Académique Documents

Professionnel Documents

Culture Documents

A Frame Work For Selecting Green and Reliable Suppliers Using Combinatorial Auctions

Transféré par

Prashanth Natarajan IyerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Frame Work For Selecting Green and Reliable Suppliers Using Combinatorial Auctions

Transféré par

Prashanth Natarajan IyerDroits d'auteur :

Formats disponibles

PURDUE UNIVERSITY

A frame Work for Selecting

Green and Reliable

Suppliers Using

Combinatorial Auctions

IE590 Final Report

Cretier, Philippe

Gopalan, Haresh

Min, Yohan

Natarajan, Prashanth

11/20/2012

TABLE OF CONTENTS

Contents

ABSTRACT ........................................................................................................................................................ 4

INTRODUCTION ............................................................................................................................................... 5

PROBLEM DEFINITION ..................................................................................................................................... 7

LITERATURE REVIEW ........................................................................................................................................ 8

FUNCTION DEVELOPMENT ............................................................................................................................. 11

4.1 BID COST ............................................................................................................................ 11

4.2 OPERATIONAL COST .............................................................................................................. 11

4.2.1 Capacity Score ..................................................................................................................................... 11

4.2.2 Lead time Score ................................................................................................................................... 12

4.2.3 Quality Score ....................................................................................................................................... 12

4.3 ENVIRONMENTAL COST .......................................................................................................... 13

4.3.1 Emissions ............................................................................................................................................. 13

4.3.2 Certification ......................................................................................................................................... 18

4.3.3 Energy Score (L

s

) .................................................................................................................................. 18

4.3.4 Wastage Score (M

s

)............................................................................................................................. 18

4.3.5 Packaging and sourcing Score (N

s

) ...................................................................................................... 18

4.4 COMBINATORIAL AUCTION ..................................................................................................... 19

EXPERIMENTAL ANALYSIS .............................................................................................................................. 21

5.1. EXAMPLE TESTED ................................................................................................................. 21

5.2. OPERATIONAL COSTS ............................................................................................................ 21

5.2.1 Capacity Score ..................................................................................................................................... 21

5.2.2 Leadtime Score .................................................................................................................................... 22

5.2.3 Quality Score ....................................................................................................................................... 23

5.3 ENVIRONMENTAL COST .......................................................................................................... 24

5.3.1 Energy Score ........................................................................................................................................ 24

5.3.2 Wastage Score .................................................................................................................................... 26

5.4 IMPACT OF THE OPERATIONAL AND ENVIRONMENTAL COSTS ............................................................ 28

DISCUSSION, CONCLUSIONS AND FUTURE WORK .......................................................................................... 30

REFERENCES ................................................................................................................................................... 31

LIST OF TABLES

Chapter III

Table 3.1: Summary of international environmental protocols and agreements

Table 3.2: Example of local regulations related electronic goods, car and chemical materials

Chapter IV

Table 4.1: Operational cost parameters description

Table 4.2: Quantified emission limitation targets in annex b to the kyoto protocol

Table 4.3: Quantified emission limitation commitment on each country

Table 4.4: Initial assigned amount of annex i parties

Table 4.5: History of carbon dioxide emissions in the us

Table 4.6: Allowable emissions from foundry cupolas

Table 4.7: Emission limits for pollutants from a designated facility

Table 4.8: NOx emissions limits for institutional boilers

Table 4.9: Elimination criteria for each area

Table 4.10: Packaging material sourcing scoring method

Chapter V

Table 5.1 Energy usage standards used in the experimental analysis

Table 5.2: Model result for three scenarios

Abstract

This project presents a combinatorial auction based methodology to solve a supplier selection

problem based not only in the asked price for a set of products, but considering also the operational

and environmental cost of each supplier. The objective is to minimize the total buyer cost subject to

the fulfillment of the demand considering the possible costs due by operational and environmental

criteria. The operational cost depends essentially on the evaluation of some defined parameters

Using Rank based relative scoring of suppliers whereas the environmental cost is defined by a mix of

the fulfillment of some defined certifications and environmental regulations and some defined

parameters, using the Rank based relative scoring of suppliers as well.

CHAPTER I

Introduction

The supply chain is a key factor within business, because it allows the movement of goods and then

to generate revenue. The economic impact of supply chain is critical, because for a company, it could

make the difference between being in and being out of the business. For instance, according the

Twenty-Second Annual State of Logistics report, published in June 2011, the supply chain costs in

United States were 8.3% of the overall US gross domestic product; an estimated of $1.25 trillion.

Considering the current highly competitive market environment, being able to maximize efficiency

through procurement, manufacturing and distribution is a must. The supply chain management

strategy tries to benefit the entire system right from upstream through midstream until

downstream. However, trying to maximize the supply chain performance only from a cost point of

view will not be longer sustainable, given that in these days and for sure in the future, the

environment factors are evolving as important conditions to maintain market share.

Environmental aspects are rapidly emerging as important factors for business organizations to

consider. Public and governmental pressure makes them change the way they do their business.

Every company wants to be go green but do not want any reduction in profits due to that. To

produce a framework for green practices to satisfy the public interest in terms of environmental

protection as well as companys interest of making profits is a big challenge for the academic world

today. Organizations have attempted to respond by developing products/services which, for

example, use less packaging, reduce pollution and/or decrease energy consumption. But a proper

framework which satisfies both sides is yet to be produced.

Humphreys, Wong and Chan [1] indicate that companies are going on board on two change

processes: reducing the number of firms in the supply chain base and establishing closer and

collaborative relationships with the remaining companies. Then, as the supply base reduces the

number of suppliers, for them implementing environmental management programs as differential

factor, could give them a competitive advantage.

In fact, trying to select the best supplier from a pool is not an easy task. Indeed, this is a big

challenge and gets harder when more variables (quantitative and qualitative) as environmental

factors or operational are added into the decision. There are many studies about supplier selection

using auctions as decision tool, however, there is no much literature about green and reliable

supplier selection.

