Académique Documents

Professionnel Documents

Culture Documents

Green Process Chemistry in The Pharmaceutical

Transféré par

ZohraDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Green Process Chemistry in The Pharmaceutical

Transféré par

ZohraDroits d'auteur :

Formats disponibles

This article was downloaded by: [Universite Laval] On: 15 October 2012, At: 15:23 Publisher: Taylor &

Francis Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House, 37-41 Mortimer Street, London W1T 3JH, UK

Green Chemistry Letters and Reviews

Publication details, including instructions for authors and subscription information: http://www.tandfonline.com/loi/tgcl20

Green process chemistry in the pharmaceutical industry

Berkeley W. Cue & Ji Zhang

a b a b

BWC Pharma Consulting, LLC, Ledyard, CT, USA

Research API, Pfizer Global Research & Development, Ann Arbor Laboratories, Pfizer, Inc., 2800 Plymouth Road, Ann Arbor, MI, 48105, USA Version of record first published: 10 Nov 2009.

To cite this article: Berkeley W. Cue & Ji Zhang (2009): Green process chemistry in the pharmaceutical industry, Green Chemistry Letters and Reviews, 2:4, 193-211 To link to this article: http://dx.doi.org/10.1080/17518250903258150

PLEASE SCROLL DOWN FOR ARTICLE For full terms and conditions of use, see: http://www.tandfonline.com/page/terms-and-conditions esp. Part II. Intellectual property and access and license types, 11. (c) Open Access Content The use of Taylor & Francis Open articles and Taylor & Francis Open Select articles for commercial purposes is strictly prohibited. The publisher does not give any warranty express or implied or make any representation that the contents will be complete or accurate or up to date. The accuracy of any instructions, formulae, and drug doses should be independently verified with primary sources. The publisher shall not be liable for any loss, actions, claims, proceedings, demand, or costs or damages whatsoever or howsoever caused arising directly or indirectly in connection with or arising out of the use of this material.

Green Chemistry Letters and Reviews Vol. 2, No. 4, December 2009, 193211

INDUSTRY REVIEW Green process chemistry in the pharmaceutical industry

Berkeley W. Cuea* and Ji Zhangb

a

BWC Pharma Consulting, LLC, Ledyard, CT, USA; bResearch API, Pzer Global Research & Development, Ann Arbor Laboratories, Pzer, Inc., 2800 Plymouth Road, Ann Arbor, MI 48105, USA (Received 7 April 2009; final version received 13 August 2009)

Key factors for deriving environmentally sustainable processes in the synthesis of pharmaceutical intermediates and products are discussed. The selection and use of solvents is emphasized as regards methods to minimize environmental impact. Case studies of successful process development to attain improved green processes are included.

Downloaded by [Universite Laval] at 15:23 15 October 2012

Keywords: green chemistry; pharmaceuticals; solvent utilization strategies

Introduction

Green Chemistry: hurt not the earth, neither the sea, nor the trees. Ronald C.D. Breslow (1)

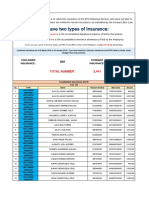

The development of new pharmaceutical products by organic synthesis over the past century has contributed to a revolution in medical care, enabling dramatic reductions in hospitalization, suffering, and death. However, this achievement is flawed if the environment is adversely impacted. With the increasing emphasis on green chemistry (2,3) recently, pharmaceutical process chemists have concentrated their focus and creative energies toward minimizing the environmental impact of their craft. This review will present a selective overview of useful means to achieve this goal, and discuss case studies of the successful modification of processes to achieve reduced resource requirements, waste generation or energy consumption. The manufacture of chemicals has the potential to generate significant amounts of waste by-products and pollutants, such as contaminated solvents, depleted reagents, and air pollutants. Pharmaceutical manufacture can be a significant contributor of these factors. For a comparison of the efficiency of the sectors of chemical manufacture, Table 1 reveals that the manufacture of drugs generates more waste and by-products in comparison to all others (4). This must be taken in context, since the medical and regulatory requirements of pharmaceutical purity will naturally lead to more waste per kilogram product as compared to making less sophisticated compounds of

*Corresponding author. Email: ctcuefamily@aol.com

ISSN 1751-8253 print/ISSN 1751-7192 online # 2009 Taylor & Francis DOI: 10.1080/17518250903258150 http://www.informaworld.com

less stringent purity, however, it does underline the challenge and opportunity for improvement presented to the pharmaceutical industry. The problem is further elaborated by a report from GlaxoSmithKline (GSK) (5,6). A life cycle study of waste produced from their Active Pharmaceutical Ingredient (API) manufacturing facilities estimated that 80% of their waste is solvent-related. Assuming other pharmaceutical companies produce a similar percentage of solvent waste, this suggests that addressing the selection, use, recovery, and disposal of solvents will contribute dramatically to alleviating this problem. While not the only means for greening pharmaceutical manufacture, solvent considerations will appear frequently in the case histories of drug process development in this review. Solvents in pharmaceutical process development and greenness factors (7,8) The selection of solvents for the synthesis of pharmaceuticals is critical on a number of levels (9). Beyond the obvious function of solvents to allow compounds to react efficiently in solution, they may further influence the particle size of the API and impact manufacturing costs by leading to difficult isolations or requiring milling. Solvents often influence the crystal form of the API, which directly determines dissolution rates, formulation, and bioavailability. The utilization of solvents also brings the disadvantage of solvent incorporation into the API. If they cannot be removed, the amount must be controlled or limited to levels that are safe to the patient. While the

194

B.W. Cue and J. Zhang

Table 2. Class II solvents and their limits in pharmaceutical products. Solvent Acetonitrile Chlorobenzene Chloroform Cyclohexane 1,2-Dichloroethene Dichloromethane 1,2-Dimethoxyethane N,N-Dimethylacetamide N,N-Dimethylforamide 1,4-Dioxane 2-Ethoxyethanol Ethyleneglycol Formamide Hexane Methanol 2-Methoxyethanol Methylbutyl ketone Methylcyclohexane N-Methylpyrrolidone Nitromethane Pyridine Sulfolane Tetralin Toluene 1,1,2-Trichloroethene Xylene PDE (mg/day) 4.1 3.6 0.6 38.8 18.7 6.0 1.0 10.9 8.8 3.8 1.6 6.2 2.2 2.9 30.0 0.5 0.5 11.8 48.4 0.5 2.0 1.6 1.0 8.9 0.8 21.7 Concentration limit (ppm) 410 360 60 3880 1870 600 100 1090 880 380 160 620 220 290 3000 50 50 1180 4840 50 200 160 100 890 80 2170

Table 1. Comparison of chemical industry sectors by quantity of byproduct per kilogram of product (3). Industry sector Oil refining Bulk chemicals Fine chemicals Pharmaceuticals Product tonnage 106108 104106 102104 10103 kg byproducts/kg product 0.1 B15 550 25100

presence of solvents in drugs is not usually considered an environmental impact, they may be considered a form of pollution for the purposes of this review as they affect us directly as does other pollution. As a means of evaluating this danger to our health, solvents require categorization. The Center for Drug Evaluation and Research (CDER) of the USA Food and Drug Administration (FDA) lists four classes of solvents organized by patient safety and environmental considerations (10). Class I solvents (i.e. benzene, carbon tetrachloride, 1,2-dichloroethane, 1,1-dichloroethylene, and 1,1,1-trichloroethane) are highly undesired based on their unacceptable toxicity or deleterious environmental impact. Class II solvents are most commonly organic solvents, such as acetonitrile, methanol, methylene chloride, tetrahydrofuran, toluene, and hexane (see Table 2). Class III solvents (i.e. acetic acid, acetone, ethanol, ethyl acetate, heptane, and dimethyl sulfoxide) have the lowest toxic potential. The lack of proven human toxicity is the main criterion for being listed as a class three solvent and the potential for demotion to class II or I is always possible. Class IV solvents (i.e. isooctane, isopropyl ether, petroleum ether, and 2-methyltetrahydrofuran) have insufficient toxicological data. Whether any of these solvents are entirely environmentally benign is debatable, which is another reason for carefully assessing the use of these solvents in pharmaceutical manufacture. Since it is clear that solvents can rarely be avoided for efficient pharmaceutical manufacture, the initial question becomes how to select as green a solvent as possible. Certain solvents may be excluded that pose potential harm to patients, operators, and the environment. Such rarely used solvents along with potential substitutes are listed in Table 3 (9). Tools are available for designing green syntheses. For instance, the Environmental Protection Agency (EPA) offers several useful websites (11). The Green Chemistry Expert System (GCES) offers guidelines and support information for devising a greenchemistry process (12). This tool includes a green

Downloaded by [Universite Laval] at 15:23 15 October 2012

From FDA website: http://www.fda.gov/cder/guidance/Q3CT& Lrev1.htm; PDE, permitted daily exposure.

solvents/reaction conditions module, which contains information on green solvent alternatives to traditional choices. Table 4 lists a variety of solvents that are generally recognized as green selection and provides a means for choosing environmentally friendly solvents for manufacture. There are two monographs that provide another source of information, one is Practical Process Research & Development and the other is Waste Minimization in Pharmaceutical Process Development: Principles, Practice, and Challenges (13,14). These are excellent sources for consideration of solvents for designing a green process. In this overview article we will summarize some of the success stories of using green chemistry principles to guide process design and the use of green solvents in the pharmaceutical industry (1519). The selection of green solvents and the improved approaches displayed in these examples were chosen based upon performance criteria, such as optimal yield, chemical reactivity and selectivity, and separation.

