Académique Documents

Professionnel Documents

Culture Documents

Fem Slab

Transféré par

Efren ElegadoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fem Slab

Transféré par

Efren ElegadoDroits d'auteur :

Formats disponibles

APPLICATION OF PLATES & SHELLS

Table of Contents Part A

1. 2. 3. 4. 5. INTRODUCTION TO PLATE AND SHELL ELEMENT ASSIGNMENT 1 SIMPLY SUPPORTED ONE-WAY SLABS ASSIGNMENT 2 TWO-WAY SLABS ASSIGNMENT 3 CANTILEVER BEAM ASSIGNMENT 4 WATER TANKS 2 6 11 15 17

APPLICATION OF PLATES & SHELLS

1.

INTRODUCTION TO PLATE AND SHELL ELEMENT The Plate/Shell finite element is based on the hybrid element formulation. The element can be 3-noded (triangular) or 4-noded (quadrilateral). If all the four nodes of a quadrilateral element do not lie on one plane, it is advisable to model them as triangular elements. The thickness of the element may be different from one node to another. "Surface structures" such as walls, slabs, plates and shells may be modeled using finite elements. For convenience in generation of a finer mesh of plate/shell elements within a large area, a MESH The user may also use the element for PLANE STRESS action only (i.e. membrane/in-plane stiffness only). The ELEMENT PLANE STRESS command should be used for this purpose.

Geometry Modeling Considerations The following geometry related modeling rules should be remembered while using the plate/shell element. The program automatically generates a fictitious fifth node "O" (center node - below) at the element center. While assigning nodes to an element in the input data, it is essential that the nodes be specified either clockwise or counter clockwise (Fig. 1.9,

below). For better efficiency, similar elements should be numbered sequentially. Element aspect ratio should not be excessive. They should be on the order of 1:1, and preferably less than 4:1. Individual elements should not be distorted. Angles between two adjacent element sides should not be much larger than 90 and never larger than 180. Following load specifications are available: Joint loads at element nodes in global directions. Concentrated loads at any user specified point within the element in global or local directions. Uniform pressure on element surface in global or local directions. Partial uniform pressure on user specified portion of element surface in 2

APPLICATION OF PLATES & SHELLS

global or local directions. Linearly varying pressure on element surface in local directions. Temperature load due to uniform increase or decrease of temperature. Temperature load due to difference in temperature between top and bottom surfaces of the element.

The distinguishing features of this finite element are: Displacement compatibility between the plane stress component of one element and the plate bending component of an adjacent element which is at an angle to the first is achieved by the elements. This compatibility requirement is usually ignored in most flat shell/plate elements. The out of plane rotational stiffness from the plane stress portion of each element is usefully incorporated and not treated as a dummy as is usually done in most commonly available commercial software. Despite the incorporation of the rotational stiffness mentioned previously, the elements satisfy the patch test absolutely. These elements are available as triangles and quadrilaterals, with corner nodes only, with each node having six degrees of freedom. These elements are the simplest forms of flat shell/plate elements possible with corner nodes only and six degrees of freedom per node. Yet solutions to sample problems converge rapidly to accurate answers even with a large mesh size. These elements may be connected to plane/space frame members with full displacement compatibility. No additional restraints/releases are required. Out of plane shear strain energy is incorporated in the formulation of the plate bending component. As a result, the elements respond to Poisson boundary conditions which are considered to be more accurate than the customary Kirchoff boundary conditions. The plate bending portion can handle thick and thin plates, thus extending the usefulness of the plate elements into a multiplicity of problems. In addition, the thickness of the plate is taken into consideration in calculating the out of plane shear. 3

APPLICATION OF PLATES & SHELLS

The plane stress triangle behaves almost on par with the well known linear stress triangle. The triangles of most similar flat shell elements incorporate the constant stress triangle which has very slow rates of convergence. Thus the triangular shell element is very useful in problems with double curvature where the quadrilateral element may not be suitable.

Stress retrieval at nodes and at any point within the element.