This project addresses the winner determination problem (WDP) in order to determine the winner

suppliers, based not only on the bids they submit, but also in the environmental and operational

attributes. Many to One combinatorial auctions arise as the tool for solving this problem. Abrache,

Gabriel, Gendreau and Rekik [2] describe the configuration of these auctions as one buyer who

needs to obtain a set G of items supplied by several potential sellers who make bids. Rekik and

Mellouli [3] proposes a model where the allocation of long-term contracts to carriers is decided with

respect to both ask-prices and unexpected hidden costs, which represent the possible additional

costs that the buyer may incur when dealing with a series of winning suppliers.

Based in the previous description, this project has three main objectives:

1. To identify operational and environmental factors which influence the company selecting

criteria,

2. To develop a framework of supplier selection process which incorporates operational and

environmental factors

3. To use the framework to develop a mathematical model for suppliers selection.

CHAPTER II

Problem Definition

This project is trying to bridge the gap between green practices to satisfy the public interest in

terms of environmental protection and companys interest of making profits by contributing a

solution to the environmental part of this big problem. Furthermore, it integrates environmental

factors with other kind of factors like quality, lead time and capacity, called in this project as

operational factors, in order to take the best decision at the moment of select a supplier.

Logistic cost has been considered in entirely monetary concept. But, nowadays as in the USA and

other countries became more aware of environmental problems owing to the climate change, air

pollution, and so forth, environmental concern has been taken in logistics field. This is how Green

Logistics is emerged.

The Green Supply Chain concept is established based on the sustainable development approach.

Green logistics is a concept that takes in consideration of environmentally, socially friendly and

economically factors. The Green Supply Chain approach seeks to reduce a product or services

ecological impact as less as possible. Currently, many companies are being proactive getting green

certifications and becoming green by themselves, but for sure, in few more years being green will be

a must in order to participate in the market. Then, the companies which are not able to meet these

green requirements, they will lose market share and as a consequence will be probably out of the

industry.

In this project we will develop a framework for supplier selection through which we are going to

address the problem of selecting green and reliable suppliers without any decrease in profits for

an organization. The reason for taking the supplier selection as the base of our project is because we

believe that is the first step for any organization, be it manufacturing or services, to do sustainable

business. They need suppliers to supply the materials for their products to be made in the first place.

If we go to the source of those materials and make it green and reliable, there will be a progressive

change in overall supply chain.

CHAPTER III

Literature Review

Several studies have been conducted to show the importance of considering attributes other than

cost for supplier selection (Rekik and Mellouli [3]). They present a reputation-based winner

determination problem for transportation procurement auctions where the allocation of long-term

contracts to carriers is decided with respect to both bid ask-prices and carriers reputation. The

objective is to manage the trade of between transport costs and the quality service during

operations. They use a concept called unexpected hidden cost to represent the possible additional

cost that the shipper may incur when dealing with a set of winning carriers and this cost depends

essentially of the carrier reputation which is evaluated by the shipper using a number of defined

service attributes.

P.K. Humphreys, Y.K. Wong, F.T.S. Chan [1] devised a framework for integrating environmental

factors into the supplier selection process. They created as decision support system for the

companies to look when selecting a supplier. They separated the environmental criteria into two

types namely Qualitative environmental criteria and Quantitative environmental criteria. These two

categories are classified into seven different sub groups, each having several sub-criteria. The

companies are divided into two types namely Proactive and reactive companies. A decision support

system which integrated these environmental criteria into the supplier selection process was built

and provides guidelines for the purchasing managers to select suppliers from an environmental

viewpoint.

To solve this problem, many to one combinatorial auction (sometimes called reverse combinatorial

auctions) arise as a convenient tool. According Abrache, Gabriel, Gendreau and Rekik [2] in this kind

of auctions configuration, one buyer needs to obtain a set G of items, supplied by several potential

sellers. A bid b is made by a seller and considering the whole set of bids B, a binary decision variable

is defined as xb = 1 if bid b wins and 0 otherwise. In order to show the powerful of reverse

combinatorial auctions, some applications of this tool in recent years which can be cited are:

trucking service acquisition for Sears Logistical Services (Ledyard et al. [4]), procurement of direct

inputs for a food manufacturer (Davenport and Kalagnanam [5]; Hohner et al. [6]), and assignment

of nationwide meal service contracts by the Chilean government (Epstein et al. [7])

Regarding the environmental regulations, currently, there are many protocols and agreements that

the countries have signed and that, obviously, affect the way in what companies do business. [8.1]

For instance: (1) Kyoto protocol is to enforce former conventions to keep the countries to observe

the agreement regarding greenhouse gases such as CO2, CH, N2O, PFCs, HFCs, and SF5, [8.2] (2)

Venna convention (Montreal Protocol) is to develop a global convention on the ozone layer. The

following table summarizes the target for each year of International regulations. [8.3]

The center ideas behind protocols are described below and summarized in table 1:

The Basel Accord is to reduce the transference of hazardous waste among countries to minimize the

toxicity of wastes generated. [8.4]

POPs (Persistent Organic Pollutants) is to restrict the production of persistent organic pollutants

intentionally produced. [8.5]

ErP (Energy-related Products) replaced Eco-Design Directive (EuP) on November 20, 2009. The old

one covered products such as a microwave and a television. The new one covers not olny products

under the EuP but also products that are energy-related but not directly use energy such as glazing

windows and showerheads. [8.6]

TABLE 3.1: SUMMARY OF INTERNATIONAL ENVIRONMENTAL PROTOCOLS AND AGREEMENTS [8]

REACH is the European Community Regulation on chemicals and their safe use (EC 1907/2006). It

deals with the Registration, Evaluation, Authorisation and Restriction of Chemical substances. [8.7]

WEEE (Waste Electric & Electrical Equipment) is for reuse, recycling and recovery of electrical

equipment. They require productors WEEE symbol labeling, recycling information, and production

details implemented on their goods. [8.8]

RoHS (Restriction on Hazardous Substances) is to prohibit the usage of hazardous substances that

Pb, Hg, Cadmium, Crom, PBBs and PBDE over the standard usage will be banned in market in EU.

