Académique Documents

Professionnel Documents

Culture Documents

Fuel Management System

Transféré par

NakkolopDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fuel Management System

Transféré par

NakkolopDroits d'auteur :

Formats disponibles

http://www.slideshare.

net/moynulbd/loss-prevention-in-bunkering

Fuel Management System Presentation Transcript

1. Bunker Manager DEMO This software will determine bunker quantity (Crude oil, Residual Fuel Oil, Gasolines, Lube oil) of tanker using the ASTM tables. AllASTM tables for quantification of petroleum products are incorporated with this software. This is a demo program, thats why most of the features shown in one page. I have tested the calculated data with DNVPS Bunker Master software and found almost same results. For a fixed vessel, this software can be made fully automated where it will take the tank sounding, tank temperature and vessel draft as input and the corrected volumes for all tanks will come from database (once generated from original calibration tables). based on tank sounding 2. FUEL MANAGER DEMOThis a fully automated software developed for a Barge Mounted Power Plant consisting 7 nos of storage tank inside the barge.Since barge list and trim are changing everyday. It requires list and trim correction for every volume determination. To manage fuel inventory, they take tank sounding, then calculate observed volume manually using list and trim correction table, then calculate standard volume and quantity in MT using another software (DNVPS Bunker Master). To determine fuel quantitymanually, it took almost an hour. After developing this software, the time reduced to just one minute. Moreover, no need to see the calibration table, no need to run Bunker Master Software. It only taking tank sounding, tank temperature, density at 15oC and barge drafts as input. All data are being stored in a database for future reference. 3. Bunker Handler (To determine loss and gain in bunkering) DemoThis is another useful software for bunker handling. It consider all factors related to bunker quantity and use dynamic material balance to determine the volume shrinkage/expansion due to the temperature difference of incoming and receiving vessel. The above picture showing an oil tanker delivering bunker in a shore tank possessing temperature 40oC and after delivery the tank temperature drops to say 30 oC. According to the calculation, the incoming vessel wont find 13.73 MT (Shrinkage quantity) oil if they ignore the temperature correction. 4. Bunker Handler (To determine loss and gain in bunkering) Demo This is another useful software for bunker handling. It consider all factors related to bunker quantity and use dynamic material balance to determine the volume shrinkage/expansion due to the temperaturedifference of incoming and receiving vessel. The above picture showing an oil tanker delivering bunker in a shore tank possessing temperature 30oC and after delivery the tank temperature increases to say 40o C. According to the calculation, the receiving vessel will pay for 13.83 MT (Expanded quantity) that they have not received if they ignore the temperature correction. 5. Fuel Terminal Manager DemoThis is another software under development to maintain the terminal fuel inventory system. 6. Expecting your valuable suggestion about this presentation Those projects are under development.If you are interested to customize/automate your fuel management system, please contact via email mdmoynul@yahoo.com or via mobile +8801816449869

Marine Fuel Oil and Fuel Oil Bunkering Procedure Presentation Transcript

1. Marine Fuel Oil and Fuel Oil BunkeringPrepared ByMd. Moynul IslamChemical EngineerExpertise on Fuels, Lubricants and Industrial Water TreatmentContactEmail : mdmoynul@yahoo.comMobile: +8801816449869 2. ContentPART-A: Marine Fuel Oil and Fuel Oil SpecificationsPART-B: Fuel Oil Delivery and Loss PreventionPART-C: Safety in Fuel Oil Handling and Storage 3. IntroductionAs a buyer, you are not buying just fuels for your power plant, you are buying the energy whichis the base of your business. Every year you are spending millions of dollars behind fuels. Andyour business profit is directly related to the quality fuels. Proper monitoring in your

