Académique Documents

Professionnel Documents

Culture Documents

3727

Transféré par

EL-MUJAHIDDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3727

Transféré par

EL-MUJAHIDDroits d'auteur :

Formats disponibles

AS 37271993

Australian Standard

Guide to residential pavements

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

This Australian Standard was prepared by Committee BD/25, Residential Slabs and Footings. It was approved on behalf of the Council of Standards Australia on 29 July 1993 and published on 11 October 1993.

The following interests are represented on Committee BD/25: Association of Consulting Engineers, Australia Australian Geomechanics Society Australian Institute of Building Surveyors Australian Timber Research Institute Australian Uniform Building Regulations Coordinating Council Building Management Authority of West Australia Cement and Concrete Association of Australia Clay Brick and Paver Institute Concrete Masonry Association of Australia Construction Industry Advisory Council, Queensland Department of Administrative ServicesAustralian Construction Services Division of Building, Construction & Engineering, CSIRO Foundation and Footings Society, Victoria Housing Industry Association, Australia Institution of Engineers, Australia Master Builders Australia Plastics Industry Association South Australian Department of Housing & Construction Steel Reinforcement Institute of Australia University of South Australia Additional interests participating in preparation of Standard: Australian Asphalt Pavement Association

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

Review of Australian Standards. To keep abreast of progress in industry, Australian Standards are subject to periodic review and are kept up to date by the issue of amendments or new editi ons as necessary. It is mportant therefore that Standards users ensure that they are in possession of the latest editi on, and any amendments thereto. Full detail s of all Australian Standards and related publi cati ons wil l be found in the Standards Australi a Catalogue of Publications; this information is supplemented each month by the magazine The Australi an Standard, which subscribing members receive, and which gives detail s of new publications, new edit ions and amendments, and of withdrawn Standards. Suggesti ons for improvements to Australian Standards, addressed to the head off ice of Standards Australi a, are welcomed. Notif ication of any inaccuracy or ambiguit y found in an Australi an Standard should be made without delay in order that the matter may be investigated and appropriate action taken.

This Standard was issued in draft form for comment as DR 92076.

AS 37271993

Australian Standard

Guide to residential pavements

First publi shed as AS 37271993.

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

PUBLISHED BY STANDARDS AUSTRALIA (STANDARDS ASSOCIATION OF AUSTRALIA) 1 THE CRESCENT, HOMEBUSH, NSW 2140

ISBN 0 7262 8473 4

AS 3727 1995

PREFACE

Work on this Guide began under the direction of Standards Australia Committee on Concrete in Buildings, and was continued by the Committee on Residential Slabs and Footings. The preparation of this Guide is in response to a widespread need for guidance in the design and construction of residential pavements.

CONTENTS

Page 1 2 3 4 5 6 7 8 9 10 11 SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 REFERENCED DOCUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 DESIGN OBJECTIVES, LIMITATIONS AND NORMAL MAINTENANCE . . . 5 PERFORMANCE OBJECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 PAVEMENT CONSTRUCTIONGENERAL . . . . . . . . . . . . . . . . . . . . . . . . . 7 CONCRETE PAVEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 SEGMENTAL PAVEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 ASPHALT PAVEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 BITUMINOUS SPRAY-SEALED PAVEMENTS . . . . . . . . . . . . . . . . . . . . . . 13

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

Copyri ght

STANDARDS AUSTRALIA

Users of Standards are reminded that copyright subsists in all Standards Austr alia publications and software. Except where the Copyri ght Act all ows and except where provided for below no publications or soft ware produced by Standards Australi a may be reproduced, stored in a retr ieval system in any form or transmitt ed by any means without prior permission in writ ing from Standards Australi a. Permission may be condit ional on an appropri ate royalty payment. Requests for permission and information on commercial software royalt ies should be directed to the head offi ce of Standards Austr alia. Standards Austr alia wil l permit up to 10 percent of the technical content pages of a Standard to be copied for use exclusively in-house by purchasers of the Standard without payment of a royalty or advice to Standards Austr alia. Standards Austr alia wil l also permit the inclusion of its copyright materi al in computer software programs for no royalt y payment provided such programs are used exclusively in-house by the creators of the programs. Care should be taken to ensure that materi al used is fr om the curr ent editi on of the Standard and that it is updated whenever the Standard is amended or revised. The number and date of the Standard should therefore be clearly identif ied. The use of materi al in print form or in computer software programs to be used commercially, with or without payment, or in commercial contracts is subject to the payment of a royalty. This policy may be vari ed by Standards Austr alia at any ti me.

AS 3727 1993

STANDARDS AUSTRALIA Australian Standard Guide to residential pavements

1 SCOPE This Guide provides guidelines for the selection and construction of pavements associated with residential buildings consisting of single houses or multiple dwellings in medium density housing development. It does not apply to the design and construction of pavements in public roads or streets. This Guide does not preclude the use of any of the following: (a) (b) (c) Methods and materials of pavement construction not referred to in this Guide. Locally proved designs. Pavements designed by a chartered professional engineer.

NOTE: The purpose of this Guide is to provide recommendations for pavements, normally associated with housing. Industrial pavements are not covered by this Guide. Roads and streets should comply with the requirements of the relevant authorities.

