Académique Documents

Professionnel Documents

Culture Documents

M 15 Mix Designs As Per IS-10262-2009

Transféré par

Prasad MsrkDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

M 15 Mix Designs As Per IS-10262-2009

Transféré par

Prasad MsrkDroits d'auteur :

Formats disponibles

M 15 Mix Designs as per IS-10262-2009

Posted in Mix Design | Email This Post

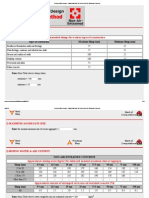

Dear All, Here i am giving the mix designs as per IS-10262-2009 which gives to change the procedure for calculating the concrete ingredients Regards Raj Mohammad Khan M-15 CONCRETE MIX DESIGN As per IS 10262-2009 & MORT&H A-1Stipulations for Proportioning 1 Grade Designation 2 Type of Cement 3 Maximum Nominal Aggregate Size 4 5 6 Workability (MORT&H 1700-4) 7 Exposure Condition 8 Degree of Supervision 9 Type of Aggregate Crushed Angular Aggregate 10 Maximum Cement Content (MORT&H Cl. 1703.2) 540 kg/m3 11 Chemical Admixture Type A-2Test Data for Materials 1 Cement Used Coromandal King OPC 53 grade Superplasticiser Confirming to IS-9103 Good Normal 25 mm (Slump) 20 mm Minimum Cement Content (MORT&H 1700-3 A) 250 kg/m3 Maximum Water Cement Ratio (MORT&H 1700-3 A) 0.5 M15 OPC 53 grade confirming to IS12269-1987

2 Sp. Gravity of Cement 3 Sp. Gravity of Water 4 Chemical Admixture 5 Sp. Gravity of 20 mm Aggregate 6 Sp. Gravity of 10 mm Aggregate 7 Sp. Gravity of Sand 8 Water Absorption of 20 mm Aggregate 0.97% 9 Water Absorption of 10 mm Aggregate 0.83% 10 Water Absorption of Sand 11 Free (Surface) Moisture of 20 mm Aggregate 12 Free (Surface) Moisture of 10 mm Aggregate 13 Free (Surface) Moisture of Sand 14 Sieve Analysis of Individual Coarse Aggregates 15 Sieve Analysis of Combined Coarse Aggregates 15 Sp.Gravity of Combined Coarse Aggregates 16 Sieve Analysis of Fine Aggregates 1 Separate Analysis Done A-3Target Strength for Mix Proportioning Target Mean Strength (MORT&H 1700-5) 25N/mm2 nil Separate Analysis Done Separate Analysis Done 2.882 1.23% nil nil 2.605 2.878 2.884 Not Used 1.00 3.15

2 Characteristic Strength @ 28 days A-4Selection of Water Cement Ratio 1 2 Adopted Water Cement Ratio A-5Selection of Water Content 1 2 3 Superplasticiser used A-6Calculation of Cement Content 1 Water Cement Ratio 2 Cement Content (135/0.5) 270 kg/m3 Which is greater then 250 kg/m3 0.5 nil Maximum Water content (10262-table2) 186 Lit. Estimated Water content for 25 mm Slump 135 Lit. 0.5 Maximum Water Cement Ratio (MORT&H 1700-3 A) 0.5 15N/mm2

A-7Proportion of Volume of Coarse Aggregate & Fine Aggregate Content 1 Vol. of C.A. as per table 3 of IS 10262 62.00% 2 Adopted Vol. of Coarse Aggregate Adopted Vol. of Fine Aggregate ( 10.65) A-8Mix Calculations 1 Volume of Concrete in m3 2 Volume of Cement in m3 (Mass of Cement) / (Sp. Gravity of Cement)x1000 3 Volume of Water in m3 0.135 0.09 1.00 65.00% 35.00%

(Mass of Water) / (Sp. Gravity of Water)x1000 4 Volume of Admixture @ 0% in m3 (Mass of Admixture)/(Sp. Gravity of Admixture)x1000 5 Volume of All in Aggregate in m3 Sr. no. 1 (Sr. no. 2+3+4) 6 Volume of Coarse Aggregate in m3 Sr. no. 5 x 0.65 7 Volume of Fine Aggregate in m3 Sr. no. 5 x 0.35 1 Mass of Cement in kg/m3 2 Mass of Water in kg/m3 3 Mass of Fine Aggregate in kg/m3 4 Mass of Coarse Aggregate in kg/m3 Mass of 20 mm in kg/m3 Mass of 10 mm in kg/m3 5 Mass of Admixture in kg/m3 6 Water Cement Ratio 0.5 nil 1460 1051 409 711 135 270 0.273 0.507 0.779 nil

A-9Mix Proportions for One Cum of Concrete (SSD Condition)

Concrete Mix Design M 20 Grade Of Concrete

Posted in Mix Design | 1. REQUIREMENTS a) Specified minimum strength = 20 N/Sq mm Email This Post

b) Durability requirements i) Exposure Moderate ii) Minimum Cement Content = 300 Kgs/cum c) Cement (Refer Table No. 5 of IS:456-2000) i) Make Chetak (Birla) ii) Type OPC iii) Grade 43 d) Workability i) compacting factor = 0.7 e) Degree of quality control Good 2. TEST DATA FOR MATERIALS SUPPLIED a) CEMENT i) Specific gravity = 3.05 ii) Avg. comp. strength 7 days = 46.5 more than 33.0 OK 28 days = 55.0 more than 43.0 OK b) COARSE AGGREGATE i) 20mm Graded Type Crushed stone aggregate Specific gravity = 2.68 Water absorption = 1.46 Free (surface) moisture = 0

c) FINE AGGREGATE (Coarse sand) i) Type Natural (Ghaggar) Specific gravity = 2.6 Water absorption = 0.5 Free (surface) moisture = 1.4