fuelmanagement system is vitally needed to run your power business profitably.So, you have the right to know about the fuel specifications and also have the right to receiveactual quantity that you have ordered to the supplier. Receiving off spec fuel or less quantity(from your ordered quantity) will ultimately impart on loss in energy. Loss in energy means lossin generation followed by loss in revenue.Your fuel supplier may settle your ordered quantity by manipulating some digits but theproblem arises later when you will use this fuel in your engines. The engines are very rude toyou about fuel consumption. To generate your desired power they will never compromise evena single drop in their consumption. They will consume exactly the required amount of fuel togenerate your ordered power to them. They will consume fuels according to your fuel quality. Ifthe calorific value of supplied fuel is high than the fuel consumption will be low and if thecalorific value is low than the fuel consumption will be high. So, you need to understand aboutbunker and bunkering procedure before entering in this world. If you supply them any off specfuel, it may be complicated to operate them smoothly or there may be severe damage toengine component following breakdown maintenance. Ultimately interruption in smooth engineoperation. 4. Origin of Marine Fuel Oils (MFO)Oil Refineries and the Production of Fuel Oil:An oil refinery is a Petrochemical Industry that converts crude oil into a range of usable products. It is designed toproduce what the market requires in the most economical and efficient manner. Crude Oil Conversion Process : Look at the flow diagram to the right. The major steps for converting crude oil into different products. Step01: Separation of Lighter Fractions: In this step, the crude oil is heated up to approx. 350 oC and enter to the Atmospheric Distillation Unit (ADU) where the most of the lightest fractions are recovered via distillation at atmospheric pressure. The bottom residue of ADU is further heated up and sends to the Vacuum Distillation Unit (VDU) where all of the volatile components are recovered via distillation at low pressure. Step-02: Production of Marine Fuel Oil The viscosity of heavy residue of VDU is very high. To produce MFO, the heavy residue is feed to the vis-breaking unit where a cutter stock (fuel oil heaving low viscosity) is used to reduce viscosity to the desired level. 5. Classification of Marine Fuel Oil Conventional Classification SystemIn maritime industry the most commonly used fuel oil classification system is as followsMGO (Marine Gas Oil) - Roughly equivalent to No. 2 fuel oil, made from distillateMDO (Marine Diesel Oil) - A blend of heavy gasoil that may contain very small amount of black refinery feed stocks, but has a low viscosity up to 12 cSt and it need not be heated for use in IC enginesIFO (Intermediate Fuel Oil) - A blend of HFO with less gasoil than MDO.MFO (Marine Fuel Oil) - Same as HFO (just another name)HFO(Heavy Fuel Oil) - Pure or nearly pure residual fuel oil, roughly equivalent to No. 6 fuel oilAnother classification system in maritime industry for fuel oil is based on their maximum viscosity in cSt at 50oCIFO-380 -Intermediate Fuel Oil with max viscosity of 380 cSt at 50 oCIFO-180 -Intermediate Fuel Oil with max viscosity of 180 cSt at 50 oCLS-380 -Los Sulfur (<1.5%) Intermediate Fuel Oil with max viscosity of 380 cSt at 50 oCLS-180 -Los Sulfur (<1.5%) Intermediate Fuel Oil with max viscosity of 180 cSt at 50 oCMGO -Marine Gas OilMGO -Marine Gas Oil 6. Classification of Marine Fuel OilBased on chain length and extraction process the fuel oils are classified as follows Serial Name Alias Type Chain Length 1 No. 1 Fuel Oil No. 1 Diesel Fuel Oil Distillate 9-16 2 No. 2 Fuel Oil No. 2 Diesel Fuel Oil Distillate 10-20 3 No. 3 Fuel Oil No. 3 Diesel Fuel Oil Distillate 10-20 4 No. 4 Fuel Oil No. 4 Residual Fuel Oil Distillate/Residual 12-70 5 No. 5 Fuel Oil Heavy Fuel Oil Residual 12-70 6 No. 6 Fuel Oil Heavy Fuel Oil Residual 20-70According to ASTM D975:2004 Diesel fuels are classified based on Maximum sulfur content Grade Description Max SulfurNo. 1-D S15 A special purpose light distillate fuel use in diesel engine applications with frequent and widely 15 ppmNo. 1-D S500 varying speeds and loads or when abnormally low operating temperatures are encountered. 500 ppmNo. 1-D S5000 More volatile compared to No.2 fuels. 5000 ppmNo. 2-D S15 A general purpose , middle distillate fuel for use in diesel engines especially in applications with 15 ppmNo. 2-D S500 relatively high loads and uniform speeds, or in diesel engines not requiring fuels having higher 500 ppmNo. 2-D S5000 volatility. 5000 ppmNo. 3 D No. 3D Diesel Fuel Oil is a middle distillate having chain length 10-20 A heavy distillate fuel, or blend of distillate and residual oil, for low and medium speed dieselNo. 4-D engines in applications involving predominantly constant speed and load These are the heavier fuel oils (residual) having chain length 12-70, which are primarily used forNo. 5 &6 heating purpose and in large marine engines.The Sxxx designation was first adopted in the D975-04 edition to distinguish grades by sulfur content. S5000 grades referred to the Regular Sulfur (RSD) grades and S15 grades referred to the Ultra Low Sulfur (ULSD) grades.