2 REFERENCED DOCUMENTS The following documents are referred to in this Guide: AS 1289 Methods of testing soils for engineering purposes 1289.E2.1 Part E Soil compaction and density tests Determination of the dry density/moisture content relation of a soil using modified compaction Standard method 1302 1304 2008 2150 2734 2758 2758.2

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

Steel reinforcing bars for concrete Welded wire reinforcing fabric for concrete Residual bitumen for pavements Asphalt (hot-mixed) Asphalt (hot-mixed) paving Guide to good practice Aggregates and rock for engineering purposes Part 2: Aggregate for sprayed bituminous surfacing Residential slabs and footings Part 1: Construction Off-street parking Part 1: Car parking facilities Concrete structures Slip resistance of pedestrian surfaces Part 1: Requirements

2870 2870.1 2890 2890.1 3600 3661 3661.1

Bituminous surfacing Sprayed work, NAASRA Technical Report, National Association of Australian State Road Authorities, January 1989 Paver Note 1, Specifying and laying clay pavers, Clay Brick and Paver Institute, February 1990

COPYRIGHT

AS 3727 1993

3 3.1

DEFINITIONS For the purposes of this Standard, the definitions below apply. Asphalt a plant-mixed combination of bitumen and graded stone aggregate.

3.2 Basecourse the main structural layer in the pavement. In a bituminous or segmental pavement, it is the layer immediately supporting the surfacing layer. In a concrete pavement, the concrete acts as both a surfacing layer and basecourse. 3.3 Bedding course a layer of sand upon which paving units are laid and, together with the paving units, forms the surfacing layer. 3.4 Bituminous spray seal a surfacing produced by the application of a continuous spray coat of bitumen followed with the application of stone aggregate. 3.5 Bound pavement a pavement surfaced with concrete, asphalt or a bituminous spray seal, which does not include paving units. 3.6 Breaking load test a three-point bending test for paving units of segmental pavements. 3.7 Clay (subgrade) fine grained soil with plastic properties when wet; it includes sandy clays and silty clays. 3.8 Collapsing soil weakly cemented granular soil subject to large settlements under load as a result of degradation by water of the cementing action. 3.9 Construction joint a joint which divides a concrete pavement into suitable lengths and widths for construction purposes. 3.10 3.11 3.12 Control joint a vertical joint used to control cracking in a pavement. Formation the prepared surface of the subgrade. Isolation joint a vertical joint which isolates the pavement from other structures.

3.13 Landslip foundation condition on a sloping site where downhill movement or failure is a design consideration. 3.14 Light traffic unrestricted operations exceeding 3t. of vehicles with a gross mass not

3.15 Medium traffic unrestricted operations of vehicles with a gross mass not exceeding 10 t, with infrequent use by heavier vehicles not exceeding statutory limits for tyre, wheel and axle loads. 3.16 Mine subsidence settlement, curvature, slope and lateral strain produced at the surface as a result of underground mining. 3.17 Pavement consists of one or more layers of material referred to as surfacing layer, basecourse and sub-base (see Figure 1).

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

3.18 Paving units segmental units which, in combination with the bedding course, form the surfacing layer. 3.19 Reactive site site consisting of a clay soil which swells on wetting and shrinks on drying by an amount that can damage buildings on light strip footings or unstiffened slabs; includes sites classified as M, H or E in accordance with AS 2870.1. 3.20 Silt (subgrade) fine-grained soil that is non-cohesive and non-plastic when wet. It can include some sand and clay. 3.21 Site classification Classification based mainly, but not entirely, on the basis of expected surface settlement or heave.

COPYRIGHT

AS 3727 1993

Site classes shall be designated as follows: Foundation Most sand and rock sites Most silt and some clay sites Moderately reactive clay sites Highly reactive clay sites Extremely reactive clay sites Filled sites Sites which include: soft soils, such as soft clays or silts or loose sands; Landslip; Mine subsidence; Collapsing soils; or soils subject to erosion. Class A S M H E A to P

For more information refer to AS 2870.1. 3.22 Slab in a concrete pavement, the main structural element. It is also the surfacing layer and basecourse. 3.23 Sub-base a secondary layer of the pavement which, if required, underlies the basecourse. It is similar to basecourse material but of a lower quality. 3.24 Subgrade the natural soil or fill underlying the pavement. 3.25 Surfacing layer the top layer of the pavement. It may be a concrete slab, segmental paving units and bedding course, a bituminous spray seal, or asphalt.

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

FIGURE 1

THE PAVEMENT LAYERS ABOVE THE SUBGRADE

4 DESIGN OBJECTIVES, LIMITATIONS AND NORMAL MAINTENANCE 4.1 Design objectives The pavement systems specified in this Guide are typical and not necessarily minima, selected on the basis of providing an acceptable probability of serviceability during the design life of the pavement. Serviceability may be assessed by the criteria given in Clause 5.

NOTE: For the geometric set-out of driveways and their clearances (taking into account approach angles) reference may be made to AS 2890.1 .