Green Chemistry Letters and Reviews

Table 3. Solvents with limited use in pharmaceutical scale-up (9). Solvent Ethyl ether Chloroform, dichloromethane Benzene Isopropyl ether CCl4, ClCH2CH2Cl HMPA Ethylene Glycol Hexane Neurological toxicity Pentane Dioxane Unfavorable issues Flammable Toxicity and environmental Toxicity Peroxide formation Mutagenicity and environmental impact Toxicity Toxicity Electrostatic discharge Heptane Flammable Teratogen Possible alternative solvent(s)

195

MTBE PhCH3/CH3CN, n-butanol or trifluorotoluene Toluene MTBE N-methylpyrrolidine 1,2-propanediol

Heptane Tetrahydrofuran (THF) or 2-Me-THF

Case studies of green processes in pharmaceutical development

Downloaded by [Universite Laval] at 15:23 15 October 2012

Sildenafil citrate (20 23) The story of the phosphodiesterase (V) inhibitor sildenafil citrate (Viagra ), the first effective oral treatment for erectile dysfunction, is well known even outside of chemical circles. In addition to alleviating distress for an underserved cohort, it has been an important component of Pfizers revenues since 1998. Behind its success is a good example of the adaptation of green chemistry in the design of the commercial manufacturing process. The first viable route developed at Pfizers UK laboratories was a linear 11 step synthesis, which gave a 4.2% overall yield from 2-pentanone (Scheme 1). While compelling and attractive chemistry, it was not suitable for large scale manufacturing due to low yield and the use of noxious compounds. As regards route selection, particularly unfortunate was the placement of a highly crystalline, easily purified intermediate in the middle of the synthesis rather than near the end.

Table 4. Most useful green solvents used in the pharmaceutical industry. Acetic acid Water Ethanol 1-Butanol 2-Butanol Acetone Butyl acetate Propyl acetate Isobutyl acetate Isopropyl acetate Methyl acetate t-Butanol Tetrahydrofuran (or 2-Me-THF) Ethyl acetate

This would require that toxic chlorosulfonic acid would appear subsequent to the point where the chemist would like to purge most impurities. In addition, this chlorosulfonation required excess chlorosulfonic acid as it functioned as both reagent and solvent, guaranteeing that substantial hazardous waste would result. While a convergent strategy is not necessarily a better or shorter synthesis, it often does improve a manufacturing process by permitting the simultaneous preparation of the components of an advanced intermediate. Advanced intermediates may thus be stockpiled and impurities tend to purge easier since when the convergence occurs, non-reacting impurities in the intermediates become dissimilar to the new intermediate. For sildenafil citrate, the redesigned chemistry became beneficial in that it increased the overall yield significantly, (average yield of last three steps 097% yield). The process redesign placed the cyclization as the last step and utilized the relatively benign reagents t-butanol and its potassium base, while the chlorosulfonation was moved earlier into the synthesis (Scheme 2). This permitted the inherent purification of the workups in the steps subsequent to the sulfonation to remove the toxic residues. The final step could now also be run in high concentration, further minimizing solvent waste. While the improved yields naturally reduced the waste, green solvents, such as water, t-butanol, and ethyl acetate had also been introduced in place of ether and chlorinated solvents. Process development established that ethyl acetate could be used over three consecutive steps (hydrogenation, acid activation, and acylation), which simplified the process and removed the need to completely exchange solvents between all steps, a major energy saving and waste elimination. Pfizer has continued to optimize the sildenafil citrate process since commercial launch. Remarkably, this research has further lowered the ratio of solvent

196

B.W. Cue and J. Zhang

O EtO O Four steps H 2N O2N Me N N 2 Pr 3 Clean cyclization reaction Toxic reagent O2S N N Me HN N Pr Me N N

Scheme 1. First preparative route to sildenal citrate.

waste/kg product over 17 years from 1300 L/kg to only 7 L/kg by minimizing solvent use, increasing solvent recovery, improving solvent selection, and telescoping steps. Only the solvents t-butanol, ethyl acetate, 2-butanone, and a trace of toluene still require disposal.

Sertraline Sertraline (Zoloft ) is an anti-depressant agent launched by Pfizer in 1991 (2426). The original synthesis utilized a Stobbe reaction to couple benzophenone with diethylsuccinate to yield a mono acid (Scheme 3). Hydrolysis and decarboxylation under strongly acidic conditions produced the butenoic acid, which was hydrogenated over a palladium catalyst to the desired 4,4-diarylbutanoic acid 10. Subsequent FriedelCrafts acylation and cyclization yielded the key racemic tetralone intermediate 11. Condensation with methylamine in the presence of titanium tetrachloride followed by catalytic reduction of the imine gave a mixture of cis and trans amines 12. The cis form was purified as its HCl salt by fractional crystallization and was subsequently resolved with D()mandelic acid to produce the desired (')-(1S, 4S)sertraline 13. There are several potential areas for improvement in this synthesis (Scheme 4). Firstly, it required four steps to establish the skeleton of the racemic tetralone, certainly a shorter route existed for this relatively simple compound. Secondly, the Friedel

O H2 N O2 N 4 Me N N Pr EtOAc 96% EtO CO2H CDI EtOAc N Me O2S N N Me 6 H2 Pd/C EtOAc

Crafts acylation required excess AlCl3 and was carried out in the hazardous solvent carbon disulfide. Finally, classic resolution using a chiral salt was required in the final step, requiring significant resources for carrying along the unwanted stereoisomer throughout the entire synthetic sequence. Obviously, this was not a green process since half of the final product was the unused diastereomer and was not recycled. The process chemistry team cleverly determined that the formation of the imine could be pushed to !95% completion by substituting the solvent from tetrahydrofuran (THF) to ethanol. The imine possessed low solubility in alcohols and as a result the equilibrium of the condensation was shifted toward the imine as it precipitated. Ethanol also permitted a telescope into the next step. As TiCl4, was no longer needed for the imine formation, the new process alleviated the difficult separation of the titanium waste and the expensive disposal problem. Optimization of the imine reduction established that the catalyst Pd/CaCO3 produced better regioselectivity than the existing catalyst system Pd/C. The ratio of cis (desired)/trans (undesired) isomers had been 6:1, while the revised processed raised the ratio to 17:1 and as a result raised the yield from 78 to 92%. The first commercial process employed in 1986 had used five solvents, including the neurotoxin hexane. Efficient process research has reduced this number to only ethanol and ethyl acetate. Overall organic solvent

Downloaded by [Universite Laval] at 15:23 15 October 2012

O Pr EtO O N H H2N N N Me O EtO HN (1) KOtBu, tBuOH, 95% (2) Citric acid, 100% O2S N N 3 N

Me N N Pr Citrate salt Me

O2S 5

Scheme 2. Convergent commercial preparation of sildenal citrate.

Green Chemistry Letters and Reviews

CO2H CO2Et CO2Et CO2Et t-BuO, t-BuOH Cl

197

O + Cl Cl

8

CO2H O

Cl

1. HBr, HOAc 2. H2, 5% Pd/C, EtOAc Cl Cl

1. SOCl2, toluene 2. AlCl3, CS2 Cl Cl

10

1. MeNH2, TiCl4 2. H2, 10% Pd/C MeHN MeHN 1. Fractional crystallization Cl Cl 2. Resolve with D-()-mandelic acid 3. HCl

11

Downloaded by [Universite Laval] at 15:23 15 October 2012

Cl

12

13

Cl

Scheme 3. Early process synthesis of sertraline.

usage has been decreased from 979 L/kg in the first commercial process to 256 L/kg in the current process, due to both process optimization and solvent recycling. Obviously, the resolution of racemic sertraline is still not efficient if the undesired enantiomer is not recycled. Preferable would be a means to exclusively produce the required diastereomer, allowing removal

NMe Pd/C , H2 TiCl4/MeNH2 toluene/hexanes THF + TiO2 THF + MeNH3Cl Cl

of the resolution step. It was possible to resolve the tetralone 11 using a simulated moving bed (SMB) chromatography (25), followed by racemization of the unwanted enantiomer since the racemic tetralone 11 was prepared in one step from an aluminum trichloride mediated reaction of 1-naphthol and ortho diclorobenzene in high yield (26). The racemate was sent back into the separation process with previously

NHMe

Cl

14

O

Cl "Imine" isolated

12 Cl

Racemic mixture cis and trans isomers isolated

(D)-mandelic acid, EtOH NHMe EtOAc HCl

NHMe HCl

"tetralone" Cl Cl Cl

13

NMe Pd/CaCO3 , H2 + H2O EtOH 1) (D)-mandelic acid, EtOH 2) MeOH recryst. Cl NHMe

Cl

14 Cl

Sertraline isolated (final product)

11 Cl

MeNH2 EtOH

Sertraline mandelate isolated

Cl

14

Cl "Imine"

12 Cl

Racemic mixture not isolated

not isolated

Scheme 4. Comparison of routes between the old and new commercial synthesis of sertraline HCl.