7. Classification of Marine Fuel Oil Modern Fuel Classification System An ASTM standard (D2069) once existed for marine fuels but it has been withdrawn. Because it was technically equivalent to ISO 8217. ASTM D2069 covered four kinds of marine distillate fuels:Grade DescriptionDMX A special purpose light distillate intended mainly for use in emergency engines. DMA (also called Marine Gas Oil MGO) is a general purpose marine distillate that must be free fromDMA traces of residual fuel. DMX and DMA are mainly used in Category 1 marine engines (< 5 liters/cylinder) . DMB (also called Marine Diesel Oil MDO) is allowed to have traces of residual fuel , which can be high in sulfur. This contamination with residual fuel mainly occurs in distribution process, when usingDMB the same supply means that are used for residual fuel. DMB is produced when fuels such as DMA are brought on board the vessel in this manner. DMB is typically used for Category 2 (5-30 liters/cylinder) and Category 3 (>= 30 liters/cylinder) engines. DMC is a grade that may contain residual fuel, and often a residual fuel blend. It is similar to No. 4-DDMC fuel and can be used in Category 2 and Category 3 marine diesel engines. Residual (Non-distillate) fuels are designated by the prefix RM(e.g. RMA, RME, etc). These fuels areResidual also identified by their nominal viscosity (e.g RMA10, RME180, etc.) 8. ISO 8217:2010 Specifications for Marine Distillate Fuels 9. ISO 8217:2010 Specifications for Marine Residual Fuels 10. Specifications of Marine Fuel Oils (MFO)In this section, we will concentrate our mind to learn about some technical detail about Marine Fuel Oil properties andcharacteristics and their Impact on the Diesel Engines. The important Parameters of marine fuel oils are listed below.1. Viscosity2. Density3. Micro Carbon Residue (MCR)4. Aluminum + Silicon5. Sodium6. Ash7. Vanadium8. CCAI9. Water10. Pour Point11. Flash Point12. Sulfur13. Total Sediment Potential (TSP)14. Acid Number15. Used Lube Oil (ULO)16. Hydrogen Sulfide1.0 Viscosity :Viscosity is the most important properties of marine fuel oils. This is a measures of a fuels resistance to flow.Fuel oil transfer process, fuel oil treatment system, fuel oil storage system and fuel oil injection system, etcare directly related to fuel viscosity. The picture in next slide showing the viscosity temperature relationshipof marine fuel oils. This chart will give a quick guide line about marine fuel oil handling like storagetemperature, pumping temperature, centrifuging temperature and injection temperature. 11. Viscosity Temperature Relationship for Marine Fuel Oil 12. Necessary Terms and Documents Used In Bunker Industry2.0 Density :By definition, density is the ratio of mass and volume. But volume is not an intensive properties, it is dependent onsurrounding pressure and temperature. So to measure density, the temperature must specify before. In maritime industry thedensity of fuel oil is expressed at 15 oC called standard density. The standard density (density at 15 oC) is more meaningfulrather than density in any other temperatures. Because this density is used to calculate following CalculationShell Calculated Carbon Aromaticity Index (CCAI)parameters of fuel: BPCalculation of engines peak pressureof engines specific fuel consumption LowerHigher Heating/Calorific Value (HHV)Calculated Ignition Index(CII) WeightVolume Correction Factor(VCF) by ASTM 54BHeating/Calorific Value (LHV) Density Conversion and soVolume ConversionCorrection Factor(WCF) by ASTM 56D onFrom the commercial point of view, density is an essential parameter to measure because residual fuel is ordered by weightbut supplied by volume. If the actual value is less than that stated, there will be a proportional shortfall in the quantity ofproduct supplied.Mass = PowerCost/Tonne $800Average Delivery 1000 MT, 8 Times/Month, 96 Times/YearStated Density at 15C = 0.991Actual Density at 15C = 0.986Overstatement in Density 0.005kg/lCost/Year in Lost Energy = $384000Be careful! In your fuel specification contract, the maximum density is specified 991 Kg/m3 at 15 oC. If you receive a fuelhaving observed density 989 at 30 oC temperature. Do not think that your fuel is within your specification. Actually this fuel isout of specification and actual density at 15 oC is 999.14. It will create problem in fuel purification system.Use ASTM 53B to convert observed density into standard density 13. Necessary Terms and Documents Used In Bunker Industry3.0 Micro Carbon Residue(MCR)/Asphaltenes :Micro Carbon Residue (MCR) also called Conradson Carbon Residue (CCR) is a measure of the tendency of a fuel to formcarbon deposits during combustion and indicates the relative coke forming tendencies of a heavy oil. Carbon-rich fuels aremore difficult to burn and have combustion characteristics which lead to the formation of soot and carbon deposits. Sincecarbon deposits are a major source of abrasive wear, the CCR value is an important parameter for a diesel engine. The type ofcarbon also can affect abrasive wear.Carbon residue is the percent of coked material remaining after a sample of fuel oil has been exposed to high temperaturesunder ASTM Method D-189