COPYRIGHT

AS 3727 1993

4.2 Limitations Pavement designs have been based on good subgrades on well-drained sites. Sites that do not comply with these conditions include reactive soil sites classified as Class H or E and problem sites classified as Class P. 4.3 Normal maintenance requirements To ensure an acceptable probability of serviceability the pavement owner must ensure a good standard of maintenance. Principles of maintenance include (i) avoidance of streetwater flow onto the pavement; (ii) (iii) (iv) maintenance of drains; regular filling of joints in segmental paving; avoidance of exceeding the design traffic loading.

NOTE: A single pass of a vehicle whose gross mass exceeds the design traffic loading by more than 40% can be permitted.

PERFORMANCE OBJECTIVES

5.1 General The criteria for acceptable performance of all pavements should be according to Clauses 5.2 to 5.6 for a period of one year after construction of the pavement.

NOTE: The one-year period has been adopted as being long enough for a pavement to be subjected to in-service conditions prior to undue influence of changing environmental conditions such as the effect of tree roots.

5.2 Cracking, subsidence and stepping The criteria for serviceability in terms of cracking, subsidence and stepping are given in Table 1. TABLE 1 PERFORMANCE CRITERIA

Condition Cracking in bound pavements Subsidence Measure Crack width Offset under 1.5 m length of the design profile (See Note 2 below) Relative surface level of adjacent paving elements within the expanse of the main pavement Limit 1.5 mm 15 mm

Stepping

5 mm

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

NO TES: 1 The above figures are additional to the construction tolerances used at the time of construction. 2 The design profile is centred over the defect and supported at its ends by equal height spacers. The change in offset is then measured relative to this design profile. 3 Shrinkage cracking in reactive subgrades can lead to loss of bedding sand under segmental pavements. A geotextile separation layer will prevent sand from entering the shrinkage cracks. 4 Cracking in this context applies to bound pavements and not to segmental pavements. 5 The stepping criterion applies only to steps within the surface of the main pavement. It shall not be applied where the main pavement abuts other structures such as edging, drainage pits, service pits, minor pavements (such as a pathway adjacent to a driveway) and pavements constructed with materials of a different type.

COPYRIGHT

AS 3727 1993

5.3 Chipping and spalling There should be no more than 10 in any adjacent 100 segmental paving units having chipped or spalled arises. There should be no chipping or spalling in concrete pavements. 5.4 Slip resistance The surface texture should have slip resistance appropriate for the pavement slopes as required by AS 3661.1. 5.5 Ponding Ponding deeper than 10 mm should not occur more than 15 minutes after cessation of rainfall. 6 6.1 MATERIALS Asphalt (hot-mixed) Hot-mixed asphalt should comply with AS 2150.

6.2 Basecourse The basecourse for asphalt and segmental paving should comprise well-graded crushed rock or gravel with a maximum particle size of 26.5 mm, and with a maximum clay content of 6% by mass. 6.3 Bitumen Bitumen should comply with AS 2008. In situ concrete should comply with the material 6.4 Concrete placed in situ provisions of AS 3600.

6.5 Cover aggregate Cover aggregate for bituminous spray sealed pavements should comply with AS 2758.2. 6.6 Fill for subgrade Fill should consist of granular material such as sand, gravel or quarry rubble. 6.7 Paving units of concrete Concrete paving units should comply with Table 3. Paving units made from fired clay should comply with 6.8 Paving units of fired clay Paver Note 1 and Table 3.

6.9 Reinforcement Reinforcement for concrete pavements should be welded wire fabric complying with AS 1304 or bar reinforcement complying with AS 1302. 6.10 Sand The bedding sand should be coarse, well-graded, washed sand free from organic materials. 6.11 Sub-base The sub-base should be a well-graded granular material such as sand, gravel or crushed rock with a maximum particle size not more than one-third of the subbase layer thickness. 7 PAVEMENT CONSTRUCTION GENERAL

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

7.1 Subgrade Topsoil containing grass roots should be removed. The formation should be trimmed to within +0, 25 mm of the design level and compacted if necessary. Subgrade fill should be well compacted to achieve the pavement performance requirement. Local soft spots should be rectified to achieve levels of strength and stiffness similar to the remainder of the subgrade. Backfill for service trenches should be compacted in layers to provide levels of strength and stiffness similar to the subgrade. Clay fill should be moist to allow compaction and reduce subsequent movement. The moisture condition of the clay should be near the long term equilibrium moisture condition. 7.2 Basecourse The basecourse should be compacted to a minimum dry density ratio of 98 percent when tested according to AS 1289.E2.1 (Modified compactive effort). This basecourse compaction requirement may be deemed to be achieved where the basecourse is compacted in layers of 100 mm maximum with at least three passes of a vibrating plate compactor or equivalent. Generally the basecourse should be finished to within 0, +25 mm of the design levels except where it abuts existing structures where it should be 0, +10 mm. The surface of the prepared basecourse should not deviate by more than 10 mm from a 3 m length of the design profile. If a sub-base layer is required, it should be compacted to the same standard.

