Académique Documents

Professionnel Documents

Culture Documents

Report On Plastic Waste

Transféré par

Rakesh KumarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Report On Plastic Waste

Transféré par

Rakesh KumarDroits d'auteur :

Formats disponibles

INDEX

NAME

Page No

1. ABSTRACT 2. INTRODUCTION 3. PROCESS 4. DETAILS OF THE PROJECT 5. COMPARISION WITH OTHER ALTERNATIVES 6. CONCLUSION 7. FUTURE SCOPE

3 4 5 6 7 8 9

ABSTRACT:

Safe disposal of waste of plastics is a serious concern all around the world. Plastics waste management is done by reduce consumption, recycling, using bio-degradable plastics, land filling, Plasma pyrolysis and energy recovery. Our prototype works by taking waste plastics and forcing them through a heated chamber, melting the plastic at a high temperature. A knife cuts the extruded material into easily stored and readily shipped nuggets called Plastofuel, which can be combusted directly in the boiler. This Plastofuel is fed to the combustion chamber where it is heated at a high temperature. When plastic melts, its vapours are then passed through the condensation chamber. These vapours get cooled and converted to the liquid fuel. This fuel if further cleaned can be utilized in the vehicles and has various other applications. The Biggest problem Decomposing of the plastic waste can be solved by converting the waste into PLASTOFUEL.

INTRODUCTION

Plastic is one of the most problematic materials used by our society because it is often made from toxic materials known to cause diseases or affect our hormonal balance. It is also very hard and energy consuming to recycle, because it takes lifetimes to degrade, which poses the greatest problem of all because it is literally everywhere. From clothes, furniture, electronic devices, and cars to food packaging, sanitary products, and medical facilities - they are all at least partly made of plastics. Just walking through your house and taking a look around will leave you shocked about how much plastic you actually use every single day. The per capita consumption of plastic in India doubled from 4 kg in 2006 to 8 kg in 2010, and would touch the global average of 27 kg per person by 2020, according to industry representatives. Among the factors driving this growth is increasing use of plastics in packaging, infrastructure, agriculture, auto motives, health care and FMCG segments.

Upon realizing this we also have to admit that in our modern society no matter how much we try to stay away from using plastic, so many things are made from it that we just cant completely avoid buying and using it. So what should we do with all the waste that comes from plastic? Recycling is the big word here. The energy saved by producing a new plastic bottle from recycling material compared to producing one from fresh material is almost 70%, or enough to light a 60-watt light bulb for six hours. By making sure you recycle all of the plastic products you use, you help regain as much energy as possible from your non-avoidable plastic waste. Aside from recycling plastic to make new products and save on energy, there are also projects aimed at turning plastic into new energy sources. Plastic is made from crude oil - the very same raw material from which fuel is made. Therefore, we have made it a goal to turn waste plastic back into crude oil so that it can be reused for powering engines or burned in heating. Using this method, waste plastic cannot only be put to actual use, but it can also help save the scarce crude oil resources left on Earth.

PROCESS DESCRIPTION The process of converting the waste plastic to alternative energy begins with heating the solid plastic with or without the presence of cracking catalyst to form liquid slurry (thermal liquefaction in the range of 370-420C), condensing the vapour with standard condensing column to form liquid hydrocarbon fuel. The process has been conducted in small scales in laboratory, on waste plastics types; LDPE (Low Density Plastic Waste)

PLASTIC

PETROL EUM

WASTE PLASTIC

FUEL

The PLASTO-FUEL is first fed into the Boiling Flask. It is heated to nearly about 400 C with the help of an electric mantle. Plastic melts at this temperature and form a liquid. Heating this liquid again form vapours

which will get cooled when passed through a condenser. The coolant (water) will take the heat from the hot vapours which will be further condensed to give oil. The oil is collected in the another chamber

Vous aimerez peut-être aussi

- Step Response of First Order System Expt ChE Lab 2Document5 pagesStep Response of First Order System Expt ChE Lab 2simonatics08Pas encore d'évaluation

- Mini Project Handout Sem I 2015-2016Document11 pagesMini Project Handout Sem I 2015-2016MuhamadYazidPas encore d'évaluation

- Application of Relux Software in Simulation and Analysis of An Energy Efficient Lighting SchemeDocument24 pagesApplication of Relux Software in Simulation and Analysis of An Energy Efficient Lighting SchemejuankrlossssPas encore d'évaluation