(Conradson) or D-524 (Ramsbottom).Asphaltenes are those components of asphalt that are insoluble in petroleum naphtha and hot heptane but are soluble incarbon disulfide and hot benzene. They can be hard and brittle and made up of large macromolecules of high molecularweight, consisting of polynuclear hydrocarbon derivatives containing carbon, hydrogen, sulfur, nitrogen, oxygen and, usually,the three heavy metals nickel, iron and vanadium.A high CCR/asphaltene level denotes a high residue level after combustion and may lead to ignition delay as well as after-burning of carbon deposits leading to engine fouling and abrasive wear. Poor engine performance caused by slow burning,high boiling point constituents results in higher thermal loading and changes in the rate of heat release in the cylinder.The carbon residue value of a fuel depends on the refinery processes employed in its manufacture. For straight run fuels, thevalue is typically 10 - 12% m/m, while for fuels from secondary refining process, the value depends on the severity of theprocesses applied. On a global basis, this value is typically 15 16%, however in some areas it can be as high as 20% m/m.Modern engines tolerant to a wide range of MCR valves. Operational experience has shown that the present generation oflarge, medium and slow speed engines designed for residual fuel can tolerate a wide range of MCR values without any adverseeffect.> 20 % High and may be problematic and cause increased fouling10 - 12 % Straight run fuels15 - 16 % Average and acceptable in modern enginesComment: Injector nozzles can become fouled using high MCR fuel. Careful control of nozzle coolingtemperature can help reduce this. 14. Necessary Terms and Documents Used In Bunker Industry4.0 Aluminum + Silicon (Catalytic Fines, CatFines) :Hard, abrasive particles, such as alumina/silica catalyst carry-over, originate in the refinery when thispowdered catalyst is added to the charge stock of a fluidic catalytic cracking (F.C.C.) unit. Due to erosionand fracture, some of the catalyst is not recovered but is carried over with the bottoms from the F.C.C.unit. Larger sized catalyst particles, >10 microns, also can be carried over if there is a defect in thecatalyst removal equipment (such as cyclone separators), if there is an upset in the operation of theF.C.C. unit, or if the heavy (low API gravity) bottoms (containing catalyst particles) are not permittedsufficient time to settle-out in heated storage (when this method is used to control catalyst carry-over).It is also possible to contaminate a clean marine residual fuel oil with catalyst particles during transport.For example, if steamship fuel (frequently containing catalyst particles) has been transported by bargeprior to moving a clean heavy fuel oil for a diesel powered ship, the barge bottom sediment will bemixed with the clean fuel oil and will contaminate it.Because cat-fines are generally small, very hard, and quite abrasive to fuel pumps,atomizers/injectors, piston rings and liners, a number of major diesel engine builders haveconcluded that 30 ppm of alumina in the bunkered fuel oil is the upper limit for successfultreatment and engine operation. The average particle size, as well as the concentration, greatlyimpacts the wear rate of engine components. Small sized catalyst particles, in the one to ten (1-10) micron range, typically cause accelerated wear in injection pumps and injectors and onlymoderate increases in cylinder assembly wear, such as piston rings, piston grooves, and liners.The larger sized catalyst particles, in the ten to seventy (10-70) micron range, typically cause veryaccelerated wear rates in the cylinder assembly area. Accelerated damage can also be expectedon injection pump inlet valves, exhaust valve seating areas, and turbocharger turbine blades.These larger sized particles have been associated with catastrophic wear rates. 15. Necessary Terms and Documents Used In Bunker Industry5.0 Sodium(Na):Sodium is an alkaline, chemically extremely active metallic element. The sodium found in fuel can comefrom several sources. But most of it is a direct result of storing and handling procedures from the time thefuel leaves the refinery until it is delivered to bunkers. Salt water contamination in barges used to transportthe fuel is not uncommon. To some extent, even salt air condensation in fuel tanks contributes to theoverall sodium content.Sodium acts as a paste (flux) for vanadium slag. When unfavorable quantities of vanadium and sodium arepresent in a fuel they react at combustion temperatures to form (eutectic) compounds with ash meltingpoints within operating temperatures. In molten form sodium/vanadium ash can corrode alloy steels, andwhen this condition is allowed to persist unchecked, high temperature corrosion, overheating, and eventualburning away of exhaust valves, valve faces, and piston crowns is not uncommon.The chief corrosive constituents in heavy fuel, oil ash formed during combustion are vanadium pentoxide,sodium sulphate, and other complex forms of these primary compounds. The chemical nature of thesecompounds and their interaction with steel surfaces on exhaust valve seats are of real concern, as therelatively low melting points of most of these compounds make them very corrosive at normal engineexhaust temperatures. The thickness of the various oxide layers depends on the temperature and theexhaust gas composition. In their molten states, the vanadium-sodium-sulfur compounds also act todissolve the exhaust valve surface ferric oxide (Fe203) layer, thus exposing the