COPYRIGHT

AS 3727 1993

7.3 Crossfalls The minimum and maximum recommended finished pavement surface crossfalls for exposed pavements are 1 percent and 10 percent respectively. Further details on surface gradients are given in AS 2890.1. 7.4 Drainage Drainage is an important consideration for preventing softening of subgrades, deterioration of wearing courses and efflorescence. Surface run-off should be collected in appropriate channels and drains and conveyed to discharge points. On a poorly drained site, it may be necessary to protect the pavement or subgrade (or both) from the effects of water. Sub-surface drains of pervious granular material and/or slotted or pervious pipes may be required under or beside the pavement. Geotextile fabric may be provided as a separation or drainage layer. Alternatively, subgrade or pavement courses may be stabilized. The finished level of any pavement abutting a wall must be below the wall damp-proof course and must not obscure any weep holes or drainage openings. 8 8.1 (a) (b) CONCRETE PAVEMENTS General Concrete pavement construction should be as follows: The construction requirements of AS 3600 should be applied except where indicated otherwise. Typical slab thickness, concrete grade, joint spacing and reinforcement should be in accordance with Table 2.

A typical cross-section of a concrete pavement is shown in Figure 2. TABLE 2 TYPICAL CONCRETE PAVEMENT SPECIFICATION FOR RESIDENTIAL APPLICATIONS

Alternative 1 Unreinforced Traffic Minimum slab thickness Minimum concrete grade Maximum control joint spacing m N20 2 Minimum reinforcing fabric Alternative 2 Maximum control joint spacing m Minimum reinforcing fabric Ref No. N.A. Alternative 3 Maximum control joint spacing m Minimum reinforcing fabric Ref No. N.A.

mm Foot and bicycle only

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

75

Light Medium NO TE:

100 150

N20 N25

2 2

3 4

F52 F72

6 6

F62 F82

Slab thickness is measured from the underside of the slab to the bottom of any top-surface patterning.

8.2 (a) (b) (c)

Sub-base A sub-base might be required to permit trafficking across the excavated subgrade; as a levelling layer to facilitate uniform concrete thickness; and as a means of assisting in the control of reactive subgrade soils.

A sub-base, if required, should not be less than 75 mm thick.

COPYRIGHT

AS 3727 1993

FIGURE 2

CONCRETE PAVEMENT ELEMENTS

8.3 (a) (b)

Reinforcement

Reinforcement for concrete should be as follows:

Slab reinforcement should be used if the panel is of irregular shape, or if the panel is a rectangle with a length/width ratio greater than 1.3:1. Where the slab surrounds another structure such as a drainage pit or has a re-entrant corner, trimming reinforcement should be used unless joints are provided. Trimming reinforcement should be not less than one Y12 bar of minimum length 600 mm. Reinforcement, where used, should be located in the top half of the slab with a minimum cover of 30 mm but not lower than the mid-depth of slab, and should be supported to retain its position by, for example, bar chairs at 1 m centres. Slab-reinforcing fabric should be lapped so that the two outermost transverse wires of one sheet overlap the two outermost wires of the sheet being lapped. Reinforcement should not be continuous through control joints. Joints

(c)

(d) (e) 8.4

8.4.1 Control joints Control joints should be provided at a spacing not greater than that shown in Table 2. Control joints may be constructed by (a) (b) formwork between concrete pours; or creating a plane of weakness to a depth of one-third to one-quarter of the pavement thickness from the surface by such means as (i) (ii) scoring the plastic concrete with a suitable tool; or inserting a proprietary crack-inducing device into plastic concrete.

A typical control joint is shown in Figure 3.

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

FIGURE 3

CONTROL JOINT

COPYRIGHT

AS 3727 1993

10

8.4.2 Isolation joints An isolation joint should be provided where a pavement adjoins a building or other rigid structure such as a drainage pit. Isolation joints should allow freedom of movement between the slab and the structure and resist the entrance of foreign matter. Typical isolation joints are shown in Figures 4 and 5.

FIGURE 4 ISOLATION JOINTS AT ACCESS HOLES AND PITS NOT AT PAVEMENT EDGES

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

DIMENSIONS IN MILLIMETRES

FIGURE 5 ISOLATION JOINTS AT ACCESS HOLES AND PITS AT PAVEMENT EDGES

COPYRIGHT

11

AS 3727 1993

9 SEGMENTAL PAVEMENTS 9.1 General A typical cross-section of a segmental pavement is shown in Figure 6. Typical thicknesses of basecourse and required breaking loads for paving units are given in Table 3. 9.2 Thickness of bedding course The bedding course should be of roughly uniform thickness and not exceeding 30 mm after compaction. 9.3 Joints Segmental pavements should be laid with nominal 3 mm joints between the paving units, except where spacer ribs are used. Joints should be filled with an appropriate sand. 9.4 Lateral restraint The entire perimeter of segmental pavements should be provided with edge restraint. Lateral support may be provided by existing structures or appropriately designed edge restraints. Examples are shown in Figure 7. TABLE 3 TYPICAL SEGMENTAL PAVEMENT SPECIFICATION FOR RESIDENTIAL APPLICATIONS

Co mp a c ted ed b a s e co u r s e t h i ckn e s s kn mm S i t e cla s s i f icat ion cl at on Class A Foot and bicycle only Light Medium 0 0 75 Class S 0 75 100 Class M 0 75 150 kN 2 3 5

T ra f f i c

M in imum mum b r ea k in g lo a d o f pa v ing uni t s pa ng un

NO TE: Segmental paving units must be able to resist cracking when subject to vehicle wheel loads. The ability to resist cracking depends on the applied wheel loads, the quality of the paving unit material and the length, width, thickness and shape of the units. It would be possible to provide a prescriptive material for each of the many combinations of case; however, it is much more practical to minimum breaking load for each load case, influencing factors.