[8.9]

ELV (End-of-Life Vehicles) was adopted to stop the problem of vehicles created between 8 and 9

million tonnes of waste in the European. [8.10]

Euro II - VI (European emission standards) determine the limits for exhaust emission gases of new

vehicles sold in EU. Nitrogen oxides (NOx), Carbon monoxide (CO) and Particulate Matter (PM) are

limited for most vehicle types such as cars, trains and similar vehicles. [8.11]

Table 2 below shows some of examples of local regulations related electronic goods, car and

chemical materials.

TABLE 3.2: EXAMPLE OF LOCAL REGULATIONS RELATED ELECTRONIC GOODS, CAR AND CHEMICAL MATERIALS

Therefore, as we presented previously, there are many regulation and protocols which are necessary

to consider at the moment of getting certain kind of product or service from a supplier, which are

not being considered if the decision is only taken by considering the supplier asked price.

CHAPTER IV

Function Development

The aim of this project is to come up with a tool which can help the buyer to decide which out of the

number of given suppliers provides the best balance of low cost, operational and a

green/environment friendly solution. In order to do that, combinatorial auctions will be used as

selection tool and the solution will be developed in four steps which are described ahead.

4.1 Bid Cost

At the beginning of the auction, the Company communicates its product requests to the market.

Based on the request, the suppliers Bid for the product. The First step is to obtain the bids submitted

by the suppliers for the products and then, all the bids are tabulated.

4.2 Operational Cost

The Operational cost is divided into three sub criteria namely Capacity, Lead time and quality. Each

criteria there is a score associated with a score where 1 is the best minimum score i.e, Best supplier

for each product will get a value of 1 and other will have values more than that based on their

performance in each criteria.

Criteria Capacity Leadtime Quality

Criteria Scores B

s,i

C

s,i

D

s,i

Supplier (s) for each

item (i)

1,1 1,1 1,1

: : :

n,m n,m n,m

Table 4.1 Operational cost parameters description

4.2.1 Capacity Score

First, Each suppliers capacity for each product is obtained. Two components make up the capacity

score. One is Fulfillment of Demand i.e. whether the supplier with his capacity for a particular

product can fulfill the demand of the customer at one go. This score can either be one or zero. If

fulfilled the score will be 1 and if not 0.

Fulfillment = 1 {if (capacity /demand) >=0}

= 0 {If (capacity /demand) <0}

The second Component is Penalty/Reward. This depends on the first component. If the supplier can

fulfill the demand with his capacity and that capacity is greater than the demand then he is given a

reward. If he cannot fulfill the demand of a particular product with his capacity then he is given a

penalty.

Reward/ Penalty = (capacity/demand) {If fulfillment =0}

= ((capacity-demand)/ (demand*100)) {If fulfillment =1}

The sum of the two scores gives the capacity score for each supplier for each product.

CAPACITY SCORE =Fulfillment of demand + Penalty/reward

Each supplier is ranked based on the above score for each product. The difference between the

minimum score supplier and the other suppliers are calculated. The best supplier gets a Final Lead

time score 1, While others will get 1 plus the difference calculated based on their ranks.

4.2.2 Lead time Score

The lead time score for each supplier for each product is calculated by first obtaining lead time

values for each supplier for delivering each product. Based On his capacity for a particular product,

supplier may need more than one lead time to satisfy the demand of the customer. Lead time values

obtained from the supplier are multiplied with a number based on the capacity of the supplier to

satisfy the demand.

Lead time score = [(Demand of product i/Capacity of the supplier s for product i) rounded off to

the Next integer]*Lead time for the product i for supplier s

C

s,I

=[(D

i

/cap

s,i

)*L

s,i

Each supplier is ranked based on the above score for each product. The difference between the

minimum score supplier and the other suppliers are calculated. The best supplier gets a Final Lead

time score 1, While others will get 1 plus the difference calculated based on their ranks.

4.2.3 Quality Score

First supplier quality certification is checked i.e. whether the supplier holds an ISO9001:2008

certification. Then the Number of defects of the products obtained from the supplier from the

previous historical data or from the Quality audit. Then operational of the supplier is

calculated from the historical data available about the supplier or from his present demand

fulfillment ability. Then the data, the service level score is obtained from difference between 100%

service level and number of defects score is obtained from difference between six sigma defect

value which is 3.4 and the supplier value. The total score is calculated by the addition of all the three

scores and rank suppliers in each product category. The difference between the minimum score

supplier and the other suppliers are calculated. The best supplier gets a Final Lead time score (D

s,i

) 1,

While others will get 1 plus the difference calculated based on their ranks.

For example, when considering the first supplier, we find the function value at each step till we

finally reach an end value which encompasses all the criteria.

Supplier s function value considering Capacity for item i = B

s,i

Supplier s function value considering Lead time for item i = C

s,i

Supplier s function value considering Quality for item i = D

s,i

Then, for instance, the final Operational cost function for supplier 1 per item i is:

B

1,i

+ C

1,i

+ D

1,i

= O

1,i

The general Operational cost function for a supplier s and item i is:

O

s,i

= B

s,i

+ C

s,i

+ D

s,i

4.3 Environmental Cost

Within the Environmental criteria, suppliers will be judged based on their availability to achieve a

minimum value on the environmental criteria selected .There are five different criteria and two

criteria are elimination criteria and other three are scoring criteria for selection. The elimination

criteria are

1. Emissions

2. Certification

The three scoring criteria are

1. Energy Score

2. Wastage Score

3. Packaging and Sourcing Score

4.3.1 Emissions

With respect to elimination process, there is contribution to the environment of each country which

should be taken into consideration where suppliers from different countries to be considered to

bear burden. Below is the emission reduction assigned in each country. In case of the US, it was -7%.

TABLE 4.2: QUANTIFIED EMISSION LIMITATION TARGETS IN ANNEX B TO THE KYOTO PROTOCOL [10]

Percentage of emission assigned in each country where over 100% means that they are entitled to

more emission than the one in the base year respectively is shown below. The US is 93, as its

obligation is 7%.

TABLE 4.3: QUANTIFIED EMISSION LIMITATION COMMITMENT ON EACH COUNTRY; ANNEX B [10]

After all, below is the amount of emission each country is allowed to emit.