underlying steel surface tofurther oxidation attack and subsequent erosion.The oxidation attack takes place by two mechanisms: gas phase oxidation and liquid phase oxidation. In thegas phase oxidation, the high temperature oxygen-containing exhaust gases react with steel to form oxides.Liquid phase oxidation (corrosion) takes place when molten sulfates and pyrosulfates in the exhaust gasesdeposit on valve surfaces. In extreme situations, similar sodium/vanadium ash corrosion attack can alsooccur downstream of the exhaust valves in the turbocharger exhaust gas turbine and blades. 16. Sodium -Vanadium Phase Diagram676.67 oC593.33 oC482.22 oC 17. Necessary Terms and Documents Used In Bunker IndustryRegardless of the manner of contamination, sodium in fuel is usually water soluble and can, therefore, beremoved with the centrifugal separator.6.0 AshThe ash contained in heavy fuel oil includes the (inorganic) metallic content, other non-combustibles and solidcontamination. The ash content after combustion of a fuel oil takes into account solid foreign material (sand, rust,catalyst particles) and dispersed and dissolved inorganic materials, such as vanadium, nickel, iron, sodium,potassium or calcium.Ash deposits can cause localized overheating of metal surfaces to which they adhere and lead to the corrosion ofthe exhaust valves. Excessive ash may also result in abrasive wear of cylinder liners, piston rings, valve seats andinjection pumps, and deposits which can clog fuel nozzles and injectors.In heavy fuel oil, soluble and dispersed metal compounds cannot be removed by centrifuging. They can form harddeposits on piston crowns, cylinder heads around exhaust valves, valve faces and valve seats and in turbochargergas sides.High temperature corrosion caused by the metallic ash content can be minimized by taking these engine designfactors into consideration; (1) hardened atomizers to minimize erosion and corrosion and (2) reduction of valveseat temperatures by better cooling.7.0 VanadiumVanadium is a metallic element that chemically combines with sodium to produce very aggressive low meltingpoint compounds responsible for accelerated deposit formation and high temperature corrosion of enginecomponents.Vanadium itself is responsible for forming slag on exhaust valves and seats on 4cycle engines, and piston crownson both 2- and 4-cycle engines, causing localized hot spots leading eventually to burning away of exhaust valves,seats and piston crowns. When combined with sodium, this occurs at lower temperatures and reduces exhaustvalve life. As the vanadium content (ppm) increases, so does the relative corrosion rate. 18. Necessary Terms and Documents Used In Bunker IndustryVanadium is oil soluble. It can be neutralized during combustion by the use of chemical inhibitors (such asmagnesium or silicon). Cooling exhaust valves and/or exhaust valve seats will extend valve and seat life. Raisingfuel/air ratios also prolongs component life. Other measures which can be used to extend component life arethe use of heat resistant material, rotating exhaust valves, and the provisions of sufficient cooling for the hightemperature parts.Vanadium content varies widely in heavy fuel oils depending on the crude oil source or crude oilmixes used by the refinery.The vanadium levels of future heavy fuel oils generally will be higher than todays. This is particularly true offuel oils produced from Venezuelan and Mexican crude. Vanadium cannot presently be economically reducedor removed by the refinery or the ships systems. The burden of coping with high vanadium levels will continueto remain with engine builders and ship operators. This tolerance must be achieved through advances inmaterials and cooling techniques and through the use of onboard treatment methods such as chemicaladditives.In general, fuel when delivered contains a small amount of sodium which is typically below 50 mg/kg. Thepresence of sea water increases this value by approximately 100 mg/kg for each per cent sea water. If notremoved in the fuel treatment process, a high level of sodium will give rise to post-combustion deposits inthe turbocharger. Although potentially harmful, these can normally be removed by water washing.High temperature corrosion and fouling can be attributed to vanadium and sodium in the fuel. Duringcombustion, these elements oxidize and form semi-liquid and low melting salts which adhere to exhaustvalves and turbochargers. In practice, the extent of hot corrosion and fouling are generally maintained at anacceptable level by employing the correct design and operation of the diesel engine. Temperature controland material selection are the principal means of minimizing hot corrosion. It is essential to ensure exhaustvalve temperatures are maintained below the temperatures at which liquid sodium and vanadium complexesare formed and for this reason valve face and seat temperatures are usually limited to below 450C. 19. Necessary Terms and Documents Used In Bunker IndustryWhen a fuel is bunkered with a vanadium level greater than that recommended by the engine designer, thereis a risk that hot corrosion and fouling may occur. One operational solution is by the use of a fuel additive,and numerous ash-modifying compounds are available. They should be used with care as situations can arisewhere the effect of the