198

B.W. Cue and J. Zhang

OMe O O OEt + O O OMe NO2 t-BuONa O EtO2C O NO2 OMe O (1) Ra-Ni/H2 (2) NaBH(OAC)3 EtO2C N H O

D-tartaric

15

16

OMe acid HO2C

rac-17

O O N * 1/2 D-tartaric acid H

20% (40% of theory)

rac-18

19

Scheme 5. Resolution route to the pyrrolidine core of ABT-546.

Downloaded by [Universite Laval] at 15:23 15 October 2012

unchromatographed material, essentially effecting a total conversion of the racemic tetralone into the desired enantiomer if run as a reiterative process. Of course, this required significant solvent consumption, but if the solvent is recycled, a greener process still results due to the more efficient use of starting materials. ABT-546 Developing a selective and efficient catalytic process is usually the best solution when asymmetry arises from prochiral starting materials. The process for the synthesis of the endothelin-A antagonist ABT-546 provides an excellent example (2729). Although a synthetic route was developed to prepare the racemic pyrrolidine core of ABT-546 (Scheme 5), it required subsequent resolution with D-tartaric acid. Yet, this process still required several recrystallizations and the resolved tartrate salt was obtained in only 40% of theory. This motivated a search for an asymmetric synthesis of the pyrrolidine core in order to provide enough material to support upcoming clinical trials. After systematic screening and analysis, a catalytic, highly enantioselective conjugate-addition process was developed in which the b-ketoester anion 15 was added to nitroolefin 16 via catalysis with 4 mole% bis(oxazoline)Mg(OTf)2 amine complex (Scheme 6). The ability to attain 88% selectivity in this addition

allowed less reliance on the tartrate salt for upgrading the chiral purity. There is a particular advantage to choosing green solvents in the final steps of a drug preparation as any residues remaining in the API produce less concern. The synthesis of ABT-546 was crafted to use water as a co-solvent for the last three steps (Scheme 7). The tartrate salt was broken with K2CO3 in THF/water, the free base residing in the THF layer. Next, bromoacetamide was added to the THF solution of free base, along with aqueous NaHCO3, and the reaction was heated until alkylation was complete. After separation, the product in the THF layer was diluted with ethanol. Finally, aqueous NaOH was used for saponification. The three step/one pot sequence provided the free base of ABT-546 in excellent yield (96%) without the need for solvent removal and extraction. LY300164 LY300164 is a potential therapeutic agent for the treatment of neurodegenerative disorders such as Alzheimers and Huntingtons disease. Lillys LY300164 process makes use of environmentally benign protocols, such as air oxidation and a biocatalytic reduction (30,31). The original synthesis consisted of a linear approach of eight steps and provided a 22% overall

O N N 20 Chiral ligand Mg(OTf)2 NMM CHCl3 mol sieves 82% yield 88% selectivity OMe O EtO2C O NO2 21 O O

O OEt +

O O OMe 16

NO2

15

Scheme 6. New approach to synthesis of the core of ABT-546.

Green Chemistry Letters and Reviews

OMe O EtO2C N H 22 Step1 O K2CO3 THF/H2O EtO2C N H OMe O Br O Step 2 CONBu2 NaHCO3 THF/H2O 18

199

* 1/2 (D)-tartaric acid OMe O EtO2C N CONBu2 23 O Step 3 NaOH THF/H2O/EtOH 96% (three steps) HO2C N CONBu2 24 ABT-546 O O

OMe

Scheme 7. Final three step in the synthesis of ABT-546.

Downloaded by [Universite Laval] at 15:23 15 October 2012

yield (Scheme 8). Several environmental disadvantages of this approach were the use of chromium trioxide (the only acceptable oxidant for making the diketone at that time), perchloric acid, borane, and hydrazine. The use of hydrazine at the last step where API contamination of genotoxic impurity (GTI) would become a major concern was particularly unfortunate. The need to dispose of 3 kg of chromium waste per kilogram of product and the heavy metal contamination of reaction vessels were powerful inducements to avoid this metal oxidation. This led to a redesign of the

synthetic route which also permitted the incorporation of several other green improvements (Scheme 9). The new route was made possible by introducing the required chirality at the beginning of the sequence by preparing the chiral alcohol 26 enzymatically instead of by the late-stage borane imine reduction. A biocatalytic reduction using resin-bound Zygosaccharomyces rouxill in water efficiently provided the chiral alcohol 26 in a remarkable 100% conversion, !99.9% ee and 96% isolated yield. This enzyme has a good process record as it has been used in the food industry for centuries. Additionally, this enzyme

O O 25 O

CH3

NaBH4 Step 1 80 %

O O 26

CH3 OH

p-NO2PhCHO HCl/benzene Step 2 92 %

O O 27 O

CH3

CrO3 / H2SO4 Step 3 46%

NO2 O O O O CH3 HClO4 Step 4 95 % O O CH3 O + [ClO4- ] 29 NO2 N2H4 Step 5 90 % O O N CH3 N 1 eq

NH2 Ph OH Ph

BH3 S(CH3)2 7 days Step 6 57% (97% ee)

28 O2N

30 O2N

O O N

CH3 Ac2O NH Step 7 95 %

O O N

CH3 RaNi, N2H4 NAc Step 8 75 %

O O N

CH3 NAc

33 O2N 31 O2N 32 LY300164 H2N 12% overall yield

Scheme 8. The initial scalable synthesis of LY300164.

200

B.W. Cue and J. Zhang

Z. rouxii AD-7 resin Step 1 96% H O O 26 p-NO2PhCHO CH3 HCl / toluene Step 2 87% O O 34 O CH3

O O 25 O

CH3

OH

NO2 NaOH, O2/N2 DMSO, DMF Step 3 O O O OH 35 NO2 H CH3 O CH3 OMs N HN CH3 O2N 37 O2N 32 H2N NaOH, EtOH O Step 6 93% O O N N O CH3 Pd/C, HCO2K EtOH, H2O Step 7 91% 33 LY300164 55% overall yield >99.9% ee O O N N H CH3 O CH3 O2N 36 CH3 H2NNHAc Toluene Step 4 O O CH3 OH N HN CH3 CH3SO2Cl, Et3N CH2Cl2, 0 C O Step 5 75% - 3 steps

Downloaded by [Universite Laval] at 15:23 15 October 2012

Scheme 9. Improved process route to LY300164.

operated at a relatively high concentration (40 g ketone/L) permitting a high throughput for a biocatalytic reaction. The chiral alcohol was carried directly into the cyclization step to form the chiral cyclic ether 34. Instead of oxidizing at this point, which would have also pointlessly destroyed the hard won chirality, a new route was developed to permit an alternative to the oxonium salt route. The oxidation required at the benyzlic center was accomplished by air via a base mediated oxidation using sodium hydroxide in DMSO to establish the hemiketal 35 (Scheme 9). This step was telescoped to react with acetylhydrazine to form 36 and then treated with mesyl chloride and triethylamine, the crystalline mesylate 37 was isolated in 75% overall yield over three steps. The beauty of this design is that chromium has been replaced by air, hydrazine by the less dangerous acetylhydrazine, and there is no further need for the persistent environmental pollutant perchloric acid to form the oxonium salt. The subsequent cyclization cleanly formed the benzodiazepine 32 in 93% isolated yield. The final step to reduce the nitro group to reveal LY300164 was first conducted with hydrazine and Raney nickel. Since the suspected carcinogen hydrazine had been eliminated from an earlier step, there was strong motivation to excise it entirely

from the process. This could be done by catalytic hydrogenation in aqueous ethanol using potassium formate as a hydrogen source. LY300164 was subsequently isolated in 91% yield. The process reconsideration resulted in a much greener process by tripling the overall yield, reducing the number of steps, substituting air for a heavy metal-induced oxidation, and developing a biocatalytic reduction for establishing the chiral center. Celecoxib Celecoxib is the active ingredient in Celebrex , the widely used COX-2 anti-inflammatory agent. This molecule is relatively simple and already possessed a reasonable synthetic process by the time it reached the developmental chemists (Scheme 10) (32,33). However, the high daily dose of up to 800 mg suggested additional process work was still mandated for the large quantities of bulk drug that would be needed. The existing preparation of the pyrazole ring required recrystallizations to remove the unreacted hydrazine 40 and the regioisomers, which were generated during the cyclization. The need for this purification added significantly to the solvent and waste disposal requirements, leading the chemists to target the ring formation for optimization to reduce the ecological footprint of the process.

Green Chemistry Letters and Reviews

H N NH2 .HCl H2NO2S 40 Improved process: O 41 H2NO2S CF3 (1) Trifluoroacetic acid, IPA (2) O O- Na+

201

39 + O F3C 38 OEt

NaOMe, IPA, MeOH N N CF3 43 (1) NaOMe, THF, MeOH (2) EtOH, H2O, HCl H N NH2 O O CF3 42 43 crude .HCl H2NO2S 40 N N CF3 IPA/water recryst H2NO2S Celecoxib, Pure

Launch Process:

Downloaded by [Universite Laval] at 15:23 15 October 2012

Scheme 10. Comparison of the commercial launch and improved processes for Celecoxib.

