Académique Documents

Professionnel Documents

Culture Documents

Norwegian Design Experiences of Unlined Pressure Shafts and Tunnels

Transféré par

Andres Mujica MorovicDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Norwegian Design Experiences of Unlined Pressure Shafts and Tunnels

Transféré par

Andres Mujica MorovicDroits d'auteur :

Formats disponibles

Published in International Conference on Hydropower. Oslo, Norway, 1987.

NORWEGIAN DESIGN AND CONSTRUCTION EXPERIENCES OF UNLINED PRESSURE SHAFTS AND TUNNELS

Arild Palmstrom Senior geo-engineer Ingenior A. B. Berdal A/S partner of Norconsult A.S Norway

SUMMARY The continuous development through 80 years of hydropower construction in Norway has lead to today's solutions of unlined waterways with up to 1000 m of hydrostatic head. Use of modern and more precise FEM design methods have resulted in safe locations of unlined pressure conduits. The increasingly common practice of checking the design values by in situ stress measurements and pore pressure measurements has contributed to the successful construction and operation of a number of high head conduits since the late seventies. In Norway there are more than 80 unlined, high head pressure shafts and tunnels. The method gives both a lower construction cost and a reduced capital cost during construction due to a shorter construction period for the entire scheme. In addition a considerable bonus is often added for faster coming on stream of the plants. Many other areas in the world have rock and topographical conditions suitable for a solution with unlined pressure waterway where considerable economical savings may be obtained.

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

1. INTRODUCTION Unlined means that no steel piping or continuous concrete lining is installed in the shaft or tunnel, with the result that the rock itself is under direct pressure from the water. The application of unlined pressure tunnels and shafts in hydropower construction started as early as 1919. The main reason was shortage of steel during and after the First World War. Four Norwegian power plants of such kind were put into operation between 1919 - 21. The benefits of the unlined design became more evident when Norwegian power houses were put underground in the 1950's, and from the middle 60's the unlined pressure shaft solution became traditional. From the late 60's the design with unlined pressure tunnels and unlined surge chamber with air cushion was introduced. Fig. 1 shows the development of steadily increasing heads in Norwegian unlined pressure conduits till today when more than 80 unlined pressure conduits with water head in excess of 150m are in use. The total length of unlined pressure shafts/tunnels in operation in Norway today is not known exactly, but is estimated to exceed 2000 km.

1200 Shaft Tunnel 1000 Nyset-Stegtje Tjodan 800 Tafjord K5

MAX. STATIC WATER HEAD (m)

600 Driva Tafjord K4 400 Tafjord K3 200 Svelgen (1921) Hovatn mla

Lomi

No information collected 0 1950 1960 1970 1980 YEAR 1990

Fig. 1. Development of unlined pressure tunnels and shafts. Modified after ref. (7).

2. IMPORTANT ROCK MASS PROPERTIES FOR UNLINED CONDUITS An unlined pressure conduit requires rock conditions able to withstand the internal water pressure both with regard to leakages and to deformations which can lead to failures. The rock material itself must therefore have a low permeability. This must also be the case for the rock masses with its joints and fractures. Even where the rock mass permeability is low, water will migrate into or out of a tunnel depending on the relation between natural ground water pressure and the pressure in the tunnel, i. e. the gradient. The main requirement is, however, that the rock mass conditions permit a steady, low leakage out of the unlined pressure conduit and that no deformations which may result in failures can develop. The main criteria for a possible unlined tunnel or shaft are therefore: - low permeability of rock material - low permeability of joints and fractures - rock stresses high enough to prevent deformations and opening of joints (hydraulic splitting) - durable rock masses (during the plant's lifetime)

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

As for all waterways in rock the rock mass conditions must be suitable for tunnelling. There are, however, no significant additional requirements for unlined conduits other than for ordinary waterways in rock. In most Norwegian hydropower projects there are portions of poorer rock mass conditions where comprehensive rock supporting works have to be carried out. In unlined pressure tunnels and shafts sealing works must often be applied in addition to reducing possible water leakages and possible washing out of soft gouge materials. It is of course important that the cases of such poor conditions are few in order to get the desired benefits out of the unlined design solution.

Table I. Important rock ground conditions for a beneficial application of unlined pressure waterways Rocks - rocks are suitable for tunnelling - rocks are "impervious" (i.e. permeability coefficient is lower than approx. 10-8 m/s) - rocks are durable Joints/weakness zones - possible to construct tunnel/shaft through the zone - limited amount of water-conductive joints where leaks may occur Rock stresses - rock stresses are high enough to prevent failure caused by hydraulic splitting in rock masses adjacent to tunnel/shaft

RESERVOIR

HEADRACE TU NNEL

PR ES SU RE

POWER STATION

SH AF T

ACCESS TUNN EL

TAIL RAC E TUNN EL

RESERVOIR

PRES SURE

POWER STATION

TUNN EL

ACCESS TUNN EL

TAIL RAC E TUNN EL

RESERVOIR

HEADRACE TU NNEL

ALT .