ash-modifier, by incorrect application, can cause further problems in the downstreampost-combustion phase.Comment: Do not run on V levels above spec for extended intervals. Watch for Na:V of 1:3 ratio.Vanadium, Sodium and Ash will cause fouling in the Turbocharger.8.0 CCAIThe most common method of assessing this aspect is by an empirical equation involving density andviscosity, known as the Calculated Carbon Aromaticity Index (CCAI). Of the two parameters, density has themajor effect. The incidence of fuels with a CCAI exceeding 870 is in the order of 0.2% , whilst those in therange 870-860 are less than 3%. 20. Necessary Terms and Documents Used In Bunker IndustryCombustion of a residual fuel is a multistage process of which one part is the ignition quality of the fuel.Fuel takes a finite time from the start of the injection to the start of combustion. During this period, fuel isintimately mixed with the hot compressed air in the cylinder where it begins to vaporize. After a short delayknown as the ignition delay, the heat of compression causes spontaneous ignition to occur.Rapid uncontrolled combustion follows as the accumulated vapor formed during the initial injection phase isvigorously burned. The longer the ignition delay, the more fuel will have been injected and vaporized duringthis pre-mixed phase and the more explosive will be the initial combustion. The second phase or diffusionburning phase of combustion is controlled by how rapidly the oxygen and remaining vaporized fuel can bemixed as the initial supply of oxygen near the fuel droplets has been used during the pre-mixed combustion.Rapid pre-mixed combustion causes very rapid rates of pressure rise in the cylinder resulting in shock waves,broken piston rings and overheating of metal surfaces. Large diesel engines are designed to withstand acertain rate of pressure rise within the cylinder although the figure will vary between different designs.Ignition performance requirements of residual fuels in large diesel engines are primarily determined byengine type and, more significantly, engine operating conditions. Fuel factors influence ignitioncharacteristics to a much lesser extent. It is for this reason that no general limits for ignition quality can beapplied, since a value which may be problematical to one engine under adverse conditions may performquite satisfactorily in many other circumstances. Engine operation under part load conditions using high CCAIfuel should be avoided.CCAI and CII are empirical attempts to estimate how long the fuel will take from injection to ignition and byimplication the likelihood of engine damage. After calculating the CCAI or CII of a fuel, the operator mustthen judge the acceptability of that fuel for effective operation in the engine. Variations of engine load, ratedspeed and design affect the likelihood of poor combustion, hence it is impossible to give precise figures thatapply to all engines. The figure above gives guidance in relation to CCAI for a number of engine types. Thisdata is derived from the results of engine simulations and published performance criteria. 21. PART-BFuel Oil Delivery and Loss Prevention 22. PART-B: Fuel Oil Delivery and Loss PreventionFuel Oil Bunkering is a fuel oil transfer process, where a large quantity of fuel is transferred from one vessel (supplier vessel) to another vessel (receiver tank or vessel) in a systematic way. In bunker industry the well established trading unit of bunker fuel is metric tones(MT). There has some technical advantages to use this unit in purchasing bunker.(1) MT is a unit of mass which is not dependent on temperature, (2) All types of energy calculations are directly related to the mass of fuel rather than volume.For the sellers, you are selling fuels, and you have to be clean and reliable in your business by supplying actual information and technical data about the fuel which you are supplying/delivering to your customer.Due to the complexity in calculation procedure and limitation of time standard procedure of bunkering is rarely followed. But without a standard measurement system, attaining accurate result is quite impossible. This is the Tomain reason of discrepancies in bunkering.The key objectives of this effort: To establish IBIAautomate the bunker calculation processes using computer. To visualize the sources ofstandard procedure in bunkering in Bangladesh. To minimize discrepancies in bunkering byerror in bunkering in Bangladesh Enhancing the fuel system monitoringremoving erroneous procedures in bunkering in HFO/LFO based power plant 23. Necessary Terms and Documents Used In Bunker IndustryDensity :We know that volume is an extensive properties which is dependent on the temperature and the pressure. So, to measure density of fuel oil, the temperature and pressure must consider. In maritime industry the density of fuel oil is expressed at 15 oC called density at standard temperature. The standard density (density at 15 oC) is more meaningful rather than density in any other temperature. Because this density is used to calculate following parameters of fuel;i. Shell Calculated Carbon Aromaticity Index (CCAI)ii. BP Calculated Ignition Index(CII)iii. Higher Heating/Calorific Value (HHV)iv. Lower Heating/Calorific Value