TABLE 4.4: INITIAL ASSIGNED AMOUNT OF ANNEX I PARTIES [10]

Emission in the US in 2012 is projected to be the one in 1990 as they are supposed to do, which is

5,000 MMT below as each country has made an effort to reduce emission concerning more about

environment impact.

Graph 4.1: Trend of USA CO2 emissions [9]

TABLE 4.5: HISTORY OF CARBON DIOXIDE EMISSIONS IN THE US [11]

There are independent rules in each state. In case of Indiana, carbon monoxide emissions shall be

released at such elevation that the maximum ground level concentration from a single source shall

not exceed twenty percent (20%) of the maximum one (1) hour Indiana ambient air quality value for

carbon monoxide. [12]

For specialized type of industry for emission limitation, find the below regarding foundries.

TABLE 4.6: ALLOWABLE EMISSIONS FROM FOUNDRY CUPOLAS [12]

Emission limits for designated facilities as below.

TABLE 4.7: EMISSION LIMITS FOR POLLUTANTS FROM A DESIGNATED FACILITY [12]

Emission limits of NOx for boiler.

TABLE 4.8: NOX EMISSIONS LIMITS FOR INSTITUTIONAL BOILERS [12]

As there are specific regulations to limit certain type of gas emission in each country, even in a state,

first, general international policy should be considered. It is divided into 3 areas for the elimination

step regarding emissions; gas emission, waste and elec. equipment. Weight factor of each criteria

derived from each policy was assigned on them. Each factor can have max. 1 which will be used for

score of the policy where 1 is the max. value. As per the related policies applied to the suppliers

concerned about, the total score can be developed by averaging the score on each policy by sum of

score of related policies over the number of the policies. For example, if the supplier couldnt meet

the requirement of gas emission of CO2, CH, N2O, PFCs, HFCs, SF5 of 5.2% down as per the Kyoto

protocol, it will get 1 in a& b respectively and according to the function 1-0.5(a+b), it would be 0. As

the supplier is unable to meet the demands held by the protocol, they will be eliminated from the

list.

TABLE 4.9: ELIMINATION CRITERIA FOR EACH AREA [8]

*1 is the best score on each policy

*Each factor is estimated with max. 1 based on criteria

*Total score is sum of score of related policies over the number of the policies

No. Area Contents Factors Criteria

Weight

Factor

Remark

a CO2,CH,N2O 5.2% down 0.5

b PFCs,HFCs,SF5 5.2% down 0.5

c CFC13 20% down 0.4

d Freon Never use 1

e Halon Never use 1

f

Carbon

tetrachloride

Never use 1

g Methyl chloroform 70% down 0.3

h Methyl bromide 70% down 0.3

i CO2 (G) 1 0.2

j Nox (G) 0.08 0.2

k CO2 (D) 0.5 0.2

l Nox (D) 0.25 0.2

m PM (D) 0.025 0.2

n Wast cross boader trading to be prohibited Waste trade Waste history Doc. Submission 1 1-n

o Pesticide, dioxine control

21 substances

prohibited

Related

hisotry Doc.

Submission

1 1-o

p

non - environment friendly goods

to be sold in EU

Friendly Good

proof

Simbol

labeling

1 1-p

q

Registration, Evaluation, Authorisation and

Restriction of Chemical substances

Chemical

registeration

Registeration

History Doc.

Submission

1 1-q

r

Prohibited material

(Pb,Hg,Crom)

Never use 1

s Recovery % 85% 0.5

t Recycling % 80% 0.5

u Collecting sys. Established 1

v Recovery % 70 - 80% 0.5

w Recycling % 50 - 70% 0.5

x

Pb, Hg, Cadmium, Crom, PBBs, PBDEs

never to use

Prohibited material

(Pb, Hg, Cadmium,

Crom, PBBs, PBDEs)

Never use 1 1-x

End-of-Life Vehicles

Waste Electric & Electrical Equipment

Policies

g/km

Green house gas to be 5.2% decreasing

CO2, CH, N2O decreasing based on 1990

PFCs, HFCs, SF5 decreasing based on 1995

Green

House

Kyoto

protocol

for the Protection of the Ozone Layer

(Montreal)

1-0.5(a+b)

1-0.4c-

0.3(g+h)-

(d+e+f)

1-

0.2Sum[i:

m]

1-r-

0.5(s+t)

1-u-

0.5(v+w)

Waste

Elec.

Equipment

Basel

Accord

Stockholm

(POPs)

ErP

REACH

ELV

WEEE

RoHS

Gas

Emission

Ozone

Vehicle

Exhaust

Gas

EURO

2 - 6

Viena

Conventi

on

4.3.2 Certification

Since this criterion is used in the elimination step, Supplier with ISO14001 certification will be put in

to selection process. The suppliers without the ISO14001 certification will be eliminated from the

supplier pool and will not be considered for selection.

4.3.3 Energy Score (Ls)

For Calculating the energy Score, First, The electricity consumption, Natural gas consumption, fuel oil

consumption used for all the twelve months of the previous year and the percentage of renewable

energy used are obtained from the supplier. Averages of those values are obtained. The other way

to do this can be using the historical data available with the company. The Averaged values are

ranked from minimum to maximum. Then the final score will be one for the minimum value supplier

and for other suppliers the final score will be one plus the difference between their value and the

minimum value.

4.3.4 Wastage Score (Ms)

For calculating wastage score, first, based on the Texas government regulations (any state

regulations in which the supplier operates can be used, we have used Texas government rules for

the ease of use) for hazardous waste materials, Each suppliers hazardous waste material emission is

obtained and the difference between the government norms and the supplier emission is calculated

for each material. The cumulative sum of all the differences for each supplier is calculated. Then the

values for percentage of hazardous waste in all waste emitted, percentage of waste recovered,

Percentage of Waste Recycled are calculated for each supplier either by obtaining information from

each supplier or by conducting audits in each suppliers institution. Availability of Waste

management system is also checked for each supplier. Then suppliers are ranked in ascending order

based on these values separately .Relative scores of these values are obtained by finding the

difference between each value and the minimum value in each category. Then the final score for

each supplier will be sum of the score of all the categories plus one.