The improvements came from a thorough understanding of the mechanistic underpinnings of the reaction. The key question concerned the formation of the 23% levels of impurity 44 (Scheme 11). The experiences with other pyrazoles during the developmental work suggested that the level of regioisomeric impurity could be much lower. The chemists discovered that the presence of water would lead to the hydrate of the diketone, which in turn influenced the formation of 44, as did the concentration of the hydrazine. Thus, the water concentration was kept low and the hydrazines effective concentration was reduced by adding it as the HCl salt instead. This salt had limited solubility in the now non-aqueous solution until the diketone sodium salt was added, which neutralized enough salt to lead to a controlled reaction. This clever self-moderating reaction reduced the production of the regioisomer to 0.5%, permitting the

SO2NH2

direct isolation of pure Celecoxib from the reaction mixture by simple water dilution and cooling. It is unusual to find a process that permits a direct isolation of the API without some additional purification. The green benefits established by the subtle, but significant changes above are numerous. Only two benign solvents (methanol and isopropanol) are now needed. The yield increased from 63 to 84%, decreasing waste production by 35% and reducing the use of the hazardous hydrazine. The reactor throughput increased 50%. The change in reaction conditions now meant that product isolation only required cooling to 208C instead of 58C. Finally, the cleaner product permitted a change in the cake wash solvent from 100% isopropanol to 50% aqueous isopropanol. This process eliminated the use of the undesirable solvents methylene chloride and hexane, and when combined with the other changes, eliminated the need for 5200 metric tons of solvent annually. Figures 1 and 2 graphically demonstrate the greening of the Celecoxib manufacture process. Quinapril Quinapril hydrochloride (Accupril ) is an angiotensin converting enzyme (ACE) inhibitor for the treatment of hypertension and congestive heart failure (34). The original manufacturing route contained a variety of undesired qualities, such as the use of

N CF3

44

Scheme 11. Impurity in the nal cyclization (42,43).

202

B.W. Cue and J. Zhang

Solvents usage in the preparation of Celecoxib IPA Ethanol Methanol THF

Kg waste/Kg Celecoxib Total waste generated in the production of Celecoxib Celecoxib NaCl TFA IPA Ethanol Methanol THF

20 18 16 14 12 10 8 6 4 2 0 Launch Process Improved

20 18 16 14 12 10 8 6 4 2 0 Launch Process Improved

Kg solvent/Kg Celecoxib

Figure 1. Solvent usage in the preparation of Celecoxib (19952002).

Figure 2. Comparison of the total waste generated in the production of Celecoxib.

Downloaded by [Universite Laval] at 15:23 15 October 2012

methylene chloride, the potentially explosive hydroxybenzotriazole, the sensitizer dicyclohexylcarbodiimide (DCC), and copious toluene volumes for removing acetic acid by solvent exchange. The key to the redesign of the quinapril process was the loss of yield due from an intramolecular cyclization that formed a diketopiperazine impurity. The rate of this side reaction of the product was greatly enhanced, when the reaction mixture was held at !558C during the three acetic acid/toluene azeotropic distillations. The redesign focused on the elimination of the use of acetic acid, which would permit minimizing diketopiperazine formation. This was accomplished by changing the starting material to the commercially available N-carboxyanhydride 45. When reacted with the isoquinolinecarboxylic acid t-butyl ester salt 46, the self-activated anhydride led to direct amide coupling, allowing the elimination of DCC, its waste product dicyclohexylurea (DCU), and the need for a chlorinated solvent. The coupling proceeded well in water and toluene (Scheme 12).

The ester was cleaved using a minimum amount of acetic acid/HCl, the salt was formed and isolation proceeded well without a lengthy solvent exchange or drying operation, but by simply adding the antisolvent acetone. A final recrystallization from acetonitrile produced the API. As a result, the overall yield increased from 58 to 90%, throughput has quadrupled, waste production has been significantly reduced, and less and greener solvents have been incorporated. Figure 3 represents these improvements graphically. Sitagliptin Hydrogenation could be the ultimate manifestation of green chemistry, when the chemical results are weighed against the environmental impact. The addition of hydrogen to unsaturated bonds can establish chirality or the formation of desired functional groups of lower-oxidation state by simple operations and high atom efficiency. Often only trace quantities of catalysts are required or if the catalyst is valuable, means

EtO2C N 45 O

CH3 O O 1. NaOH, H2O, toluene + BSA . HN 46 O O 2. cat. HOAc, toluene 47 EtO2C N H CH3 N O O O

Anh. HCl Toluene/ HOAc acetone

EtO2C N H

CH3 N O 48 CO2H O

Acetonitrile recrystallization

EtO2C HCl N H

CH3 N O 49 CO2H

HCl

Quinapril HCl

Scheme 12. New quinapril process.

Green Chemistry Letters and Reviews

Solvent amount (kg/100 kg product)

3000 2500 2000 1500 1000 500 0

203

Methylene chloride

Acetic acid Original process

Toluene New process

Acetone

Figure 3. Solvent use comparison in original process and new process.

Downloaded by [Universite Laval] at 15:23 15 October 2012

for its recovery can be designed. The scope of the reaction is broad, the reagent is cheap, and the environmental impact of the reaction is usually minimal if the solvent can be recovered in some manner (3841). The establishment of stereogenic centers via catalytic asymmetric hydrogenation is particularly valued in pharmaceutical process chemistry, since it often permits foregoing resolution or multistep alternative chemistry. The story of the process development of sitagliptin provides an example of the effective use of this technique (3537). Sitagliptin is a new treatment for type two diabetes via inhibition of the DPP-IV enzyme. Merck used a first-generation synthesis of sitagliptin to prepare about 100 kg for clinical trials, which proceeded by the asymmetric hydrogenation of a b-ketoester catalyzed by (S)-binapRuCl2triethylamine complex in 94% ee (Scheme 13). The ester was hydrolyzed to yield a b-hydroxy carboxylic acid,

followed by further transformation to a protected b-lactam and then coupled to a triazole. Subsequent deprotection then revealed the key b-amino acid moiety and the drug was isolated as its phosphoric acid salt. This had potential for evolving into a manufacturing process, however, the numerous steps correspondingly increased the amount of reagents and volume of solvents used. A better process was sought for scale up. One means for eliminating steps is to avoid the use of protecting groups, effectively removing two steps required to protect the starting material and subsequently deprotect the product. Such an idea was incorporated into the second generation synthesis of sitagliptin. The asymmetric hydrogenation of an enamine would be a more efficient means to synthesize the b-amino acid moiety, but a significant drawback was the requirement of an acyl protecting group on the nitrogen atom. This group is usually considered

F F One step F F O OH F 50 Six steps Old route F F F NHR O N N N N CF3 Pd, H2 F New route F 51 NH2 O N N N N CF3 F Chiral L with Rh MeOH H2 F NH2 O N N N N CF3

53

Sitagliptin

52

Scheme 13. Process incorporating catalytic asymmetric hydrogenation for the preparation of sitagliptin.

204

B.W. Cue and J. Zhang completely eliminated aqueous waste streams. As this second-generation synthesis will create 220 kg less waste for each kilogram of sitagliptin manufactured, Merck expects to eliminate the formation of at least 150 million kilograms of waste over the lifetime of the drug.

Downloaded by [Universite Laval] at 15:23 15 October 2012

indispensable for chelation between the reactant and the metal catalyst in order to lead to high reactivity and selectivity. Remarkably, the process chemists discovered a completely unprecedented transformation: the asymmetric catalytic hydrogenation of unprotected enamines in high optical purity and yield, in this case catalyzed by rhodium with a ferrocenyl phosphine ligand (Josiphos). In collaboration with Solvias, this process was perfected and along with several other process changes, it became the manufacturing route. Crafting a new synthetic sequence permitted the reduction step to be run at the end, which minimized the quantity of the expensive catalyst needed, allowed !95% recovery of the rhodium, and only revealed the reactive amino group of sitagliptin in the final step. The new synthesis has only three steps and increases the overall yield by nearly 50%. Implementing the new route on a manufacturing scale has reduced the amount of waste by !80% and

Saxagliptin Although chiral drugs can be prepared by asymmetric chemical transformations, the use of microbial- or enzyme-catalyzed reactions has advantages over traditional chemical processes. Several have been already described in this review. Many chemoenzymatic processes are stereoselective and can be carried out at ambient temperatures and atmospheric pressure, which typically reduces cost, hazards, and minimizes the probability of undesired side-reactions that may occur under forcing conditions. Furthermore, biocatalytic processes are generally carried out in aqueous

OH H2N O N

CN 54 Saxagliptin (BMS-477118)

HO

1. LiAlH4 2. (ClCO)2, DMSO CH2Cl2 O 55

NH2 57 NaHSO3 KCN 65%

OH

O 56

HO N H CN 12 N HCl HOAc, 80C 16h, 78%

HO N H COOH

20% Pd(OH)2 50 psi H2 MeOH/HOAc H2N 60 COOH (Boc)2O K2CO3 DMF KMnO4 2% KOH HO 51% BocHN 62 COOH BocHN 61 COOH

58

59

Scheme 14. Original preparative route for the preparation of (S)-3-hydroxyadamantylglycine.