PR ES S

PRES SURE T UNN EL

UR E

PIPELINE TU NNEL

SH AF T

POWER STATION

Fig. 2. Different design solutions with unlined pressure tunnels and shafts

3. COMMON DESIGN OF UNLINED PRESSURE CONDUITS Fig. 2 shows the three main types of design solutions in current use. The pressure conduits have to be located deep enough to ensure sufficient rock pressure to withstand the internal water pressure. When the power house is located underground the distance with steel pipe from the turbine to the unlined tunnel/shaft portion can be made very short. This is highly beneficial since costs of such high pressure steel conduits are often very high.

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

1000

NYSET-ST EGGJE

MAX. UNLIN ED HEAD (m)

TJODAN

800

TAFJORD K V

600

HOVATN TAFJORD K IV

400

BYRTE JR UNDLAN D SA KALVEDALEN SMVAT NA GOU LASJOKKA

FJONE TYSSO II 200

SKOR A RTEREN

BJER KA

0 0 0. 3 1.0 1.2 1.4 1.6 1.8 2.0 2.2 CALCU LAT ED FACTOR OF SAF ET Y (F ) CALCU LAT ED FROM F EM MOD EL CALCU LAT ED FROM OVERBURD EN CRIT ERION LARGE, UNC ON TROLLED LEAKAGES OCCU RED

Fig. 3. Differences in factor-of safety based on the overburden and the FEM criterion for some Norwegian pressure tunnels and shafts. Modified after ref. (12).

It should be mentioned here that the rock types encountered have mostly been as expected. Insufficient rock stresses, sometimes in connection with unfavourable fractures, have caused the failures mentioned, the reason being that the design principles used at that time did not provide for adequate rock cover and hence the stress conditions became critical. Initiated by the experience gained from these failures, the design criteria have been further developed. This has gradually lead to today's design principles. Fig. 3 illustrates the difference in safety factors for the overburden design criterion compared with the FEM-analysis criterion. The FEM method gives a safety factor less than 1.0 for those unsuccessful projects. Had this design method been applied in those projects, the conduits would probably have been located differently and the failures would thus have been evaded. It should be stated here that all the eight failed power plants have been repaired by extending the steel pipe, by a reasonable increase in cost, and that all of them are in use today.

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

The FEM design diagrams have been developed at the Norwegian Institute of Technology, Trondheim. This work was initiated by Prof. Rolf Selmer-Olsen. A set of standard two-dimensional FEM diagrams have been worked out. As most Norwegian power houses are located inside valley sides, these diagrams represent valley slopes varying from 14 75o. A conservative assumption of h/w = 0.5 and a Poisson's ratio = 0.2 has been applied. The principle of this method is that the minimum rock stress shall be higher than the operational interior water pressure at the same location. These standard diagrams represent a useful tool in the feasibility stage of the project. They make it possible to find a preliminary location of the pressure tunnel/shaft, a location which in many cases has turned out to be the final one. The topography at the actual site must often be ."transformed" to cover the standard valley side profile. An example of this is shown in fig. 4, and the location is chosen based on the values representing the valley side and the internal water pressure. The use of this method is further described by Selmer-Olsen (13) and Broch (7, 8).

HWL = 896 800 H/d = 1.0 H/d = 1.1 0.9 1.25 1.3 500

fa Safety

UN LI NE D

ACTUAL TOPGRAPHY

TOPOGRAPHY IN FEM-MODEL

HWL

0.7

ctor F = 1.2

60

O

0.5

H/d = 1.25 for F = 1.2

0.3 0

1.5 -200 -200

SCALE

0 100 200 300 400 500m

Fig. 4. Transformation of the actual valley side profile at Tjodan Power Plant to be applied in standard FEM diagrams. Modified after ref. (12).

3 = 15.2 9 8

3 = 14.3 3 = 12.3 7

SANDTRAP PENSTOCK

3 = 12.7 3 = 11.1 3 = 21.5 5 4 6

LEGEND

12.3 7

POWER STATION

3 = 18 1

Hole for hydraulic fracturing test. Hole no. 7, 3 = 12.3 MPa

25 Scale

50m

Fig. 5. Hydraulic splitting tests carried out for the Nyset-Steggje power plant. Max. head on unlined rock is 1000 meters (after ref. (4).

