Académique Documents

Professionnel Documents

Culture Documents

Interface Trap Density of MOS, Raquibul Hassan, Tawsif Salam, 2011

Transféré par

Mohammed Tawsif SalamCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Interface Trap Density of MOS, Raquibul Hassan, Tawsif Salam, 2011

Transféré par

Mohammed Tawsif SalamDroits d'auteur :

Formats disponibles

Raquibul Hassan

061310045

M. Tawsif Salam

061069045

Instructor

Dr. K.M.A. Salam

NORTH SOUTH UNIVERSITY

Dhaka, Bangladesh

2 | P a g e

ASSERTION

This is to state that this project is entirely our original work. No part of this work has been submitted

elsewhere fully or partially for the award of any other degree or diploma. In addition we assure that

any material reproduced in this project has been properly acknowledged.

Students Name and Signature

__________________________

Raquibul Hassan

ID: 061310045

__________________________

M. Tawsif Salam

ID: 061069045

3 | P a g e

APPROVAL

The project tilted Measurement of Interface Trap Density of MOS has been submitted to the

following respected members of the Board of Examiners of the department of Electrical Engineering

& Computer Science in partial fulfillment of the requirements for the degree of Bachelor of Science

in Electronics and Telecommunication Engineering on the December 30, 2009 by the following

students has been accepted satisfactory.

Raquibul Hassan (061310045)

M. Tawsif Salam (061069045)

_____________________________ _____________________________

Dr. K.M.A. Salam Dr. Miftahur Rahman

Assistant Professor Professor and Chairman

Department of Electrical Engineering Department of Electrical Engineering

& Computer Science & Computer Science

North South University North South University

(Advisor)

4 | P a g e

ABSTRACT

In our research work we are to make attempt to find out the interface trap density parameters of the

extensively used oxides in semiconductor devices, followed by the effort to show a comparison

between those of the oxides. We are to work on different high-k materials like hafnium dioxide,

aluminium oxide, titanium dioxide, hafnium silicate and compare the properties with silicon dioxide

to reach a conclusion that which of these materials would be the most favorable with respect to the

parameters concerning interface trap density D

it

to perform certain operations i.e. device scaling.

5 | P a g e

ACKNOWLEDGEMENT

We are thankful to Almighty Allah SWT at the first place. We would also like to mention the love

and support of our families, that of our parents in particular, without which we could not have been

somewhere near to the completion.

Our deepest gratitude is to our academic and advisor Dr. K.M.A. Salam whose kind thoughts were

always with us. Mentions of our work to all extents would rightfully have to have his name too

without whose help we could not have overcome a number of obstacles we had faced.

We would like to express our deepest gratitude to Professor Dr. Miftahur Rahman, the chairman of

the Department of Electrical Engineering & Computer Science, for his kind guidance over the topic

and areas of our research at the initial stage.

Among the others we would like to thank, there is Syed Nafeesul Islam who was always there when

we needed a help. Many others of our well-wishers were there who are not being named all here for

understandable reasons, but we cannot do without mentioning them to acknowledge their help and

support and we wish every good to them.

6 | P a g e

TABLE OF CONTENTS

Assertion ---------------------------------------------------------------------------------------------- 2

Approval ---------------------------------------------------------------------------------------------- 3

Acknowledgement ----------------------------------------------------------------------------------- 4

Abstract ------------------------------------------------------------------------------------------------5

List of Figures ---------------------------------------------------------------------------------------- 6

List of Tables ----------------------------------------------------------------------------------------- 7

Chapter 1

Introduction ---------------------------------------------------------------------------------------------- 9

Chapter 2

Background & Review --------------------------------------------------------------------------------- 10

2.1 MOSFET ----------------------------------------------------------------------------------10

2.1.1 Overview of MOSFET ------------------------------------------------------10

2.1.2 Organization and Operations of MOSFET Substances ------------------10

2.2 MOS Capacitor ---------------------------------------------------------------------------12

2.2.1 Function of MOS Capacitor ------------------------------------------------ 12

2.2.2 Frequency of MOS Capacitor and Effects -------------------------------- 13

2.3 Scaling ------------------------------------------------------------------------------------ 14

2.3.1 Necessities, Rules and Limitations of Scaling --------------------------- 14

2.4 High-K ------------------------------------------------------------------------------------ 16

2.5 Properties of High-K -------------------------------------------------------------------- 17

2.6 Interface Trap Density ------------------------------------------------------------------ 18

2.6.1 Nature of Interface Trap Density in Oxide Stack Gates ---------------- 19

2.6.2 Role of Interface Trap Density behind Degradation of MOSFET----- 19

2.6.3 Correlation between Leakage Current & Interface Trap Density ------ 19

Chapter 3

Methodology -------------------------------------------------------------------------------------------- 19

3.1 Scaling Flat-Band and Threshold Voltage -------------------------------------------- 19

3.2 Reasons for choosing the oxides ------------------------------------------------------- 19

3.3 The oxide type ---------------------------------------------------------------------------- 20

3.3.1 Silicon Dioxide --------------------------------------------------------------- 20

3.2.2 Hafnium Dioxide ------------------------------------------------------------- 20

3.3.3 Hafnium Silicate -------------------------------------------------------------- 21

3.4 Charge of the Oxides --------------------------------------------------------------------- 21

3.5 The Doping Concentration -------------------------------------------------------------- 21

Chapter 4

Implementation ------------------------------------------------------------------------------------------ 22

4.1 Calculation of Flat-band Voltage and Threshold Voltage --------------------------- 22

4.2 Interface Trapped Density Calculation ------------------------------------------------- 23

Chapter 5

Result of Simulation ------------------------------------------------------------------------------------ 24

Chapter 6

Conclusion ----------------------------------------------------------------------------------------------- 28

Bibliography --------------------------------------------------------------------------------------------- 30

Addendum I- Codes -------------------------------------------------------------------------------------32

7 | P a g e

LIST OF FIGURES

1. (Fig 2.1) Structure of MOSFET, pg-11

2. (Fig 2.2) MOS capacitor Structure, pg-12

3. (Fig 2.3) The Three Modes of MOS Capacitor, pg-13

4. (Fig 2.4) Gate length vs. Technology Node, pg-14

5. (Fig 5.1) Typical Capacitance-Voltage curve, pg-25

6. (Fig 5.2) curve for high frequency capacitance, pg-25

7. (Fig 5.3) curve for low frequency capacitance, pg-26

8. (Fig 5.4) high frequency and low frequency c-v curve showing impact of

fast interface states, pg-26

9. (Fig 5.5) comparison plot of Dit values, pg-27

8 | P a g e

LIST OF TABLES

1. (Table 3.1) Characteristics of the metal oxides, pg-20

2. (Table 3.2) Charge of oxides, pg-21

3. (Table 5.2) Comparison of Dit values for the oxides, pg-26

9 | P a g e

Chapter

1

INTRODUCTION

MOSFETs, standing for metaloxidesemiconductor field-effect transistors, presently are the most

extensively used as integrated chips for random access memories, processors, flash memories and

other application specified integrated circuitries (ASIC). MOSFET was invented in 1959 by Dawon

Kahng and Martin M. Atalla at Bell Laboratories in accordance with a principle proposed by Julius

Edgar Lilienfeld in 1925. A trend existed to form MOSFETs where aluminium was used as the

metal, silicon oxide as the oxide and silicon as the semiconductor substrate in MOSFETs until mid

the 1970s, when polycrystalline silicon or simply polysilicon started being used prevalently.