Green Chemistry Letters and Reviews

Phenylalanine dehydrogenase O 63 Ammonium formate COOH NADH NAD OH COOH 64 CO2 BocHN 62 COOH

205

OH

OH H2N

Scheme 15. Enzymatic reaction used for preparation of (S)-3-hydroxyadamantylglycine.

solutions using less toxic chemicals, potentially minimizing the waste generation. Saxagliptin (54) is a DPP-IV inhibitor under development by Bristol-Myers Squibb (42,43). (S)-N-BOC-3-hydroxyadamantylglycine 62 is a key intermediate which was originally prepared by an asymmetric Strecker reaction, which is required highly toxic potassium cyanide (Scheme 14). By using a modified phenylalanine dehydrogenase, the BristolMyers Squibb (BMS) enzyme technology group successfully set the chiral center in 64 by an enzymatic reductive amination of keto acid 63 (Scheme 15), reducing the number of steps from five to only one by redesigning the process chemistry, eliminating the need for cyanide and the expensive chiral reagent, (R)()-2-phenylglycinol, poor oxidation using potassium permanganate in the final step, and this reductive amination used water as solvent. Enzymes also facilitated a reaction on the dihydropyrrole portion of saxagliptin. Candida antartica lipase B (CALB) mediated ammonolysis of the ester with ammonium carbamate as the ammonia donor to yield the amide (Scheme 16). The inclusion of Ascarite and calcium chloride as adsorbents for carbon dioxide and ethanol byproducts, respectively, increased the yield to 98%, furnishing high purity amide (99.9% ee) in 81% isolated yield with minimal side product formation.

Solvent categories and their utility in pharmaceutical manufacture Water as a process solvent Water is the ultimate green solvent (44). Besides its presence in many biocatalytic reactions, water may be used in a surprisingly large variety of reactions as solvent or cosolvent. Several more examples of the use of water as solvent are worth mentioning. The first synthesis of ziprasidone (Geodon ), an atypical anti-psychotic agent, was not suitable for pilot plant scale-up. Initially, the two fragments were joined by alkylation of 68 with 69 in the presence of NaI and Na2CO3 in organic solvent, to produce ziprasidone in 20% yield. When water was used as the solvent to improve the solubility of the reagents, the yield increased to 9094% (Scheme 17) (45). Danofloxacin 73 is a quinolone anti-bacterial drug for treating infections in livestock (4649). The product-forming amination step was improved by conducting it in pressurized water in order to permit a higher temperature and reaction rate (Scheme 18). It was then isolated in 91% yield and high quality by filtration at the isoelectric pH. In addition, pyridine, 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU), toluene, and alcohols, all used in an earlier process were no longer needed. An efficient one-pot synthesis of dibromopyridazinone 77, an intermediate to ABT-963 (50), has been

Downloaded by [Universite Laval] at 15:23 15 October 2012

O O

N O O

Candida antartica lipase B NH2CO2NH4 CaCl2 /Ascarite

O O

N O 66 NH2

Steps R O 67 N CN

65

Scheme 16. Saxagliptin revised process for pyrrole ring amidation.

O Cl Cl

68

N H

HCl + S N

69

NH

1. H2O/Na2CO3 heat ~20 hrs. 2. IPA 9094% S N N

70

O N H Cl Ziprasidone

Scheme 17. Water as solvent during ziprasidone coupling.

206

B.W. Cue and J. Zhang

O F F N CO2H + H3C N N 2 HBr H 72 1. KOH, 610 h 130140oC 2. NaHCO3 91% 71 73 O N HO2C N Danofloxacin N CH3 F

Scheme 18. Water as solvent under pressure to permit higher reaction temperature.

Downloaded by [Universite Laval] at 15:23 15 October 2012

developed that incorporates water as a solvent over three consecutive steps (Scheme 19) (51). This process was used to prepare 22 kg of dibromopyridazinone 77 in 82% overall yield and 96% purity without further purification. Many drug molecules and intermediates will have limited solubility in water if there are not a sufficient number of hydrophilic groups present. The use of phase-transfer catalysis (PTC) is a special case for water as a process solvent and can often ameliorate solubility problems as well as improve many reactions. PTC technology is simple, cheap, reliable, and has found many applications in industry manufacture. For instance, NaOH may be used as the ringclosing base under PTC conditions (Scheme 20) (52). Sodium hydroxide was added to the reagents and catalytic tetrabutylammonium chloride in THF/H2O at 458C, leading to the cyclized product in 96% yield. A practical pilot-scale synthesis of 4-vinyl-2, 3-dihydrobenzofuran 84 is done using PTC for dehydrohalogenation (Scheme 21) (54). The use of chiral PTC has recently become more common for the preparation of chiral, enantio-enriched compounds from prochiral substances (5559). Chiral PTC often makes use of the cinchona alkaloids because the parent alkaloids are inexpensive,

readily available in both pseudoenantiomeric forms, and can be easily quaternarized to a variety of different salts. An illustrative example is the alkylation of a phenylindanone using chiral PTC in 98% yield and 92% ee (Scheme 22) (6062). It was proposed that the chiral induction step involved an ion-pair in which the enolate anion fit on top of the catalyst, positioned by electrostatic and hydrogen-bonding effects, as well as pp stacking interactions between the aromatic rings in the catalyst and the enolate. The electrophile then preferentially approached the ion-pair from the open top (front) face. A crystal structure of the catalyst supports this interpretation. Suzuki couplings may be conducted in water as a cosolvent. A multikilogram-scale synthesis of a biphenyl carboxylic acid derivative using a Pd/ C-mediated Suzuki coupling in aqueous methanol is possible, which produces an improved yield of the desired product as well as leaves low residual Pd levels in the product (Scheme 23). Practical and efficient epoxidation of aromatic olefins may be accomplished using Oxone in ethyl acetatewater (Scheme 24). This oxidant/solvent system is the best choice for the required chemistry for environmental reasons. The reported method is suitable for large-scale synthesis (53).

O Br O Br OH

F H2N 74 F

HBr/water NaNO2 0C, 0.5 h

SnCl2 HBr/water

F HBr H2NHN 75 F

76 water 8090C

F F O Br Br 77 N N Yield: 82% > 22.0 kg O S O 78 ABT-963 F HO O O N N F

Scheme 19. Water as green solvent in the process chemistry.

Green Chemistry Letters and Reviews

Cl H2N Me Br 79 Cl 80 NaOH, TBAC cat., THF:H2O (2.5:1), 20C O Cl 81 O HN Me Br 96% 82 NaOH, THF:H2O (1:1) TBAC cat., 4045C, 1 h O N Me Br

207

Scheme 20. Water as solvent in ring-closing under PTC condition.

Solvent-free processes (63) The ultimate of green chemistry could be defined as being totally free of solvents or any other chemicals beyond those that will comprise the product. Solventfree processes may theoretically eliminate waste and be energy efficient, but for large-scale chemical manufacture it is not hazard-free. Without using solvent as heat transfer media and heat sinks in exothermic reactions, the consequences of a runaway reaction can be devastating. A greater understanding of the thermal characteristics of solvent-free reaction is essential before any increase in scale should be considered (64). But there are some instances of solventless chemistry related to pharmaceutical manufacture, if excess reagents are not considered to represent solvent. Dihydropyrimidinone derivatives hold promising biological properties and often may be prepared using modifications of the Biginelli reaction: the acid-catalyzed three-component condensation of a 1,3-dicarbonyl compound, an aldehyde, and urea (Scheme 25). Recently, a simple synthesis of dihydropyrimidinones by a solvent-free and catalyst-free Biginelli condensation has been reported at kilogram scale (65). These reaction conditions were also mild enough to tolerate a variety of sensitive functionalities. No solvents or catalyst was used and suggests solvents can be eschewed for narrowly defined structures. Solvent-free catalytic asymmetric reactions have the potential to be safe, cost saving, and environmental-friendly processes (66). In 1997, a breakthrough in the isolation of terminal epoxides with high enantioselectivity by hydrolytic kinetic resolution of epoxides was reported (Scheme 26) (67). Such resolved epoxides or diols are useful synthons in pharmaceutical chemistry. Water serves as a nucleophile in the presence of catalytic (salen)Co(OAc) to open epoxides. The reaction possesses the process advantages that the hydrolytic kinetic resolution of

O Cl 0.5 eq Bu4N+OH 0.1 eq KI 10 eq NaOH H2O, 50C, 8390% 83 84 O

Downloaded by [Universite Laval] at 15:23 15 October 2012

propylene oxide has been performed on large scale (!200 kg) and the remaining catalyst can be recycled at least three times without loss of activity or enantioselectivity (68). To control exothermicity, conducting solvent-free reactions at low temperature is a promising means to achieve a viable synthesis. The organocatalytic conjugate addition of nitroalkanes to nitroolefins using a modified cinchona alkaloid catalyst is an example (Scheme 27) (69). At 08C, this solvent-free reaction afforded the desired product in 81% ee and 83% yield. A less attractive feature was that the low temperature also reduced the reaction rate, requiring days for acceptable reaction completion. The reaction was considered safe for operation at large scale once a thermodynamic investigation (differential scanning calorimetry, DSC, and thermal gravimetric analysis, TGA) was completed, always a good idea in process chemistry. Ionic liquids There has been an increase in research of ionic liquids as solvents in recent years (70). Many of the researchers in this area promote the usefulness of ionic liquids in the synthesis of molecules important to the pharmaceutical industry in reactions, such as FriedelCrafts alkylations or acylations (71), Heck couplings (72), alkylations (73,74), and various condensations (75). It is unclear if any direct pharmaceutical applications have appeared yet. While ionic liquid advocates cite their low volatility and ability to recycle as green attributes, this is only one consideration. Until the issues of cost, safety, regulatory acceptance of ionic solvents residue in APIs, and the lack of generality are addressed, their utility remains undefined. Supercritical carbon-dioxide (76 78) Supercritical fluids are finding application in the pharmaceutical industry for solving difficult process and formulation problems. Supercritical fluids exhibit a pressure-tunable dissolving power with a liquid-like density and gas-like transport properties. They possess the attractive property of easy separation from the substrate once the chemistry is complete by simply

Scheme 21. Dehydrohalogenation under PTC conditions.