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

1000 HWL 896 800

600

ELEVATION (m)

400

F = 1.0

F = 1.2 200 F = 2.0 0 0 F = 1.8 -200 F = 1.6 -400 F = 1.4 LOOSE DEPOSITS

Fig. 6. From the FEM analysis and the measured in situ rock stresses it is possible to calculate the factor of safety along the unlined pressure shaft with regard to hydraulic splitting and failure. The example is from the Tjodan power plant. (after ref. (12))

For some projects a special FEM analysis have been performed where the actual topographical and geological conditions at the site have been put into the model. By this analysis it is also possible to carry out calculations for various magnitudes of the assumed stress levels or other changeable conditions. As mentioned earlier there are always uncertainties regarding the true magnitude of the rock stresses occurring at the actual site. If the factor of safety used in the calculations is less than about 1.5, the rock stresses at the site should be verified by stress measurements. A relocation of the pressure conduit should be evaluated if the safety factor is less than about 1.15. Local conditions may, however, often play important role in these evaluations. 5. MEASURES DURING CONSTRUCTION AND FILLING UP OF THE SYSTEM In addition to the possible measurements of rock stress it is important - at least for projects with high gradient from the pressure conduit - to carry out a conscientious registration of the rock conditions encountered during tunnelling, with special emphasis on water leakages. This information will form the basis for evaluating rock support and water sealing of possible leakages to be performed before the unlined tunnel/shaft is filled with water.

Reinforcement bar

Rock bolt

AF

T

TURE FRAC

Grouted area

ZON E

DETAIL

Fracture zone

SH AF T

Shotcrete

Packer location

Grout holes

DETAIL of sealing works

Fig. 7. Rock support and sealing of a fracture zone in a shaft.

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

HEAD m 300 FILLING PAUSE FOR LEAKAGE MEASUREMENT

200

100

0 0 10 20 30 40 50 60 hour TIME

Fig. 8. Example of controlled, slow filling of a pressure conduit. (after ref. (9))

The last measure to be carried out to fulfil a safe construction of the unlined pressure waterway is a controlled and slow filling up of the system. The reason for this is explained in the following: - While a shaft or tunnel is being excavated, and afterwards, joints and pores in the surrounding rocks are drained and often emptied, a situation observed in the fact that the leakage fed by the groundwater is often greatly reduced over time. - When the system later is filled with water, the emptied joints and pores around the shaft become filled too. This generation of build-up of pressures may introduce a chance for deformations and a later possible washing-out of joints. - If leakage measurements are done during first, slow filling, unforeseen leakages can be observed early so that the tunnel system can be emptied in time before flooding occurs and major damage is caused.

LEAKAGE (l/s)

5 PO WE R PLA NT Le LEIRDLA ( sha ft) J 4 L JRUNDLAND (tu nnel)

L LOMI ( tun nel) T TJO DA N (shaft)

3 J

540 m HE AD

T L 2 450 m 237 m 710 m

1 Le J J 166 m 97 m 0 0 10 20 30 40 5 0 HO UR 405 m

TIME

Fig. 9. Measured net water leakage out from various unlined high pressure shafts/tunnels. Modified after ref. (9) and (12).

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

It is normal procedure to fill a shaft in steps or intervals of 10 - 30 hours. During the intervals the water level in the shaft is continuously and accurately monitored by an extra-sensitive manometer. By deducting for the inflow of natural groundwater and the measured leakage through the plug cone, it is possible to calculate the net leakage out from the unlined pressure tunnel/ shaft to the surrounding rock masses. From the about 5 - 6 pressure tunnels/shafts where leakage measurements have been carried out, an average permeability coefficient of 1 - 10 10-9 m/s has been calculated. With this very low permeability a leakage of 0.5 - 5 1/s per km has been measured. 6. BENEFITS OF UNLINED PRESSURE TUNNELS/SHAFTS The benefits of the solution of unlined pressure shaft/tunnel are these: - Cost savings during construction caused by the fact that the lining with steel penstock with concrete embedment is omitted. - A normally reduced construction time meaning an earlier start-up of the power plant and reduced capital costs. - A normally simpler design of the waterways. In many cases it is possible to omit construction adits, which in areas with steep topography can be of substantial costs. Finally it should be mentioned that the calculated cost savings at Tjodan power plant were about 6 mill. USD. The costs connected which geo-investigations, rock stress measurements and controlled filling up was 1 % of that saved amount. 7. CONCLUSION The successful design of the unlined pressure tunnel/shaft is ensured by: - a safe location with respect to the actual geology and topography (i.e. rock stress conditions) - a well planned concrete plug both in connection with the cone and the possible adit - a slow, controlled, first filling-up of the unlined waterway system - possible later emptying of the conduit and the later refilling should be done slowly to avoid possible deformations. Table II. Main evaluations during various design stages of an unlined pressure conduit.