Polysilicon is used mostly because of its formation of a diamond cubic crystal structure that appears

to be mechanically a more stable structure than other known forms. Thus, the name metal at the

augmentation of MOSFET may be recognized as a misnomer as the previously used metal gate

material has been replaced by polysilicon.

MOSFETs have frequently been scaled down in size over the past decade, since the inception to be

specific. For example, Intel Corporation in late 2009 has had a process through production

introducing MOSFETs with 32 nanometer channel length, whereas this length once was several

micrometers long. This process of scaling down the MOSFET size is called MOSFET scaling, or

simply scaling.

George Earle Moore, a co-founder of Intel Corporation, theorized the process of scaling stating that

the number of transistors on an integrated circuit doubles every two years. Widely known as

Moores Law, it was introduced in a paper he published in April 1965. However in 2005 Moore

eventually concluded the law saying about a miniaturization limit, i.e. no further scaling will be

possible in next two or three generations as the transistors would reach the atomic level by size.

The thickness of the silicon dioxide gate dielectric in MOSFETS has steadily decreased, which

increased the gate capacitance and thereby device performances, as the transistors have decreased in

size. As the thickness scales below 2nm, leakage currents due to tunneling increase drastically,

leading to power consumption and reduced device reliability. Replacing the silicon dioxide gate

dielectric with a high-K material allows increased gate capacitance without the leakage effects.

When this dielectric constant K is too high, the charge also increases, meaning accumulation of too

much charge between the insulator and the substrate. This particular phenomenon of charge

accumulation is known as interface trapped density (D

it

).

10 | P a g e

Chapter

2

BACKGROUND & REVIEW

In this chapter, brief descriptions on MOSFETs structure, operation and the scaling process are

presented eventually continuing to the discussion on interface trap density.

2.1 MOSFET

MOSFET is the field effect transistor meant to switch or amplify electronic signals.

Based on the principle proposed in 1925 by the Austrian-Hungarian (Ukraine in present days)

physicist Julius E. Lilienfeld, Bell Laboratories scientists Dawon Kahng and Martin Atalla, from

Korea and Egypt respectively, invented MOSFET in 1959. Though the initial formation of a

MOSFET comprised aluminium, silicon oxide and silicon respectively as metal, oxide and

semiconductor, polysilicon was introduced to replace aluminium in mid 1970s, mostly because of its

uniquely stable diamond cubic crystal structure.

2.1.1 Overview of MOSFET

MOSFETs structure thus the basic operation consists of an insulated gate electrode and two contacts

having a conducting channel between them. A voltage on the oxide-insulated gate electrode induces

the channel between the contacts, known as source and drain. Pragmatically, MOSFET works by

electronically varying the width of a channel along which charge-carriers (electrons and holes) flow.

The width of the channel, a criterion for the performance of MOSFET, is controlled by the gate

voltage. As the voltage is applied between the two terminals, the generated electric field permeates

the oxide to create the inversion layer. This inversion layer is the semiconductor-insulator

interface. The channels can be n-type or p-type, making the MOSFETs to be called nMOS and

pMOS respectively.

2.1.2 Organization and Operations of MOSFET Substances

To explain the MOS structure, a silicon substrate is taken to grow a layer of SiO

2

on its top and then

to deposit a layer of polysilicon in order to obtain the formation of a MOSFET.SiO

2

acts as a planar

11 | P a g e

capacitor in the process because of its ability to store energy (

r

or K= 3.9) over an applied voltage.

One of the electrodes here is replaced by a semiconductor.

A MOS structure adapts the mechanism to distribute charges after a voltage is applied across. For

example- if a positive voltage V

GB

is applied to a p-type semiconductor, a depletion layer is created

between the gate and body resulted by the forcing away of positive holes from the insulator-

semiconductor interface. The process leaves a carrier-free region of negatively charged ions to

exposure which concentrates to form in an inversion layer thinly located next to the insulator-

semiconductor interface. Here we may define the threshold voltage, which is the gate voltage where

volume density of electrons at inversion layer and the volume density of holes at body are the same.

Operations of MOSFET are based on the charge concentration adaption of a MOS capacitance

between the body and gate electrodes, located above the body and insulated from the other regions

of the device by a dielectric layer (an oxide i.e. SiO

2

). In case of nMOS, the source and drain are

n+ regions and the body is p region. Electrons from the source enter the inversion layer or the p-

region-oxide interface if the gate voltage is significantly above the threshold voltage. On other hand

in cases of the gate voltage below the threshold voltage, sub-threshold leakage current able to flow

between source and drain is low as the channel is lightly populated.

(Fig 2.1) Structure of MOSFET

In cases of pMOS, the source and drains are p+ regions and the body is a n region. When a

negative gate-to-source voltage (positive source-to-gate) is applied, it creates a p-channel at the

surface of the n-region, analogous to the n-channel case, but with opposite polarities of charges and

voltages. When a voltage less negative than the threshold value (a negative voltage for p-channel) is

applied between gate and source, the channel disappears and only a very small sub-threshold current

can flow between the source and the drain.

12 | P a g e

2.2 MOS Capacitor

MOS capacitor is a voltage dependent capacitor consisting of a metal-oxide-semiconductor layer

structure. Details on threshold voltage of the transistor as well as the quality of oxide-

semiconductor interface may belong to the analysis of MOS capacitors.

Structure of a metal oxide semiconductor often comprises silicon, silicon dioxide and aluminium

as the semiconductor, oxide and metal respectively. Metal in most of the cases may be replaced

by extensively doped polysilicon layers as gate electrode. Contacts are made to the metal and to

the semiconductor. A voltage is applied to the metal while the semiconductor is grounded.

(Fig 2.2) MOS capacitor Structure

2.2.1 Function of MOS Capacitor

The capacitance of a MOS structure is voltage dependent since the semiconductor region under

the oxide can be either depleted of carriers, can accumulate carriers or an inversion layer can be

formed. For instance,

For a p-type substrate one finds that for a large negative voltage, V

G

, applied to the metal,

holes are attracted to the interface, causing accumulation.

A positive voltage on the other hand repels the holes that are present in the p-type

material and thereby creates a depletion layer.

A larger positive voltage at the gate causes sufficient bending of the energy bands in the

semiconductor at the interface so that inversion occurs, i.e. a change from holes being

the majority carrier type to electrons.

An even larger positive voltage causes strong inversion where the carrier density at the

oxide-semiconductor interface exceeds that of the opposite carrier type in the substrate.

13 | P a g e

(Fig 2.3) The Three Modes of MOS Capacitor

2.2.2 Frequency on MOS Capacitor and Effects

The low frequency capacitance is measured when the semiconductor is in thermal equilibrium at

any time during which the AC voltage is applied. Such measurement is sometimes called the

quasi-static capacitance measurement. On the other hand, high frequency is used for the

concentration of minority carriers to not follow the applied AC voltage so that it maintains its

value as determined by the DC bias voltage. Both capacitance measurements are performed as a

function of the bias voltage, which is slowly swept from accumulation, through depletion into

inversion. High frequency capacitance is same as the oxide capacitance under accumulation

conditions. Since carriers can easily be moved to and from the interface, the charges build up at

both sides of the oxide as in a parallel plate capacitor. This change as the applied bias voltage

becomes positive, creating a depiction layer in the semiconductor. This depletion layer prevents

carriers from moving towards the semiconductor-oxide interface. The variation of the charge

therefore occurs at the edge of the depletion region so that the measured capacitance is the series

connection of the oxide capacitance and the depletion layer capacitance.