4.3.5 Packaging and sourcing Score (Ns)

The method chosen for scoring Sourcing of packaging materials is a direct function of how far the

material has to travel before reaching the supplier i.e how far the seller of the material is from the

supplier. The method developed is such that a supplier is not penalized if he sources the packaging

material within the warehouse or the DC but is penalized if he doesnt. The sourcing divisions are

local, national and international and the penalty for each increases as follows:

Source Penalty

Within Supplier D.C or Warehouse 0

Local (100 Mile Radius) 1

National (1000 Mile Radius) 3

International (>1000 Miles) 5

TABLE 4.10:PACKAGING MATERIAL SOURCING SCORING METHOD

After the elimination step, remaining suppliers are sent into a scoring process in which they are

scored in three different categories. Since values obtained are for each supplier, For using in the

objective function, We can specify the environmental score for each supplier each product using the

formulation below.

Energy usage for supplier s for item i = L

s,i

Packaging for supplier s for item i = M

s,i

Returns handling capacity for supplier s for item i = N

s,i

The general environmental cost function for a supplier s and item i is:

E

s,i

= L

s,i

+ M

s,i

+ N

s,i

4.4 Combinatorial Auction

In order to fill the buyer request, the supplier s S submits a set of bids B to the market. A bid b

B(s) made by the supplier is defined as b = (I

b

, p

b

), where I

b

is a subset of items that supplier s offers

to serve (I

b

I) and p

b

is the price that the supplier requires to be paid I

b

to be supplied.

Furthermore, for each supplier s S there is a operational cost O

s,i

associated with each item i I

b

.

Then, the cost C

s,b

associated with a bid b = (I

b

, p

b

) submitted by a supplier s is given by:

Similarly, for each supplier s S there is an environmental cost E

s,i

associated with each item i. Then,

the cost E

s,b

associated with a bid b = (I

b

, p

b

) submitted by a supplier s is given by:

The two costs described previously mean that; if s bid b wins, the buyer will pay the asked price p

b

and probably an additional cost given by either operational or environmental costs or both of them.

This is given by the effect of the attributes described previously in sections 4.2 and 4.3.

Then, the problem is modelled by using binary variables x

b

defined for each bid b B. Variable x

b

= 1

if bid b wins, and o if it loses. A constant parameter

bi

is defined for item i I and for each bid b B,

in order to indicate whether bid b covers set of items i. That is

bi

= 1 if i I

b

or o otherwise.

Then the auction looks for minimizing the total cost paid by the buyer, which includes the asked

price, operational cost and environmental cost. The model includes the objective function and the

e e

_

e

e

e

=

b

I i

i s b s

O C

, ,

e

e

=

b

I i

i s b s

E E

, ,

e

e e

e

constrains: The first one, guarantees that each item is covered at least once by supplier bids, and the

second one is the integrity constrain. The model is formulated as showed below:

( )

{ } 1 , 0

1

. .

min

) (

, ,

e

>

+ +

e

e e

b

B b

b bi

S s s B b

b b s b s b

x

x

t s

x E C P

o

CHAPTER V

Experimental Analysis

In this chapter, we will assess the proposed supplier selection model in real life contexts. The main

goal is to compare the proposed model which minimizes the total cost (bid, operational and

environmental costs) and the traditional model which only considers the minimization of the bid

(price asked by the supplier) as decision criteria. The impact will be measured using the total cost

obtained in both scenarios as comparison metric. In order to be able to compare both the proposed

model, a set of instances is generated and the features of the problem are controlled by the number

of products, the number of suppliers, the number of bids, operational costs and environmental

costs.

5.1. Example tested

For this example, we used as input the number of suppliers [S], the number of items [I] and the

number of bids [B]. Three combinations ([S],[I],[B]) were considered: ([5],[10],[50]), ([7],[7],[40]) and

([10],[5],[50]). The demand for each item [i I] was randomly generated using numbers between

100 and 1000. Similarly, the unitary price asked by each supplier [s S] for a given product [i I] was

randomly generated with values between 50 and 100. Then the total price [b B] asked by a supplier

for a given item [i I] is computed by multiplying its unitary cost by the total amount of products

offered. Finally, for auction ([7],[7],[40]), the suppliers that bid for each product were randomly

assigned.

5.2. Operational costs

5.2.1 Capacity Score

The capacity for each supplier for each product is randomly generated between 100 and 1000.The

two steps fulfillment and the penalty/reward values are calculated using the formula

Fulfillment =1 {if (capacity /demand) >=0}

=0 {If (capacity /demand) <0}

Reward/ Penalty= (capacity/demand) {if fulfillment =0}

= ((capacity-demand)/ (demand*100)) {if fulfillment =1}

e

e e

e

e

Then fulfillment and penalty are added together to get a total capacity score, which is then ranked in

ascending order for each supplier for each product.

Then the difference between each suppliers value and minimum value is calculated for each

product for each supplier which is the relative score. Then the final capacity score is calculated by

Adding one to the result of the relative score to each cell value.

5.2.2 Leadtime Score

The lead time score for each supplier for each product is calculated by first obtaining lead time

values for each supplier for delivering each product which we created using random numbers

between 1 and 15. Based On his capacity for a particular product, supplier may need more than one

lead time to satisfy the demand of the customer. The first table values are obtained by using ceiling

function in excel to round off to nearest integer as follows:

Ceiling [Demand of product i/Capacity of the supplier s for product i)

Lead time Score values obtained from the supplier are multiplied with a number based on the

capacity of the supplier to satisfy the demand.

Lead time score = [(Demand of product i/Capacity of the supplier s for product i) rounded off to the

Next integer]*Lead time for the product i for supplier s

C

s,I

=[(D

i

/cap

s,i

)*L

s,i

Then each supplier is ranked based on the above score for each product.

The difference between the minimum score supplier and the other suppliers are calculated. The best

supplier gets a Final Lead time score 1, While others will get 1 plus the difference calculated based

on their ranks.

5.2.3 Quality Score

The Number of defective products is randomly generated between 3 and 233 i.e., between 6 sigma

and 5 sigma value, assuming that every supplier will have at least 5 sigma quality. Then the Service

level of the supplier is calculated from the suppliers present demand fulfillment ability

The service level score is obtained from difference between 100% service level and number of

defects score is obtained from difference between six sigma defect value which is 3.4 and the

supplier value.