- Research On Heat Transfer Coefficient of Horizontal Tube Falling Film Evaporator PDFDocument7 pagesResearch On Heat Transfer Coefficient of Horizontal Tube Falling Film Evaporator PDFdonyaPas encore d'évaluation

- Heat Transfer Mcqs PDF 1heat Transfer MCQ Heat Transfer Mcqs PDF 1heat Transfer MCQDocument62 pagesHeat Transfer Mcqs PDF 1heat Transfer MCQ Heat Transfer Mcqs PDF 1heat Transfer MCQPrapPas encore d'évaluation

- Astm D 570-1998Document4 pagesAstm D 570-1998Anonymous ntZm8aUSuPas encore d'évaluation

- Determination of Vapor PressuresDocument2 pagesDetermination of Vapor PressuresMyvizhi SomasundaramPas encore d'évaluation

- Polynomial Interpolation SICLABDocument16 pagesPolynomial Interpolation SICLABAlexander Diaz AlvarezPas encore d'évaluation

- MS Excel in MathEdDocument57 pagesMS Excel in MathEdLesette Ambito PatricioPas encore d'évaluation

- Fluid Mechanics LAB OKDocument42 pagesFluid Mechanics LAB OKNabilahJasmiPas encore d'évaluation

- Chem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodheaDocument16 pagesChem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodhearahmanPas encore d'évaluation

- Heat Transfer May2004 NR 310803Document8 pagesHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryPas encore d'évaluation

- Plant Design Leacture 1Document29 pagesPlant Design Leacture 1Abdisa GemechuPas encore d'évaluation

- Lab 05 - Extended SurfacesDocument12 pagesLab 05 - Extended SurfacesMuhammad FarhanPas encore d'évaluation

- Waste Treatment Fro, BreweryDocument13 pagesWaste Treatment Fro, BrewerysunliasPas encore d'évaluation

- Modelling and Simulation of The Water-Gas Shift in A Packed Bed Membrane ReactorDocument87 pagesModelling and Simulation of The Water-Gas Shift in A Packed Bed Membrane ReactorWu ChengliangPas encore d'évaluation

- Inverse Square Law of HeatDocument9 pagesInverse Square Law of HeatAl Drexie BasadrePas encore d'évaluation

- Advance Fluid Lab ManualDocument55 pagesAdvance Fluid Lab ManualchristianPas encore d'évaluation

- Chapters 1 (b2)Document11 pagesChapters 1 (b2)queenless21100% (2)

- Using A Teaching Model To Correct Known Misconceptions in ElectrochemistryDocument7 pagesUsing A Teaching Model To Correct Known Misconceptions in ElectrochemistryObaa HanPas encore d'évaluation

- Public Administration in BangladeshDocument32 pagesPublic Administration in BangladeshSaif RayhanPas encore d'évaluation

- Prelab 3 Response of First and Second Order SystemsDocument7 pagesPrelab 3 Response of First and Second Order SystemsDean Joyce AlborotoPas encore d'évaluation

- Chemical EngineeringDocument123 pagesChemical EngineeringJinu Madhavan0% (1)

- The Haber and Contact ProcessesDocument3 pagesThe Haber and Contact Processesjavison_501100% (1)

- SedimentationDocument6 pagesSedimentationgnino2Pas encore d'évaluation

- Meen 464 Lab 2 Linear Radial Heat Conduction 1-24-2020Document15 pagesMeen 464 Lab 2 Linear Radial Heat Conduction 1-24-2020Shoaib AhmedPas encore d'évaluation

- Chemostat in SeriesDocument23 pagesChemostat in SeriesMailiw AshfordPas encore d'évaluation

- AbstractDocument10 pagesAbstractmarkPas encore d'évaluation

- Fig. 1 - Introduction To Nano TechnologyDocument10 pagesFig. 1 - Introduction To Nano Technologymaian sajaPas encore d'évaluation

- Bachelor of Chemical EngineeringDocument29 pagesBachelor of Chemical EngineeringJian LiangPas encore d'évaluation

- Shell Momentum BalanceDocument13 pagesShell Momentum BalanceSandra Enn BahintingPas encore d'évaluation

- Drying Processes: Mr. Pankaj Kusum Ramdas KhuspeDocument9 pagesDrying Processes: Mr. Pankaj Kusum Ramdas KhuspedadaPas encore d'évaluation

- E 102Document123 pagesE 102saleem alhajri0% (1)