Inversion occurs finally at the interface as a larger positive voltage is applied. The presence of

inversion layer makes the depletion layer width almost independent of the applied voltage,

yielding a constant and minimal capacitance. The latter can be obtained from a series connection

of the oxide capacitance and the minimum capacitance of the depletion layer.

As soon the bias voltage is swept rapidly while performing a high capacitance measurement, the

condition of deep depletion appears. As the capacitor is bias from depletion into inversion the

inversion layer needs to be formed. This inversion layer is formed by thermal generation of

minority carriers in absence of light. Since the inversion layer density is much larger than the

thermal equilibrium value of the minority carrier density in the substrate, the time required to

generate the inversion layer is orders of magnitude larger than the minority carrier life time,

typically of the order of seconds in high quality silicon. The absence of the inversion layer

causes the depletion layer to be larger than its thermal equilibrium value, thereby lowering the

capacitance of the MOS structure.

14 | P a g e

The substrate doping is obtained from the MOS capacitance in inversion. The capacitance should

be independent of the applied voltage, but equals to the series connection of the oxide

capacitance and the capacitance of the depletion region. The potential across the depletion region

is 21 Fl so that the doping concentration can be obtained from the depletion layer capacitance..

The oxide capacitance too is obtained from the MOS Capacitance bias in accumulation, but this

time independent of the bias voltage and equals to the oxide capacitance

Flat-band capacitance may be calculated using the result from the exact solution described in the

following section. This enables to identify the flat-band voltage of the MOS for which u

F

= 0

Volt. The difference between the measured flat-band voltage and the expected value based on the

position of the Fermi level in the gate and the substrate is typically attributed to charge located at

the oxide-semiconductor interface or the charge in the oxide.

2.3 Scaling

In microelectronics, scaling refers to the scaling of geometric dimension of the intergraded

circuits, most of the cases being subject to reduction of the lateral geometric dimension of

devices and interconnects. International Technology Roadmap of Semiconductors (ITRS)

comprises the issue of scaling the constantly decreasing size of MOSFETs introduces some

difficulties associated with the fabrication process of semiconductor devices.

(Fig 2.4) Gate length vs. Technology Node

2.3.1 Necessities, Rules and Limitations of Scaling

Scaling appears being a vital issue in microelectronics as it is desired to have smaller size of

MOSFETs, mostly because,

As MOSFETs act like resistors at the ON state, it means that smaller MOSFETs will allow

more current to pass than that of bigger MOSFETs.

15 | P a g e

As smaller MOSFETs have smaller gates, this means the capacitance is lower which

contributes to lower switching times, i.e. higher processing speeds.

The simplest reason is, smaller MOSFETs mean occupation of smaller areas, which leads to

both the reduction of cost and more computing power in the same area.

However, propositions over the issue of scaling comprise some principles of the process, which

we may discuss as the rules of scaling,

Increase packing density and chip functionality.

Increase device current and speed.

Lower cost (increase cost effectiveness).

Constant Voltage gain

Constant-field scaling

Keeping the channel length smaller than a micrometer is a challenge in MOSFET production.

Even a more common limiting factor of scaling is the difficulties in the fabrication process of

semiconductor devices. There also exist operational problems in cases of smaller MOSFETs.

The voltage applied to the gate must be reduced to maintain reliability due to small MOSFET

geometries. To maintain performance, the threshold voltage of the MOSFET has to be reduced as

well As threshold voltage is seduced, the t cannot be completely turned off, resulting in a weak-

inversion layer, which consumes power in the form of sub-threshold leakage.

The switching time is roughly proportional to the gate capacitance of gates. However, with

transistors becoming smaller and more transistors being placed on the chip, interconnect

capacitance is increasing. This leads to increased delay and lower performance. The ever-

increasing density of MOSFETs is causing problems of heat generation that can impair circuit

operation. Circuits operate slower at high temperatures, and have reduced reliability and shorter

lifetimes. Heat sinks and other cooling methods are now required for integrated circuits.

The gate oxide, an insulator between the gate and channel, should be made as thin as possible to

increase the channel conductivity and performance when the transistor is on and to reduce sub-

threshold leakage when the transistor is off. However, with gate oxides of thickness around 1.2

nm tunneling leakage occurs between the gate and channel, leading to increased power

consumption. High-k dielectrics with larger dielectric constant than silicon dioxide, such as

hathium and zirconium silicates and oxides, are now researched to reduce the gate leakage.

Increasing the dielectric constant of the gate oxide material allows a thicker layer while

maintaining a high capacitance. The higher thickness reduces the tunneling current between the

gate and the channel.

2.4 High-K

The term high-K dielectric means the material (used in semiconductor manufacturing processes)

having high dielectric constant K as compared to silicon dioxide.

16 | P a g e

The thickness of the commonly used oxide SiO

2

gate dielectric has steadily decreased to increase

the gate capacitance and thereby device performance, as transistors has decreased in size. As the

thickness scales below 2nm, leakage currents due to tunneling increase drastically, leading to

power consumption and reduced device reliability. Increased gate capacitance without the

leakage effects is allowed by replacing the silicon dioxide gate dielectric with a high-K material.

As transistors shrink, leakage current can increase. Managing that leakage is crucial for reliable

high-speed operation, and is becoming an increasingly important factor in chip design. Intel has

made a significant breakthrough in solving the chip power problem, identifying a new high-k

(Hi-k) material called hafnium to replace the transistors silicon dioxide gate dielectric, and new

metals to replace the polysilicon gate electrode of NMOS and PMOS transistors. These new

materials reduce gate leakage more than 100-fold, while delivering record transistor

performance.

2.5 Properties of High-K Materials

High-k stands for high dielectric constant, a measure of how much charge a material can hold.

Different materials similarly have different abilities to hold charge. High-k materials, such as

hafnium dioxide (HfO2) zirconium dioxide (ZrO

2

) and titanium dioxide (TiO

2

) inherently have a

dielectric constant or k above 3.9. The dielectric constant also relates directly to transistor

performance. The higher k increases the transistor capacitance so that the transistor can switch

properly between and on and off states.

In pursuit of achieving record performance for both NMOS and PMOS technologies, Intel

identified the right high-k material and gate electrode materials. By moving to a new high-k

material, Intel was able to keep the drive current at the same level as with older material.

The exponentially increasing heat of chips with the increase in transistors is seen as a challenge

in semiconductor industry. Leakage control through new high-k materials is one of many steps

toward making transistors run cooler. As high-k gate dielectrics can be several times thicker,

they reduce gate leakage by over 100 times. As a result, these devices run cooler. This shift to a

new material will be one of the most significant in the evolution of the metal- oxide silicon

(MOS) transistor.

There are some disadvantages of high-k materials.

Firstly, if the dielectric constant is too high, then the charge also increases. This means that too

much charge accumulates between the insulator and the substrate. When charge accumulates

between the insulator and the substrate, this phenomenon is known as interface trapped density

(Dit).

17 | P a g e

Secondly, the problem with Hafnium Oxide is that it crystallizes above 700C but Hafnium

Silicate remains amorphous above 1000C.

Thirdly, the problem with Aluminum Oxide is that it accumulates too much negative charge.

When the charge increases, the interface trapped density (D

it

) also increases. This will result in

the shift of the flat-band voltage and as a result the threshold voltage will also increase. Increase

in the threshold voltage means that the leakage current will also increase. This is a disadvantage

with high-k materials since their dielectric constant is too high whereas the dielectric constant of

silicon is perfect to use.