Plate Element Local Coordinate System The orientation of local coordinates is determined as follows: The vector pointing from I to J is defined to be parallel to the local x- axis. The cross-product of vectors IJ and IK defines a vector parallel to the local z-axis, i.e., z = IJ x IK. The cross-product of vectors z and x defines a vector parallel to the local y- axis, i.e., y = z x x. The origin of the axes is at the center (average) of the 4 joint locations (3 joint locations for a triangle).

APPLICATION OF PLATES & SHELLS

Following are the items included in the ELEMENT STRESS output. SQX, SQY = Shear stresses (Force/ unit len./ thk.) SX, SY, SXY = Membrane stresses (Force/unit len./ thk) MX, MY,MXY = Moments per unit width (Force x Length/length) (For Mx, the unit width is a unit distance parallel to thelocal Y axis. For My, the unit width is a unit distance parallel to the local X axis. Mx and My cause bending,while Mxy causes the element to twist out-of-plane.) SMAX, SMIN = Principal stresses in the plane of the element (Force/unit area). The 3rd principal stress is 0.0 TMAX = Maximum 2D shear stress in the plane of the element (Force/unit area) VONT, VONB = 3D Von Mises stress at the top and bottom surfaces TRESCAT, TRESCAB = Tresca stress, where TRESCA = MAX[ |(SmaxSmin)| ,

APPLICATION OF PLATES & SHELLS

2.

ASSIGNMENT 1

SIMPLY SUPPORTED ONE-WAY SLABS

Problem Statement : 1. For a given slab simply supported(pinned) on two edges, we will find the convergence on bending moment using finite element analysis with help of computer software. 2. For the same panel understanding the behavior of panel with edge beams of different sizes. Data : Slab Panel : 3m x 6m Loading : Slab : 10kN/m2 150mm

For the given problem we will start the meshing of panel from 1m x 1m and use mesh refinement for convergence. Analysis will be done using staad-prov8i software.

APPLICATION OF PLATES & SHELLS

Results:

Element size mxm 1.00 0.50 0.30 0.25 0.20 0.15 0.10

4.00 2.00 0.00 % Error -2.00 -4.00 -6.00 -8.00 -10.00 -12.00

No. of Elements 18 72 200 288 450 800 1800

BM kN.m 10.20 10.93 11.40 11.50 11.60 11.60 11.60

% error in Thickness BM m 10.29 0.15 -2.93 0.15 1.32 0.15 2.17 0.15 3.02 0.15 3.02 0.15 3.02 0.15

Convergence

18

72

200

288

450

800

1800

No. of elem ents

APPLICATION OF PLATES & SHELLS

Exact solution = w*l^2/8 = 11.25 kN.m Conclusion : From the above results we can conclude that the bending moments in the slab converges to exact solution by mesh refinement . For the element size 0.5m x 0.5m we get minimum +positive error and for element size 0.3m x 0.3m we get minimum negative error. Refinement of mesh further does help, and the negative error goes on increasing till the element size of 0.1m x 0.1m.

PART 2 Here we will model the supporting edge with beam elements instead of pinned supports of different sizes and get the results of bending moments for both slab and beam and check with exact classical solution.

APPLICATION OF PLATES & SHELLS

Results:

Beam size mmxmm 300x300 300x450 300x600 300x750 300x900 300x1200

BM in slab kN.m 13.40 12.00 11.61 11.46 11.39 11.32

BM in beam kN.m 40.88 55.45 60.81 63.00 64.03 64.88

% error in BM -65.12 -21.73 -11.00 -7.14 -5.42 -4.04

Convergence

0.00 -10.00 -20.00 % Error -30.00 -40.00 -50.00 -60.00 -70.00 Size of Beam 300x300 300x450 300x600 300x750 300x900 300x1200

APPLICATION OF PLATES & SHELLS

300x900 BM = 69.5kN.m

300x600 BM = 55.6kN.m

Conclusion : From the above results it can be concluded that, increasing the size of edge beams the result converges to exact solution. Hence relative stiffness of beams and slab is governing criteria for convergence of the bending moments for both, beam and slab. If the sizes of supporting beams are lesser than required, there is no slabbeam effect and act together as slab elements with just edged having more stiffness. Again if the sizes of edge beams are different in sizes, the results are higher for stiffer beam and carry more bending moments than the one which is comparatively weaker.

10

APPLICATION OF PLATES & SHELLS

3.