3. TARGET MEAN STRENGTH (TMS) a) Statistical constant K = 1.65 b) Standard deviation S = 4.6 Thus, TMS = 27.59 N/Sqmm 4. SELECTION OF W/C RATIO a) As required for TMS = 0.5 b) As required for Moderate Exposure = 0.55 Assume W/c ratio of 0.5 5. DETERMINATION OF WATER & SAND CONTENT For W/C = 0.6 C.F. = 0.8 Max. Agg. Size of 20 mm a) Water content = 186 Kg/cum b) Sand as percentage of total aggregate by absolute volume = 35 % Thus, Net water content = 180.42 Kg/cum Net sand percentage = 33 %

6. DETERMINATION OF CEMENT CONTENT W/c ratio = 0.5 Water content = 180.42 Kg/cum Thus, Cement content = 360.84 Kg/cum Adequate for moderate exposure Say 360 Kg/cum 7. DETERMINATION OF COARSE AND FINE AGGREGATE CONTENT Assume entrapped air as 2 % Thus, 0.98 cum = [180.42+360/3.05 + {1/0.33}*{fa/2.6}]/1000 & 0.98 cum = [180.42+360/3.05 + {1/0.67}*{Ca/2.68}]/1000 Hence, fa = 584 Kg/cum Ca = 1223.8 Kg/cum The final mix proportions of M-20 grade of concrete become:-

Note: 1 The above recommended mix design must be verified, by actual cube tests. 2 The mix design is based on the quality and grading of the materials actually supplied,

by the client. Any variation in quality and gradation will result in changes in the mix design.

M-20 Mix Designs as per IS-10262-2009

Posted in Mix Design | Dear Again Regards Raj Mohammad Khan I am back with M-20 Mix Designs as per Email This Post All IS-10262-2009

M-20 CONCRETE MIX DESIGN As per IS 10262-2009 & MORT&H A-1 Stipulations for Proportioning 1 Grade Designation 2 Type of Cement 3 Maximum Nominal Aggregate Size 4 5 6 Workability (MORT&H 1700-4) 7 Exposure Condition 8 Degree of Supervision 9 Type of Aggregate Crushed Angular Aggregate 10 Maximum Cement Content (MORT&H Cl. 1703.2) 540 kg/m3 11 Chemical Admixture Type A-2 Test Data for Materials Superplasticiser Confirming to IS9103 Good Normal 25 mm (Slump) Minimum Cement Content (MORT&H 1700-3 A) 20 mm 250 kg/m3 M20 OPC 53 grade confirming to IS12269-1987

Maximum Water Cement Ratio (MORT&H 1700-3 A) 0.5

1 Cement Used 2 Sp. Gravity of Cement 3 Sp. Gravity of Water 4 Chemical Admixture 5 Sp. Gravity of 20 mm Aggregate 6 Sp. Gravity of 10 mm Aggregate 7 Sp. Gravity of Sand 8 Water Absorption of 20 mm Aggregate 9 Water Absorption of 10 mm Aggregate 10 Water Absorption of Sand 11 Free (Surface) Moisture of 20 mm Aggregate 12 Free (Surface) Moisture of 10 mm Aggregate 13 Free (Surface) Moisture of Sand 14 Sieve Analysis of Individual Coarse Aggregates 15 Sieve Analysis of Combined Coarse Aggregates 15 Sp. Gravity of Combined Coarse Aggregates2.882 16 Sieve Analysis of Fine Aggregates A-3 Target Strength for Mix Proportioning Separate Analysis Done nil Separate Analysis Done Separate Analysis Done 1.23% nil nil 0.83% 0.97% 2.605 2.878 2.884 Not Used 1.00 3.15 Coromandal King OPC 53 grade

1 Target Mean Strength (MORT&H 1700-5) 30N/mm2 2 Characteristic Strength @ 28 days A-4 Selection of Water Cement Ratio 1 2 Adopted Water Cement Ratio A-5 Selection of Water Content 1 Maximum Water content (10262-table-2) 2 Estimated Water content for 25 mm Slump 145 Lit. 3 Superplasticiser used A-6 Calculation of Cement Content 1 Water Cement Ratio 2 Cement Content (145/0.5) 290 kg/m3 Which is greater then 250 kg/m3 0.5 nil 186 Lit. 0.5 Maximum Water Cement Ratio (MORT&H 1700-3 A) 0.5 20N/mm2

A-7 Proportion of Volume of Coarse Aggregate & Fine Aggregate Content 1 Vol. of C.A. as per table 3 of IS 10262 2 Adopted Vol. of Coarse Aggregate Adopted Vol. of Fine Aggregate ( 1-0.65) A-8 Mix Calculations 1 Volume of Concrete in m3 2 Volume of Cement in m3 (Mass of Cement) / (Sp. Gravity of Cement)x1000 Volume of Water in m3 0.09 1.00 65.00% 35.00% 62.00%

0.145

(Mass of Water) / (Sp. Gravity of Water)x1000 4 Volume of Admixture @ 0% in m3 (Mass of Admixture)/(Sp. Gravity of Admixture)x1000 5 Volume of All in Aggregate in m3 Sr. no. 1 (Sr. no. 2+3+4) 6 Volume of Coarse Aggregate in m3 Sr. no. 5 x 0.65 7 Volume of Fine Aggregate in m3 Sr. no. 5 x 0.35 1 Mass of Cement in kg/m3 2 Mass of Water in kg/m3 3 Mass of Fine Aggregate in kg/m3 4 Mass of Coarse Aggregate in kg/m3 Mass of 20 mm in kg/m3 Mass of 10 mm in kg/m3 5 Mass of Admixture in kg/m3 6 Water Cement Ratio 0.5 nil 1429 1029 400 696 145 290 0.267 0.496 0.763 nil

A-9 Mix Proportions for One Cum of Concrete (SSD Condition)