STAGE CONCEPT STUDY FEASIBILITY DETAILED DESIGN PROCEDURE/INVESTIGATION study of topographical conditions; main, rough geological (mapping) view; estimate of possible location (overburden criteria or FEM standard diagrams). geological mapping; probable location based on FEM standard diagrams; detailed geological mapping; planned location based on special FEM analyses adapted to the topographical, geological and assumed rock stress conditions. rock stress measurements in access tunnel at the planned location of the cone to verify the magnitude of the assumed rock stresses (a possible relocating of the cone may be done at this stage); follow up of the geological conditions during construction of the pressure conduit; rock supporting works; sealing of fractures/zones where possible leakages may occur; controlled, slow filling-up the first time of the pressure conduit together with leakage measurements. slow filling or emptying of the pressure conduit.

DURING CONSTRUCTION

DURING PRODUCTION

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

The unlined pressure tunnel/shaft design has proved successful for many Norwegian hydro power projects. have made this possible, are not specific for Norway. The geological and topographical conditions which not specific for Norway. There exist lot of similar features in other parts of the world where the unlined pressure conduit design may be most beneficial to many future power plants. 8. ACKNOWLEDGEMENT The author would like to express thanks to senior civil engineer Erland Kleivan for valuable discussions and for help to improve the English text.

9. REFERENCES (1) Bergh-Christensen, J. 1974. Failure of the unlined pressure tunnel at the Askora hydropower plant (in Norwegian). Fjellsprengningsteknikk-Bergmekanikk, Oslo, Norway, 1974. (2) Bergh-Christensen, J. and Kjolberg, R. 1982 Investigations for Norway's longest unlined pressure shaft. Water Power and Dam Construction 34:4. (3) Bergh-Christensen, J. 1982 Design of unlined pressure shaft at Mauranger powerplant, Norway. ISRM Symposium Aachen. Balkema publishers. (4) Bergh-Christensen, J. 1985 Design of unlined pressure shaft at Nyset-Steggje hydropower project (in Norwegian). Fjellsprengningsteknikk-Bergmekanikk, Oslo, Norway 1985. Tapir publishers. (5) Bjorlykke, S., Selmer-Olsen, R. 1972 Necessary overburden for caverns with high internal water or air pressure (in Norwegian). Report no. 6, Department of Geology, Technical University of Norway. (6) Brekke, T. L., Bjorlykke, S., and Blindheim, O.T. 1970 Finite element analysis of the Byrte unlined pressure shaft failure. Symposium on Large permanent underground openings, Oslo, Norway. Universitetsforlaget publishers. (7) Broch, E., 1982 Development of unlined pressure shafts and tunnels in Norway. Underground space, vol. 8, 1984 (8) Broch, E., 1984 Unlined pressure tunnels in areas of complex topography. Water Power & Dam Construction, 36:11. (9) Buen, B., Palmstrom, A. 1982 Design and supervision of unlined hydropower shafts and tunnels with head up to 590 meters. ISRM Symposium Aachen. Balkema publishers. (10) Myrseth, O. and Lien, R. 1982 High pressure tunnel systems at Sima powerplant. ISRM Symposium Aachen. Balkema publishers. (11) Norwegian Geotechnical Institute, 1972 Norwegian unlined tunnels and shafts with more than 100 m static head (in Norwegian). Internal report, Norwegian Geotechnical Institute, Oslo.

Arild Palmstrom: Norwegian Design and Construction Experiences of Unlined Pressure Shafts and Tunnels Published in International Conference on Hydropower. Oslo, Norway, 1987.

10

(12) Palmstrom, A., Kollstrom, J. I. 1985 Construction of the unlined pressure shaft at Tjodan power plant (in Norwegian). Fjellsprengningsteknikk - Bergmekanikk. Tapir, Trondheim publishers. (13) Selmer-Olsen, R. 1970 Experience with unlined pressure shafts in Norway. Symposium on large permanent underground openings, Oslo, Norway. Universitetsforlaget publishers. (14) Selmer-Olsen, R. 1974 Underground openings filled with high-pressure water or air. Bull.Int.Ass. Engineering Geology 9. (15) Selmer-Olsen, R. 1985 Experience gained from unlined high pressure tunnels and shafts in hydroelectric poser stations in Norway. Norwegian soil and rock engineering association, publ. no 3. (16) Vogt, J. H. L. 1922 Pressure tunnels and geology (in Norwegian). Report no. 93. Norwegian Geological Survey (NGU), Oslo, Norway. .

