha, Et AlDocument7 pagesAmitha, Et AlAMAANIPas encore d'évaluation

- Quality Characteristics and Functional and AntioxiDocument14 pagesQuality Characteristics and Functional and AntioxiMed Lamine RabhiPas encore d'évaluation

- Nutritional Properties and Fatty Acid Profile of Coconut Crab Birgus Latro (Decapoda: Anomura: Coenobitidae) From North Maluku, IndonesiaDocument10 pagesNutritional Properties and Fatty Acid Profile of Coconut Crab Birgus Latro (Decapoda: Anomura: Coenobitidae) From North Maluku, Indonesiaindex PubPas encore d'évaluation

- Project Review 1Document16 pagesProject Review 1florjuliette4Pas encore d'évaluation

- Fermented FishDocument13 pagesFermented FishAdrian StanPas encore d'évaluation

- Foods: A Comprehensive Review On The Processing of Dried Fish and The Associated Chemical and Nutritional ChangesDocument28 pagesFoods: A Comprehensive Review On The Processing of Dried Fish and The Associated Chemical and Nutritional ChangesShivam KalitaPas encore d'évaluation

- Assessing The Post-Harvest Chemical and Microbial Changes in The Meat of Rohu (Labeo Rohita) Kept Under Different Storage ConditionsDocument5 pagesAssessing The Post-Harvest Chemical and Microbial Changes in The Meat of Rohu (Labeo Rohita) Kept Under Different Storage ConditionsDwi IryantiPas encore d'évaluation

- Issn 2094-1749Document123 pagesIssn 2094-1749arianlyncaraldePas encore d'évaluation

- Articulo para El Punto 4Document9 pagesArticulo para El Punto 4Anayivi DiazPas encore d'évaluation

- Additions of Extract Turmeric On THDocument11 pagesAdditions of Extract Turmeric On THErmaya AulianaPas encore d'évaluation

- Treatment of Industrial Wastewater by Using Banana Peels and Fish ScalesDocument5 pagesTreatment of Industrial Wastewater by Using Banana Peels and Fish ScalesdonyokiPas encore d'évaluation

- 1239-Main Manuscript-11875-1-10-20230526Document7 pages1239-Main Manuscript-11875-1-10-20230526Erika APas encore d'évaluation

- Atributos Sensoriales de Carpa Herbívora Con Quitosano Almacenados A 4°C-2017Document13 pagesAtributos Sensoriales de Carpa Herbívora Con Quitosano Almacenados A 4°C-2017Camilo Huertas CamposPas encore d'évaluation

- Fractionation of Protein Hydrolysates of Fish Waste Using Membrane Ultrafiltration: Investigation of Antibacterial and Antioxidant ActivitiesDocument8 pagesFractionation of Protein Hydrolysates of Fish Waste Using Membrane Ultrafiltration: Investigation of Antibacterial and Antioxidant Activitiessumaiya rahmanPas encore d'évaluation

- Effect of Turmeric On The Quality of Canned African Catfish in Tomato Sauce During Storage at 25°C and 45°CDocument10 pagesEffect of Turmeric On The Quality of Canned African Catfish in Tomato Sauce During Storage at 25°C and 45°CAdekunbi MalomoPas encore d'évaluation

- Conversión de Subproductos Del Procesamiento de La Pesca en Huevos SaladosDocument8 pagesConversión de Subproductos Del Procesamiento de La Pesca en Huevos SaladosKaren BenteoPas encore d'évaluation

- The Use of Effective Microorganisms (Em) As A Probiotic On Cultured Nile Tilapia Oreochromis NiloticusDocument22 pagesThe Use of Effective Microorganisms (Em) As A Probiotic On Cultured Nile Tilapia Oreochromis NiloticusRusmawanto Ketua OsisPas encore d'évaluation

- Chemical and Physicochemical Properties of Almond Nut: September 2015Document11 pagesChemical and Physicochemical Properties of Almond Nut: September 2015DanaPas encore d'évaluation

- Rahim 2021 IOP Conf. Ser. Earth Environ. Sci. 763 012006Document11 pagesRahim 2021 IOP Conf. Ser. Earth Environ. Sci. 763 012006Sri Wahyuni RahimPas encore d'évaluation

- Anchovi Khedkar Reprint PDFDocument8 pagesAnchovi Khedkar Reprint PDFZandrex S. AguillonPas encore d'évaluation

- Levels and Health Risk Assessment of Heavy MetalsDocument14 pagesLevels and Health Risk Assessment of Heavy Metalsmoshiur rahmanPas encore d'évaluation

- Chemical Composition and Physicochemical PDFDocument10 pagesChemical Composition and Physicochemical PDFolapade paulPas encore d'évaluation