Therefore by analyzing the high-k materials we can say that Hafnium Silicate is the most desired

material among all of them. One reason is because it has silicon in it, which keeps the dielectric

constant from becoming too high. But still we need to analyze the graphical representation of all

the high-k materials using MATLAB simulation to be exactly sure. Therefore although high-k

has some disadvantages, but still it is a good trade-off from silicon dioxide because it gives us

new possibilities to improve the MOS capacitor by scaling.

2.6 Interface Trapped density

The fact that these defects can change their charge state relatively faster in response to changes

of the gate bias refers to the term fast interface states.

The fast interface states or tarps can move above or below the Fermi level in response to the bias

as the surface potential in a MOS device is varied, because their position relative to the band-

edges are fixed. Having it known that the energy level below the Fermi level have a high

probability of occupancy by electrons while levels above Fermi level tend to be empty, it is

observed that a fast interface state moving above the Fermi level would tend to give up its

trapped electron to the semiconductor (or equivalently capture a hole). To explain, the same fast

interface state below the Fermi level captures an electron (or gives up a hole). The fast interface

states give rise to a capacitance which is in parallel with depletion capacitance in the channel

(and hence is additive) since charge storage results in capacitance. This combination is in series

with the insulator capacitance C

i

.

The fast interface states contribute to the low frequency capacitance CLF, but not to the high

frequency capacitance CHF. Because the fast interface states can keep pace with the low

frequency variations of the gate bias (~1-1000 Hz) but not at extremely high frequencies (~1

MHz).

18 | P a g e

2.6.1 Nature of Interface Trap Density in Oxide Stack Gates

The classical concept and theory suggest that the degradation of MOS transistors is caused by

interface trap generation resulting from hot carrier injection. Experiments that use the

deuterium isotope effect to probe the mechanism for interface trap generation in n-MOS

transistors in the presence of hot hole and electron injection show that hot carrier injection into

the gate oxide exhibits essentially no isotope effect, whereas channel hot electrons at the

interface exhibit a large isotope effect. This leads to the conclusion that channel hot electrons,

not carriers injected into the gate oxide, are primarily responsible for interface trap generation for

standard hot carrier stressing.

Traps in the high- gate stacks play a crucial role in threshold voltage, channel mobility, and

reliability. We have carried out an extensive experimental investigation of interface traps in the

Si/SiO2/HfO2/TaN structures employing a powerful new admittance spectroscopy technique for

leaky gate dielectrics, to extract the trap parameters - trap density, trap energy, trap capture

cross-section, and trap location. The experiments were carried out on MOS (Metal- Oxide-

Semiconductor) capacitors on wafers with graded SiO2 thickness. The flat-band voltage roll-off

remains a very important phenomenon, explanations for which are not unanimous. We have

carried out extensive measurements of the flat-band voltage as a function of the EOT (Equivalent

Oxide Thickness) on a large number of MOS structures having different thickness of the SiO2

layer and two sets of HfO2 layer thickness. We report the observed correlation between the

flatband voltage variation with EOT with the change in the interface trap density with the EOT.

2.6.2 Role of Interface Trap Density behind Degradation of MOSFET

The classical concept and theory suggest that the degradation of MOS transistors is caused by

interface trap generation resulting from hot carrier injection. Experiments that use the

deuterium isotope effect to probe the mechanism for interface trap generation in n-MOS

transistors in the presence of hot hole and electron injection show that hot carrier injection into

the gate oxide exhibits essentially no isotope effect, whereas channel hot electrons at the

interface exhibit a large isotope effect. This leads to the conclusion that channel hot electrons,

not carriers injected into the gate oxide, are primarily responsible for interface trap generation for

standard hot carrier stressing.

2.6.3 Correlation between Leakage Current & Interface Trap Density

As gate oxide is scaled below the direct tunneling regime, gate leakage current has become the

dominant concern especially for nonvolatile memories and complementary metaloxide

semiconductor CMOS logic circuits for low power and portable applications. In thick oxides,

gate leakage is due primarily to stress-induced leakage current which has both transient and

steady-state components. Another important phenomenon in thin oxide is quasi breakdown. This

is characterized by a localized leakage current of much higher magnitude than conventional

SILC but lower than complete breakdown. The gate leakage current after QB shows steplike

fluctuations, which is due to the occurrences and modulation of multiple QB spots at different

spatial locations.

19 | P a g e

Chapter

3

METHODOLOGY

3.1 Scaling Flat-Band and Threshold voltage

The amount of leakage current increases with the sealing of transistors as the oxide layer

thickness decreases. Thickness of the oxide layer has to be increased to improve this condition,

for the threshold voltage being scaled and the leakage current minimized. But with conventional

devices the oxide thickness cannot be increased, as a result we have to change the structure of the

device. In place of silicon oxide we can use other oxides like Hafnium Dioxide and Lead Oxide.

The C-V curve is a practical way to determine the variation of the Threshold Voltage and the

Flat-band Voltage. This variation mainly occurs due to the change in the dielectric constant k

of the oxide used and the charge of the oxides Compared to silicon dioxide the other oxides that

we are using have a substantial higher dielectric constant.

Our purpose of the research is to compare the different oxides used graphically and to obtain the

best possible outcome for the device. Also to establish the fact that the capacitancevoltage

graph used gives an accurate result. The following parameters are going to be tested during our

comparison like

a) The dielectric constant.

b) The oxide thickness.

3.2 Reasons for choosing the oxides

Silicon dioxide is a good insulator. Replacing the SiO2 with a material having a different

dielectric constant is not as simple as it may seem. The material bulk and interface properties

must be comparable to those of silicone dioxide, which are remarkably good. For instance,

thermodynamic stability with respect to silicon, stability under thermal conditions relevant to

microelectronic fabrication, low diffusion coefficients, and thermal expansion match are quite

critical. With these objectives in mind, recent research on high-k dielectrics has primarily

focused on metal oxides and their silicates, Among these, the group JVb transition metals Zr and

Hf have generated a substantial amount of investigations. Aluminum and Titanium have also

been two other metals, which have been considered. These metals and their oxides are

20 | P a g e

compatible with silicon and that is one of the reasons for considering these. The table 3.1 shows

the characteristics of the metal oxides.

Oxides

Doping

Concentration

(em

3

)

Thickness,

L

ox

(nm)

Dielectric

Constant, K

ox

Band Gap,

Eg (ev)

Silicon dioxide (SiO2)

10

16

1.5 3.9 1.12

Hafnium Dioxide (HfO2)

10

16

.5 25 6

Hafnium Silicate (HfSiO4)

10

16

1.5 15 -

(Table 3.1) Characteristics of the metal oxides

3.3 The oxide type

Here are the brief discussions on different oxides used and their properties. We begin with the

most commonly used oxide in the existing MOSFETs.

3.3.1 Silicon Dioxide

Being an important constituent of a great many minerals and gemstones, Silicon dioxide (silica)

is one of the most commonly encountered substances in both daily life and in electronics

manufacturing. Crystalline silicon dioxide is used both in pure form and mixed with related

oxides. Under exposure to oxygen, a silicon surface oxidizes to form silicon dioxide (SiO

2

).

Native silicon dioxide is a high-quality electrical insulator and can be used as a barrier material

during impurity implants of diffusion, for electrical isolation of semiconductor devices, as a

component in MOS transistors, or as an interlayer dielectric in multilevel metallization structures

such as multichip modules. Silicon has become a prevalent semiconductor material used in

integrated circuits today mostly because of its ability to form a native oxide was one of the

primary processing considerations.

3.2.2 Hafnium Dioxide

Hafnium (IV) oxide is the inorganic compound with the formula Hf0 Also known as hafnia, this

colorless solid is one of the most common arid stable compounds of hafnium. It is an electrical

insulator with a band gap of approximately 6eV.