The total score is calculated by the addition of all the three scores.

Then suppliers are ranked in each product category. The difference between the minimum score

supplier and the other suppliers are calculated. The best supplier gets a Final Lead time score (D

s,i

) 1,

While others will get 1 plus the difference calculated based on their ranks.

5.3 Environmental Cost

5.3.1 Energy Score

For Calculating the energy Score, First, The electricity consumption, Natural gas consumption, fuel oil

consumption used for all the twelve months of the previous year and the percentage of renewable

energy used are generated using random numbers using normal distribution. The means of the

distributions are chosen based on the industry average as given below.

TABLE 5.1 ENERGY USAGE STANDARDS USED IN THE EXPERIMENTAL ANALYSIS

Using the values in the above table as the means for the distributions concerned with the data for

each supplier we created the following table in which average values of energy usage is calculated.

The Averaged values are ranked from minimum to maximum. Then for each supplier in each

category, the difference between their energy usage value and the minimum energy usage value is

calculated.

1 Average Warehouse Space 17,400 square feet

2 AverageElectricity Usage IN US warehouses 7.6 Kwh/sqft/yr

3 Average Natural Gas Usage 20,900 Btu/sqft/yr

4 Average Fuel Oil usage in one warhouse 19.2 kbtu/sqft/yr

5 Average Electricity Usage in one warehouse 132240 Kwh/yr

6 Average Natural Gas Usage in One Warehouse 363.66 M Btu/yr

7 Average Fuel Oil usage in one warehouse 334080 kbtu/yr

8 Average Electricity Usage in one warehouse 11020 Kwh/month

9 Average Natural Gas Usage in One Warehouse 30.305 M Btu/Month

10 Average Fuel Oil usage in one warehouse 27840 Kbtu/month

201.7391304 gallons/month

Then the Total Energy score will be one for the minimum value supplier and for other suppliers the

final score will be one plus the difference between their value and the minimum value.

5.3.2 Wastage Score

For calculating wastage score, first, based on the Texas government regulations (any state

regulations in which the supplier operates can be used, we have used Texas government rules for

the ease of use) for hazardous waste materials, Each suppliers hazardous waste material emission is

obtained and the difference between the government norms and the supplier emission is calculated

for each material.

The cumulative sum of all the differences for each supplier is calculated. Then the values for

percentage of hazardous waste in all waste emitted, percentage of waste recovered, Percentage of

Waste Recycled are calculated for each supplier by randomly generating numbers based on industry

Average.

Availability of Waste management system is also checked for each supplier. Then suppliers are

ranked in ascending order based on these values separately .Relative scores of these values are

obtained by finding the difference between each value and the minimum value in each category.

Then the final score for each supplier will be sum of the score of all the categories plus one.

Total Wastage

score

Supplier 1 1.540

Supplier 2 1.117

Supplier 3 1.143

Supplier 4 1.336

Supplier 5 1.167

5.3.3 Packaging and Sourcing Score

The development of the Packaging and Sourcing score is based on the distance the material has to

travel to the supplier. The more the distance the higher the penalty and vice-versa. As sample

example from the tables is:

Packaging

Material Distance of Source Penalty Material Distance of Source Penalty Material Distance of Source Penalty

1 871 3 1 157 2 1 1562 3

2 2604 5 2 452 2 2 566 3

3 810 3 3 142 2 3 2928 5

1 1200 3 1 142 2 1 3961 5

2 397 2 2 385 2 2 1663 3

3 1608 3 3 940 3 3 336 2

1 849 3 1 644 3 1 2512 5

2 2026 5 2 728 3 2 4692 5

3 173 2 3 875 3 3 123 2

1 2663 5 1 511 3 1 3981 5

2 510 3 2 741 3 2 3461 5

3 355 2 3 316 2 3 2116 5

1 519 3 1 486 2 1 3701 5

2 2039 5 2 940 3 2 901 3

3 1911 3 3 642 3 3 396 2

Supplier 1

Supplier 2

Supplier 3

Supplier 4

Supplier 5

Product 1 Product 2 Product 3

Thus from the tables above, it can be seen that Supplier 3 is the best as they have the lowest Penalty

Score.

5.4 Impact of the operational and environmental costs

In order to measure the impact of considering operational and environmental costs, we compare

two scenarios. In the first case (scenario 1), suppliers are selected taking in account the bid,

operational and environmental costs, whereas in the second case (scenario 2), suppliers are selected

base only on the asked price. In scenario 1, the total potential cost incurred by the buyer is given by

the model presented in chapter 4:

In this case, the optimal set of suppliers is selected taking in account the total cost which considers:

asked price, operational cost and environmental cost. In this part, the total cost can be separated in

two parts: the asked price that the buyer will pay for sure and the operational and environmental

costs that will be paid likely during the operation.

In scenario 2, we solved a modified version of the auction model defined in chapter 4:

( )

{ } 1 , 0

1

. .

min

) (

e

>

e

e e

b

B b

b bi

b

S s s B b

b

x

x

t s

x P

o

Solving this model, we found the optimal solution by minimizing only the bid (asked price), which

represents the cost that the buyer has to paid anyways. Then, given this solution, we determine the

additional costs associated to operational costs and environmental costs which are likely to be paid

during the operation time. The operational costs are: ( )

e e

+

S s s B b

b b s b s

x E C

) (

, ,

.

Penalty Total Relative Score = R Score

Supplier 1 28 0.03571 1.03571

Supplier 2 25 0.04000 1.04000

Supplier 3 31 0.03226 1.03226

Supplier 4 33 0.03030 1.03030

Supplier 5 29 0.03448 1.03448

( )

{ } 1 , 0

1

. .

min

) (

, ,

e

>

+ +

e

e e

b

B b

b bi

S s s B b

b b s b s b

x

x

t s

x E C P

o

Table xx summarized the results obtained for each scenario after running the models for each

combination. For each scenario, we present the detail of total price asked by the suppliers (bid),

total operational cost, total environmental cost and finally, total cost for each combination.