208

B.W. Cue and J. Zhang

OH N H Cl Cl + MeO 85 H CH3Cl 86 O

N+

R Cl Cl MeO 95% yield 92% ee CH3 87 O

10 mole% Chiral PTC 50% aq NaOH toluene

Scheme 22. First chiral PTC for alkylation in pharmaceutical process.

O Pd/C, Na2CO3 HO2C 89 9396% B(OH)2 90 N

O N

Me Br

Me CO2H

Scheme 23. Water as solvent for a Suzuki coupling reaction.

R2 90

Oxone R1 EtOAcH2O 20C R2

O R1 91

Scheme 24. Oxone epoxidation in two-phase system.

releasing the pressure. This unique combination of properties is ideally suited for developing processes for reacting, extracting, purifying, and recrystallizing pharmaceuticals as well as producing new forms that cannot be obtained by traditional processing technologies. By far the most exploited supercritical fluid has been liquidized carbon-dioxide. This can be a green reaction solvent, assuming the gas is captured after processing. Recently, process chemists in Boehringer Ingelheim Pharmaceuticals developed a practical method for the removal of ruthenium byproducts by supercritical-fluid extraction in the synthesis of macrocyclic compound BILN2061 (79). Supercritical carbondioxide was used to remove the Ru catalyst and its derived byproducts from a ring-closing metathesis reaction. This method was implemented in a semi-

continuous fashion and allowed for efficient removal of the toxic metal impurities to meet the specifications for the final drug substance. Besides chemistry, this solvent can be profitably used for form establishment. Some pharmaceutical compounds are difficult to micronize by conventional grinding or jet milling. For example, materials that have a low-melting point or are waxy cannot be ground or milled. Some supercritical-fluid processes have been developed to first dissolve the pharmaceutical compound and then effect precipitation by pressure decrease. Alternatively, the gas can act as an anti-solvent causing recrystallization from solution because of a solubility decrease when the gas and liquid solvent contract. Poor aqueous solubility of drug candidates presents a significant problem in drug development. Among various strategies to address solubility issues, reducing the particle size is a common option. Recently, a processing technique called rapid expansion of a supercritical solution into a liquid solvent (RESOLV) has been used to reduce the drug particle size and offers advantages in clean, non-toxic drug formulation research (80). For example, this technology has been applied to a pair of anti-inflammatory drugs: ibuprofen and naproxen. The RESOLV process produced exclusively nanoscale (less than 100 nm) ibuprofen and naproxen particles suspended in aqueous solutions. These suspensions are protected from particle agglomeration and precipitation by using common polymeric and oligomeric stabilizing agents. This technology may serve as a green process for nanosizing other drugs for formulation and

Downloaded by [Universite Laval] at 15:23 15 October 2012

O O R2 92 O R1 + R3-CHO + H2N 94 X NH2 Neat 100105C, 1 h 7885% R2 R1 95

R3 NH N H X

93

Scheme 25. Solvent-free Biginelli condensation.

Green Chemistry Letters and Reviews

(R,R)(salen)Co(OAc) (0.2 mol) + Me 1 mol 96 H2O 0.55 mol 5C25C, 12 h solvent-free Me 97 Cycle 1 44% yield 98.6% ee Cycle 2 46% yield 98.5% ee Cycle 3 48% yield 98.5% ee O + Me 98 50% yield 98% ee 50% yield 98% ee 50% yield 98% ee OH OH

209

Scheme 26. Hydrolytic kinetic resolution of propylene oxide.

NO2 NO2 10 mol% Cinchona alkaloid NO2 Cl 101 83% yield 81% ee

Downloaded by [Universite Laval] at 15:23 15 October 2012

NO2 99

+ Cl 100

0C, days solvent-free

Scheme 27. Asymmetric organocatalytic Michael addition under solvent-free conditions.

sustained-release requirements (81). Additional applications of supercritical fluids in the controlled release of drugs have appeared (82). Conclusion Many of the green chemistry principles are not new to pharmaceutical industry chemists, but represent the way good process development is done. They do represent a new area of focus to further reduce manufacturing costs, build in greater process robustness, and to diminish the environmental footprint of the industry. It is clear from the US Presidential Green Chemistry Challenge awards awarded to industry companies that there is much successful activity in redesigning pharmaceutical processes. This trend will certainly continue. Green chemistry is rapidly being adopted by process chemists and engineers, and not only because it is the right thing to do. Cost is also a factor. A Tufts University study suggests that average R&D costs for developing a drug have increased dramatically since the mid 1970s from $55 million to over $800 million in 2000 (83,84). As the industry continues to come under pressure to hold down the cost of drugs, the adoption of an environmentally benign approach to drug candidate synthesis will contribute by reducing the increasing costs of reagent procurement and waste disposal. In conclusion, we hope the representative examples illustrated in this selective review have provided incentives for further work in developing green pharmaceutical processes. Eventually, there will be

no need to emphasize green chemistry to pharmaceutical chemists as it will become the natural course of action when the ultimate good to the company, patient, and environment is considered. Acknowledgements

The authors would like to thank Dr. Leo Letendre of Pzer PGRD, Michigan Labs provided the green chemistry package of Celecoxib and Ms. Sandra Jennings of Pzer PGRD, Michigan Labs provided the green chemistry package of Quinapril. We are grateful to Drs. Mike T. Williams and Timothy T. Curran for proofreading this manuscript and provided valuable comments.

References

(1) Breslow, R. The Greening of Chemistry. Chem. & Eng. News 1996, (Aug 26), 72. (2) Anastas, P.T.; Williamson, T.C., Eds.; Green Chemistry: Frontiers in Benign Chemical Syntheses and Processes; Oxford University Press: Oxford, UK, 1998. (3) Anastas, P.; Warner, J., Eds.; Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998. (4) Sheldon, R.A. Chem. Ind. 1992, 23, 903906; Sheldon, R.A. Chem. Tech. 1994, 24, 3847. (5) Jimenez-Gonzalez, C.; Curzons, A.D.; Constable, D.J.C.; Cunningham, V.L. Int. J. LCA 2004, 9, 115 121. (6) Curzons, A.D.; Jimenez-Gonzalez, C.; Duncan, A.L.; Constable, D.J.C.; Cunningham, V.L. Int. J. LCA 2007, 12, 272280. (7) Sheldon, R.A. Green Chem. 2005, 7, 267278.