M-30 Mix Designs as per IS-10262-2009

Posted in Mix Design | Email This Post

Dear All Again Regards Raj Mohammad Khan I am back with M-30 Mix Designs as per IS-10262-2009

M-30 CONCRETE MIX DESIGN As per IS 10262-2009 & MORT&H A-1 Stipulations for Proportioning 1 Grade Designation 2 Type of Cement 3 Maximum Nominal Aggregate Size 4 5 6 Workability (MORT&H 1700-4) 7 Exposure Condition 8 Degree of Supervision 9 Type of Aggregate 10 Maximum Cement Content (MORT&H Cl. 1703.2) 11 Chemical Admixture Type A-2 Test Data for Materials 1 Cement Used 2 3 Sp. Gravity of Cement Sp. Gravity of Water 3.15 1.00 Coromandal King OPC 53 grade Crushed Angular Aggregate 540 kg/m3 Superplasticiser Confirming to IS9103 Good Normal 50-75 mm (Slump) 20 mm Minimum Cement Content (MORT&H 17003 A) 310 kg/m3 Maximum Water Cement Ratio (MORT&H 1700-3 A) 0.45 M30 OPC 53 grade confirming to IS12269-1987

4 Chemical Admixture 5 Sp. Gravity of 20 mm Aggregate 6 Sp. Gravity of 10 mm Aggregate 7 Sp. Gravity of Sand 8 Water Absorption of 20 mm Aggregate 9 Water Absorption of 10 mm Aggregate 10 Water Absorption of Sand 11 Free (Surface) Moisture of 20 mm Aggregate nil 12 Free (Surface) Moisture of 10 mm Aggregate nil 13 Free (Surface) Moisture of Sand 14 Sieve Analysis of Individual Coarse Aggregates 15 Sieve Analysis of Combined Coarse Aggregates 15 Sp. Gravity of Combined Coarse Aggregates 2.882 16 Sieve Analysis of Fine Aggregates A-3 Target Strength for Mix Proportioning 1 Target Mean Strength (MORT&H 1700-5) 2 Characteristic Strength @ 28 days 30N/mm2 42N/mm2 Separate Analysis Done nil Separate Analysis Done Separate Analysis Done 1.23% 0.83% 0.97% 2.605 2.878 2.884 BASF Chemicals Company

A-4 Selection of Water Cement Ratio 1 2 Adopted Water Cement Ratio A-5 Selection of Water Content 1 Maximum Water content (10262-table-2) 2 3 Superplasticiser used A-6 Calculation of Cement Content 1 Water Cement Ratio 2 Cement Content (160/0.42) 380 kg/m3 Which is greater then 310 kg/m3 0.42 0.5 % by wt. of cement Estimated Water content for 50-75 mm Slump 186 Lit. 160 Lit. 0.42 Maximum Water Cement Ratio (MORT&H 1700-3 A) 0.45

A-7 Proportion of Volume of Coarse Aggregate & Fine Aggregate Content 1 Vol. of C.A. as per table 3 of IS 10262 2 Adopted Vol. of Coarse Aggregate Adopted Vol. of Fine Aggregate ( 1-0.62) A-8 Mix Calculations 1 Volume of Concrete in m3 2 Volume of Cement in m3 (Mass of Cement) / (Sp. Gravity of Cement)x1000 3 Volume of Water in m3 (Mass of Water) / (Sp. Gravity of Water)x1000 Volume of Admixture @ 0.5% in m3 0.160 0.12 1.00 62.00% 38.00% 62.00%

0.00160

(Mass of Admixture)/(Sp. Gravity of Admixture)x1000 5 Volume of All in Aggregate in m3 Sr. no. 1 (Sr. no. 2+3+4) 6 Volume of Coarse Aggregate in m3 Sr. no. 5 x 0.62 7 Volume of Fine Aggregate in m3 Sr. no. 5 x 0.38 1 Mass of Cement in kg/m3 2 Mass of Water in kg/m3 3 Mass of Fine Aggregate in kg/m3 4 Mass of Coarse Aggregate in kg/m3 Mass of 20 mm in kg/m3 Mass of 10 mm in kg/m3 5 Mass of Admixture in kg/m3 6 Water Cement Ratio 0.42 1.90 1283 924 359 711 160 380 0.273 0.445 0.718

A-9 Mix Proportions for One Cum of Concrete (SSD Condition)

M-35 Mix Designs as per IS-10262-2009

Posted in Mix Design | Email This Post

Dear All Again I am back Regards Raj Mohammad Khan with M-35 Mix Designs as per IS-10262-2009

CONCRETE MIX DESIGN As per IS 10262-2009 & MORT&H A-1 1 Grade Designation 2 Type of Cement 3 Maximum Nominal Aggregate Size 4 5 6 Workability (MORT&H 1700-4) 7 Exposure Condition 8 Degree of Supervision 9 Type of Aggregate 10 11 Chemical Admixture Type A-2 1 Cement Used 2 Sp. Gravity of Cement 3 Sp. Gravity of Water 4 5 Chemical Admixture Sp. Gravity of 20 mm Aggregate BASF Chemicals Company 2.884 1.00 3.15 Coromandal King OPC 53 grade Test Data for Materials Crushed Angular Aggregate Maximum Cement Content (MORT&H Cl. 1703.2) 540 kg/m3 Superplasticiser Confirming to IS9103 Good Normal 50-75 mm (Slump) Minimum Cement Content (MORT&H 1700-3 A) Maximum Water Cement Ratio (MORT&H 1700-3 A) 20 mm 310 kg/m3 0.45 M35 OPC 53 grade confirming to IS12269-1987 Stipulations for Proportioning