- Plastics and Fibers PaperDocument38 pagesPlastics and Fibers Paperleo besaPas encore d'évaluation

- Applied Engineering Economics: Dr. Scott J. Amos, PEDocument1 pageApplied Engineering Economics: Dr. Scott J. Amos, PESucher EolasPas encore d'évaluation

- Applications of Fluid Mechanics in DiffeDocument11 pagesApplications of Fluid Mechanics in DiffeGodwin King-NyamadorPas encore d'évaluation

- Humidification and Drying ProblemsDocument2 pagesHumidification and Drying ProblemsKuo SarongPas encore d'évaluation

- Lab Rep - Experiment 1Document6 pagesLab Rep - Experiment 1Clifford Dwight Ricanor100% (1)

- Assignment FormattingDocument4 pagesAssignment FormattingJr CallangaPas encore d'évaluation

- Klein GDocument196 pagesKlein Gagbas20026896Pas encore d'évaluation

- Modeling and Simulation of Polymerization of Lactide To PolylacticDocument7 pagesModeling and Simulation of Polymerization of Lactide To Polylactickeyur1109Pas encore d'évaluation

- Heat TransferDocument39 pagesHeat TransferAnonymous 0zrCNQPas encore d'évaluation

- Potato Plastic Lab ModuleDocument4 pagesPotato Plastic Lab ModuleAnoif Naputo AidnamPas encore d'évaluation

- FR Experiment 3Document7 pagesFR Experiment 3m kimPas encore d'évaluation

- 8.3 - Packed-Bed ReactorsDocument20 pages8.3 - Packed-Bed ReactorsDotaKINGPas encore d'évaluation

- Home Cultures - Identity, Consumption and The HomeDocument23 pagesHome Cultures - Identity, Consumption and The HomeAna Nikezic50% (2)

- Lecture 7. HumidificationDocument29 pagesLecture 7. HumidificationNOBLEMAN100% (1)

- CBB3024 Flowsheeting 1Document93 pagesCBB3024 Flowsheeting 1Yunaida YusoffPas encore d'évaluation

- Armfield Rising Film EvaporatorDocument2 pagesArmfield Rising Film EvaporatorEvy Citra Ayu NegariPas encore d'évaluation

- Assignment 1 of Manufacturing ProcessDocument6 pagesAssignment 1 of Manufacturing ProcessMehedi HasanPas encore d'évaluation

- Heat Transfer - SK MondalDocument97 pagesHeat Transfer - SK MondalMiguelaTayPas encore d'évaluation

- Polymer Strain Stress CurveDocument15 pagesPolymer Strain Stress CurvearelanopPas encore d'évaluation

- 09 Manual ReluxCADDocument29 pages09 Manual ReluxCADcaro caritoPas encore d'évaluation

- Simplex Minimization ProblemDocument22 pagesSimplex Minimization ProblemShreyasKamatPas encore d'évaluation

- Heat Conduction (Linear)Document7 pagesHeat Conduction (Linear)Yi Ling GohPas encore d'évaluation

- The Sustainable Solution: Plastic Granulate Production in Action: Money from trashD'EverandThe Sustainable Solution: Plastic Granulate Production in Action: Money from trashPas encore d'évaluation

- ReportDocument7 pagesReportRaja HarjaiPas encore d'évaluation

- EPFDocument5 pagesEPFnpkannaPas encore d'évaluation

- Making Biodegradable PlasticsDocument4 pagesMaking Biodegradable PlasticsRowin Mark SabornidoPas encore d'évaluation

- Gasoline Grade Fuel From Metalized PETDocument10 pagesGasoline Grade Fuel From Metalized PETjimbo09Pas encore d'évaluation

- Periodic ClassificationDocument60 pagesPeriodic ClassificationRakesh KumarPas encore d'évaluation

- Mutual and Self InductanceDocument53 pagesMutual and Self InductanceTrungpv PhamPas encore d'évaluation

- Test Series:1Chemistry MM: 50Document1 pageTest Series:1Chemistry MM: 50Rakesh KumarPas encore d'évaluation

- Life ProcessesDocument6 pagesLife ProcessesRakesh KumarPas encore d'évaluation

- Ias Book 2015Document49 pagesIas Book 2015Rahul SharmaPas encore d'évaluation

- A Technical Report ON Centre of Pressure ONA Plane Surface ExperimentDocument13 pagesA Technical Report ON Centre of Pressure ONA Plane Surface ExperimentVictor OwolekePas encore d'évaluation