210

B.W. Cue and J. Zhang

(29) Barnes, D.M.; Ji, J.; Zhang, J.; King, S.A.; Wittenberger, S.J.; Morton, H.E. ACS Symposium Series 2002, 817 (From Bench to Pilot Plant), 4559. (30) Anderson, B.A.; Hansen, M.M.; Vicenzi, J.T.; Zmijewski, M.J. In Process Chemistry in the Pharmaceutical Industry; Gadamasetti, K.G., Ed.; Marcel Dekker: New York, 1999, pp 263282. (31) Anderson, B.A.; Hansen, M.M.; Harkness, A.R.; Henry, C.L.; Vicenzi, J.T.; Zmijewski, M.J. J. Am. Chem. Soc. 1995, 117, 1235812359. (32) Letendre, L. (Pzer). Green Chemistry in the Redesign of the Celecoxib Process: Summary for the Presidential Green Chemistry Challenge Awards Program, 2005. (33) Talley, J.J.; Penning, T.D.; Collins, P.W.; Rogier, Jr., D.J.; Malecha, J.W.; Miyashiro, J.M.; Bertenshaw, S.R.; Khanna, I.K.; Granets, M.J.; (G.D. Searle and Co., USA). WO 95/15316; Penning, T.D.; Talley, J.J.; Bertenshaw, S.R.; Carter, J.S.; Collins, P.W.; Docter, S.; Graneto, M.J.; Lee, L.F.; Malecha, J.W.; Miyashiro, J.M.; Rogers, R.S.; Rogier, D.J.; Yu, S.S.; Anderson, G.D.; Burton, E.G.; Cogburn, J.N.; Gregory, S.A.; Koboldt, C.M.; Perkins, W.E.; Seibert, K.; Veenhuizen, A.W.; Zhang, Y.Y.; Isakson, P.C. J. Med. Chem. 1997, 40, 13471365. (34) Jennings, S. (Pzer). A Green Process for the Synthesis of Quinapril Hydrochloride: Summary for the Presidential Green Chemistry Challenge Awards Program, 2005. (35) Hansen, K.B.; Balsells, J.; Dreher, S.; Hsiao, Y.; Kubryk, M.; Palucki, M.; Rivera, N.; Steinhuebel, D.; Armstrong III, J.D.; Askin, D.; Grabowski, E.J.J. Org. Proc. Res. Dev. 2005, 9, 634639. (36) Hsiao, Y.; Rivera, N.R.; Rosner, T.; Krska, S.W.; Njolito, E.; Wang, F.; Sun, Y.; Armstrong III, J.D.; Grabowski, E.J.J.; Tillyer, R.D.; Spindler, F.; Malan, C. J. Am. Chem. Soc. 2004, 126, 99189919. (37) Clausen, A.M.; Dziadul, B.; Cappuccio, K.L.; Kaba, M.; Starbuck, C.; Hsiao, Y.; Dowling, T.M. Org. Proc. Res. Dev. 2006, 10, 723726. (38) Blaser, H-U.; Studer, M. Green Chem. 2003, 5, 112 117. (39) Blaser, H-U.; Malan, C.; Pugin, B.; Spindler, F.; Steiner, H.; Studer, M. Adv. Synth. Catal. 2003, 345, 103151. (40) Noyori, R.; Hashiguchi, S. Acc. Chem. Res. 1997, 30, 97102. (41) Jessop, P.G.; Ikariya, T.; Noyori, R. Chem. Rev. 1999, 99, 475494. (42) Hanson, R.L.; Goldberg, S.L.; Brzozowski, D.B.; Tully, T.P.; Cazzulino, D.; Parker, W.L.; Lyngberg, O.K.; Vu, T.C.; Wong, M.K.; Patel, R.N. Adv. Synth. Catal. 2007, 349, 13691378. (43) Augeri, D.J.; Robl, J.A.; Betebenner, D.A.; Magnin, D.R.; Khanna, A.; Robertson, J.G.; Wang, A.; Simpkins, L.M.; Taunk, P.; Huang, Q.; Han, S-P.; Abboa-Offei, B.; Cap, M.; Xin, L.; Tao, L.; Tozzo, E.; Welzel, G.E.; Egan, D.M.; Marcinkeviciene, J.; Chang, S.Y.; Biller, S.A.; Kirby, M.S.; Parker, R.A.; Hamann, L.G. J. Med. Chem. 2005, 48, 50255037.

(8) Clark, J.H.; Tavener, S.J. Org. Pro. Res. Dev. 2007, 11, 149155. (9) Anderson, N.G. In Art of Drug Synthesis; Johnson, D.S., Li, J.J., Eds.; John Wiley & Sons: Hobooken, New Jersey, 2007; pp 1128. (10) Guidance for Drugs in USA Food and Drugs Administration. http://www.fda.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/default.htm (accessed Oct 15, 2009). (11) USA Green Chemistry Website. http://www.epa.gov/ greenchemistry (accessed Oct 15, 2009). (12) EPA Green Chemistry GCES Tool. http://www. epa.gov/greenchemistry/pubs/gces.html (accessed Oct 15, 2009). (13) Gadamasetti, K.G., Ed. Process Chemistry in the Pharmaceutical Industry; Marcel Dekker: New York, 1999, pp 317 and reference cited therein. (14) Zhang, T.Y. In Handbook of Green Chemistry and Technology; Clark, J., Macquarrie, D., Eds.; Blackwell Science: Oxford, UK, 2002; pp 306320. (15) Butters, M.; Catterick, D.; Craig, A.; Curzons, A.; Dale, D.; Gillmore, A.; Green, S.P.; Marziano, I.; Sherlock, J-P.; White, W. Chem. Rev. 2006, 106, 3002 3027. (16) Constable, D.J.C.; Dunn, P.J.; Hayler, J.D.; Humphrey, G.R.; Leazer, Jr., J.L.; Linderman, R.J.; Lorenz, K.; Manley, J.; Pearlman, B.A.; Wells, A.; Zaks, A.; Zhang, T.Y. Green Chem. 2007, 9, 411420. (17) Zhang, T.Y. Chem. Rev. 2006, 106, 25832595. (18) Anderson, N.G., Ed. Practical Process Research & Development; Academic Press: San Diego, CA, 2000; pp 81108. (19) Nelson, W.M., Ed. Green Solvents for Chemistry; Perspectives and Practice; Oxford University Press: New York, 2003. (20) Dunn, P.J.; Galvin, S.; Hettenbach, K. Green Chem. 2004, 6, 4348. (21) Dunn, P.J. In Process Chemistry in the Pharmaceutical Industry; Gadamasetti, K.G., Braish, T., Eds.; CRC Press: Boca Raton, FL, 2008; pp 267277. (22) Dale, D.J.; Draper, J.; Dunn, P.J.; Hughes, M.L.; Hussain, F.; Levett, P.C.; Ward, G.B.; Wood, A.S. Org. Proc. Res. Dev. 2002, 6, 767772. (23) Dale, D.J.; Dunn, P.J.; Golightly, C.; Hughes, M.L.; Levett, P.C.; Pearce, A.K.; Searle, P.M.; Ward, G.; Wood, A.S. Org. Proc. Res. Dev. 2000, 4, 1722. (24) Taber, G.P.; Psterer, D.M.; Colberg, J.C. Org. Proc. Res. Dev. 2004, 8, 385388 and references therein. (25) Pais, L.S.; Loureiro, J.M.; Rodrigues, A.E. Separ. Purif. Technol. 2000, 20, 6777. (26) Chem. Eng. News 2002, 80 (29), 4562. (27) Ji, J.; Barnes, D.M.; Zhang, J.; King, S.A.; Wittenberger, S.J.; Morton, H.E. J. Am. Chem. Soc. 1999, 121, 1021510216. (28) Barnes, D.M.; Ji, J.; Fickes, M.G.; Fitzgerald, M.A.; King, S.A.; Morton, H.E.; Plagge, F.A.; Preskill, M.; Wagaw, S.H.; Wittenberger, S.J.; Zhang, J. J. Am. Chem. Soc. 2002, 124, 1309713105.

Downloaded by [Universite Laval] at 15:23 15 October 2012

Green Chemistry Letters and Reviews

(44) Li, C-J. Chem. Rev. 2005, 105, 30953166; Li, C-J. In Organic Reactions in Water; Lindstroem, U.M., Ed.; Blackwell: Oxford, UK, 2007; p 92. (45) Bowles, P. (Pzer Inc., USA). Process for preparing aryl piperazinyl-heterocyclic compounds. US Patent 5206366, April 27, 1993. (46) McGuirk, P.R.; Jefson, M.R.; Mann, D.D.; Elliott, N.C.; Chang, P.; Cisek, E.P.; Cornell, C.P.; Gootz, T.D.; Haskell, S.L. J. Med. Chem. 1992, 35, 611620. (47) Howard, H.R.; Lowe III, J.A.; Seeger, T.F.; Seymour, P.A.; Zorn, S.H.; Maloney, P.R.; Ewing, F.E.; Newman, M.E.; Schmidt, A. J. Med. Chem. 1996, 39, 143148. (48) Urban, F.J.; Breitenbach, R.; Gonyaw, D. Synth. Commun. 1996, 26, 16291638. (49) Walinsky, S.W.; Fox, D.E.; Lambert, J.F.; Sinay, T.G. Org. Proc. Res. Dev. 1999, 3, 126130. (50) Kerdesky, F.A.; Leanna, M.R.; Zhang, J.; Li, W.; Lallaman, J.E.; Ji, J.; Morton, H.E. Org. Process Res. Dev. 2006, 10, 512517. (51) Zhang, J.; Morton, H.E.; Ji, J. Tetrahedron Lett. 2006, 47, 87338735. (52) Ennis, D.S.; McManus, J.; Wood-Kaczmar, W.; Richardson, J.; Smith, G.E.; Carstairs, A. Org. Proc. Res. Dev. 1999, 3, 248252. (53) Hashimoto, N.; Kanda, A. Org. Proc. Res. Dev. 2002, 6, 405406. (54) Rao, M.; Yang, M.; Kuehner, D.; Grosso, J.; Deshpande, R.P. Org. Proc. Res. Dev. 2003, 7, 547550. (55) Hashimoto, T.; Maruoka, K. Chem. Rev. 2007, 107, 56565682. (56) Ooi, T.; Maruoka, K. Angew. Chem., Int. Ed. 2007, 46, 42224266. (57) ODonnell, M.J. Acc. Chem. Res. 2004, 37, 506517. (58) Lygo, B.; Andrews, B.I. Acc. Chem. Res. 2004, 37, 518525. (59) ODonnell, M.J. In Catalytic Asymmetric Synthesis, 2nd ed.; Ojima, I., Ed.; Wiley-VCH: New York, 2000; pp 727756 and reference cited therein. (60) Hughes, D.; Dolling, U.; Ryan, K.; Schoenwaldt, E.; Grabowski, E. J. Org. Chem. 1987, 52, 47454752. (61) Dolling, U.; Davis, P.; Grabowski, E. J. Am. Chem. Soc. 1984, 106, 446447. (62) Dolling, U.; Grabowski, E.; Pines, S. Process using achiral co-catalyst promoter for chirl phase transfer alkylation process for an enantiomer of a substituted