ASSIGNMENT 2

TWO-WAY SLABS

Problem Statement : 1. 2. 3. Comparative study of two-way slabs bending moments using IS-456 guidelines (Table 26) and finite element analysis. Convergence of results for slab with line loads. Effect on panel under consideration due to change in size of adjacent panel.

Data : Slab Panel : 5m x 6m Loading : Slab : 10kN/m2 150mm

Boundary condition : One short edge continuous (case 8)

For the given problem we will start the meshing of panel from 1m x 1m and use mesh refinement for convergence. Analysis will be done using staad-prov8i software. Results

Element size mxm 1.00 0.50 0.25 0.20 0.10 No. of Elements 30 120 480 750 3000 IS-456 BM MX +ve 11.20 11.30 11.40 11.50 11.50 14.75 BM MY +ve 10.20 10.30 10.40 10.40 10.45 10.75 BM MX -ve 0.00 0.00 0.00 0.00 0.00 0.00 BM MY -ve 12.10 17.40 20.90 21.70 23.20 14.25 % error BM X+ve -31.70 -30.53 -29.39 -28.26 -28.26 % error BM Y+ve -5.39 -4.37 -3.37 -3.37 -2.87 % error BM Yve -17.77 18.10 31.82 34.33 38.58

Convergence

60.00 40.00 % Error 20.00 0.00 -20.00 -40.00 -60.00 No. of Elements 0 500 1000 1500 2000 2500 3000 3500 MX+ve My +ve MY -ve

11

APPLICATION OF PLATES & SHELLS

12

APPLICATION OF PLATES & SHELLS

13

APPLICATION OF PLATES & SHELLS

Conclusion : For the given case, the mesh refinement converges the positive X and Y moments for size 0.25m x 0.25m. From the results it can be concluded that the positive moments from IS456 table is higher than results from finite elements analysis after convergence. For negative Y moments the results crosses the exact solution for element size between 1.0m x 1.0m to 0.5m x 0.5m. So for negative moments further mesh refinement add to positive error and the results of finite element analysis are more than the one calculated from IS-456, which is exactly opposite of the case with positive moments. Also on changing the size of adjacent panel by half of the original, there is decrease in negative moments at support and increase in mid span moments.

14

APPLICATION OF PLATES & SHELLS

4.

ASSIGNMENT 3

CANTILEVER BEAM

Problem Statement : Convergence of results for cantilever beam with concentrated load at end. Data : Beam span : 3m Loading : Size : 10kN at free end 300x600mm

For the given problem we will start meshing size from 0.2m x 0.2m and further refinement will be done to get the convergence.

Results :

15

APPLICATION OF PLATES & SHELLS

Element size No. of mxm Elements 0.2mx0.2m 45 0.15mx0.15m 80 0.10mx0.1m 180 0..05mx0.5m 720

BM kN.m 25.8 27.4 28.6 29.511

% error BM -16.50 -9.55 -4.73 -1.66

Convergence

0.00 0 -5.00 % Error -10.00 -15.00 -20.00 No. of Elements BM 100 200 300 400 500 600 700 800

Conclusion : For the given problem we can conclude that the result for bending moments converges to exact solution for the plate size of 0.05m x 0.05m. Also the results vary for different width of beam, here we tried to converge the results for beam size of 300x600mm The results for width other than 300mm, the bending moments are different for same number of elements. Hence unlike classical solution, where we dont take the effect of width in calculation of bending moments, in finite element analysis the width of beam influences the bending moments.

16

APPLICATION OF PLATES & SHELLS

5.

ASSIGNMENT 4

WATER TANKS

Problem Statement : Comparison of .moments, shear and hoop forces for water tanks using FEM and IS-3370. a) Rectangular tanks b) Cylindrical tanks Data : a) Rectangular tanks Tank size : Loading : Wall: 3.75m x 5.0m hieght 50kN/m 150mm

For the given problem we will use the meshing of panel 0.25m x 0.25m as we have concluded this size from above examples