6 Sp. Gravity of 10 mm Aggregate 7 Sp. Gravity of Sand 8 Water Absorption of 20 mm Aggregate 9 Water Absorption of 10 mm Aggregate 10 Water Absorption of Sand 11 12 13 Free (Surface) Moisture of Sand 14 15 15 16 Sieve Analysis of Fine Aggregates A-3 1 Target Mean Strength (MORT&H 1700-5) 47N/mm2 2 Characteristic Strength @ 28 days A-4 1 2 Selection of Water Cement Ratio Maximum Water Cement Ratio (MORT&H 1700-3 A) Adopted Water Cement Ratio 0.45 0.4 35N/mm2 Target Strength for Mix Proportioning Separate Analysis Done Sieve Analysis of Individual Coarse Aggregates Sieve Analysis of Combined Coarse Aggregates Sp.Gravity of Combined Coarse Aggregates nil Separate Analysis Done Separate Analysis Done 2.882 Free (Surface) Moisture of 20 mm Aggregate Free (Surface) Moisture of 10 mm Aggregate 1.23% nil nil 0.83% 0.97% 2.605 2.878

A-5 1

Selection of Water Content Maximum Water content (10262-table-2) 186 Lit.

2 3

Estimated Water content for 50-75 mm Slump Superplasticiser used

160 Lit. 0.5 % by wt. of cement

A-6 1

Calculation of Cement Content Water Cement Ratio 0.4 400 kg/m3 Which is greater then 310 kg/m3

2 Cement Content (160/0.42) A-7 1 Vol. of C.A. as per table 3 of IS 10262 2 Adopted Vol. of Coarse Aggregate 62.00% Adopted Vol. of Fine Aggregate ( 1-0.62) 38.00% A-8 1 Volume of Concrete in m3 2 Volume of Cement in m3 (Mass of Cement) / (Sp. Gravity of Cement)x1000 3 Volume of Water in m3 (Mass of Water) / (Sp. Gravity of Water)x1000 4 Volume of Admixture @ 0.5% in m3 (Mass of Admixture)/(Sp. Gravity of Admixture)x1000 Volume of All in Aggregate in m3 0.00168 0.160 0.13 1.00 Mix Calculations 62.00%

Proportion of Volume of Coarse Aggregate & Fine Aggregate Content

0.711

Sr. no. 1 (Sr. no. 2+3+4) 6 Volume of Coarse Aggregate in m3 Sr. no. 5 x 0.62 7 Volume of Fine Aggregate in m3 Sr. no. 5 x 0.38 A-9 1 Mass of Cement in kg/m3 2 Mass of Water in kg/m3 3 Mass of Fine Aggregate in kg/m3 4 Mass of Coarse Aggregate in kg/m3 Mass of 20 mm in kg/m3 Mass of 10 mm in kg/m3 5 Mass of Admixture in kg/m3 6 Water Cement Ratio 0.40 2.00 1271 915 356 704 160 400 0.270 0.441

Mix Proportions for One Cum of Concrete (SSD Condition)

Mix Design For M35 Grade Of Concrete

Posted in Mix Design | Email This Post The mix design for M35 Grade Of Concrete for pile foundations provided here is for reference purpose only. Actual site conditions vary and thus this should be adjusted as per the location and other factors. Grade of Concrete : M35 Characteristic Strength (Fck) : 35 Mpa Standard Deviation : 1.91 Mpa* Target Mean Strength : T.M.S.= Fck +1.65 x S.D.

(from I.S 456-2000) = 35+ 1.651.91 = 38.15 Mpa Test Data For Material: Aggregate Type : Crushed Specific Gravity Cement : 3.15 Coarse Aggregate : 2.67 Fine Aggregate : 2.62 Water Absorption: Coarse Aggregate : 0.5% Fine Aggregate : 1.0 % MIX DESIGN Take Sand content as percentage of total aggregates = 36% Select Water Cement Ratio = 0.43 for concrete grade M35 (From Fig 2. of I.S. 10262- 1982) Select Water Content = 172 Kg (From IS: 10262 for 20 mm nominal size of aggregates Maximum Water Content = 186 Kg/ M3 ) Hence, Cement Content= 172 / 0.43 = 400 Kg / M3 Formula for Mix Proportion of Fine and Coarse Aggregate: 1000(1-a0) = {(Cement Content / Sp. Gr. Of Cement) + Water Content +(Fa / Sp. Gr.* Pf )} 1000(1-a0) = {(Cement Content / Sp. Gr. Of Cement) + Water Content +Ca / Sp. Gr.* Pc )} Where Ca = Coarse Aggregate Content Fa = Fine Aggregate Content Pf = Sand Content as percentage of total Aggregates = 0.36 Pc = Coarse Aggregate Content as percentage of total Aggregates. = 0.64

a0 = Percentage air content in concrete (As per IS :10262 for 20 mm nominal size of aggregates air content is 2 %) = 0.02 Hence, 1000(1-0.02) = {(400 /3.15) + 172 +(Fa / 2.62 x 0.36)} Fa = 642 Kg/ Cum As the sand is of Zone II no adjustment is required for sand. Sand Content = 642 Kg/ Cum 1000(1-0.02) = {(400 /3.15) + 172 +(Ca / 2.67 x 0.64)} Hence, Ca = 1165 Kg/ Cum From combined gradation of Coarse aggregates it has been found out that the proportion of 53:47 of 20 mm & 10 mm aggregates produces the best gradation as per IS: 383. Hence, 20 mm Aggregates = 619 Kg And 10 mm Aggregates = 546 Kg To obtain slump in the range of 150-190 mm water reducing admixture brand SP430 from Fosroc with a dose of 0.3 % by weight of Cement shall be used. Hence the Mix Proportion becomes: Units Kg/ M3 Cement : Sand: Coarse Aggregates = 1 : 1.6 : 2.907

Cem W/C Water Sand 20mm 10mm Admix 400 0.43 172 1 0.43 635 1.6 619 1.547 564 1.36 1.2 0.003