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

specification of a minimum quality of length, width, thickness, shape and load provide a performance requirement of since this will account for all of the

10 ASPHALT PAVEMENTS 10.1 General An asphalt residential pavement may be constructed as a full depth asphalt pavement or consist of a combination of sub-base, basecourse and asphalt surfacing. A typical cross-section of an asphalt pavement is shown is Figure 8. Typical pavement specifications are given in Table 4. 10.2 Preparation for pavement construction The subgrade should be sprayed with a soil sterilizer to stop unwanted plant growth. The surface of the basecourse prior to laying asphalt should be firm and free of surface water or loose material and dust. Immediately prior to placing asphalt, the surface of the basecourse should be tack coated with a bituminous emulsion spray in accordance with AS 2734. Where full depth asphalt is placed directly on the subgrade, a tack coat is not required.

COPYRIGHT

AS 3727 1993

12

FIGURE 6

SEGMENTAL PAVEMENT ELEMENTS

(a) Exposed edge restraint

(b) Concealed edge restr aint

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

(c) Wall egde restraint

FIGURE 7

TYPICAL EDGE RESTRAINT DETAILS

COPYRIGHT

13

AS 3727 1993

10.3 Asphalt Asphalt should be manufactured, laid and compacted in accordance with AS 2150 and AS 2734. Mixes should generally be AC 10, AC 7, or AC 5, having nominal maximum size aggregates of 10 mm, 7 mm and 5 mm respectively and have mix proportions that conform to those given in AS 2734. Class 170 bitumen should be selected for the binder, except for extremely high ambient temperature areas where Class 320 should be used. 10.4 Surface finish The asphalt pavement should be compacted while hot (above 140C) to achieve a dense, smooth surface, free of roller marks or loose material. Except in inaccessible areas where vibratory plates and hand tampers are permissible, the compaction should be by mechanized rollers. Finished surface levels should be within 10 mm of the specified level at any point, and the surface on a plane section should not deviate by more than 10 mm from the bottom of a 3 m long straightedge laid in any direction. The minimum site density of the compacted mix should be 95 percent of the 50 blow Marshall density of the laboratory compacted mix as specified in AS 2150. TABLE 4 TYPICAL ASPHALT PAVEMENT SPECIFICATION FOR RESIDENTIAL APPLICATIONS

Asphalt and Basecourse Traffic Foot and bicycle only Light Medium Class A foundation 25 mm AC 5 50 mm base 30 mm AC 10 100 mm base 35 mm AC 10 150 mm base Class S or M foundation 25 mm AC 5 100 mm base 30 mm AC 10 150 mm base 35 mm AC 10 200 mm base Full depth asphalt Class A foundation 50 mm AC 5 75 mm AC 10 100 mm AC 10 Class S or M foundation 75 mm AC 5 100 mm AC 10 125 mm AC 10

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

FIGURE 8

ASPHALT PAVEMENT ELEMENTS

11

BITUMINOUS SPRAY-SEALED PAVEMENTS

11.1 General Except where otherwise required by this Clause, spray-sealed surfaces should be constructed in accordance with the NAASRA Technical Report. A typical cross-section of a bituminous spray seal pavement is shown in Figure 9. Typical pavement specifications are given in Table 5. 11.2 Surface preparation The subgrade should be sprayed with a soil sterilizer to stop unwanted plant growth. Compaction of sub-base materials should be in accordance with Clause 7.2. The surface prior to sealing should be free from surface water, loose material and dust.

COPYRIGHT

AS 3727 1993

14

11.3 Prime coat If specified, a light priming coat of cut back bitumen (AMC 0 50/50 bitumen/cutter) may be applied prior to sealing. Sealing should not occur while the primer remains wet to the touch. 11.4 Bitumen application Bitumen should be sprayed on the surface at a constant application rate that is determined in accordance with the NAASRA Technical Report. Likely application rates for 10 mm nominal aggregates would be 1.5 L/m2 to 1.3 L/m 2. Certified spray tankers should be used for all but the smallest areas. 11.5 Aggregate spreading Clean, dry aggregate, precoated where specified, should be spread on the sprayed bitumen as soon as practical after spraying. The aggregate should then be incorporated into the bitumen using a roller. The time between spraying and completed incorporation of the aggregate at any one point should not exceed 20 min. Application rates for aggregate are calculated in accordance with the NAASRA Technical Report. When aggregate is evenly spread and fully embedded by rolling, all loose stones should be removed by sweeping. TABLE 5 TYPICAL SPRAY-SEALED PAVEMENT SPECIFICATION FOR RESIDENTIAL APPLICATIONS

Thickness of courses, mm Traffic Foot and bicycle only Light Medium Class A foundation Base 100 150 200 (or 100 Sub-base + 100) Class S or M foundation Base 125 230 (or 100 150 (or 100 Sub-base

+ 130) 150 + 200)

NOTE: Figures in parentheses indicate alternative materials and thickness.