Vous aimerez peut-être aussi

- Installation Guide For Instrument Cables, Conduits and Cable TraysDocument35 pagesInstallation Guide For Instrument Cables, Conduits and Cable TraysImran Mohiuddin100% (1)

- Tunnel and Shaft Construction For The Pingston Hydro ProjectDocument11 pagesTunnel and Shaft Construction For The Pingston Hydro ProjectZeynep Ahmet GülerPas encore d'évaluation

- WARNING SIGNS OF KICKSDocument45 pagesWARNING SIGNS OF KICKSMartin RiwuPas encore d'évaluation

- 205 Paper 350 - Design of The SMART Project-ADocument12 pages205 Paper 350 - Design of The SMART Project-Aodri5Pas encore d'évaluation

- Underground Construction TechonologyDocument107 pagesUnderground Construction TechonologyJose David GarciaPas encore d'évaluation

- Goel R.K. (2008) - Evaluation of TBM Performance in A Himalayan TunnelDocument11 pagesGoel R.K. (2008) - Evaluation of TBM Performance in A Himalayan TunnelAndres Mujica MorovicPas encore d'évaluation

- The Seventh Terzaghi LectureDocument28 pagesThe Seventh Terzaghi LectureJulio Solano100% (1)

- Tunnelling under squeezing rock conditionsDocument99 pagesTunnelling under squeezing rock conditionsPremnath Yadav100% (1)

- Development of SCL in UKDocument6 pagesDevelopment of SCL in UKRajesh SinghPas encore d'évaluation

- Analysis of Tunnel Support Design To Withstand Spalling Induced by BlastingDocument9 pagesAnalysis of Tunnel Support Design To Withstand Spalling Induced by BlastingSajjad AnwarPas encore d'évaluation

- Burnley Tunnel Fire A Courts Perspective Tunneling Journal March 2013Document4 pagesBurnley Tunnel Fire A Courts Perspective Tunneling Journal March 2013ALARP (Arnold Dix)100% (1)

- Full Text 01Document170 pagesFull Text 01123456Pas encore d'évaluation

- Oliveira Daniela GG 201809 PHDDocument286 pagesOliveira Daniela GG 201809 PHDDaniela Garroux RadhaPas encore d'évaluation

- Crockford A., Diederichs M., Heinz H. (2011) - TBM Selection and Performance Prediction For Shallow Tunnels in Interbedded Sandstones and SiltstonesDocument6 pagesCrockford A., Diederichs M., Heinz H. (2011) - TBM Selection and Performance Prediction For Shallow Tunnels in Interbedded Sandstones and SiltstonesAndres Mujica MorovicPas encore d'évaluation

- Latest Technology Ofunderground Rock Cavern Excavation in JapanDocument18 pagesLatest Technology Ofunderground Rock Cavern Excavation in JapanpbldzcmsPas encore d'évaluation

- Comparison of Tunnelling Methods Natm and Adeco-RsDocument7 pagesComparison of Tunnelling Methods Natm and Adeco-RsTony ChanPas encore d'évaluation

- Publication No 17 WEB PDFDocument90 pagesPublication No 17 WEB PDFAndres CampusanoPas encore d'évaluation

- Flow Assurance Presentation - Rune Time 3Document27 pagesFlow Assurance Presentation - Rune Time 3Adeel Jamil100% (1)

- 1 Laigle - Large and Deep Caverns FV2Document56 pages1 Laigle - Large and Deep Caverns FV2pawan paudelPas encore d'évaluation

- Ground Vibrations and Air Blasts: Causes, Effects and AbatementDocument21 pagesGround Vibrations and Air Blasts: Causes, Effects and AbatementDinesh KumarPas encore d'évaluation

- Diederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During TunnelingDocument28 pagesDiederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During Tunnelingfatihkaya_16Pas encore d'évaluation

- Geotechnical Design of Long High-Speed Rail TunnelsDocument27 pagesGeotechnical Design of Long High-Speed Rail TunnelsjodaobiuanPas encore d'évaluation

- Heat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)Document14 pagesHeat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)nadir adel100% (1)

- Sopport of Tunnel in Weak Rock-Jacobs AssociatesDocument22 pagesSopport of Tunnel in Weak Rock-Jacobs AssociateswjzabalaPas encore d'évaluation

- Diaphragm Wall - Soletanch BachyDocument4 pagesDiaphragm Wall - Soletanch BachymlakkissPas encore d'évaluation

- Shaft Design - NepalDocument9 pagesShaft Design - NepalBinodPas encore d'évaluation

- Geotek-Rock Engineering For UndergroundDocument48 pagesGeotek-Rock Engineering For UndergroundKiky Rizky IsalPas encore d'évaluation

- Design and Construction of Large Span Tunnels and Caverns in Sydney, AustraliaDocument9 pagesDesign and Construction of Large Span Tunnels and Caverns in Sydney, Australiadafo407Pas encore d'évaluation

- 81 PalmstromStille On Ground Behaviour and Tools PDFDocument19 pages81 PalmstromStille On Ground Behaviour and Tools PDFJacky LeongPas encore d'évaluation