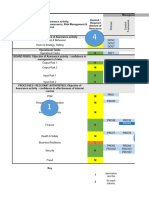

TABLE 5.2: MODEL RESULT FOR THREE SCENARIOS

For scenario 1, the bid represents on average a 55% of the total costs that could be incurred by the

buyers, whereas the operational and environmental costs represent on average a 45% of the total

costs. Similarly for scenario 2, the bid represents on average a 50% of the total costs that could be

incurred by the buyers, whereas the operational and environmental costs represent on average a

50% of the total costs. Therefore, as expected, scenario 1 increases the total bid costs paid by the

buyer versus decreases the operational and environmental costs, nevertheless, the buyer is paying a

higher bid cost, the total cost is lower when the operational and environmental costs are taken in

account.

These results shows that is very important not only to consider the supplier asked price, because

there are other costs that sometimes are hidden which can affect dramatically the final total cost

that the buyer has to paid. A holistic analysis that considers different potential costs is important to

be conducted, since as we showed in this study, important savings can be obtained due costs that

are hidden, but are very likely to appear during supply process.

Scenario 1

s/I/B Bid Operational Environmental Total cost

10/50/5 352,246 216,477 186,328 755,051

7/40/7 251,541 73,499 63,269 388,309

5/50/10 125,462 29,952 32,175 187,589

Scenario 2

s/I/B Bid Operational Environmental Total cost

10/50/5 324,166 220,101 218,646 762,913

7/40/7 250,202 78,857 68,181 397,239

5/50/10 121,697 48,975 48,470 219,142

CHAPTER VI

Discussion, Conclusions and Future work

Each time more and more companies are concerned to be economic and environmental sustainable,

then important factors as quality, lead time, pollution yield, certification, etc. have to be considered

at the time to evaluate the supply chain as a whole. Additionally, many markets ask for very high

standards in terms of quality, operational and environmental certifications, where if a company is

not able to ensure those standards through its supply chain, the chances to get a percentage of

participation is almost null.

Off late sustainability has become a key point in the development and progress of companies around

the globe. The three pillars which are Economic Sustainability, Social Sustainability and

Environmental Sustainability have to be given equal importance. We proposed a model to select

suppliers considering not only the bid (asked price) that the supplier offers, but other criteria as

operational and environmental attributes which ensure, in certain way, the sustainability of the

company through the procurement segment of its supply chain. The model provides a basic tool to

evaluate a pool of suppliers and ensure to select the best combination in terms of bid, operational

and environmental costs, by minimizing the total cost that the buyer could pay. As we showed in this

study, an average saving of 6% was obtained by minimizing the total cost which considers

operational and environmental criteria.

This models aims to be a tool that helps buyer to reduce uncertainty by considering more factors

than only the asked price. Having the possibility to incorporate other factors that are present or may

potentially appear, the buyer has the choice to decide if paying more it is worthwhile as a return for

getting better operational and environmental conditions.

With respect to eliminating process, country contribution to environment where each suppliers are

from have to be considered to evaluate them to put on the list of elimination as different country

has different burden that they have to observe. Since there are more and more international

companies emerged, a specific burden to keep the environmental regulations on each country could

be applied to the factories where it is based on and applicable to the related countries. Because the

degree of weight factor to each country and each area is controversial, more aspects have to be

considered to this elimination process.

As future work, this model can be modified and more factors can be added in order to run different

scenarios. One improvement could be to incorporate different values from different environmental

acts customizing the tool for suppliers of different countries. On the other hand, even though the

model was tested with random data generated as we explained previously, it would be worth to test

this model with a more accurate companys historical data in order to show the real potential of our

model as a decision tool.

CHAPTER VII

References

[1] P.K. Humphreys, Y.K. Wong, F.T.S. Chan, Integrating environmental criteria into the supplier

selection process, Journal of Materials Processing Technology 138 (2003) 349356

[2] Abrache, Gabriel Crainic, Gendreau, Rekik, Combinatorial auctions, Ann Oper Res (2007) 153:

131164

[3] M Rekik, and S Mellouli, Reputation-based winner determination problem for combinatorial

transportation procurement auctions, Journal of the Operational Research Society (2012) 63, 1400

1409

[4] Ledyard, J. O., Olson, M., Porter, D., Swanson, J. A., & Torma, D. P. (2002). The first use of a

combined value auction for transportation services. Interfaces, 32(5), 214.

[5] Davenport, A. J., & Kalagnanam, J. R. (2001). Price negotiations for procurement of direct inputs.

In Mathematicsof the Internet: E-auctions and markets. Berlin: Springer.

[6] Hohner, G., Rich, J., Ng, E., Reid, G., Davenport, A. J., Kalagnanam, J. R., Lee, H. S., & An, C. (2003).

Combinatorial and quantity-discount procurement auctions benefit mars, incorporated and its

suppliers. Interfaces, 33(1), 2335.

[7] Epstein, R., Henrquez, L., Cataln, J., Weintraub, G. Y., & Martinez, C. (2002). A combinatorial

auction improves school meals in Chile. Interfaces, 32(6), 114.

[8] International regulatory policies

8.1 http://www.oecd.org

8.2 http://unfccc.int/kyoto_protocol/items/2830.php

8.3 http://www.vienna.convention.at/

8.4 http://www.basel.int/

8.5 http://www.chem.unep.ch/pops/

8.6 http://ec.europa.eu/enterprise/policies/sustainable-business/ecodesign/index_en.htm

8.7 http://ec.europa.eu/enterprise/sectors/chemicals/reach/index_en.htm

8.8 http://ec.europa.eu/environment/waste/weee/index_en.htm

8.9 http://www.rohsguide.com/

8.10 http://ec.europa.eu/environment/waste/elv_index.htm

8.11 http://ec.europa.eu/environment/air/transport/road.htm

[9] USA CO2 emissions may drop to 1990 levels this year, Posted on July 2, 2012 by Anthony Watts

http://wattsupwiththat.com/2012/07/02/us-co2-emissions-may-drop-to-1990-levels-this-year/

[10] Kyoto Protocol reference manual Climate Change Secretariat (UNFCCC) & KYOTO PROTOCOL TO