(LHV)v. Volume Correction Factor(VCF) by ASTM 54Bvi. Weight Correction Factor(WCF) by ASTM 56Dvii. Volume Conversionviii. Density Conversion and so onBe careful! In your fuel specification contract, the maximum density is specified 991 Kg/m3 at 15 oC. If you receive a fuel having observed density 989 at 30 oC temperature. Do not think that your fuel is within your specification. Actually this fuel is out of specification and actual density at 15 oC is 999.14TABLE ASTM 53B is used for density correction from observed density to standard density 24. Purchase Bunker by Mass rather than by VolumeObserve the pictures below, fuel oil is being shipped from a hotter region to a cooler region. The volume is different but the mass is remaining the same. So trading fuel by mass is more convenient rather than by volume. As a large volume of fuel is involved in bunkering and its quite impossible to measure the fuel quantity by mass using a weight measuring machine. Thats why the mass (an intensive properties) of fuel is measured indirectly from volume and density (two extensive properties of fuel). Converting fuel volume into mass is not an easy job just by multiplying the observed volume with observed density. Its a critical job. Mass should be calculated following standard procedure. Accuracy in calculation procedure is important as fuel oil is not a low valued product like water. Hence, care should be taken before calculating the mass. The cost of small error in calculation procedure is much more higher than spending small effort in standard measurement. 25. Purchase Bunker by Mass rather than by VolumeObserve the column chart below, an oil tanker carrying fuel oil from one location to another location.Location 01:Temperature in Location 01 = 50 oCQuantity by Mass in Location 01 = 1413.09 MTQuantity by Volume in Location 01 = 1500 m3Location 02:Temperature in Location 02 = 30 oCQuantity by Mass in Location 02 = 1413.09 MTQuantity by Volume in Location 02 = 1478.48 m3Location 03:Temperature in Location 03 = 15 oCQuantity by Mass in Location 03 = 1413.09 MTQuantity by Volume in Location 03 = 1462.85 m3 1520 1500 1480 1460 1440 Volume(m^3) 1420 Mass (MT) 1400 1380 1360 50 30 15 26. Sounding TapeHow To Take Sounding?Follow the steps mentioned below to take sounding on a ship using the sounding tape.1) Make sure the bob is tightly held with the tape using a strap hook. Ensure that the tape is not damaged anywhere in between to avoid dropping of bob or tape inside the pipe.2) Know the last reading (reference height) of the tank in order to have a rough idea whether to take sounding or ullage.3) Apply water/ oil finding paste to get exact readings.4) Drop the tape inside the pipe and make sure it strikes the striker plate.5) Coil up the tape and check for impression of paste and then note the sounding.6) Check the trim and list of the ship to read the correct reading for volumetric content of the ship.7) Note down the sounding in the record book with signature of the officer in charge.Sounding Measuring Tape For Manual measurement of sounding, a measuring tape normally made up of brass and steel with a weighted bob attached at the end of the tape is used. Sounding pastes are also available for both water and gas oil which highlights the level of fluid in tape. 27. Reading Draft marksProcedure for Reading Draft Marks: Draft marks are numbers marked on each side of the bow and stern of the vessel. Draft marks show the distance from the bottom of the keel to the waterline. Use the small boat to go around the ship and get as near as possible to the draft mark for best viewing. This process is hard to do and involves many rules of conduct to gain the correctness and accuracy of Draft Survey itself Why accuracy in drafts reading is important? The reason is that, the tanks of a tanker is calibrated based on prcised measurement. The capacity table is generated by using accurately measured drafts. Your unintentional mistakes in drafts measurement will affect your entire calculation. So, try to collect data as accurate as possible by avoiding common error in measurement. 28. Types of HydrometersHydrometers for Oil: A hydrometer is an instrument used to measure the specific gravity(or relative density) of liquids. Hydrometers for oils are specifically designed for the testing of oil and petroleum products, and are made in accordance with national and international standards. They can be supplied with calibration certificates, or certificates showing traceability to national NAMAS standards. Hydrometers varies depending on the scales and field of applications. The common types of hydrometers are as follows: Specific Gravity Hydrometers (spgr 60/60 oF) calibrated at 60 oF Density Hydrometers calibrated at 20 oC (at 68 oF) API/ASTM Hydrometers Baume Hydrometers Brix Hydrometers Twaddle Hydrometers Plain Form HydrometersHow to use a hydrometer: Before using the hydrometer Make sure both the hydrometer and hydrometer jar are clean. If the liquid to be tested is not at room temperature, allow it to reach room temperature before testing. Pour the liquid carefully into the hydrometer jar to avoid the formation of air bubbles. Do this by pouring it slowly down the side of the jar. Stir the liquid gently, avoiding the formation of air bubbles.Comment: Visually, Density Hydrometer and Specific Gravity Hydrometer are same but differ