Hafnia is used as a high-k dielectric in capacitors. Hafnium-based oxides are currently leading

candidates to replace silicon oxide as a gate insulator in field effect transistors the advantage for

21 | P a g e

transistors is its high dielectric constant: The dielectric constant of Ht0 is 25 while the dielectric

constant of HfO2 is 25, while the dielectric constant of SiO2 is only 3.9.

The compound appears to have been chosen by both IBM and Intel as a substrate for future

integrated circuits, where it may help in the continuing effort to increase logic density and clock

speeds, or to lower power consumption, in computer processors.

3.3.3 Hafnium Silicate

Hafnium silicate (HfSiO4) is a chemical compound, a silicate of hafnium. Thin films of hafnium

silicate and zirconium silicate produced by chemical vapor deposition, most often MOCVD, can

be used as a high-k dielectric as a replacement for silicon dioxide in semiconductors. It has an

average dielectric constant of 15 which makes it suitable of the oxide usage.

3.4 Charge of the Oxides

Large charges the used high-k oxides have (compared to SiO

2

) get trapped between the insulator

and oxide giving rise to a phenomenon called the interface trapped density. The higher the

charge, the higher the interface trapped density. There is a shift in the flat-band voltage because

of this interface trapped density and it results in an increased threshold voltage. This also results

in an increase of the leakage current. Therefore high-k oxides with minimum dielectric constant

are to be chosen e.g. Hafnium Silicate, where high-k is not so high since the silicon in the

compound keeps the dielectric constant steady.

Oxides Charge (Coulomb)

SiO2

6.4*10

.

-9

HfO2 1.12*10

.

-7

HfSiO4 1.44*10

.

-8

(Table 3.2) Charge of oxides

3.5 The Doping Concentration

All electronic and optical semiconductor devices incorporate dopants as a crucial ingredient of

their device structure. Almost all of the basic MOSFET parameters are affected by the

distribution of dopants in the device. Doping refers to the process of introducing impurity atoms

into a semiconductor region in a controllable manner in order to define the electrical properties

of this region. The doping with donors and acceptors allows modifying the electron and hole

concentration in silicon in a very large range from 1013 cm3 up to 1021 cm3. The carrier

concentration can also be varied spatially quite accurately which is used to produce pn-junctions

and built-in electric fields.

22 | P a g e

Chapter

4

IMPLEMENTATION

The MOS (Metal Oxide Semiconductor) capacitor consists of a metal-oxide- semiconductor layer

structure, which forms a voltage dependent capacitor. This particular structure has been studied

extensively because it is present in all MOS transistors. The MOS capacitor is voltage dependent and

we have used this varying voltage to determine the Capacitance of the device.

Our purpose is to obtain a graph which represents the Capacitance- Voltage characteristics of a MOS

device, which; we can later manipulate to get our desired outcome.

As the capacitor is voltage dependent, first when a negative voltage is applied holes are attracted to

the interface, causing accumulation. A positive voltage on the other hand repels the holes that are

present in the p-type material and thereby creates a depletion layer. A larger positive voltage at the

gate causes sufficient bending of the energy bands in the semiconductor at the interface so that

inversion occurs, i.e. a change from holes being the majority carrier type to electrons. So the

capacitance has three equations in three cases. We have used these equations to generate the graph.

4.1 Calculation of Flat-band Voltage and Threshold Voltage

We have calculated the Flat-band voltage from the equation below,

V

fb

= u

ms

Q

ss

/ C

ox

Where,

V

fb

= The Flat-band Voltage

u

ms

= The work function difference between the metal and the semiconductor

Q

ss

= The surface charge density

C

ox

= Capacitance of the oxide

Afterwards we have calculated the Threshold Voltage

ox

C

fp

Na e

s

fp fb

V

th

V / * 2 * * * * 2 * 2

|

|

.

|

\

|

|

|

.

|

\

|

u e + u + =

23 | P a g e

4.2 Interface Trapped Density Calculation

We have calculated the interface trapped density from the equation below

Where,

= Insulator capacitance

= Low frequency capacitance

= High frequency capacitance

q = electron charge

24 | P a g e

Chapter

5

RESULT OF SIMULATION

We have taken a conventional way of plotting the Capacitance-Voltage curve. Our instructor

provided us with the testing values of capacitance for both high and low frequency for their

corresponding gate voltage.

0

50

100

150

200

250

300

-10 -8 -6 -4 -2 0 2 4 6 8 10

Gate voltage V

g

(Volts)

C

a

p

a

c

i

t

a

n

c

e

p

F

Figure 5.1 Typical Capacitance-Voltage curve.

From our simulation, for High frequency we got the following figure,

Figure 5.2 curve for high frequency capacitance

25 | P a g e

And for low frequency we got the following figure.

Figure 5.3 curve for low frequency capacitance

Figure 5.4 high frequency and low frequency c-v curve showing impact of fast interface states

26 | P a g e

Oxides D

it

SiO2 -0.2

HfSiO4 0.48

TiO2 0.5

Al2O3 0.55

(Table 5.2) Comparison of D

it

values for the oxides

Figure 5.5 comparison plots of D

it

values

From the above figures we can say our c-v curve plotting is a success. As the fast interface states

can keep pace with the low frequency variations of the gate bias(~1-1000 Hz), but not at

extremely high frequencies(~1 MHz). So the fast interface states contribute to the low frequency

capacitance but not to the high frequency capacitance , we have plotted SiO

2

and HfSiO

4

, TiO

2

, Al

2

O

3

. The difference in the D

it

value is because HfSiO

4

, TiO

2

, Al2O

3

are high k

27 | P a g e

material. So when the dielectric constant is high then the charge also increases. This means that

too much charge accumulates between the insulator and the substrate. When the charge

increases, interface trapped density also increases.

In the above figure we have plotted SiO2 and HfSiO4 that is Hafnium Silicate. It is a special kind of

oxide where a thin film of hafnium dioxide is deposited on a layer of silicon dioxide. The difference

in the Dit value is because HFSiO4 is a high k material. So when the dielectric constant is high then

the charge also increases. This means that too much charge accumulates between the insulator and

the substrate. When the charge increases, interface trapped density also increases.

28 | P a g e

Chapter

6

CONCLUSION

From the observation we did earlier, we can state we can conclude that Hafnium Silicate

(HfSiO

4

) is the most desired among all the high-k materials. The problem with Aluminum Oxide

is that it accumulates too much negative charge. When the charge increases, the interface trapped

density (Dit) also increases. This results in the shift of the flat-band voltage and as a result the

threshold voltage also increases. Increase in the threshold voltage means that the leakage current

also increases. This is a disadvantage with highk materials since their dielectric constant is too

high whereas the dielectric constant of silicon is perfect to use. Therefore by analyzing the high

materials we can say that Hafnium Silicate is the most desired material among the others. The

reason may be that it has silicon in it which keeps the dielectric constant from becoming too high

and keeps it steady. From our simulation we showed Hafnium Silicate has larger interface

trapped density compared to SiO2. Although high-k has some disadvantages, but still it is a good

trade-off from silicon dioxide because it gives us new possibilities to improve the MOS capacitor

by scaling.

29 | P a g e

ADDENDA

30 | P a g e

Addendum

I

BIBLIOGRAPHY

1. E.F. Schubert,Rensselacr Polytechnic Institute, 2003

2. OMara, William C. (1990). Handbook of Semiconductor Silicon Technology, William

Andrew Inc. p. 349352. ISBN 0815512376. Retrieved 2008-02-24.