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

FIGURE 9

BITUMINOUS SPRAY-SEALED PAVEMENT ELEMENTS

COPYRIGHT

This document has expired. To access the current document, please go to your on-line service.Please note that material accessed via our on-line subscription services is not intended for off-line storage, and such storage is contrary to the licence under which the service is supplied.

This page has been left intentionally blank.

Accessed by Cardno Holdings Pty Ltd on 01 Sep 2012

Vous aimerez peut-être aussi

- AS2699.1 Built-In Components For Masonryconstruction Part 1 - Wall TiesDocument48 pagesAS2699.1 Built-In Components For Masonryconstruction Part 1 - Wall Tiestoddlbyrnes25% (4)

- 1562-3 Design and Installation of Sheet Roof and Wall Cladding Part 3: PlasticDocument22 pages1562-3 Design and Installation of Sheet Roof and Wall Cladding Part 3: PlasticVasko Drogriski100% (1)

- 1720.3-2016 - Timber Structures - Residential BuildingsDocument121 pages1720.3-2016 - Timber Structures - Residential BuildingsMark Carroll-Chilts100% (1)

- Australian Standard: Roof TilesDocument10 pagesAustralian Standard: Roof TilesVeetoau Joseph100% (1)

- As 2758.1-1998 Concrete AggregatesDocument28 pagesAs 2758.1-1998 Concrete AggregatesArogya Raju Pudhota100% (3)

- As 3735-2001 Concrete Structures Retaining LiquidsDocument27 pagesAs 3735-2001 Concrete Structures Retaining Liquidsmod67% (3)

- Australian Standard: Guide To Residential PavementsDocument6 pagesAustralian Standard: Guide To Residential PavementsCity AspirePas encore d'évaluation

- Earth 4678-2002 (+A2)Document8 pagesEarth 4678-2002 (+A2)Deny Sadik0% (1)

- 4440 2004Document8 pages4440 2004Awais Safder Malik0% (1)

- 4455 1-2008Document29 pages4455 1-2008Zhi Ming CheahPas encore d'évaluation

- AS 3700 - 2011 Masonry Structures - WebDocument10 pagesAS 3700 - 2011 Masonry Structures - Webreza100% (1)

- As 2327.1-2003 Composite Structures - Simply Supported BeamsDocument129 pagesAs 2327.1-2003 Composite Structures - Simply Supported BeamsMikeChanPas encore d'évaluation

- As 2050-2002 PDFDocument28 pagesAs 2050-2002 PDFNick100% (1)

- AS NZS 1477-2006 PVC Pipes and FittingsDocument41 pagesAS NZS 1477-2006 PVC Pipes and Fittingsvinylreddy007Pas encore d'évaluation

- 4773.1-2015 - Masonry in Small Buildings - DesignDocument109 pages4773.1-2015 - Masonry in Small Buildings - DesignMark Carroll-Chilts100% (1)

- 4773.2-2015 - Masonry in Small Buildings - ConstructionDocument97 pages4773.2-2015 - Masonry in Small Buildings - ConstructionMark Carroll-Chilts100% (5)

- AS 4773.1-2010 Masonry in Small BDG (Amdt 1-2011) PDFDocument108 pagesAS 4773.1-2010 Masonry in Small BDG (Amdt 1-2011) PDFYHK3001100% (7)

- AS 3798-1996 Guidelines On Earthworks For Commercial and ResDocument43 pagesAS 3798-1996 Guidelines On Earthworks For Commercial and ResBrad La PortaPas encore d'évaluation

- As 1170.1Document7 pagesAs 1170.1garrybieber0% (1)

- AS 1604.1-2005 Specification For Preservative Treatment - Sawn and Round TimberDocument49 pagesAS 1604.1-2005 Specification For Preservative Treatment - Sawn and Round Timberskishark100% (1)

- As 3850-2003 Tilt-Up Concrete ConstructionDocument8 pagesAs 3850-2003 Tilt-Up Concrete ConstructionSAI Global - APACPas encore d'évaluation

- 3700-2011 (+A2) - Australian Standards - Masonry StructuresDocument9 pages3700-2011 (+A2) - Australian Standards - Masonry StructuresJulianne RamonedaPas encore d'évaluation

- As 4773.1-2010 Masonry in Small Buildings DesignDocument9 pagesAs 4773.1-2010 Masonry in Small Buildings DesignSAI Global - APAC0% (12)

- As 4055-2006 Wind Loads For HousingDocument7 pagesAs 4055-2006 Wind Loads For HousingSAI Global - APACPas encore d'évaluation

- As 4678-2002 Earth-Retaining StructuresDocument8 pagesAs 4678-2002 Earth-Retaining StructuresSAI Global - APAC50% (4)

- As 3735-2001 Concrete Structures For Retaining LiquidsDocument27 pagesAs 3735-2001 Concrete Structures For Retaining LiquidsTony PedaPas encore d'évaluation

- 3600-2018 v2Document10 pages3600-2018 v2Abid Ahmad0% (5)

- 3725 2007 PDFDocument49 pages3725 2007 PDFdhavalPas encore d'évaluation

- 4534-2006 Pre PDFDocument6 pages4534-2006 Pre PDFAhmad Jukliv Pandu YoedhawanPas encore d'évaluation