- HLA HART Concept of LawDocument19 pagesHLA HART Concept of LawHarneet KaurPas encore d'évaluation

- Lab 6 Data VisualizationDocument8 pagesLab 6 Data VisualizationRoaster GuruPas encore d'évaluation

- Cisco Nexus 7000 Introduction To NX-OS Lab GuideDocument38 pagesCisco Nexus 7000 Introduction To NX-OS Lab Guiderazzzzzzzzzzz100% (1)

- Orange County Sheriff's Office SeaWorld Death Investigative ReportDocument43 pagesOrange County Sheriff's Office SeaWorld Death Investigative ReportWESH2News100% (1)

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFDocument9 pagesPamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaPas encore d'évaluation

- AMC Middle Primary Years 3 and 4 - SolutionsDocument6 pagesAMC Middle Primary Years 3 and 4 - SolutionsSherry JiangPas encore d'évaluation

- 2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Document28 pages2009-04-CEN-TC121 N1574 Working Programme CEN TC 121Manuel ValentePas encore d'évaluation

- Datasheet TBJ SBW13009-KDocument5 pagesDatasheet TBJ SBW13009-KMarquinhosCostaPas encore d'évaluation

- HTML Editor 8Document13 pagesHTML Editor 8Guru PrasadPas encore d'évaluation

- Marisa Wolf Final New ResumeDocument2 pagesMarisa Wolf Final New Resumeapi-403499166Pas encore d'évaluation

- NBCC 2015 Seismic Design Examples in S-FRAME AnalysisDocument91 pagesNBCC 2015 Seismic Design Examples in S-FRAME AnalysisMike Smith100% (1)

- Contemplation (Murāqaba) and Spiritual Focus/attention (Tawajjuh) in The Pre-Mujaddidi Naqshibandi OrderDocument5 pagesContemplation (Murāqaba) and Spiritual Focus/attention (Tawajjuh) in The Pre-Mujaddidi Naqshibandi OrderShahmir ShahidPas encore d'évaluation

- Ielts Reading Actual Tests With Suggested Answers Oct 2021 JDocument508 pagesIelts Reading Actual Tests With Suggested Answers Oct 2021 JHarpreet Singh JohalPas encore d'évaluation

- Cesars WayDocument20 pagesCesars WayToni TursićPas encore d'évaluation

- Detailed Lesson Plan (DLP) Format: Learning Competency/iesDocument1 pageDetailed Lesson Plan (DLP) Format: Learning Competency/iesErma JalemPas encore d'évaluation

- Śāntarak ItaDocument8 pagesŚāntarak ItaÁtilaPas encore d'évaluation

- BROMINE Safety Handbook - Web FinalDocument110 pagesBROMINE Safety Handbook - Web Finalmonil panchalPas encore d'évaluation

- Lesson Plan - Sight Word ObservationDocument2 pagesLesson Plan - Sight Word Observationapi-253277023Pas encore d'évaluation

- 4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Document11 pages4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Melrose FabianPas encore d'évaluation

- Recruitment Process Outsourcing PDFDocument4 pagesRecruitment Process Outsourcing PDFDevesh NamdeoPas encore d'évaluation

- Estocell - Data Sheet - 14-07-06Document2 pagesEstocell - Data Sheet - 14-07-06LeoRumalaAgusTatarPas encore d'évaluation

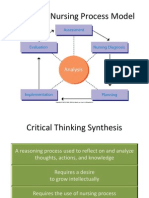

- NUR 104 Nursing Process MY NOTESDocument77 pagesNUR 104 Nursing Process MY NOTESmeanne073100% (1)

- DesignDocument402 pagesDesignEduard BoleaPas encore d'évaluation

- Application of SPACE MatrixDocument11 pagesApplication of SPACE Matrixdecker444975% (4)

- The English We SpeakDocument2 pagesThe English We Speakcaeronmustai100% (1)

- Assignment On Unstable or Astatic Gravimeters and Marine Gravity SurveyDocument9 pagesAssignment On Unstable or Astatic Gravimeters and Marine Gravity Surveyraian islam100% (1)

- Self-Actualization in Robert Luketic'S: Legally Blonde: A HumanisticDocument10 pagesSelf-Actualization in Robert Luketic'S: Legally Blonde: A HumanisticAyeshia FréyPas encore d'évaluation

- Research Paper OutlineDocument2 pagesResearch Paper Outlineapi-270769683Pas encore d'évaluation