Mix Design M-40 Grade

Posted in Mix Design | Email This Post The mix design M-40 grade for Pier (Using Admixture Fosroc) provided here is for reference purpose only. Actual site conditions vary and thus this should be adjusted as per the location and other factors. Parameters for mix design M40 Grade Designation = M-40 Type of cement = O.P.C-43 grade Brand of cement = Vikram ( Grasim ) Admixture = Fosroc ( Conplast SP 430 G8M ) Fine Aggregate = Zone-II

Sp. Gravity Cement = 3.15 Fine Aggregate = 2.61 Coarse Aggregate (20mm) = 2.65 Coarse Aggregate (10mm) = 2.66 Minimum Cement (As per contract) = 400 kg / m3 Maximum water cement ratio (As per contract) = 0.45 Mix Calculation: 1. Target Mean Strength = 40 + (5 X 1.65) = 48.25 Mpa 2. Selection of water cement ratio:Assume water cement ratio = 0.4 3. Calculation of cement content: Assume cement content 400 kg / m3 (As per contract Minimum cement content 400 kg / m3) 4. Calculation of water: 400 X 0.4 = 160 kg Which is less than 186 kg (As per Table No. 4, IS: 10262) Hence o.k. 5. Calculation for C.A. & F.A.: As per IS : 10262 , Cl. No. 3.5.1 V = [ W + (C/Sc) + (1/p) . (fa/Sfa) ] x (1/1000) V = [ W + (C/Sc) + {1/(1-p)} . (ca/Sca) ] x (1/1000) Where V = absolute volume of fresh concrete, which is equal to gross volume (m3) minus the volume of entrapped air , W = mass of water ( kg ) per m3 of concrete , C = mass of cement ( kg ) per m3 of concrete , Sc = specific gravity of cement, (p) = Ratio of fine aggregate to total aggregate by absolute volume , (fa) , (ca) = total mass of fine aggregate and coarse aggregate (kg) per m3 of Concrete respectively, and Sfa , Sca = specific gravities of saturated surface dry fine aggregate and Coarse aggregate respectively. As per Table No. 3 , IS-10262, for 20mm maximum size entrapped air is 2% . Assume F.A. by % of volume of total aggregate = 36.5 %

0.98 = [ 160 + ( 400 / 3.15 ) + ( 1 / 0.365 ) ( Fa / 2.61 )] ( 1 /1000 ) => Fa = 660.2 kg Say Fa = 660 kg. 0.98 = [ 160 + ( 400 / 3.15 ) + ( 1 / 0.635 ) ( Ca / 2.655 )] ( 1 /1000 ) => Ca = 1168.37 kg. Say Ca = 1168 kg. Considering 20 mm : 10mm = 0.6 : 0.4 20mm = 701 kg . 10mm = 467 kg . Hence Mix details per m3 Cement = 400 kg Water = 160 kg Fine aggregate = 660 kg Coarse aggregate 20 mm = 701 kg Coarse aggregate 10 mm = 467 kg Admixture = 0.6 % by weight of cement = 2.4 kg. Recron 3S = 900 gm Water: cement: F.A.: C.A. = 0.4: 1: 1.65: 2.92 Observation: A. Mix was cohesive and homogeneous. B. Slump = 110mm C. No. of cube casted = 12 Nos. 7 days average compressive strength = 51.26 MPa. 28 days average compressive strength = 62.96 MPa which is greater than 48.25MPa Hence the mix is accepted.

Mix Design M-50 Grade

Posted in Mix Design | Email This Post The mix design M-50 grade (Using Admixture Sikament) provided here is for reference purpose only. Actual site conditions vary and thus this should be adjusted as per the location and other factors.

Parameters for mix design M50 Grade Designation = M-50 Type of cement = O.P.C-43 grade Brand of cement = Vikram ( Grasim ) Admixture = Sika [Sikament 170 ( H ) ] Fine Aggregate = Zone-II Sp. Gravity Cement = 3.15 Fine Aggregate = 2.61 Coarse Aggregate (20mm) = 2.65 Coarse Aggregate (10mm) = 2.66 Minimum Cement (As per contract) =400 kg / m3 Maximum water cement ratio (As per contract) = 0.45 Mix Calculation: 1. Target Mean Strength = 50 + ( 5 X 1.65 ) = 58.25 Mpa 2. Selection of water cement ratio:Assume water cement ratio = 0.35 3. Calculation of water: Approximate water content for 20mm max. Size of aggregate = 180 kg /m3 (As per Table No. 5 , IS : 10262 ). As plasticizer is proposed we can reduce water content by 20%. Now water content = 180 X 0.8 = 144 kg /m3 4. Calculation of cement content:Water cement ratio = 0.35 Water content per cum of concrete = 144 kg Cement content = 144/0.35 = 411.4 kg / m3 Say cement content = 412 kg / m3 (As per contract Minimum cement content 400 kg / m3 ) Hence O.K. 5. Calculation for C.A. & F.A.: [ Formula's can be seen in earlier posts]Volume of concrete = 1 m3 Volume of cement = 412 / ( 3.15 X 1000 ) = 0.1308 m3 Volume of water = 144 / ( 1 X 1000 ) = 0.1440 m3 Volume of Admixture = 4.994 / (1.145 X 1000 ) = 0.0043 m3 Total weight of other materials except coarse aggregate = 0.1308 + 0.1440 +0.0043 = 0.2791 m3