- Lechler Brochure Tank Equipment Cleaning enDocument84 pagesLechler Brochure Tank Equipment Cleaning enAnonymous lswzqloPas encore d'évaluation

- Overcoming Squeezing in The Yacambu Quibor Tunnel PDFDocument33 pagesOvercoming Squeezing in The Yacambu Quibor Tunnel PDFajgarcesv7301Pas encore d'évaluation

- Tunneling in Swelling RocksDocument7 pagesTunneling in Swelling Rocksmic85Pas encore d'évaluation

- 3-day CertificateDocument25 pages3-day Certificateganesh kondikire100% (8)

- Rock Burst Mechanisms: BY: Saqib Ahmad Saki Eg Grad Colloquium Ms - Cv/EsDocument21 pagesRock Burst Mechanisms: BY: Saqib Ahmad Saki Eg Grad Colloquium Ms - Cv/EsDinesh KumarPas encore d'évaluation

- EFNARC (1999) - Excecution of SprayingDocument8 pagesEFNARC (1999) - Excecution of SprayingAndres Mujica MorovicPas encore d'évaluation

- EFNARC Guidelines Shotcrete enDocument35 pagesEFNARC Guidelines Shotcrete enourebooks100% (1)

- In-Situ Stress MeasurementDocument10 pagesIn-Situ Stress Measurementhagh1234Pas encore d'évaluation

- Robles Diversion Dam DDR 30percentDocument55 pagesRobles Diversion Dam DDR 30percentRodrigo Alvarez ArenasPas encore d'évaluation

- ASCE Paper PDFDocument8 pagesASCE Paper PDFLeandroPas encore d'évaluation

- CaissonsDocument30 pagesCaissonsYashu YashuPas encore d'évaluation

- On-Line Certificate in Tunneling at The University of Texas at AustinDocument16 pagesOn-Line Certificate in Tunneling at The University of Texas at Austinkulbrsingh4975Pas encore d'évaluation

- Water Control: ChairmanDocument23 pagesWater Control: ChairmanswhuntPas encore d'évaluation

- Site Formation Project Planning and ImplementationDocument116 pagesSite Formation Project Planning and ImplementationgkutPas encore d'évaluation

- M5 East - The Design of Australia's Longest Driven Motorway TunnelDocument7 pagesM5 East - The Design of Australia's Longest Driven Motorway TunnelHarold TaylorPas encore d'évaluation

- Analytical Tools For Managing Rock Fall Hazards in Australian Coal Mine RoadwaysDocument150 pagesAnalytical Tools For Managing Rock Fall Hazards in Australian Coal Mine RoadwaysScott DownsPas encore d'évaluation

- Rock Nail Design Guidelines for Central Texas Roadway CutsDocument353 pagesRock Nail Design Guidelines for Central Texas Roadway CutsThaungMyintPas encore d'évaluation

- Lombardi TunnelDocument26 pagesLombardi Tunnelani1167Pas encore d'évaluation

- Oslo Navet Tunnelboremaskiner NDocument55 pagesOslo Navet Tunnelboremaskiner NSérgio BernardesPas encore d'évaluation

- Composite Tunnel Linings Closed-Form SolutionDocument22 pagesComposite Tunnel Linings Closed-Form SolutionLuis ZhanPas encore d'évaluation

- Main tunnel lining types and considerations for designDocument13 pagesMain tunnel lining types and considerations for designSkshukla Shukla0% (1)

- Technical Considerations For The Design and Construction of Mine Seals To Withstand Hydraulic Heads in Underground MinesDocument9 pagesTechnical Considerations For The Design and Construction of Mine Seals To Withstand Hydraulic Heads in Underground Minesc.wolkePas encore d'évaluation

- Nce 1217 LR PDFDocument95 pagesNce 1217 LR PDFErnie Ernie100% (1)

- Time Dependent Movements On The Billy Bishop Toronto City Airport Pedestrian Tunnel, Ontario, CanadaDocument15 pagesTime Dependent Movements On The Billy Bishop Toronto City Airport Pedestrian Tunnel, Ontario, CanadaAndrew CushingPas encore d'évaluation

- 3-Room and PillarDocument67 pages3-Room and Pillardenis mejiaPas encore d'évaluation

- Geo Technical Investigation Volume 1Document23 pagesGeo Technical Investigation Volume 1Cele Adu-wusuPas encore d'évaluation

- Design Strengths For Over Consolidated Clays and Clay Shales Technical PaperDocument11 pagesDesign Strengths For Over Consolidated Clays and Clay Shales Technical Papermikegibbons27100% (1)

- Tunneling Business Magazine - 2016Document60 pagesTunneling Business Magazine - 2016yodainsaatPas encore d'évaluation