3. 1965-Moores Law Predicts the Future of Integrated Circuits. Computer History

Museum.

4. Intel 45nm Hi-k Silicon Technology, Retrived May, 2010.

5. Principles of Electronic Devices, Bart J. Van Zeghbroeck 1996

6. International Technology Roadmap for Sethiconductors,2009

7. Robert H. Dennard, Fritz H. Gaensslen, HwaNien Yu, V Leo Rideout, Ernest Bassours,

and Andre R. LcBlanc, Design of Ion-Implanted MOSEETs with Very Small Physical

Dimensions, IEEEE J. Solid State Circuits, SC-9 (5), 256 (1974)

8. Kaushik Roy, Kiat Seng Yeo (2004). Low Voltage, Low Power VLSI Subsystems.

McGraw-Hill Professional., p. 44. ISBN 007 143786X

9. Moore, Gordon E. (1965). Cramming more components onto integrated circuits .

Electronics Magazine. pp. 4. Press_Releases/Gordon_Moore_1965_Article.pdf. Retrieved

2006-1 1-11.

10. 1965 Moores Law Predicts the Future of Integrated Circuits. Computer History

Museum. 2007. Retrieved 2010-05-19.

11. Disco, Cornelius; van der Meulen, Barend (1998). Getting new technologies together. New

York: Walter de Gruyter. pp. 206207. Retrieved 23 August 2008.

12. IEEE Spectrum: The High-k Solution, Retrieved July, 2010

13. Mark T. Bohr, Robert S. Chau, Tahir Ghani, Kaizad Mistry, I ugh-k Solution, October

2007

14. Lynn Townsend White, Jr. (1961). Eilmer of Malmesbury, an Eleventh Century Aviator:

A Case Study of Technological Innovation, Its Context and

15. Tradition. Technology and Culture 2 (2).

16. Greenwood, Norman N.; Earnshaw, A. (1984), chemistry c the Elements, Oxford:

Pergamon, pp. 1117-19, ISBN 0-08-022057-6.

17. Greenwood, Norman N.; Earnshaw, A. (1984), Chemistry of the Elements, Oxford:

Pergamon. pp. 1117-19, ISBN 0-08-022057-6

18. G.D. Wilk, R.M. Wallace, J.m. Anthony, High-k gate dielectric: Current status and

materials properties consideration. J.Appl. Phys. APPLIED PHYSICS REVIEW, Vol.89,

number 9 (2901) 5243

19. Review article by Wilk et al. in the Journal of Applied Physics, Table I

31 | P a g e

20. Intel Says Chips Will Run Faster, Using L Power. New York Times, 2007-01-27.

21. Prof. Dr. Helmut Foil, University of Kid, Semiconductor Skript, Retrieved August,

2010.

22. S. K. Lei, Interface trap generation in silicon dioxide when electronsare captured by

trapped holes, J. Appl. Phys., vol. 54, pp. 25402546, 1983.

23. B. S. Doyle, M. Bourcerie, J.-C. Marchetaux, and A. Boudou, Interface trap creation and

charge trapping in the medium-to-high gate voltage range during hot carrier stressing of n-

MOS transistors, IEEE Trans. Electron Devices, vol. 37, pp. 744754, 1990.

32 | P a g e

Addendum

II

CODE

%% Dit Calculation

ci=[1.73e-6 8.85e-6 1.42e-4 9.96e-6];

vg=[-0.22 0.48 0.5 0.55];

%%SiO2 data

clf_s=7e-12;

chf_s=4.3e-12;

q_s=1.6e-19;

%%HFSiO4 data

clf_hf=7.72e-11;

chf_hf=4.53e-12;

q_hf=1.6e-19;

%%TiO2 data

clf_t=7.78e-11;

chf_t=4.54e-12;

q_t=1.6e-19;

%%Al2O3 data

clf_a=7.81e-11;

chf_a=4.43e-12;

q_a=1.6e-19;

%%Calculation of Dit

my_dit(1)=((ci(1)*clf_s)/(ci(1)-clf_s)-(ci(1)*chf_s)/(ci(1)-

chf_s))/q_s;

fprintf('Dit for SiO2');

disp(my_dit(1));

my_dit(2)=((ci(2)*clf_hf)/(ci(2)-clf_hf)-(ci(2)*chf_hf)/(ci(2)-

chf_hf))/q_hf;

fprintf('Dit for HF');

disp(my_dit(2));

my_dit(3)=((ci(3)*clf_t)/(ci(3)-clf_t)-(ci(3)*chf_t)/(ci(3)-

chf_t))/q_t;

fprintf('Dit for TiO2');

disp(my_dit(3));

33 | P a g e

my_dit(4)=((ci(4)*clf_a)/(ci(4)-clf_a)-(ci(4)*chf_a)/(ci(4)-

chf_a))/q_a;

fprintf('Dit for Al2O3');

disp(my_dit(4));

%%Point plot

plot(vg,my_dit,'O');

xlabel('Vg---->');

ylabel('Dit---->');

text(0.4,my_dit(2),'Dit For HF');

text(-0.2,my_dit(1),'Dit For SiO2');

text(0.56,my_dit(4)*1.01,'Dit For Al2O3');

text(0.51,my_dit(3)*0.98,'Dit For TiO2');

grid on;

%% Chf values

chf=[4.50E-12

4.49E-12

4.50E-12

4.61E-12

4.48E-12

4.44E-12

4.49E-12

4.47E-12

4.54E-12

4.50E-12

4.47E-12

4.42E-12

4.48E-12

4.37E-12

4.32E-12

4.34E-12

4.47E-12

4.73E-12

5.25E-12

6.06E-12

8.10E-12

1.53E-11

3.18E-11

4.98E-11

6.13E-11

6.76E-11

7.16E-11

7.41E-11

7.59E-11

7.73E-11

7.83E-11

7.90E-11

7.98E-11

8.03E-11

8.07E-11

8.10E-11

8.14E-11

8.17E-11

34 | P a g e

8.19E-11

8.21E-11

8.24E-11

];

%% Vg values

vg=[1.3

1.2

1.1

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

-0.4

-0.5

-0.6

-0.7

-0.8

-0.9

-1

-1.1

-1.2

-1.3

-1.4

-1.5

-1.6

-1.7

-1.8

-1.9

-2

-2.1

-2.2

-2.3

-2.4

-2.5

-2.6

-2.7

];

%% Clf values

clf=[8.82E-11

8.23E-11

8.20E-11

8.14E-11

8.10E-11

35 | P a g e

8.03E-11

7.97E-11

7.86E-11

7.78E-11

7.62E-11

7.35E-11

6.99E-11

6.36E-11

5.06E-11

2.43E-11

7.89E-12

6.28E-12

7.08E-12

7.69E-12

8.76E-12

1.08E-11

1.67E-11

3.26E-11

5.04E-11

6.19E-11

6.84E-11

7.24E-11

7.48E-11

7.69E-11

7.81E-11

7.90E-11

7.99E-11

8.06E-11

8.10E-11

8.15E-11

8.19E-11

8.25E-11

8.25E-11

8.27E-11

8.29E-11

8.32E-11

];

%% Curve Plot

plot(vg,chf,vg,clf,'--');

legend('Chf vs. Vg','Clf vs. Vg');

xlabel('Voltage (Vg)-------->');

ylabel('Capacitance (Chf) & (Clf)-------->');

Vous aimerez peut-être aussi

- Multiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessD'EverandMultiscale Modeling of Additively Manufactured Metals: Application to Laser Powder Bed Fusion ProcessPas encore d'évaluation