- 7.biochemical and Structural Characterization of Sturgeon FishDocument10 pages7.biochemical and Structural Characterization of Sturgeon FishJonathanCoralPas encore d'évaluation

- LWT - Food Science and Technology: Shengmin LuDocument6 pagesLWT - Food Science and Technology: Shengmin LuErika Arisetiana DewiPas encore d'évaluation

- Ultrasonication in Seafood Processing and Preservation - 2022 - Applied Food RDocument10 pagesUltrasonication in Seafood Processing and Preservation - 2022 - Applied Food RLê Quốc Đăng KhoaPas encore d'évaluation

- Peningkatan Mutu Dan Daya Simpan Ikan Pi 09142db9Document13 pagesPeningkatan Mutu Dan Daya Simpan Ikan Pi 09142db9KinantiPas encore d'évaluation

- International Journal of Pharma and Bio Sciences Issn 0975-6299Document5 pagesInternational Journal of Pharma and Bio Sciences Issn 0975-6299Kwan Silvea X LimaPas encore d'évaluation

- Araujo 2020Document9 pagesAraujo 2020Rey AlegrosoPas encore d'évaluation

- Bekasam Ikan Wader Pari Menggunakan Berbagai Macam Olahan Beras Terhadap Sifat Mikrobiologi Dan OrganoleptikDocument9 pagesBekasam Ikan Wader Pari Menggunakan Berbagai Macam Olahan Beras Terhadap Sifat Mikrobiologi Dan OrganoleptikjehanPas encore d'évaluation

- Ceballos Proposal TLE9Document9 pagesCeballos Proposal TLE9Ray MarkPas encore d'évaluation

- Vu 2016Document34 pagesVu 2016ARCILLA, NICO ANDREI SALAVERIAPas encore d'évaluation

- Cyprian Dissertation PDFDocument203 pagesCyprian Dissertation PDFLieven VermeulenPas encore d'évaluation

- Quality and Food Safety of Fishery Products Marketed in Selayar Islands RegencyDocument6 pagesQuality and Food Safety of Fishery Products Marketed in Selayar Islands RegencyMamta AgarwalPas encore d'évaluation

- Chicken Project Uganda Space ProposalDocument19 pagesChicken Project Uganda Space ProposalCoronwokers Homebase100% (1)

- Agro Technology Park in MARDI, Cameron HighlandsDocument4 pagesAgro Technology Park in MARDI, Cameron HighlandsDanelle SammyPas encore d'évaluation

- Rajbon Bihar, RangamatiDocument6 pagesRajbon Bihar, RangamatiSADIA AFRINPas encore d'évaluation

- Comparing-Biofloc-Clear-Water-Ras For Shrimp FarmingDocument8 pagesComparing-Biofloc-Clear-Water-Ras For Shrimp FarmingFardan SpacePas encore d'évaluation

- Soil RajeshDocument15 pagesSoil RajeshMir'atun Nissa QuinalendraPas encore d'évaluation

- Living in The Environment 18th Edition Miller Test BankDocument19 pagesLiving in The Environment 18th Edition Miller Test Bankgiangdoankqb1rc100% (26)

- Chapter 4 (Ag. Waste Characteristics) PDFDocument40 pagesChapter 4 (Ag. Waste Characteristics) PDFshii anihsPas encore d'évaluation

- Troll Pits 5e PDFDocument45 pagesTroll Pits 5e PDFAnonymous 2UAIvU04F100% (2)

- Apllication of Nano Technology in HorticultureDocument54 pagesApllication of Nano Technology in HorticultureSomendra MeenaPas encore d'évaluation

- Pubmed ResultDocument2 841 pagesPubmed ResultDian Setya BudiPas encore d'évaluation

- KVK Telephone DirectoryDocument162 pagesKVK Telephone DirectorySuresh SharmaPas encore d'évaluation

- ENVIRONMENTAL OUTLOOK To 2050 The Consequences of Inaction 2Document8 pagesENVIRONMENTAL OUTLOOK To 2050 The Consequences of Inaction 2Abcvdgtyio Sos RsvgPas encore d'évaluation

- History of AnjarDocument24 pagesHistory of AnjarJoseph SakrPas encore d'évaluation

- International Journal of Heritage StudiesDocument18 pagesInternational Journal of Heritage StudiesKari GordonPas encore d'évaluation

- Belay Wuzer SSIP Irr. Agr. ReportDocument52 pagesBelay Wuzer SSIP Irr. Agr. ReportAbiued EjiguePas encore d'évaluation

- Name: - Reading Practice Course 5Document1 pageName: - Reading Practice Course 5Daniela DuquePas encore d'évaluation