- The Stability of The Slopes of Earth Dams-ReiniusDocument9 pagesThe Stability of The Slopes of Earth Dams-ReiniusAnonymous GnfGTwPas encore d'évaluation

- RockEng09 ProceedingsDocument258 pagesRockEng09 Proceedingsdafo407Pas encore d'évaluation

- 15h30 Garland Likins 23 06 Plenaria 4x3Document71 pages15h30 Garland Likins 23 06 Plenaria 4x3Paula NejaimPas encore d'évaluation

- Benefits of Rock Cavern Development for Hong KongDocument23 pagesBenefits of Rock Cavern Development for Hong KongjausingchiPas encore d'évaluation

- FaultsDocument22 pagesFaultsDJanesaSPas encore d'évaluation

- Stability of An Immersed Tunnel in Offshore Conditions Under Deep Water Wave ImpactDocument8 pagesStability of An Immersed Tunnel in Offshore Conditions Under Deep Water Wave ImpactRonald HeijmansPas encore d'évaluation

- 2013 WTC2013Geneve-ChuquicamataUnderground PDFDocument9 pages2013 WTC2013Geneve-ChuquicamataUnderground PDFIvo FritzlerPas encore d'évaluation

- Water control key to Norwegian tunnel designDocument10 pagesWater control key to Norwegian tunnel designsonusk777Pas encore d'évaluation

- DSI ALWAG-Systems Pantex Lattice Girders EDocument8 pagesDSI ALWAG-Systems Pantex Lattice Girders Epramods_8Pas encore d'évaluation

- 1 s2.0 S0886779802000263 MainDocument10 pages1 s2.0 S0886779802000263 MainSteve VagliettiPas encore d'évaluation

- Improvement in The Overall Efficiency of Mining Equipment PDFDocument7 pagesImprovement in The Overall Efficiency of Mining Equipment PDFAndres Mujica MorovicPas encore d'évaluation

- Lötschberg Base TunnelDocument8 pagesLötschberg Base TunnelAndres Mujica MorovicPas encore d'évaluation

- Productivity and Cost Management - Franz Wentzel PDFDocument28 pagesProductivity and Cost Management - Franz Wentzel PDFDian'z AbimakznyuzzPas encore d'évaluation

- Improvement in The Overall Efficiency of Mining Equipment PDFDocument7 pagesImprovement in The Overall Efficiency of Mining Equipment PDFAndres Mujica MorovicPas encore d'évaluation

- Yagiz S. Et Al. (2009) - Factors Influencing Performance of Hard Rock Tunnel Boring 2Document6 pagesYagiz S. Et Al. (2009) - Factors Influencing Performance of Hard Rock Tunnel Boring 2Andres Mujica MorovicPas encore d'évaluation

- Moon H. (2001) - A Comparative Study On Five Assessment Systems of TBM TunnellingDocument9 pagesMoon H. (2001) - A Comparative Study On Five Assessment Systems of TBM TunnellingAndres Mujica MorovicPas encore d'évaluation

- Broch E., Grov E. (2008) - Construction of Long Traffic Tunnels in NorwayDocument10 pagesBroch E., Grov E. (2008) - Construction of Long Traffic Tunnels in NorwayAndres Mujica MorovicPas encore d'évaluation

- Optimization Linear Programming in The MineCus Material Haulage PDFDocument23 pagesOptimization Linear Programming in The MineCus Material Haulage PDFAndres Mujica MorovicPas encore d'évaluation

- 6 PDFDocument8 pages6 PDFAndres Mujica MorovicPas encore d'évaluation

- Bilgin N. Et Al. (2005) - From Research To Practice Development of Rapid Excavation Technologies 2Document8 pagesBilgin N. Et Al. (2005) - From Research To Practice Development of Rapid Excavation Technologies 2Andres Mujica MorovicPas encore d'évaluation

- Ramezanzadeh A. - Performance Prediction Models For Hard Rock Tunnel Boring MachinesDocument15 pagesRamezanzadeh A. - Performance Prediction Models For Hard Rock Tunnel Boring MachinesAndres Mujica MorovicPas encore d'évaluation

- Pelizza S. (2000) - TBM Bored Long Rock TunnelsDocument3 pagesPelizza S. (2000) - TBM Bored Long Rock TunnelsAndres Mujica MorovicPas encore d'évaluation

- Lötschberg SafetyDocument6 pagesLötschberg SafetyAndres Mujica MorovicPas encore d'évaluation

- Double Shield TBM 2009 USDocument2 pagesDouble Shield TBM 2009 USAndres Mujica MorovicPas encore d'évaluation

- Barton N. (2005) - A Critique of Qtbm. Tunnels and Tunnelling InternationalDocument4 pagesBarton N. (2005) - A Critique of Qtbm. Tunnels and Tunnelling InternationalAndres Mujica MorovicPas encore d'évaluation