- Engineering Energy Aluminum Conductor Composite Core (ACCC) and Its ApplicationD'EverandEngineering Energy Aluminum Conductor Composite Core (ACCC) and Its ApplicationPas encore d'évaluation

- Distribution TransformerDocument57 pagesDistribution TransformerRaj Kiran100% (4)

- Literature Review of Laser WeldingDocument7 pagesLiterature Review of Laser Weldingafmzamdswsfksx100% (1)

- Proceedings of Spie:, Qyhvwljdwlrqrigluhfwphwdovlqwhulqj Surfhvvrilurqsrzghuzlwkorzodvhu SrzhuDocument8 pagesProceedings of Spie:, Qyhvwljdwlrqrigluhfwphwdovlqwhulqj Surfhvvrilurqsrzghuzlwkorzodvhu Srzhu21adPas encore d'évaluation

- Lpvlsi Full TBDocument417 pagesLpvlsi Full TBKandikattu Abhilash100% (3)

- Low-Power VLSI Circuits and SystemsDocument33 pagesLow-Power VLSI Circuits and SystemsSYAMALAPas encore d'évaluation

- Industry Standard FDSOI Compact Model BSIM-IMG for IC DesignD'EverandIndustry Standard FDSOI Compact Model BSIM-IMG for IC DesignPas encore d'évaluation

- Basic Principles of STT-MRAM Cell Operation in Memory ArraysDocument36 pagesBasic Principles of STT-MRAM Cell Operation in Memory Arrayscvkxwnxrh8Pas encore d'évaluation

- Machining Stability of Wedm of TitaniumDocument139 pagesMachining Stability of Wedm of TitaniumSrinivas DsPas encore d'évaluation

- ReportDocument39 pagesReportcmmath75Pas encore d'évaluation

- 1.L.ji a 2nd Order Σ-Δ Modulator as Readout Circuit for SOI MEMS Accelerometers,2009Document88 pages1.L.ji a 2nd Order Σ-Δ Modulator as Readout Circuit for SOI MEMS Accelerometers,2009kvintacadPas encore d'évaluation

- Designing A Strain Measurement System Based On Circle Grid Analysis For Sheet Metal Forming ApplicationsDocument30 pagesDesigning A Strain Measurement System Based On Circle Grid Analysis For Sheet Metal Forming ApplicationsVilas KulkarniPas encore d'évaluation

- Design and Analysis of Fast Low Power Srams: June 2002Document154 pagesDesign and Analysis of Fast Low Power Srams: June 2002Vikas JainPas encore d'évaluation

- AdnanDocument445 pagesAdnanAdnan AliPas encore d'évaluation

- DR09051 DR09051Document292 pagesDR09051 DR09051Hemantha BalasuriyaPas encore d'évaluation

- Adaptive Orbital Pipe Welding - Hamidreza LatifiDocument140 pagesAdaptive Orbital Pipe Welding - Hamidreza LatifiMalcolm DiamondPas encore d'évaluation

- A Low-Cost Open-Source Metal 3-D PrinterDocument8 pagesA Low-Cost Open-Source Metal 3-D PrinterLong GiaPas encore d'évaluation

- A Review Paper On Cmos, Soi and Finfet Technology: Einfochips Pvt. Ltd. Ahmedabad, Asic Physical Design EngineerDocument10 pagesA Review Paper On Cmos, Soi and Finfet Technology: Einfochips Pvt. Ltd. Ahmedabad, Asic Physical Design EngineerRohit JangidPas encore d'évaluation

- Project Report On Integrated CircuitDocument20 pagesProject Report On Integrated CircuitSushil Kumar67% (6)

- Thyristor ApplicationDocument29 pagesThyristor ApplicationSasi prasadPas encore d'évaluation

- Study of An n-MOSFET by Designing at 100 NM and Simulating Using SILVACO ATLAS SimulatorDocument10 pagesStudy of An n-MOSFET by Designing at 100 NM and Simulating Using SILVACO ATLAS Simulatorliviu9nanoPas encore d'évaluation

- 10-Conduits - Culverts - and PipesDocument87 pages10-Conduits - Culverts - and Pipes2003_335Pas encore d'évaluation

- Machining Stability of Wire EDM of TitaniumDocument122 pagesMachining Stability of Wire EDM of TitaniumJamadagniParitiPas encore d'évaluation

- GLIG2015 BrochureDocument16 pagesGLIG2015 BrochurecsudhaPas encore d'évaluation

- Advanced Driver Circuits: Technical ReportDocument52 pagesAdvanced Driver Circuits: Technical ReportAditya Kumar JaiswalPas encore d'évaluation

- Tutorial PADRE Simulation ToolsDocument45 pagesTutorial PADRE Simulation Toolsss626Pas encore d'évaluation

- Conference ProgramDocument30 pagesConference ProgramAhmad KusumaatmajaPas encore d'évaluation

- (Alexander A. Demkov, Alexandra Navrotsky) Materials Fundamentals of Gate DielectricsDocument477 pages(Alexander A. Demkov, Alexandra Navrotsky) Materials Fundamentals of Gate Dielectricsemmanuel799Pas encore d'évaluation

- CMOS Transistor Layout KungFuDocument39 pagesCMOS Transistor Layout KungFuAyo Iji100% (5)

- Study of Gate Length and Performance of Undoped Body Soi MosfetsDocument5 pagesStudy of Gate Length and Performance of Undoped Body Soi MosfetseditorijaiemPas encore d'évaluation

- Design of An Arduino Based Firefighting RobotDocument52 pagesDesign of An Arduino Based Firefighting RobotMuhammad HuzaifaPas encore d'évaluation

- PHD Thesis On Metal CuttingDocument7 pagesPHD Thesis On Metal Cuttingafknmwhjn100% (2)

- Service Life Assessment of Reinforced Concrete Structures Based On Numerical Analysis of Chloride Ingress Into ConcreteDocument102 pagesService Life Assessment of Reinforced Concrete Structures Based On Numerical Analysis of Chloride Ingress Into ConcreteBOUADOUPas encore d'évaluation

- Amp Qb.Document6 pagesAmp Qb.svkarthik83Pas encore d'évaluation

- VLSI Fabrication and CharacterizationDocument40 pagesVLSI Fabrication and CharacterizationKarthik RamasamyPas encore d'évaluation

- AWS-Welding Journal-March 2014Document155 pagesAWS-Welding Journal-March 2014ran.ben.ariePas encore d'évaluation

- (Dr.P.S.bimbhra) Power ElectronicsDocument788 pages(Dr.P.S.bimbhra) Power ElectronicsVenkat100% (1)

- Footstep Energy Harvesting Using PiezoelectricityDocument53 pagesFootstep Energy Harvesting Using PiezoelectricityKavirajJayaraman86% (7)

- A Low Cost Open Source Metal 3 D PrinterDocument8 pagesA Low Cost Open Source Metal 3 D PrinterJayPas encore d'évaluation

- MSF 1029 15Mei2021MF1Document10 pagesMSF 1029 15Mei2021MF1rheyneillborasPas encore d'évaluation

- OPDK-1.6 User Manual 2014Document86 pagesOPDK-1.6 User Manual 2014Mukti MehraPas encore d'évaluation

- Construction Practice of Distribution TransformerDocument58 pagesConstruction Practice of Distribution TransformerRaj Kiran100% (3)

- Semiconductors SimplifiedDocument18 pagesSemiconductors SimplifiedbelindaPas encore d'évaluation