17

APPLICATION OF PLATES & SHELLS

18

APPLICATION OF PLATES & SHELLS

Vertical b/H 0.75

Table 1 x/H 0 1/4 1/2 3/4 1 Table 1 x/H 0 1/4 1/2 3/4 1 Table 2 x/H 0 1/4 1/2 3/4 1 Table 2 x/H 0 1/4 1/2 3/4 1 Table 3 x/H 0 1/4 1/2 3/4 1 Table 3 x/H 0 1/4 1/2 3/4 1 y = 0 (Centre) MX staad %error 5.00 5.37 6.82 10.00 7.87 -27.10 12.50 11.74 -6.48 8.75 9.72 9.98 -6.25 -3.18 -96.36 y = b/4 (Quarter ) MX staad %error 1.25 0.75 -66.67 2.50 0.97 -157.73 3.75 2.47 -51.82 3.75 3.19 -17.55 -3.75 -1.85 -103.14 y = b/2 (at wall) MX staad %error -8.75 -6.57 -33.18 -13.75 -12.54 -9.65 -21.25 -19.79 -7.39 -16.25 -17.81 8.75 0.00 -1.07 100.00 y = 0 (Centre) MX staad %error 6.25 5.35 -16.82 10.00 8.11 -23.30 13.75 13.13 -4.72 15.00 9.89 -51.67 0.00 2.54 100.00 y = 0 (Centre) MY staad %error 0.00 -0.12 100.00 1.25 0.91 -36.91 6.25 5.13 -21.83 8.75 7.76 -12.76 -30.00 -20.67 -45.14 y = b/4 (Quarter ) MX staad %error 1.25 0.75 -66.67 2.50 0.89 -179.64 5.00 2.39 -109.21 5.00 3.91 -27.91 0.00 1.09 100.00 y = b/4 (Quarter ) MY staad %error 0.00 -0.09 100.00 0.00 -0.05 100.00 2.50 2.00 -25.00 3.75 4.00 6.25 -18.75 -11.91 -57.43 y = b/2 (at wall) MX staad %error -10.00 -6.42 -55.69 -16.25 -12.86 -26.38 -27.50 -21.76 -26.36 -32.50 -24.45 -32.92 0.00 -3.52 100.00 y = b/2 (at wall) MY staad %error 0.00 -0.61 100.00 -2.50 -2.51 0.40 -3.75 -3.26 -15.03 -3.75 -2.77 -35.38 0.00 -1.07 100.00 y = 0 (Centre) MX staad %error 0.00 1.02 100.00 7.50 6.68 -12.28 13.75 12.90 -6.59 13.75 14.02 1.93 0.00 2.54 100.00 y = 0 (Centre) MY staad %error 0.00 -0.15 100.00 1.25 1.00 -25.00 6.25 4.34 -44.11 12.50 14.02 10.83 0.00 3.55 100.00 y = b/4 (Quarter ) MX staad %error 0.00 0.15 100.00 2.50 1.06 -135.85 3.75 2.48 -51.27 6.25 3.93 -59.03 0.00 1.09 100.00 y = b/4 (Quarter ) MY staad %error 0.00 -0.11 100.00 0.00 -0.27 100.00 2.50 1.42 -75.56 7.50 4.71 -59.40 0.00 2.12 100.00 y = b/2 (at wall) MX staad %error 0.00 -1.23 100.00 -15.00 -10.91 -37.45 -27.50 -21.53 -27.76 -31.25 -24.42 -27.95 0.00 -3.52 100.00 y = b/2 (at wall) MY staad %error 0.00 -0.59 100.00 -3.75 -2.21 -69.68 -5.00 -3.64 -37.36 -6.25 -3.89 -60.59 0.00 -0.72 100.00 y = 0 (Centre) MY staad %error 0.00 0.49 100.00 1.25 1.65 24.24 6.25 4.80 -30.21 11.25 10.00 -12.50 0.00 3.55 100.00 y = b/4 (Quarter ) MY staad %error 0.00 0.08 100.00 0.00 0.42 100.00 2.50 1.68 -48.81 6.25 4.75 -31.58 0.00 2.12 100.00 y = b/2 (at wall) MY staad %error 0.00 -0.36 100.00 -2.50 -1.84 -35.87 -5.00 -3.59 -39.31 -6.25 -3.90 -60.46 0.00 -0.72 100.00

Horizontal b/H 0.75

Vertical b/H 0.75

Horizontal b/H 0.75

Vertical b/H 0.75

Horizontal b/H 0.75

19

APPLICATION OF PLATES & SHELLS

Conclusion : For the water tank wall panels, with the given panel ratio and wall thickness the results are having 50% error This error may be due to the fact that IS-3370 coefficients does not take into effect the thickness of wall panel of tank apart from the width and height.

b) Cylindrical tanks Tank size : Loading : Wall: 5m (Height) x 6m (Radius) 50kN/m 150mm

Boundary conditions : Top of tank Free and bottom hinged IS 3370 : Table 12,13 and 14.