- UNEP Mainstreaming Gender in Environmental Assessment and Early WarningDocument95 pagesUNEP Mainstreaming Gender in Environmental Assessment and Early WarningMa Karla Ligaya CastroPas encore d'évaluation

- Крестьяне в СредневековьеDocument356 pagesКрестьяне в СредневековьеDaniel100% (1)

- Organic Is Life. Knowledge For Tomorrow 2011 Korea PDFDocument384 pagesOrganic Is Life. Knowledge For Tomorrow 2011 Korea PDFIuri AmazonasPas encore d'évaluation

- ShippersDocument80 pagesShipperssakshi tandonPas encore d'évaluation

- Science ScriptDocument3 pagesScience ScriptLouie Jay SilangPas encore d'évaluation

- International Aquafeed - March - April 2016 FULL EDITIONDocument72 pagesInternational Aquafeed - March - April 2016 FULL EDITIONInternational Aquafeed magazinePas encore d'évaluation

- Sep 2022Document12 pagesSep 2022L Sudhakar ReddyPas encore d'évaluation

- American Gardener 0102 2017Document64 pagesAmerican Gardener 0102 2017valysa100% (1)

- Bamboo FarmsDocument28 pagesBamboo FarmsSendil KumarPas encore d'évaluation

- Soil Erosion Measurement and Control TechniquesDocument12 pagesSoil Erosion Measurement and Control TechniquessezaitanyoluPas encore d'évaluation

- Harmeet Training ReportDocument51 pagesHarmeet Training Reportmanan ahujaPas encore d'évaluation

- Briquettes Handbook-FAO PDFDocument134 pagesBriquettes Handbook-FAO PDFArnaldo Benitez100% (2)

- Tractor Operated Laser Land LevelerDocument18 pagesTractor Operated Laser Land Levelerkajako kajoPas encore d'évaluation

- Guidelines For Planning Cattle Feedlots MF3392Document2 pagesGuidelines For Planning Cattle Feedlots MF3392DendenGalitPas encore d'évaluation

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingD'EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingÉvaluation : 4 sur 5 étoiles4/5 (9)

- The Obesity Code: Unlocking the Secrets of Weight LossD'EverandThe Obesity Code: Unlocking the Secrets of Weight LossÉvaluation : 4 sur 5 étoiles4/5 (6)

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyD'EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyÉvaluation : 4 sur 5 étoiles4/5 (11)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldD'EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterD'EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterÉvaluation : 3.5 sur 5 étoiles3.5/5 (487)

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyD'EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyÉvaluation : 4 sur 5 étoiles4/5 (1)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookD'EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Mexican Today: New and Rediscovered Recipes for Contemporary KitchensD'EverandMexican Today: New and Rediscovered Recipes for Contemporary KitchensÉvaluation : 4 sur 5 étoiles4/5 (6)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideD'EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideÉvaluation : 4 sur 5 étoiles4/5 (6)

- Authentic Mexican: Regional Cooking from the Heart of MexicoD'EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoPas encore d'évaluation

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomD'EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomÉvaluation : 4 sur 5 étoiles4/5 (1)

- Magnolia Table, Volume 3: A Collection of Recipes for GatheringD'EverandMagnolia Table, Volume 3: A Collection of Recipes for GatheringÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingD'EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingPas encore d'évaluation

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsD'EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsPas encore d'évaluation

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayD'EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayÉvaluation : 4 sur 5 étoiles4/5 (4)

- Chicano Eats: Recipes from My Mexican-American KitchenD'EverandChicano Eats: Recipes from My Mexican-American KitchenPas encore d'évaluation

- Poilâne: The Secrets of the World-Famous Bread BakeryD'EverandPoilâne: The Secrets of the World-Famous Bread BakeryPas encore d'évaluation

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthD'EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthÉvaluation : 2 sur 5 étoiles2/5 (1)

- Keto Friendly Recipes: Easy Keto For Busy PeopleD'EverandKeto Friendly Recipes: Easy Keto For Busy PeopleÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Binging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsD'EverandBinging with Babish: 100 Recipes Recreated from Your Favorite Movies and TV ShowsPas encore d'évaluation

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingD'EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingÉvaluation : 4 sur 5 étoiles4/5 (3)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoD'EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoPas encore d'évaluation

- Just Feed Me: Simply Delicious Recipes from My Heart to Your PlateD'EverandJust Feed Me: Simply Delicious Recipes from My Heart to Your PlateÉvaluation : 2 sur 5 étoiles2/5 (1)

- Waiting: The True Confessions of a WaitressD'EverandWaiting: The True Confessions of a WaitressÉvaluation : 3 sur 5 étoiles3/5 (7)