- Assignment 2: Rayyan Sayeed 1MS12EC098Document17 pagesAssignment 2: Rayyan Sayeed 1MS12EC098RayyanSayeedPas encore d'évaluation

- Crompton Greaves Training ReportDocument45 pagesCrompton Greaves Training ReportStuti ShrivastavaPas encore d'évaluation

- PLTCM Project at Tata SteelDocument24 pagesPLTCM Project at Tata SteelRama Ranjan Samantaray0% (1)

- Effects of Internal Fields in Quantum Dots: OpensiucDocument69 pagesEffects of Internal Fields in Quantum Dots: OpensiucdasdfsadPas encore d'évaluation

- Btech ThesisDocument40 pagesBtech Thesisਸਰਦਾਰ Supreet SinghPas encore d'évaluation

- A Subthreshold Analysis of Triple-Material Cylindrical Gate-All-Around (TM-CGAA) MosfetsDocument66 pagesA Subthreshold Analysis of Triple-Material Cylindrical Gate-All-Around (TM-CGAA) MosfetsSameer MansuriPas encore d'évaluation

- Signature Redacted Signature RedactedDocument91 pagesSignature Redacted Signature RedactedElias AsmarPas encore d'évaluation

- Design for High Performance, Low Power, and Reliable 3D Integrated CircuitsD'EverandDesign for High Performance, Low Power, and Reliable 3D Integrated CircuitsPas encore d'évaluation

- Millimeter-Wave Digitally Intensive Frequency Generation in CMOSD'EverandMillimeter-Wave Digitally Intensive Frequency Generation in CMOSPas encore d'évaluation

- Relevant Characteristics of Power Lines Passing through Urban AreasD'EverandRelevant Characteristics of Power Lines Passing through Urban AreasPas encore d'évaluation

- Basic Financial Statement Analysis SampleDocument2 pagesBasic Financial Statement Analysis SampleMohammed Tawsif SalamPas encore d'évaluation

- Basic Financial Statement Analysis SampleDocument2 pagesBasic Financial Statement Analysis SampleMohammed Tawsif SalamPas encore d'évaluation

- Dissertation ScratchDocument1 pageDissertation ScratchMohammed Tawsif SalamPas encore d'évaluation

- Sample InvoiceDocument1 pageSample InvoiceMohammed Tawsif SalamPas encore d'évaluation

- Comparison Based On Financial RatiosDocument2 pagesComparison Based On Financial RatiosMohammed Tawsif SalamPas encore d'évaluation

- Sample Curriculum VitaeDocument24 pagesSample Curriculum VitaeMohammed Tawsif SalamPas encore d'évaluation

- Sample Curriculum VitaeDocument24 pagesSample Curriculum VitaeMohammed Tawsif SalamPas encore d'évaluation

- Managing in Changing and Difficult Times: The Case of World AirlinesDocument11 pagesManaging in Changing and Difficult Times: The Case of World AirlinesMohammed Tawsif SalamPas encore d'évaluation

- Oceans 11 ScreenplayDocument154 pagesOceans 11 ScreenplayMohammed Tawsif Salam100% (3)

- Approach To Research Topic, Question and ObjectivesDocument2 pagesApproach To Research Topic, Question and ObjectivesMohammed Tawsif SalamPas encore d'évaluation

- Journal Article - Session 1Document19 pagesJournal Article - Session 1Mohammed Tawsif SalamPas encore d'évaluation

- 2023 Occ 1ST ExamDocument3 pages2023 Occ 1ST ExamSamantha LaboPas encore d'évaluation

- Gland Pharma LimitedDocument1 pageGland Pharma LimitedParas MaloutPas encore d'évaluation

- Gestalt Peeling The Onion Csi Presentatin March 12 2011Document6 pagesGestalt Peeling The Onion Csi Presentatin March 12 2011Adriana Bogdanovska ToskicPas encore d'évaluation

- Six Models of OrganizationDocument5 pagesSix Models of Organizationmh_sadri100% (1)

- Ich GuidelinesDocument5 pagesIch GuidelinesdrdeeptisharmaPas encore d'évaluation

- Elaine Risley's Character DevelopmentDocument12 pagesElaine Risley's Character Developmenterlooay100% (1)

- Environment Setup - User Manual PDFDocument38 pagesEnvironment Setup - User Manual PDFambrishPas encore d'évaluation

- Outlook Errors & SMTP ListDocument19 pagesOutlook Errors & SMTP Listdixityog0% (1)

- Population, Sample and Sampling TechniquesDocument8 pagesPopulation, Sample and Sampling TechniquesMuhammad TalhaPas encore d'évaluation

- SQL Data Base ResumeDocument3 pagesSQL Data Base ResumeraamanPas encore d'évaluation

- Student Management System Project in C++Document3 pagesStudent Management System Project in C++rainu sikarwarPas encore d'évaluation

- Gavrov Sergey Modernization of Russia The Post of Imperial TransitDocument238 pagesGavrov Sergey Modernization of Russia The Post of Imperial TransitGavrov, Sergey Nazipovich100% (1)

- Teaching PortfolioDocument25 pagesTeaching Portfolioazazel28Pas encore d'évaluation

- Legal PhilosophyDocument22 pagesLegal Philosophygentlejosh_316100% (2)

- An Introduction To Genre Theory: January 1997Document16 pagesAn Introduction To Genre Theory: January 1997pratolectusPas encore d'évaluation

- Internal Audit Report Template 1Document8 pagesInternal Audit Report Template 1Zia MalikPas encore d'évaluation

- Fehling Solution "B" MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesFehling Solution "B" MSDS: Section 1: Chemical Product and Company IdentificationAnnisaPas encore d'évaluation

- Assignment - Value Stream Map - Narrative - Coffee Beans Ver1.3Document3 pagesAssignment - Value Stream Map - Narrative - Coffee Beans Ver1.3Sakthi VelPas encore d'évaluation

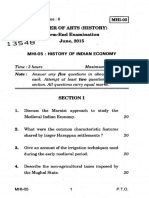

- Mhi 05 12Document6 pagesMhi 05 12aravPas encore d'évaluation

- Funda 2 Online Backup Data File - 12 MayDocument4 pagesFunda 2 Online Backup Data File - 12 Mayapi-3745527Pas encore d'évaluation

- 4.9 The Joukowski Mapping: Circles To EllipsesDocument12 pages4.9 The Joukowski Mapping: Circles To EllipsesPerita CromagnoliPas encore d'évaluation

- Oracle AlertsDocument3 pagesOracle AlertstsurendarPas encore d'évaluation

- Alfredo Espin1Document10 pagesAlfredo Espin1Ciber Genesis Rosario de MoraPas encore d'évaluation

- 495 TextDocument315 pages495 TextSaiful LahidjunPas encore d'évaluation

- Diagnosing Borderline Personality DisorderDocument12 pagesDiagnosing Borderline Personality DisorderAnonymous 0uCHZz72vwPas encore d'évaluation

- To Fur or Not To FurDocument21 pagesTo Fur or Not To FurClaudia CovatariuPas encore d'évaluation

- Endocrine System Lesson Plan-1Document2 pagesEndocrine System Lesson Plan-1Je Lan NiePas encore d'évaluation

- PID Piping Instrumentation Diagram Software enDocument2 pagesPID Piping Instrumentation Diagram Software enavailmePas encore d'évaluation

- HSE Communication ProcedureDocument7 pagesHSE Communication ProcedureWanda QurniaPas encore d'évaluation

- 90204-1029DEC - External IO Manual (F Series)Document108 pages90204-1029DEC - External IO Manual (F Series)vasilisaPas encore d'évaluation