Volume of coarse and fine aggregate = 1 0.2791 = 0.7209 m3 Volume of F.A. = 0.7209 X 0.33 = 0.2379 m3 (Assuming 33% by volume of total aggregate ) Volume of C.A. = 0.7209 0.2379 = 0.4830 m3 Therefore weight of F.A. = 0.2379 X 2.61 X 1000 = 620.919 kg/ m3 Say weight of F.A. = 621 kg/ m3 Therefore weight of C.A. = 0.4830 X 2.655 X 1000 = 1282.365 kg/ m3 Say weight of C.A. = 1284 kg/ m3 Considering 20 mm: 10mm = 0.55: 0.45 20mm = 706 kg . 10mm = 578 kg . Hence Mix details per m3 Increasing cement, water, admixture by 2.5% for this trial Cement = 412 X 1.025 = 422 kg Water = 144 X 1.025 = 147.6 kg Fine aggregate = 621 kg Coarse aggregate 20 mm = 706 kg Coarse aggregate 10 mm = 578 kg Admixture = 1.2 % by weight of cement = 5.064 kg. Water: cement: F.A.: C.A. = 0.35: 1: 1.472: 3.043 Observation: A. Mix was cohesive and homogeneous. B. Slump = 120 mm C. No. of cube casted = 9 Nos. 7 days average compressive strength = 52.07 MPa. 28 days average compressive strength = 62.52 MPa which is greater than 58.25MPa Hence the mix accepted.

Vous aimerez peut-être aussi

- M-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Document4 pagesM-30 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For Proportioning Grade Designation M30Kumkum MukherjeePas encore d'évaluation

- M30 Design CalculationDocument6 pagesM30 Design Calculationjeffkarthick1Pas encore d'évaluation

- Mix Design Using Is CodeDocument67 pagesMix Design Using Is CodeNilesh SaksenaPas encore d'évaluation

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignGlyn A. Brinquez100% (1)

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocument9 pagesDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedPas encore d'évaluation

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraPas encore d'évaluation

- Concrete Mix Design: RequirmentsDocument56 pagesConcrete Mix Design: RequirmentssushilkumarPas encore d'évaluation

- Mix Design M30 PDFDocument4 pagesMix Design M30 PDFDharmendra SahuPas encore d'évaluation

- Lab Manual DCSDocument27 pagesLab Manual DCSvassihayPas encore d'évaluation

- Concrete Mixed Design For C30Document2 pagesConcrete Mixed Design For C30raju_420034520Pas encore d'évaluation

- M-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeDocument3 pagesM-80 Grade Pumpable Concrete: by Kaushal Kishore Materials Engineer, RoorkeeSai CharanPas encore d'évaluation

- Conrete Mix Design ACI and JSCE Example. (20+33 Mpa)Document8 pagesConrete Mix Design ACI and JSCE Example. (20+33 Mpa)nirmaljoshi100% (1)

- Concrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFDocument10 pagesConcrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFThomas CrowePas encore d'évaluation

- Self Compacting ConcreteDocument27 pagesSelf Compacting ConcreteJatin MaggoPas encore d'évaluation

- 7-SCC C60 Mix Design MDC 2Document1 page7-SCC C60 Mix Design MDC 2Kelly JuarezPas encore d'évaluation

- Concrete Mixed Design MethodDocument11 pagesConcrete Mixed Design Methodabdicasis rashidPas encore d'évaluation

- Concrete Mix Design CalculationDocument10 pagesConcrete Mix Design CalculationHari RPas encore d'évaluation

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignIvo StanilovPas encore d'évaluation

- Optimal Mix Design For Pervious ConcreteDocument9 pagesOptimal Mix Design For Pervious ConcretejanakarajPas encore d'évaluation

- Material Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Document1 pageMaterial Supplier or Certifier Type/Gradation Astm Date S.G. Quantity %Waqas SadiqPas encore d'évaluation

- Design Mix PCC BlockDocument8 pagesDesign Mix PCC Blockvikrant987Pas encore d'évaluation

- Concrete MIx Design SummaryDocument4 pagesConcrete MIx Design SummaryAmarPas encore d'évaluation

- Concrete Mix DesignDocument6 pagesConcrete Mix DesignIndunil HerathPas encore d'évaluation

- Concrete Mix Design ExampleDocument2 pagesConcrete Mix Design ExampleMohamed Naheeb Aboobucker100% (1)

- Mix DesignDocument29 pagesMix Designshahhassa9Pas encore d'évaluation

- Design Mix ConcreteDocument7 pagesDesign Mix ConcreteAnand.5Pas encore d'évaluation

- On MIX DesignDocument27 pagesOn MIX DesignGaurav naddaPas encore d'évaluation

- m60 Grade of Concrete Design Mix Procedure With Opc 53 Grade Cement and AlccofineDocument5 pagesm60 Grade of Concrete Design Mix Procedure With Opc 53 Grade Cement and AlccofineNitinLambaPas encore d'évaluation

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignRony BaloyiPas encore d'évaluation

- Design of Cement Concrete Mix For M30 Grade ConcreteDocument8 pagesDesign of Cement Concrete Mix For M30 Grade ConcreteNarendra BokrePas encore d'évaluation

- Flexural Strength of ConcreteDocument2 pagesFlexural Strength of ConcretedhanishaPas encore d'évaluation

- Concrete Mix DesignDocument24 pagesConcrete Mix Designvishnumani3011Pas encore d'évaluation

- AAC Blcok Test ReportDocument1 pageAAC Blcok Test ReportEyutt HghghPas encore d'évaluation

- Mix Design M40Document3 pagesMix Design M40D21Pas encore d'évaluation

- 3.3 Road Note No. 4-1Document40 pages3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Concrete Mix Design Step by Step Full CalculationDocument11 pagesConcrete Mix Design Step by Step Full CalculationtalatzahoorPas encore d'évaluation

- MIX Proportioning: Design Consideration: Obtaining Good WorkabilityDocument20 pagesMIX Proportioning: Design Consideration: Obtaining Good Workabilityshahid aliPas encore d'évaluation

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirPas encore d'évaluation

- Ds - Concrete Mix DesignDocument51 pagesDs - Concrete Mix DesignDarshan ShahPas encore d'évaluation