- As 4654.1-2009 Waterproofing Membrane Systems For Exterior Use - Above Ground Level MaterialsDocument8 pagesAs 4654.1-2009 Waterproofing Membrane Systems For Exterior Use - Above Ground Level MaterialsSAI Global - APAC0% (1)

- As 3700-2001 Masonry StructuresDocument9 pagesAs 3700-2001 Masonry StructuresSAI Global - APAC17% (18)

- As 4226-2008 Guidelines For Safe Housing DesignDocument9 pagesAs 4226-2008 Guidelines For Safe Housing DesignSAI Global - APAC0% (1)

- AS 1576.2 (2009) Scaffolding - Couplers and Accessories PDFDocument61 pagesAS 1576.2 (2009) Scaffolding - Couplers and Accessories PDFBastian PutraPas encore d'évaluation

- As 1562.3-2006 Design and Installation of Sheet Roof and Wall Cladding PlasticDocument7 pagesAs 1562.3-2006 Design and Installation of Sheet Roof and Wall Cladding PlasticSAI Global - APAC0% (2)

- As 3996-2006 Access Covers and GratesDocument7 pagesAs 3996-2006 Access Covers and GratesSAI Global - APACPas encore d'évaluation

- Australian/New Zealand StandardDocument8 pagesAustralian/New Zealand StandardcrisPas encore d'évaluation

- MasonryDocument8 pagesMasonryMarito da Silva Alves0% (1)

- As 3600Document10 pagesAs 3600ToniHospitaler0% (4)

- As 1725.4-2010 Chain Link Fabric Fencing Cricket Net Fencing EnclosuresDocument8 pagesAs 1725.4-2010 Chain Link Fabric Fencing Cricket Net Fencing EnclosuresSAI Global - APACPas encore d'évaluation

- Review of AS2870-2011Document3 pagesReview of AS2870-2011Kristin Munoz0% (1)

- 2870 11 SeminarDocument49 pages2870 11 SeminarOwen LinPas encore d'évaluation

- As 1170.4 - 2007 - Structural Design ActionsDocument57 pagesAs 1170.4 - 2007 - Structural Design ActionsDrRat P Ratanamalaya100% (5)

- As 3500.3.1-1998 National Plumbing and Drainage Stormwater Drainage - Performance RequirementsDocument7 pagesAs 3500.3.1-1998 National Plumbing and Drainage Stormwater Drainage - Performance RequirementsSAI Global - APACPas encore d'évaluation

- Preface: AS/NZS 1170.3:2003/amdt 1/2007-04-02Document7 pagesPreface: AS/NZS 1170.3:2003/amdt 1/2007-04-02Antonio Moralejo GilPas encore d'évaluation

- As 3660.3-2000 Termite Management Assessment Criteria For Termite Management SystemsDocument8 pagesAs 3660.3-2000 Termite Management Assessment Criteria For Termite Management SystemsSAI Global - APACPas encore d'évaluation

- Australian Standard: Inspection of Buildings Part 1: Pre-Purchase Inspections - Residential BuildingsDocument37 pagesAustralian Standard: Inspection of Buildings Part 1: Pre-Purchase Inspections - Residential BuildingswestozzPas encore d'évaluation

- 5100.5 - Conrete Design PDFDocument229 pages5100.5 - Conrete Design PDFAndy100% (1)

- AS2159 - 2009 - Piling Design & InstallationDocument97 pagesAS2159 - 2009 - Piling Design & InstallationMansoor AliPas encore d'évaluation

- 5100Document229 pages5100Zac Francis DaymondPas encore d'évaluation

- Ccaaguide2003 t49 Res Floors Web TBRDocument47 pagesCcaaguide2003 t49 Res Floors Web TBRLaura KinnearPas encore d'évaluation

- As NZS 1170.3-2003 Structural Design Actions Snow and Ice ActionsDocument8 pagesAs NZS 1170.3-2003 Structural Design Actions Snow and Ice ActionsSAI Global - APAC0% (2)

- As 3798-2007 Guidelines On Earthworks For Commercial and Residential DevelopmentsDocument8 pagesAs 3798-2007 Guidelines On Earthworks For Commercial and Residential DevelopmentsSAI Global - APAC0% (1)

- As 3623-1993 Domestic Metal FramingDocument7 pagesAs 3623-1993 Domestic Metal FramingSAI Global - APAC0% (1)

- Australian Standard: Guidelines For The Erection of Building SteelworkDocument0 pageAustralian Standard: Guidelines For The Erection of Building SteelworkZoran MatevPas encore d'évaluation

- Austroads Technical ReportDocument27 pagesAustroads Technical ReportelexdosPas encore d'évaluation

- Australian/New Zealand Standard: Vehicle Support StandsDocument17 pagesAustralian/New Zealand Standard: Vehicle Support StandsRiski FebriantoPas encore d'évaluation

- As 1160-1996Document18 pagesAs 1160-1996Alexandru LetPas encore d'évaluation

- Australian StandardDocument20 pagesAustralian StandardVasko DrogriskiPas encore d'évaluation

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionD'EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionPas encore d'évaluation

- A State-of-the-Art Guide for Post-Installed ReinforcementD'EverandA State-of-the-Art Guide for Post-Installed ReinforcementPas encore d'évaluation