Results

Hoop Tension IS 3370 Moment My IS 3370

7.95 37.05 66.60 97.65 131.40 168.60 206.10 230.40 229.35 119.85 42.75

-0.03 29.38 59.10 89.75 122.55 159.47 197.78 228.12 225.07 153.30 0.00

-0.01 -0.02 -0.06 -0.13 -0.18 -0.04 0.56 1.89 2.78 3.66 1.57

0.00 0.00 0.00 -0.13 -0.13 -0.12 0.03 1.53 3.29 4.17 0.00

20

APPLICATION OF PLATES & SHELLS

Hoop Tension

Vertical Mom ents

kN -100.00 0.00 0 100.00 200.00 300.00

-1.00 0.00 0 1.00

kNm 2.00 3.00 4.00 5.00

mt.

mt.

IS 3370 Staad

IS 3370 Staad

21

APPLICATION OF PLATES & SHELLS

Conclusion: For the given case, the results of staad pro and IS 3370 coefficients are nearly same with negligible, 1% error in case of hoop tension and about 13% error in moments.

22

Vous aimerez peut-être aussi

- Load CalculationDocument4 pagesLoad CalculationMalayKumarDebPas encore d'évaluation

- Individual Footing With MomentsDocument2 pagesIndividual Footing With MomentseramitdhanukaPas encore d'évaluation

- Experimental Observations and Parametric Study of Piled Raft Foundation Using PlaxisDocument7 pagesExperimental Observations and Parametric Study of Piled Raft Foundation Using PlaxisAngelinSavioPas encore d'évaluation

- Floor Slab LIFTDocument3 pagesFloor Slab LIFTV.m. RajanPas encore d'évaluation

- Amendment No. 3 June 2018 TO Is 15658: 2006 Precast Concrete Blocks For Paving - SpecificationDocument3 pagesAmendment No. 3 June 2018 TO Is 15658: 2006 Precast Concrete Blocks For Paving - Specificationraviteja036Pas encore d'évaluation

- Steel - 07-Prof. Zahid Siddiqi PDFDocument75 pagesSteel - 07-Prof. Zahid Siddiqi PDFMuhammad AhmedPas encore d'évaluation

- Optimal Deign of Pile FoundationDocument13 pagesOptimal Deign of Pile FoundationJustin Johnson100% (1)

- Node Nodal Degrees of Freedom: 1. The Definition of The Finite Element Method (FEM)Document32 pagesNode Nodal Degrees of Freedom: 1. The Definition of The Finite Element Method (FEM)KomarudinPas encore d'évaluation

- Civil Standard & Code No Area Code Standard AstmDocument10 pagesCivil Standard & Code No Area Code Standard AstmTri SeptaPas encore d'évaluation

- How To Design Steel Roof Truss in STAAD Pro - Structural Analysis Forum - Structural Analysis - Bentley CommunitiesDocument2 pagesHow To Design Steel Roof Truss in STAAD Pro - Structural Analysis Forum - Structural Analysis - Bentley CommunitiesLiya ElizabethPas encore d'évaluation

- Civil Engineering Department: Government Engineering Colleg BilaspurDocument11 pagesCivil Engineering Department: Government Engineering Colleg Bilaspurtinu sahuPas encore d'évaluation

- 5-Design of Raft FoundationDocument2 pages5-Design of Raft FoundationheshamPas encore d'évaluation

- EARTHQUAKE LATERAL FORCE ANALYSIS (STATIC VS DYNAMIC) PDFDocument41 pagesEARTHQUAKE LATERAL FORCE ANALYSIS (STATIC VS DYNAMIC) PDFJoshua Magat100% (1)

