Académique Documents

Professionnel Documents

Culture Documents

Supply Chain Management

Transféré par

Saurav GangulyDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Supply Chain Management

Transféré par

Saurav GangulyDroits d'auteur :

Formats disponibles

Supply Chain Management

Since many decades, Supply chain management has proven to be a major component of organizational competitive strategy to enhance the productivity and profitability, but not until recently the need of a robust and comprehensive supply chain performance management system has been recognized. Supply chain management is a very critical success factor for any organization today because it affects the strategic and tactical decisions and also the operations planning and control. The Supply chain Performance measurement and metrics play an important role in setting objectives, evaluating performance, benchmarking and baselining the processes and determining the future courses of action for the supply chain and in turn the organization. Hence their importance in the overall organizational cycle cant be undermined. It is said that You cannot improve what you cannot measure. Measuring the performance of underlying activities and components is the first step in the decision making process. Hence, a proper performance measurement system needs to be in place so that organizational goals and achievement of those goals can be measured, thus allowing the effectiveness of the strategy and techniques employed to be assessed. Earlier, when the organizational philosophy used to be Supply creates its own demand, the focus of the organization understandably was on mass production. Even the performance measurement also used to be focused on mainly cost and profitability parameters. But as the supply chain theory evolved, people started talking about end consumer needs, customer satisfaction, process integration to create better responsiveness etc., the need for other comprehensive measures arose. Organizations started realizing the importance of both financial and non-financial measures in balanced manner. Then came, the balanced scorecard theory proposed by Kaplan and Norton (1992) which emphasized the need of performance measurement along four broad areas i.e. the financial perspective, the Customer perspective, the internal business process perspective and the learning and growth perspective. It holds true for the supply chain performance measurement as well, where the focus was earlier on only operational efficiency and effectiveness, but today the perspective of other stakeholders like customers are equally important to be included. In this report, we will explore the various options and will define a comprehensive framework for the performance of a supply chain.

Performance Measurement and Metrics in Supply Chain Management

To design a comprehensive measurement system, the metrics that are used in performance measurement must truly capture the essence of the supply chain performance. The measurement system should facilitate the assignment of metrics to where they would be most appropriate. For effective performance measurement and continuous improvement, measurement goals must be in synergy with the overall organisational goals and metrics selected should not be unidimensional but should reflect a reasonable balance between financial and non-financial measures that can be related to strategic, tactical and operational levels of decision making and control. In general, the metrics must be able to:

Define the current state of organization/supply chain from the perspectives of all the stakeholders Provide feedback to facilitate continuous improvement Facilitate the performance trend analysis by tracking the metrics Allow the organization to fix accountability and devise a incentive system based on the real data and not subjective judgements and conjectures. Allow baselining and benchmarking and also scalability

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- DR Raja R Choudhury: Emotion ManagementDocument25 pagesDR Raja R Choudhury: Emotion Managementambuj joshiPas encore d'évaluation

- I.I The Background of The StudyDocument7 pagesI.I The Background of The StudytanbaroPas encore d'évaluation

- Pune Introduction To CommunicationresearchDocument25 pagesPune Introduction To CommunicationresearchTrending MakPas encore d'évaluation

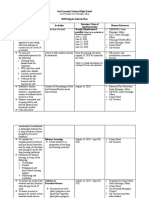

- Interim Guidelines For Assessment and GradingDocument47 pagesInterim Guidelines For Assessment and GradingRodel Camposo100% (1)

- MIT Project Media LabDocument92 pagesMIT Project Media LabDarul QuthniPas encore d'évaluation

- Teacher ResumeDocument2 pagesTeacher ResumeRoss GeraldPas encore d'évaluation

- Middle Childhood Fact SheetDocument2 pagesMiddle Childhood Fact Sheetapi-252472215Pas encore d'évaluation

- Math MnemonicsDocument21 pagesMath Mnemonicsapi-290300066100% (1)

- Collective S1 2019-2020Document6 pagesCollective S1 2019-2020Karim El HadPas encore d'évaluation

- Citation in English For Academic and Professional PurposesDocument39 pagesCitation in English For Academic and Professional PurposesJade JirehDelight Pile Panolino0% (1)

- The SAMR Model: Background and Exemplars: Ruben R. Puentedura, PH.DDocument69 pagesThe SAMR Model: Background and Exemplars: Ruben R. Puentedura, PH.DJess DjbPas encore d'évaluation

- Organisational CultureDocument10 pagesOrganisational CultureRAKESH SHARMA100% (1)

- 2400-Article Text-8965-1-10-20200131Document14 pages2400-Article Text-8965-1-10-20200131Daffa AfrialPas encore d'évaluation

- 2020 Brigada Eskwela PlanDocument3 pages2020 Brigada Eskwela PlanEdmar De Guzman Jane92% (12)

- Exam 2nd Year of Secondary School.Document2 pagesExam 2nd Year of Secondary School.Maria BlancoPas encore d'évaluation

- 1 AassignmentDocument3 pages1 Aassignmentapi-563854597Pas encore d'évaluation

- Day 5 - Creating Awareness Lesson PlanDocument3 pagesDay 5 - Creating Awareness Lesson Planapi-208906039Pas encore d'évaluation

- Bovee bct13 Inppt 14Document33 pagesBovee bct13 Inppt 14mzPas encore d'évaluation

- Unpacking The Self LESSON 1: The Physical SelfDocument2 pagesUnpacking The Self LESSON 1: The Physical SelfWALLANG, Nicol B.Pas encore d'évaluation

- HOMEROOM DLLweek-1-2Document3 pagesHOMEROOM DLLweek-1-2Gerald Rosario FerrerPas encore d'évaluation

- Using Vernier Calipers - Experimental Skill and InvestigationDocument6 pagesUsing Vernier Calipers - Experimental Skill and InvestigationsmartamjadPas encore d'évaluation

- Chapter 5 - Cognitive EngineeringDocument39 pagesChapter 5 - Cognitive EngineeringBaraa AbeadPas encore d'évaluation

- Fashion Design: London College of Contemporary ArtsDocument2 pagesFashion Design: London College of Contemporary ArtsNely GrigelovaPas encore d'évaluation

- Prep - DR - DeteraDocument2 pagesPrep - DR - DeteraJohn PaulPas encore d'évaluation

- G. V. Chulanova: Ministry of Education and Science of Ukraine Sumy State UniversityDocument75 pagesG. V. Chulanova: Ministry of Education and Science of Ukraine Sumy State UniversityNastiaPas encore d'évaluation

- Motivational Diagnostic TestDocument2 pagesMotivational Diagnostic TestJam PecasalesPas encore d'évaluation

- Unit 3 Vocabulary and Grammar RevisionDocument4 pagesUnit 3 Vocabulary and Grammar RevisionVane YestePas encore d'évaluation

- E-Waste Chapter 3Document23 pagesE-Waste Chapter 3Privilege T MurambadoroPas encore d'évaluation

- IE 31: Industrial Organization and Management Lecture 1: Introduction To Organizations and ManagementDocument33 pagesIE 31: Industrial Organization and Management Lecture 1: Introduction To Organizations and Managementhannah30Pas encore d'évaluation

- Focus4 2E Workbook Answers PDF CognitionDocument1 pageFocus4 2E Workbook Answers PDF CognitionАртур ШаблоPas encore d'évaluation