- How Much Cement, Sand and Water Is Required For 12mm Thick Plastering - HapphoDocument7 pagesHow Much Cement, Sand and Water Is Required For 12mm Thick Plastering - HapphoJatinder BhatiaPas encore d'évaluation

- Mix Design 8 2Document6 pagesMix Design 8 2Eulogio JameroPas encore d'évaluation

- M-25 Design MixDocument7 pagesM-25 Design MixAbhishek GoundPas encore d'évaluation

- Lean Concrete Base Mix DesignDocument18 pagesLean Concrete Base Mix DesignZaher J. Yazeji0% (1)

- IS Code Method of Mix Design Using SuperplasticizerDocument29 pagesIS Code Method of Mix Design Using SuperplasticizerJameel KhanPas encore d'évaluation

- Mix Design c40Document13 pagesMix Design c40Jaime Manalili LandinginPas encore d'évaluation

- Concrete Mix Design (Notes) PDFDocument11 pagesConcrete Mix Design (Notes) PDFMohamad Khaled Nordin100% (1)

- Is Mix DesignDocument6 pagesIs Mix Designsanthu256Pas encore d'évaluation

- Mix Design For M35 Grade of ConcreteDocument4 pagesMix Design For M35 Grade of ConcretePaulos Wodajenehe TessemaPas encore d'évaluation

- DoE Mix Design ExamplesDocument8 pagesDoE Mix Design Examplesعابد خواجہPas encore d'évaluation

- Final Aac PDFDocument7 pagesFinal Aac PDFindrajit sodhaPas encore d'évaluation

- Concrete Mix DesignDocument93 pagesConcrete Mix Designjaffna100% (3)

- Concrete Mix Design CalculationDocument12 pagesConcrete Mix Design CalculationRaihan Alisha Nabila100% (1)

- Mr. K.R.Thanki (BE Civil) Lecturer Civil Engineering Department Government Poly Technic, Junagadh, Gujarat-IndiaDocument42 pagesMr. K.R.Thanki (BE Civil) Lecturer Civil Engineering Department Government Poly Technic, Junagadh, Gujarat-IndiaserenePas encore d'évaluation

- 45mpa Mix DesignDocument2 pages45mpa Mix DesignSamuel YekoPas encore d'évaluation

- SCC - M30 (BGS) NTH3-2015NewDocument4 pagesSCC - M30 (BGS) NTH3-2015NewrajupetalokeshPas encore d'évaluation

- M-25 Concrete Mix DesignDocument23 pagesM-25 Concrete Mix DesignAjith RamuPas encore d'évaluation

- M20 Mix DesignDocument4 pagesM20 Mix DesignAvnish raiPas encore d'évaluation

- M-25 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For ProportioningDocument5 pagesM-25 Concrete Mix Design As Per IS 10262-2009 & MORT&H A-1 Stipulations For ProportioningSiddharth PednekarPas encore d'évaluation

- m30 Mix DesignDocument4 pagesm30 Mix DesignAvnish raiPas encore d'évaluation

- M-25 Concrete Mix Design As Per IS 10262-2009 & MORT&HDocument4 pagesM-25 Concrete Mix Design As Per IS 10262-2009 & MORT&HMK VPas encore d'évaluation

- Nirali BG Catalogue April 2023Document53 pagesNirali BG Catalogue April 2023arun sainiPas encore d'évaluation

- Johnson Marbonite Floor 40x40cm 12mm THK Catalogue RJKT Jan 23Document12 pagesJohnson Marbonite Floor 40x40cm 12mm THK Catalogue RJKT Jan 23Prasad MsrkPas encore d'évaluation

- Traditional Telugu Brahmin Marriage CeremonyDocument16 pagesTraditional Telugu Brahmin Marriage CeremonycidBookBee75% (4)

- Prayer at NightDocument1 pagePrayer at NightPrasad MsrkPas encore d'évaluation

- Erica Digital TDocument1 pageErica Digital TPrasad MsrkPas encore d'évaluation

- Johnson Porcelano 80x160 60x120 19.5x120 60x60cm Catalogue VJWD Nov 22Document120 pagesJohnson Porcelano 80x160 60x120 19.5x120 60x60cm Catalogue VJWD Nov 22Prasad MsrkPas encore d'évaluation

- BPCL - HSD RATES AT HYD - 15.01.2017 TO 15.12.2017 AND ON 19.06.2017 (ReplyDocument 13.07.2018)Document1 pageBPCL - HSD RATES AT HYD - 15.01.2017 TO 15.12.2017 AND ON 19.06.2017 (ReplyDocument 13.07.2018)Prasad MsrkPas encore d'évaluation

- Galvanized Iron PipesDocument1 pageGalvanized Iron PipesAsh PrakPas encore d'évaluation

- Ts 22 C 7532 Puc CertificateDocument1 pageTs 22 C 7532 Puc CertificatePrasad MsrkPas encore d'évaluation

- RTI Online - Online RTI Information System BPCL DT 18.07.2018Document1 pageRTI Online - Online RTI Information System BPCL DT 18.07.2018Prasad MsrkPas encore d'évaluation

- MoRT&H Specifications For Road and Bridge Works (Fifth Revision) 2013 PDFDocument906 pagesMoRT&H Specifications For Road and Bridge Works (Fifth Revision) 2013 PDFSwapnil Rudrawar100% (1)

- Bajaj Allianz General Insurance Company LTD.: ReceiptDocument1 pageBajaj Allianz General Insurance Company LTD.: ReceiptPrasad MsrkPas encore d'évaluation

- Budugu KathaluDocument43 pagesBudugu Kathalutaaimelbourne100% (4)

- Rti BPCL 19062018 PDFDocument1 pageRti BPCL 19062018 PDFPrasad MsrkPas encore d'évaluation