- Effe. Section HeightDocument132 pagesEffe. Section HeightNaresh SharmaPas encore d'évaluation

- Staad Pro-Different Floor LoadsDocument28 pagesStaad Pro-Different Floor LoadsV.m. Rajan100% (1)

- Analysis and Design of SlabsDocument6 pagesAnalysis and Design of SlabsricardoPas encore d'évaluation

- Pile Design & Analysis of Single Piles. ExamplesDocument61 pagesPile Design & Analysis of Single Piles. ExamplesMohammed HussainPas encore d'évaluation

- Comparison of Seismic Response of Multi-Storied Structures With and Without Soil Structure InteractionDocument4 pagesComparison of Seismic Response of Multi-Storied Structures With and Without Soil Structure InteractionAkhil LamdadePas encore d'évaluation

- 3pile PilecapDocument4 pages3pile Pilecapsivaraju1100% (1)

- Record of Water Pressure Test Pltu Bantaeng, Sulawesi SelatanDocument7 pagesRecord of Water Pressure Test Pltu Bantaeng, Sulawesi SelatandoddyPas encore d'évaluation

- Indeterminate Structure AnalysisDocument17 pagesIndeterminate Structure Analysispranjal singhPas encore d'évaluation

- Unit2 - Plate Load TestDocument30 pagesUnit2 - Plate Load TestSajja Satish Assistant Professor, CE, VRSECPas encore d'évaluation

- Chapter 1 - Introduction To RCDocument34 pagesChapter 1 - Introduction To RCBeanPas encore d'évaluation

- Analysis and Design of A Combined Triangular Shaped Pile Cap Due To Pile EccentricityDocument7 pagesAnalysis and Design of A Combined Triangular Shaped Pile Cap Due To Pile Eccentricityazhar ahmad100% (1)

- Transportation Engineering Lab Manual: Submitted To: Submitted byDocument42 pagesTransportation Engineering Lab Manual: Submitted To: Submitted byMuhammad AhmedPas encore d'évaluation

- Slab-On-Grade Reinforcing DesignDocument9 pagesSlab-On-Grade Reinforcing DesignAdam GreenlawPas encore d'évaluation

- RC Desktop Toolkit v2Document27 pagesRC Desktop Toolkit v2pbharadwaj545Pas encore d'évaluation

- CE4070 Structural Modelling Yield Line Analysis of Slab IETDocument18 pagesCE4070 Structural Modelling Yield Line Analysis of Slab IETkartheepan100% (1)

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocument3 pagesMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezPas encore d'évaluation

- Settlement of Loaded Ground - Immediate and Consolidation SettlementDocument4 pagesSettlement of Loaded Ground - Immediate and Consolidation SettlementDiana CiurtePas encore d'évaluation

- Heat of Hydration StressesDocument7 pagesHeat of Hydration StressesAnkur BarsainyaPas encore d'évaluation

- Slope Stability 03092022Document3 pagesSlope Stability 03092022Tanmay KalolaPas encore d'évaluation

- 01 - 3D Abutment Foundation PileDocument28 pages01 - 3D Abutment Foundation PileJimmy GodfreyPas encore d'évaluation

- Load-Penetration Curve: Control NoDocument1 pageLoad-Penetration Curve: Control NoGerryBoD.BagtasJr.Pas encore d'évaluation

- 3rd Year 2nd Sem QuestionsDocument98 pages3rd Year 2nd Sem Questionssourav_jucivilPas encore d'évaluation

- Two Cycle Moment Distribution Method ProcedureDocument5 pagesTwo Cycle Moment Distribution Method ProcedureAnonymous nwByj9L50% (2)

- Bearing Capacity Analysis BaruDocument6 pagesBearing Capacity Analysis BaruFerdinand Yesaya NapitupuluPas encore d'évaluation

- GLT Engineers Private, Singapore: Foundation DesignDocument2 pagesGLT Engineers Private, Singapore: Foundation DesignRio HandokoPas encore d'évaluation

- L&T TechnicalDocument5 pagesL&T TechnicalvigneshwarimahamuniPas encore d'évaluation