- Bilgin N. Et Al. (2006) - TBM Cutting Performance in IstanbulDocument3 pagesBilgin N. Et Al. (2006) - TBM Cutting Performance in IstanbulAndres Mujica MorovicPas encore d'évaluation

- Javad M. (2009) - The Reliability of A TBMDocument6 pagesJavad M. (2009) - The Reliability of A TBMAndres Mujica MorovicPas encore d'évaluation

- Barton N. (1996) - Characterization and Seismic For Design and Execution of TBM ProjectsDocument16 pagesBarton N. (1996) - Characterization and Seismic For Design and Execution of TBM ProjectsAndres Mujica MorovicPas encore d'évaluation

- Risk Management TrendsDocument278 pagesRisk Management TrendsAndres Mujica Morovic100% (1)

- CHEMIST LICENSURE EXAM TABLEDocument8 pagesCHEMIST LICENSURE EXAM TABLEJasmin NewPas encore d'évaluation

- FMC Product OverviewDocument32 pagesFMC Product OverviewGustavoSilvinoSilvinoPas encore d'évaluation

- HexaneDocument3 pagesHexaneIan RidzuanPas encore d'évaluation

- Hydrostatic Testing Procedure 02250-1Document2 pagesHydrostatic Testing Procedure 02250-1RanielPas encore d'évaluation

- Sugar Industry in Pakistan (17-UGLC-650)Document16 pagesSugar Industry in Pakistan (17-UGLC-650)Waqar IbrahimPas encore d'évaluation

- 7 Transformer-ProtectionDocument42 pages7 Transformer-Protectionmuaz_aminu1422Pas encore d'évaluation

- DCVDocument35 pagesDCVTanoj Patro100% (1)

- ACB17 - ALC Plant Quotation by EssarconDocument2 pagesACB17 - ALC Plant Quotation by EssarconSamrat PrajapatiPas encore d'évaluation

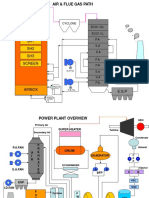

- Air & Flue Gas Path CFBCDocument2 pagesAir & Flue Gas Path CFBCJAY PARIKHPas encore d'évaluation

- Fundamental Behavior of FireDocument1 pageFundamental Behavior of FireirfanPas encore d'évaluation

- Turbo CompressorDocument6 pagesTurbo Compressorrajanrane420Pas encore d'évaluation

- Ega125 gr05 Emsc SG 0001 20200925Document238 pagesEga125 gr05 Emsc SG 0001 20200925api-292325707Pas encore d'évaluation

- Pharmaceutical Refrigerators with Built-In FreezerDocument2 pagesPharmaceutical Refrigerators with Built-In FreezerEslam HassanPas encore d'évaluation

- Fundamental Laws of Chemistry Explained Atomic Theory DevelopmentDocument10 pagesFundamental Laws of Chemistry Explained Atomic Theory DevelopmentDonni MaruliPas encore d'évaluation

- 3 Goshu 3Document18 pages3 Goshu 3nega cheruPas encore d'évaluation

- Technical Specification TREO CF I48CA1Document1 pageTechnical Specification TREO CF I48CA1Razvan CorciuPas encore d'évaluation

- Introduction To Batteries - BatteryDocument17 pagesIntroduction To Batteries - BatteryJ dixojoPas encore d'évaluation

- Techniques de Commande Des Machines Electriques - Cours Et Problèmes..Document2 pagesTechniques de Commande Des Machines Electriques - Cours Et Problèmes..Tko ToolPas encore d'évaluation

- The Petroleum (Refining Conversion Transmission and Midstream Storage) Act 2013Document80 pagesThe Petroleum (Refining Conversion Transmission and Midstream Storage) Act 2013African Centre for Media ExcellencePas encore d'évaluation

- Pump QuotationsDocument3 pagesPump Quotationsdibyendu65Pas encore d'évaluation

- Sil IndexDocument162 pagesSil IndexBenjamin Strickland100% (1)

- Pure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MDocument2 pagesPure Epoxy Primer (Zinc and Lead Free) 1 X 50 M Micaceous Iron Oxide 2 Pack Epoxy 2 X 100 M Polyurethane-Acrylic 1 X 50 M Total 300 MTrịnh Đức HạnhPas encore d'évaluation

- Alfa Laval Koltek MH Valve enDocument8 pagesAlfa Laval Koltek MH Valve enjpsingh75Pas encore d'évaluation

- MMTDocument36 pagesMMTAvoyPas encore d'évaluation

- Clase 05 - Chapter 9 - AAS-experimentalDocument44 pagesClase 05 - Chapter 9 - AAS-experimentalLuisa GallegoPas encore d'évaluation