211

(63) (64) (65) (66) (67) (68) (69) (70) (71) (72) (73) (74) (75) (76) (77) (78) (79)

(80) (81)

(82)

(83) (84)

uorenyloxyacetic acid. US Patent 4605761, August 12, 1986. Tanaka, K., Ed. Solvent-Free Organic Synthesis; Wiley-VCH: Weinheim, Germany, 2003. Correa, W.H.; Edwards, J.K.; McCluskey, A.; McKinnon, I.; Scott, J.L. Green Chem. 2003, 5, 3033. Ranu, B.C.; Hajra, A.; Dey, S.S. Org. Proc. Res. Dev. 2002, 6, 817818. Walsh, P.J.; Li, H.; de Parrodi, C.A. Chem. Rev. 2007, 107, 25032545. Tokunaga, M.; Larrow, J.F.; Kakiuchi, F.; Jacobsen, E.N. Science 1997, 277, 936939. Jacobsen, E.N. Acc. Chem. Res. 2000, 33, 421431. Wang, J.; Li, H.; Zu, L.; Jiang, W.; Wang, W. Adv. Synth. Catal. 2006, 348, 20472050. Hough, W.L.; Rogers, R.D. Bull. Chem. Soc. Jpn. 2007, 80, 22622269. Jain, N.; Kumar, A.; Chauhan, S.; Chauhan, S.M.S. Tetrahedron 2005, 61, 10151060. Calo, V.; Nacci, A.; Monopoli, A. Eur. J. Org. Chem. 2006, 17, 37913802. Earle, M.J. ACS Symposium Series 2002, 818 (Ionic Liquids), 90. Chowdhury, S.; Mohan, R.; Scott, J.L. Tetrahedron 2007, 63, 2363. Enders, D.; Niemeier, O.; Henseler, A. Chem. Rev. 2007, 107, 56065655. Dzyuba, S.V.; Bartsch, R.A. Angew. Chem. Inter. Ed. 2003, 42 (2), 148150. Prajapati, D.; Gohain, M. Tetrahedron 2004, 60 (4), 815833. Leitner, W. Acc.Chem. Res. 2002, 35 (9), 746756. Gallou, F.; Saim, S.; Koenig, K.J.; Bochniak, D.; Horhota, S.T.; Yee, N.K.; Senanayake, C.H. Org. Proc. Res. Dev. 2006, 10, 937940. Pathak, P.; Meziani, M.J.; Desai, T.; Sun, Y-P. J. Am. Chem. Soc. 2004, 126 (35), 1084210843. Subramaniam, B.; Saim, S.; Rajewski, R.; Stella, V.J. ACS Symposium Series 2001, 766 (Green Engineering), 96110. Tom, J.W.; Lim, G.B.; Debenedetti, P.G.; Prudhomme, R.K. ACS Symposium Series 1993, 514 (Supercritical Fluid Engineering Science), 238257. DiMasi, J.A.; Hansen, R.W.; Grabowski, H.G. J. Health Econ 2003, 22, 151185. Pisano, G.P.; Wheelwright, S.C. Harvard Business Rev. 1995, 73 (5), 93105.

Downloaded by [Universite Laval] at 15:23 15 October 2012

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The OxenDocument6 pagesThe OxenZohraPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- (Christopher J. Flinn) The Minimum Wage and LaborDocument321 pages(Christopher J. Flinn) The Minimum Wage and LaborZohraPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Pronoun Case WorksheetDocument1 pagePronoun Case WorksheetZohra100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Non Discrimination PolicyDocument5 pagesNon Discrimination PolicyZohraPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Outreach Is Better Than Selection For Increasing DiversityDocument4 pagesOutreach Is Better Than Selection For Increasing DiversityZohraPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Writing DialogueDocument14 pagesWriting DialogueZohra100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Leadership in The Age of Transparency: Valuation of Externalities For Sustainable DevelopmentDocument4 pagesLeadership in The Age of Transparency: Valuation of Externalities For Sustainable DevelopmentZohraPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Examination at The Womb DoorDocument1 pageExamination at The Womb DoorZohra0% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Stylistic Analyis of Katie Meluaz The FloodDocument5 pagesStylistic Analyis of Katie Meluaz The FloodZohraPas encore d'évaluation

- Eavan Boland - Text NotesDocument4 pagesEavan Boland - Text NotesZohra100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Agriculture IntroductionDocument5 pagesAgriculture IntroductionZohraPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Muslim RuleDocument2 pagesMuslim RuleZohraPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Proj Muse - Lord of The FliesDocument9 pagesProj Muse - Lord of The FliesZohraPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Margaret AttwoodDocument10 pagesMargaret AttwoodZohra0% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Alternative Ending For Great ExpectationsDocument4 pagesAlternative Ending For Great ExpectationsZohraPas encore d'évaluation

- Prelude by Words WorthDocument14 pagesPrelude by Words WorthZohra100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Multi-Wing Engineering GuideDocument7 pagesMulti-Wing Engineering Guidea_salehiPas encore d'évaluation

- Meat Plant FeasabilityDocument115 pagesMeat Plant FeasabilityCh WaqasPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Exercises - Fluid MechanicsDocument3 pagesExercises - Fluid MechanicsgemnikkicPas encore d'évaluation

- NRF Nano EthicsDocument18 pagesNRF Nano Ethicsfelipe de jesus juarez torresPas encore d'évaluation

- Present Continuous Exercises Test 1 - Positive Statements ExerciseDocument2 pagesPresent Continuous Exercises Test 1 - Positive Statements Exerciseangel omar peraltaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Notes Marriage and Family in Canon LawDocument5 pagesNotes Marriage and Family in Canon LawmacPas encore d'évaluation

- Dr. Nastiti K - Manajemen Asma Pada Anak 2018 PDFDocument72 pagesDr. Nastiti K - Manajemen Asma Pada Anak 2018 PDFagnesspratiwiPas encore d'évaluation

- Maintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBDocument10 pagesMaintenance Instructions, Parts Identification & Seal Kits For Series 2H / 2HD / 2HB & 3H / 3HD / 3HBAtaa AssaadPas encore d'évaluation

- Current Concepts of Enzyme Histochemistry in Modern PathologyDocument11 pagesCurrent Concepts of Enzyme Histochemistry in Modern PathologyRosa AquinoPas encore d'évaluation

- ZX110to330 ELEC E PDFDocument1 pageZX110to330 ELEC E PDFYadi100% (1)

- DX340LC: Crawler ExcavatorDocument20 pagesDX340LC: Crawler ExcavatorFeristha Meriani TabitaPas encore d'évaluation

- Employee Final SettlementDocument1 pageEmployee Final SettlementZeeshan Mirza0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Yogananda Scientific HealingDocument47 pagesYogananda Scientific HealingSagar Pandya100% (4)

- Epo-Fix Plus: High-Performance Epoxy Chemical AnchorDocument3 pagesEpo-Fix Plus: High-Performance Epoxy Chemical Anchormilivoj ilibasicPas encore d'évaluation

- MajorProjects 202112 e 1Document64 pagesMajorProjects 202112 e 1xtrooz abiPas encore d'évaluation

- Valve Material SpecificationDocument397 pagesValve Material Specificationkaruna34680% (5)

- Electri RelifDocument18 pagesElectri Relifsuleman247Pas encore d'évaluation

- Pe 3 Syllabus - GymnasticsDocument7 pagesPe 3 Syllabus - GymnasticsLOUISE DOROTHY PARAISO100% (1)

- Behavior Specific Praise Statements HandoutDocument3 pagesBehavior Specific Praise Statements HandoutDaniel BernalPas encore d'évaluation

- 2019 06 28 PDFDocument47 pages2019 06 28 PDFTes BabasaPas encore d'évaluation

- Aldehydes, Ketones, Carboxylic Acids, and EstersDocument11 pagesAldehydes, Ketones, Carboxylic Acids, and EstersNATURE COMPUTERPas encore d'évaluation

- Offender TypologiesDocument8 pagesOffender TypologiesSahil AnsariPas encore d'évaluation

- 7 UpDocument3 pages7 UpRajeev TripathiPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDocument53 pagesGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADPas encore d'évaluation

- Management of Preterm LaborDocument2 pagesManagement of Preterm LaborpolygonePas encore d'évaluation

- Rooftop Rain Water Harvesting in An Educational CampusDocument9 pagesRooftop Rain Water Harvesting in An Educational CampusAkshay BoratiPas encore d'évaluation

- Soalan 9 LainDocument15 pagesSoalan 9 LainMelor DihatiPas encore d'évaluation

- Review - Practical Accounting 1Document2 pagesReview - Practical Accounting 1Kath LeynesPas encore d'évaluation

- Kyocera Fleet Services White Paper: SecurityDocument20 pagesKyocera Fleet Services White Paper: SecurityHoratiu OanaPas encore d'évaluation

- Nitric AcidDocument7 pagesNitric AcidKuldeep BhattPas encore d'évaluation

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisD'EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisÉvaluation : 5 sur 5 étoiles5/5 (8)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisD'EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisÉvaluation : 4.5 sur 5 étoiles4.5/5 (42)