- Analyse and Design of Truss by STADProDocument18 pagesAnalyse and Design of Truss by STADProSuvajit BisaiPas encore d'évaluation

- Design Example of A Six Storey Building: Dr. H. J. ShahDocument51 pagesDesign Example of A Six Storey Building: Dr. H. J. ShahArman MoralesPas encore d'évaluation

- Cement ConcreteDocument39 pagesCement ConcreteVihar VariaPas encore d'évaluation

- BRE Mix Design Example 2Document7 pagesBRE Mix Design Example 2Amos kiprutoPas encore d'évaluation

- Compressive Strength of Concrete CubesDocument3 pagesCompressive Strength of Concrete CubesoneakshayPas encore d'évaluation

- DOM Wheebox 719 Full Highlighted-MergedDocument1 095 pagesDOM Wheebox 719 Full Highlighted-MergedSunnyPas encore d'évaluation

- Revision of Is - 1893 Part 1Document8 pagesRevision of Is - 1893 Part 1BMSF khaliqePas encore d'évaluation

- Elements of Soil Mechanics, 8th Edition Bearing Capacity FactorsDocument14 pagesElements of Soil Mechanics, 8th Edition Bearing Capacity Factorsthiru2025Pas encore d'évaluation

- Columns: Designing To Eurocode 2Document10 pagesColumns: Designing To Eurocode 2Roberts LaamsPas encore d'évaluation

- Introduction To Bridge DesignDocument67 pagesIntroduction To Bridge DesignSukrit GhoraiPas encore d'évaluation

- Design of Pile CapsDocument33 pagesDesign of Pile Capsadane mekonnenPas encore d'évaluation

- CBC - Design Assisstant - June 2019Document36 pagesCBC - Design Assisstant - June 2019G. S. YadavPas encore d'évaluation

- DCP Paige Green 2009Document82 pagesDCP Paige Green 2009Joel Johnson KimatarePas encore d'évaluation

- LEC3. COMPRESSIBILITY OF SOIL - Part1Document53 pagesLEC3. COMPRESSIBILITY OF SOIL - Part1Gerald MoaresPas encore d'évaluation

- RCDC FE-Sample Problem 4-PileRaftDocument19 pagesRCDC FE-Sample Problem 4-PileRaftRoberto Pérez León100% (1)

- Eccentric Footing Design PDFDocument9 pagesEccentric Footing Design PDFmsiddiq1Pas encore d'évaluation

- Composite Columns IDocument15 pagesComposite Columns IHeng Kimseng100% (1)

- BH 60 PDFDocument1 pageBH 60 PDFcivixxPas encore d'évaluation

- Transit Center - Structural Design Calculations1Document26 pagesTransit Center - Structural Design Calculations1yan naingPas encore d'évaluation

- Staadpro PDFDocument23 pagesStaadpro PDFmessstuffPas encore d'évaluation

- Good Tutorial About Trees and Landscapes ClipmappingDocument12 pagesGood Tutorial About Trees and Landscapes ClipmappingEfren ElegadoPas encore d'évaluation

- CARPET TutorialDocument13 pagesCARPET TutorialEfren ElegadoPas encore d'évaluation

- IES Light: 1. Unit MattersDocument5 pagesIES Light: 1. Unit MattersEfren ElegadoPas encore d'évaluation

- Local Government Code of The PhilippinesDocument281 pagesLocal Government Code of The PhilippinesAbdul Halim ReveloPas encore d'évaluation

- Specifications: General ConditionsDocument3 pagesSpecifications: General ConditionsEfren ElegadoPas encore d'évaluation

- 365 Days of Writing Prompts PDFDocument89 pages365 Days of Writing Prompts PDFasdfsafsdlkjlkjasdfPas encore d'évaluation

- Camera TutorialDocument21 pagesCamera TutorialEfren ElegadoPas encore d'évaluation

- DPWH Department OrdersDocument1 pageDPWH Department OrdersEfren Elegado100% (1)

- Skyline PigeonDocument1 pageSkyline PigeonEfren ElegadoPas encore d'évaluation

- Sample of Construction MaterialDocument2 pagesSample of Construction MaterialEfren ElegadoPas encore d'évaluation

- A 3 Storey Classroom BildingDocument19 pagesA 3 Storey Classroom BildingEfren ElegadoPas encore d'évaluation