THE UNITED NATIONS FRAMEWORK CONVENTION ON CLIMATE CHANGE UNITED NATIONS 1998

[11] U.S. Energy Information Administration / Monthly Energy Review October 2012

[12] INDIANA ARTICLE 9, CARBON MONOXIDE EMISSION RULES; ARTICLE 10, NITROGEN OXIDES

RULES; ARTICLE 11, EMISSION LIMITATIONS FOR SPECIFIC TYPES OF OPERATIONS

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Guidetoproductmetrics Mixpanel PDFDocument20 pagesGuidetoproductmetrics Mixpanel PDFAnjaneya SastryPas encore d'évaluation

- Cost Accounting A Managerial Emphasis Canadian 7th Edition Horngren Solutions Manual 1Document36 pagesCost Accounting A Managerial Emphasis Canadian 7th Edition Horngren Solutions Manual 1maryreynoldsxdbtqcfaje100% (23)

- Green Supplier Selection Using AuctionsDocument32 pagesGreen Supplier Selection Using AuctionsPrashanth Natarajan IyerPas encore d'évaluation

- Group 1 - Presentation IE 632Document21 pagesGroup 1 - Presentation IE 632Prashanth Natarajan IyerPas encore d'évaluation

- Operating Room SchedulingDocument20 pagesOperating Room SchedulingPrashanth Natarajan IyerPas encore d'évaluation

- 12 Seater Business Jet Design: A Conceptual ApproachDocument24 pages12 Seater Business Jet Design: A Conceptual ApproachPrashanth Natarajan IyerPas encore d'évaluation

- Design and Fabrication of An Unmanned Aerial VehicleDocument129 pagesDesign and Fabrication of An Unmanned Aerial VehiclePrashanth Natarajan Iyer100% (1)

- Original PDF Economic Geography An Institutional Approach 2nd PDFDocument23 pagesOriginal PDF Economic Geography An Institutional Approach 2nd PDFwilbur.hensley963100% (33)

- AT&T INC., DIRECTV GROUP HOLDINGS, LLC, and TIME WARNER INC.Document237 pagesAT&T INC., DIRECTV GROUP HOLDINGS, LLC, and TIME WARNER INC.Camila SansonPas encore d'évaluation

- JD Deloitte Analyst Trainee Risk&FinancialAdvisoryDocument3 pagesJD Deloitte Analyst Trainee Risk&FinancialAdvisoryganduharami702Pas encore d'évaluation

- Decathlon CaseDocument15 pagesDecathlon CaseLeena CorahaiPas encore d'évaluation

- Cafe Coffee DayDocument72 pagesCafe Coffee DayMerwyn FernandesPas encore d'évaluation

- 17 System Audit ChecklistDocument35 pages17 System Audit ChecklistAmbika Paramasivam100% (1)

- Q 2:what Is Software Architecture Important?Document6 pagesQ 2:what Is Software Architecture Important?malik ArshPas encore d'évaluation

- How To Use The Flash Tool For Xperia PDFDocument12 pagesHow To Use The Flash Tool For Xperia PDFjefferstevenPas encore d'évaluation

- Interfacing Cloud Base Data Into Your Reliability Program PDFDocument22 pagesInterfacing Cloud Base Data Into Your Reliability Program PDFMuhammad HaroonPas encore d'évaluation

- LGCD Residential Building Plan (RBG)Document8 pagesLGCD Residential Building Plan (RBG)Sidra HanifPas encore d'évaluation

- New Construction vs. In-Service IntegrityDocument23 pagesNew Construction vs. In-Service IntegrityBrian MarinPas encore d'évaluation

- Etymology and Pronunciation: Metallurgy Is A Domain ofDocument6 pagesEtymology and Pronunciation: Metallurgy Is A Domain ofMonika KshetriPas encore d'évaluation

- MSCI-2116 Principles of AccountingDocument6 pagesMSCI-2116 Principles of AccountingSahar ShahzadiPas encore d'évaluation

- Project 2Document16 pagesProject 2e-space e-spacePas encore d'évaluation

- Final Deck April 12, 2018 Group 6 Group Name: BLAZE 22 Madinmc K33Document72 pagesFinal Deck April 12, 2018 Group 6 Group Name: BLAZE 22 Madinmc K33Van TisbePas encore d'évaluation

- John Loucks: Slides byDocument45 pagesJohn Loucks: Slides byRicky M. CalaraPas encore d'évaluation

- Object Oriented Programming in AbapDocument3 pagesObject Oriented Programming in Abapmirza_2010Pas encore d'évaluation

- Template Assurance MapDocument12 pagesTemplate Assurance MapcvacaPas encore d'évaluation

- H01 - Principles of TaxationDocument9 pagesH01 - Principles of TaxationRachel FuentesPas encore d'évaluation

- Docs Bit Shares OrgDocument380 pagesDocs Bit Shares OrgAdriano De L. AlvesPas encore d'évaluation

- Annexure ADocument5 pagesAnnexure AsgacrewariPas encore d'évaluation

- JAIBB - GFI - (Module-C) - CEO and Senior ManagementDocument15 pagesJAIBB - GFI - (Module-C) - CEO and Senior ManagementNaz MahoonPas encore d'évaluation

- Intermediate Accounting III ReviewerDocument3 pagesIntermediate Accounting III ReviewerRenalyn PascuaPas encore d'évaluation

- Bucharest Retail Market 2021Document15 pagesBucharest Retail Market 2021Mircea MerticariuPas encore d'évaluation

- School Supply Drive ToolkitDocument13 pagesSchool Supply Drive ToolkitDiane Annaliese AquinoPas encore d'évaluation

- Airtran Airways CPM: Critical Success Factors Weight Rating Weighted Score 0.0 To 1.0 1 To 4Document4 pagesAirtran Airways CPM: Critical Success Factors Weight Rating Weighted Score 0.0 To 1.0 1 To 4Usama Rehman KhanPas encore d'évaluation

- Factors Affecting Foreign Direct Investment in Nigeria - InvestSmallDocument5 pagesFactors Affecting Foreign Direct Investment in Nigeria - InvestSmallKantPas encore d'évaluation