- Traffic Engineering Manual Volume 2 Chapter 3 Signs and Devices General Principles June2014 Ed 4Document8 pagesTraffic Engineering Manual Volume 2 Chapter 3 Signs and Devices General Principles June2014 Ed 4EL-MUJAHIDPas encore d'évaluation

- Traffic Engineering Manual Volume 2 Chapter 10 Direction Signs and Route Numbering NonFreewaySep 2013 Ed 3Document126 pagesTraffic Engineering Manual Volume 2 Chapter 10 Direction Signs and Route Numbering NonFreewaySep 2013 Ed 3EL-MUJAHIDPas encore d'évaluation

- Open Channel FlowDocument59 pagesOpen Channel FlowZaid HadiPas encore d'évaluation

- 2041Document105 pages2041EL-MUJAHIDPas encore d'évaluation

- Biblical Names and Their MeaningsDocument58 pagesBiblical Names and Their MeaningsKumina Issachar0% (1)

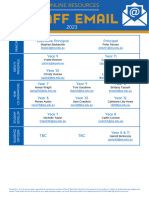

- 2023 Teacher Email ListDocument5 pages2023 Teacher Email ListmunazamfbsPas encore d'évaluation

- March For Our LivesDocument22 pagesMarch For Our LivesLucy HanPas encore d'évaluation

- An Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyDocument10 pagesAn Eastern Orthodox Understanding of The Dangers of Modernity and TechnologyTimothy ZelinskiPas encore d'évaluation

- I Pmtea 2020 HandoutDocument94 pagesI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- Brosur YSIO X.preeDocument20 pagesBrosur YSIO X.preeRadiologi RSUD KilisuciPas encore d'évaluation

- Days Papers 2001Document341 pagesDays Papers 2001jorgefeitoza_hotmailPas encore d'évaluation

- Brahms Symphony No 4Document2 pagesBrahms Symphony No 4KlausPas encore d'évaluation

- Bossypants Autobiography and Womens SelvesDocument26 pagesBossypants Autobiography and Womens SelvesCamila Paz GutiérrezPas encore d'évaluation

- Matrix PBX Product CatalogueDocument12 pagesMatrix PBX Product CatalogueharshruthiaPas encore d'évaluation

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaPas encore d'évaluation

- Web-Based Attendance Management System Using Bimodal Authentication TechniquesDocument61 pagesWeb-Based Attendance Management System Using Bimodal Authentication TechniquesajextopePas encore d'évaluation

- Data Network Unit 6 - UCDocument15 pagesData Network Unit 6 - UCANISHA DONDEPas encore d'évaluation

- De Thi Chon Hoc Sinh Gioi Cap Tinh Mon Tieng Anh Lop 12 So GD DT Thanh Hoa Nam Hoc 2015 2016Document11 pagesDe Thi Chon Hoc Sinh Gioi Cap Tinh Mon Tieng Anh Lop 12 So GD DT Thanh Hoa Nam Hoc 2015 2016Thuy LinggPas encore d'évaluation

- Psychoanalytic Theory byDocument43 pagesPsychoanalytic Theory byjoy millano100% (1)

- The Reason: B. FlowsDocument4 pagesThe Reason: B. FlowsAryanti UrsullahPas encore d'évaluation

- Concrete Specification (BS8500)Document3 pagesConcrete Specification (BS8500)teh100% (1)

- Pelayo PathopyhsiologyDocument13 pagesPelayo PathopyhsiologyE.J. PelayoPas encore d'évaluation

- Newsletter 1-2021 Nordic-Baltic RegionDocument30 pagesNewsletter 1-2021 Nordic-Baltic Regionapi-206643591100% (1)

- DN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFDocument64 pagesDN102-R0-GPJ-Design of Substructure & Foundation 28m+28m Span, 19.6m Width, 22m Height PDFravichandraPas encore d'évaluation

- Muscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityDocument11 pagesMuscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityPierePas encore d'évaluation

- Spare Part PhilosophyDocument27 pagesSpare Part Philosophyavaisharma50% (2)

- Play ClawDocument2 pagesPlay ClawFrenda SeivelunPas encore d'évaluation

- Women Are Better Managers Than MenDocument5 pagesWomen Are Better Managers Than MenCorazon ValdezPas encore d'évaluation

- Research Group 3 11abmb1Document32 pagesResearch Group 3 11abmb1arianePas encore d'évaluation

- Project Chalk CorrectionDocument85 pagesProject Chalk CorrectionEmeka Nicholas Ibekwe100% (6)

- Cambridge IGCSE: CHEMISTRY 0620/42Document12 pagesCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaPas encore d'évaluation

- CUBE Dealer Book 2009Document280 pagesCUBE Dealer Book 2009maikruetzPas encore d'évaluation

- John Wren-Lewis - NDEDocument7 pagesJohn Wren-Lewis - NDEpointandspacePas encore d'évaluation

- Openvpn ReadmeDocument7 pagesOpenvpn Readmefzfzfz2014Pas encore d'évaluation

- Healthymagination at Ge Healthcare SystemsDocument5 pagesHealthymagination at Ge Healthcare SystemsPrashant Pratap Singh100% (1)