- Aroon IndicatorDocument15 pagesAroon IndicatorChiranjib ParialPas encore d'évaluation

- BUITEMS Entry Test Sample Paper NAT IGSDocument10 pagesBUITEMS Entry Test Sample Paper NAT IGSShawn Parker100% (1)

- Python - 1Document86 pagesPython - 1Muhammad FarooqPas encore d'évaluation

- Homework IDocument4 pagesHomework Ikjmd092399Pas encore d'évaluation

- Sample Problem ThermoDocument25 pagesSample Problem ThermoJonnah Faye Mojares0% (1)

- Study Pack and Formulae of Chapter 4Document15 pagesStudy Pack and Formulae of Chapter 4RatanakPas encore d'évaluation

- Project & Quality ManagementDocument15 pagesProject & Quality ManagementJayson SoguilonPas encore d'évaluation

- Course Description CatalogDocument56 pagesCourse Description CatalogstefPas encore d'évaluation

- Planbook AlgebraDocument15 pagesPlanbook Algebraapi-233970614Pas encore d'évaluation

- bcs301 MathsDocument4 pagesbcs301 Mathssuhasg027Pas encore d'évaluation

- Vector Calculus QuestionsDocument3 pagesVector Calculus Questionsrachitzan10Pas encore d'évaluation

- SI FM 2e SM Chap14Document78 pagesSI FM 2e SM Chap14ttaerack100% (1)

- Basic GaDocument4 pagesBasic GaParameswararao BillaPas encore d'évaluation

- Como Baixar o ForgeDocument3 pagesComo Baixar o ForgejohncenaatuttutuPas encore d'évaluation

- Correct Answer: 3Document11 pagesCorrect Answer: 3Neha VermaPas encore d'évaluation

- Fast Hardware Computation of X Mod Z: J. T. Butler T. SasaoDocument5 pagesFast Hardware Computation of X Mod Z: J. T. Butler T. Sasaoshashank guptaPas encore d'évaluation

- Matemática de BlockchainsDocument200 pagesMatemática de BlockchainspedroPas encore d'évaluation

- Problem Shortlist With Solutions: 52 International Mathematical OlympiadDocument77 pagesProblem Shortlist With Solutions: 52 International Mathematical OlympiadHimansu Mookherjee100% (1)

- ModelingSCBF PDFDocument28 pagesModelingSCBF PDFadnanraisahmedPas encore d'évaluation

- Applied ProbDocument11 pagesApplied ProbPrerana Rai BhandariPas encore d'évaluation

- Fea Module 1Document56 pagesFea Module 1NAVADE SATISHPas encore d'évaluation

- F HG I KJ F HG I KJ: Differentiation CPP (Basics)Document3 pagesF HG I KJ F HG I KJ: Differentiation CPP (Basics)Pratham SharmaPas encore d'évaluation

- Problem Solving & Decision Making (HBO)Document5 pagesProblem Solving & Decision Making (HBO)Leofold Laluna Salas Jr.Pas encore d'évaluation

- Sequence Impedance in Different Power EquipmentsDocument7 pagesSequence Impedance in Different Power EquipmentsMadhusudhan Srinivasan0% (1)

- 12th Mathematics Holiday HomeworkDocument19 pages12th Mathematics Holiday HomeworkArshdeep SinghPas encore d'évaluation

- Simulia Isight Brochure PDFDocument6 pagesSimulia Isight Brochure PDFlingesh1892Pas encore d'évaluation

- Report Lab#4Document8 pagesReport Lab#4ibrahim100% (2)

- CAD & Parameters: Chapter NineDocument50 pagesCAD & Parameters: Chapter NineNshuti Rene Fabrice100% (1)

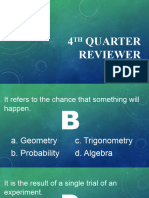

- 4th Quarter ReviewerDocument19 pages4th Quarter ReviewerJhel ChristianPas encore d'évaluation

- SPM TRIAL STK EXAM 2013 Paper 2 AnswerDocument11 pagesSPM TRIAL STK EXAM 2013 Paper 2 AnswerRofi HussainPas encore d'évaluation