- Minutes of Dec-Aicte-Ugc MeetingDocument109 pagesMinutes of Dec-Aicte-Ugc MeetingPrasad Msrk100% (1)

- 9C404 7Document23 pages9C404 7Prasad MsrkPas encore d'évaluation

- Pressure Vessel Steels - Astm A516Document6 pagesPressure Vessel Steels - Astm A516septo982Pas encore d'évaluation

- Department of Technical Education Andhra PradeshDocument51 pagesDepartment of Technical Education Andhra PradeshPrasad MsrkPas encore d'évaluation

- 9C404 8Document15 pages9C404 8Prasad MsrkPas encore d'évaluation

- 9C404 5Document48 pages9C404 5Prasad MsrkPas encore d'évaluation

- Dec Approved Institutions ListDocument8 pagesDec Approved Institutions ListPrasad MsrkPas encore d'évaluation

- Civil Engineering ConstructionDocument1 pageCivil Engineering ConstructionPrasad MsrkPas encore d'évaluation

- Document of Engiish WordsDocument89 pagesDocument of Engiish WordsPrasad MsrkPas encore d'évaluation

- Department of Technical Education Andhra PradeshDocument51 pagesDepartment of Technical Education Andhra PradeshPrasad MsrkPas encore d'évaluation

- Required Codal Revisions As On 2012-2013Document14 pagesRequired Codal Revisions As On 2012-2013yunuswsaPas encore d'évaluation

- 121 Hyderabad MMTSDocument7 pages121 Hyderabad MMTSPrasad MsrkPas encore d'évaluation

- Quartile1 PDFDocument2 pagesQuartile1 PDFHanifah Edres DalumaPas encore d'évaluation

- Exercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedDocument3 pagesExercise On Word Formation 2 (Unit 2 - Advanced) : Tran Dai Nghia High School For The GiftedEveryonehateshiuzo 2.0Pas encore d'évaluation

- Aquaculture Scoop May IssueDocument20 pagesAquaculture Scoop May IssueAquaculture ScoopPas encore d'évaluation

- Automatic Train OperationDocument6 pagesAutomatic Train OperationAnupam KhandelwalPas encore d'évaluation

- Manuscript FsDocument76 pagesManuscript FsRalph HumpaPas encore d'évaluation

- Pitot/Static Systems: Flight InstrumentsDocument11 pagesPitot/Static Systems: Flight InstrumentsRoel MendozaPas encore d'évaluation

- Minimalist KWL Graphic OrganizerDocument2 pagesMinimalist KWL Graphic OrganizerIrish Nicole AlanoPas encore d'évaluation

- Danika Cristoal 18aDocument4 pagesDanika Cristoal 18aapi-462148990Pas encore d'évaluation

- Hypothesis Testing - IDocument36 pagesHypothesis Testing - Isai revanthPas encore d'évaluation

- Principles Involved in Baking 1Document97 pagesPrinciples Involved in Baking 1Milky BoyPas encore d'évaluation

- 2nd APJ Abdul Kalam Essay Writing CompetitionDocument2 pages2nd APJ Abdul Kalam Essay Writing CompetitionANURAG SINGHPas encore d'évaluation

- Us Navy To Evaluate Anti Submarine Warfare Training SystemDocument2 pagesUs Navy To Evaluate Anti Submarine Warfare Training SystemVictor PileggiPas encore d'évaluation

- Skincare Routine Order Cheat SheetDocument10 pagesSkincare Routine Order Cheat SheetYel Salenga100% (3)

- Reading Part 2Document14 pagesReading Part 2drama channelPas encore d'évaluation

- Colour FastnessDocument37 pagesColour FastnessSivakumar K100% (1)

- Kelas ChondrichtyesDocument15 pagesKelas ChondrichtyesanitagustinawatiPas encore d'évaluation

- Multi Organ Dysfunction SyndromeDocument40 pagesMulti Organ Dysfunction SyndromeDr. Jayesh PatidarPas encore d'évaluation

- Data SiEMEx School SafetyPreparedness 25 26 NOVDocument81 pagesData SiEMEx School SafetyPreparedness 25 26 NOVSuraj RajuPas encore d'évaluation

- Raneem AlbazazDocument33 pagesRaneem AlbazazGordana PuzovicPas encore d'évaluation

- Notes Transfer of Thermal EnergyDocument12 pagesNotes Transfer of Thermal Energymahrosh mamoon100% (2)

- Harmonic Analysis of Separately Excited DC Motor Drives Fed by Single Phase Controlled Rectifier and PWM RectifierDocument112 pagesHarmonic Analysis of Separately Excited DC Motor Drives Fed by Single Phase Controlled Rectifier and PWM RectifierGautam Umapathy0% (1)

- Las Tech Drafting 3Q WKDocument13 pagesLas Tech Drafting 3Q WKClemenda TuscanoPas encore d'évaluation

- BIO 201 Chapter 11 LectureDocument34 pagesBIO 201 Chapter 11 LectureDrPearcyPas encore d'évaluation

- End of Summer Course Test August 2021Document16 pagesEnd of Summer Course Test August 2021Thanh Nguyen vanPas encore d'évaluation

- Exam 3 DynamicsDocument7 pagesExam 3 DynamicsJulioPas encore d'évaluation

- Sample Appellant BriefDocument6 pagesSample Appellant BriefKaye Pascual89% (9)

- SOPDocument16 pagesSOPjerome marquezPas encore d'évaluation

- The Working of KarmaDocument74 pagesThe Working of KarmaSuhas KulhalliPas encore d'évaluation

- Ruhangawebare Kalemera Godfrey Thesis PDFDocument116 pagesRuhangawebare Kalemera Godfrey Thesis PDFYoobsan Tamiru TTolaaPas encore d'évaluation

- Designing and Building A Computer TableDocument9 pagesDesigning and Building A Computer Tablemaster_codersPas encore d'évaluation