in scale and calibration temperatures. Before using the hydrometer be sure about the type so that you can select right ASTM tables for density/specific gravity correction. Because the ASTM tables for density and specific gravity correction are different. For density hydrometer ASTM53B and for specific gravity hydrometer ASTM 23B are used. 29. How to take reading from a hydrometer?How to take reading from a hydrometer: Carefully insert the hydrometer into the liquid, holding it at the top of the stem, and release it when it is approximately at its position of equilibrium. Note the reading approximately, and then by pressing on the top of the stem push the hydrometer into the liquid a few millimetres and no more beyond its equilibrium position. Do not grip the stem, but allow it to rest lightly between finger and thumb. Excess liquid on the stem above the surface can affect the reading. Release the hydrometer; it should rise steadily and after a few oscillations settle down to its position of equilibrium. If during these oscillations the meniscus is crinkled or dragged out of shape by the motion of the hydrometer, this indicates that either the hydrometer or the surface of the liquid is not clean. Carefully clean the hydrometer stem. If the meniscus remains unchanged as the hydrometer rises and falls, then the hydrometer and liquid surface are clean, and a reading can be taken. The correct scale reading is that corresponding to the plane of intersection of the horizontal liquid surface and the stem. This is not the point where the surface of the liquid actually touches the hydrometer stem. Take the reading by viewing the scale through the liquid, and adjusting your line of sight until it is in the plane of the horizontal liquid surface. Do not take a reading if the hydrometer is touching the side of the hydrometer jar. 30. Measuring The TemperatureMeasuring The Temperature: Using a suitable thermometer, take the temperature of the liquid immediately after taking the hydrometer reading. If there is any chance of a change in the temperature of the liquid it is safer to take the temperature both before and after the hydrometer reading. A difference of more than 1C means that the temperature is not stable, and the liquid should be left to reach room temperature. If the temperature of the liquid is not the same as that on the hydrometer scale, the hydrometer reading should have a correction due to temperature applied. Handling the Hydrometer The hydrometer should never be held by the stem, except when it is being held vertically. When holding the stem, always hold it by the top, as finger-marks lower down can affect the accuracy of the instrument. Always handle with care. 31. Necessary Terms and Documents Used In Bunker IndustryLIST and TRIM Correction Table: A certified calibration table for LIST and TRIM correction table.Calibration Tables: A certified capacity table derived from the tank dimension to measure the bulk volume by providing tank sounding/ullage data. Make sure that the calibration table is original and accurate. It is not unknown for duplicate barge tables to be used. At first sight they appear in order but have, in fact, been modified to the advantage of the supplier. Inserted pages, photocopies, corrections, different print and paper types are all indications of tampering.Meter Readings: If fuel oil delivery is determined by a meter reading, air may be pumped which will reduce the amount actually delivered. Meter readings record a volume which has to be converted to weight by knowledge of the density.Ullage: The delivery barge contends that seals on sounding pipes cannot be broken. The statement is usually backed by excuses such as customs seals or a seized sounding cock. As an alternative to gauging the tanks,fuel oil is delivered by meter and air is pumped through the meter to increase the measured delivery displayed Counter measures - dont agree to meter only fuel oil deliveries. 32. ASTM D1250: Standard Guide for Use of the Petroleum Measurement TablesASTM D1250: This guide explains in detail about use of the following petroleum measurement tablesTABLE VOLUME NAME5A VOLUME I GENERALIZED CRUDE OILS CORRECTION OF OBSERVED API GRAVITY TO API GRAVITY AT 60 oF5B VOLUME II GENERALIZED PRODUCTS CORECTION OF OBSERVED API GRAVITY TO API GRAVITY AT 60 oF6A VOLUME I GENERALIZED CRUDE OILS CORRECTION OF VOLUME TO 60oF AGAINST API GRAVITY AT 60oF6B VOLUME II GENERALIZED PRODUCTS CORRECTION OF VOLUME TO 60oF AGAINST API GRAVITY AT 60oF VOLUME CORRECTION FACTORS FOR INDIVIDUAL AND SPECIAL APPLICATIONS VOLUME CORRECTION TO 60oF6C VOLUME III AGAINST THERMAL COEFFICIENTS A 60oF23A VOLUME IV GENERALIZED CRUDE OILS CORRECTION OF OBSERVED RELATIVE DENSITY TO RELATIVE DENSITY AT 60/60oF23B VOLUME V GENERALIZED PRODUCTS CORRECTION OF OBSERVED RELATIVE DENSITY TO RELATIVE DENSITY AT 60/60 oF24A VOLUME IV GENERALIZED CRUDE OILS CORRECTION OF VOLUME TO 60oF AGAINST RELATIVE DENSITY 60/60oF24B VOLUME V GENERALIZED PRODUCTS CORRECTION OF VOLUME TO 60oF AGAINST RELATIVE

DENSITY 60/60oF VOLUME CORRECTION FACTORS FOR INDIVIDUAL AND SPECIAL APPLICATIONS VOLUME CORRECTION TO 60oF24C VOLUME VI AGAINST THERMAL COEFFICIENTS A 60oF53A VOLUME VII GENERALIZED CRUDE OILS CORRECTION OF OBSERVED DENSITY TO DENSITY AT 15oC53B VOLUME VIII GENERALIZED PRODUCTS CORRECTION OF OBSERVED DENSITY TO DENSITY AT 15oC54A VOLUME VII GENERALIZED CRUDE OILS CORRECTION OF VOLUME TO 15oC AGAINST DENSITY AT 15oC54B VOLUME VIII GENERALIZED PRODUCTS CORRECTION OF VOLUME TO 15oC AGAINST DENSITY AT 15oC VOLUME CORRECTION FACTORS FOR INDIVIDUAL AND SPECIAL APPLICATIONS VOLUME CORRECTION TO 15oC54C VOLUME IX AGAINST THERMAL COEFFICIENTS A T 15oC56D WEIGHT CORRECTION FACTOR AGAINST DENSITY AT 15oC 33. Petroleum Measurement Tables 23A CRUDE OILS 23B OIL PRODUCTS RELATIVE DENSITY AT OBSERVED TEMPERATURE RELATIVE DENSITY AT OBSERVED TEMPERATURE 0.827 0.829 0.831 0.833 0.835 0.837 0.941 0.943 0.945 0.947 0.949 0.951 TEMP F CORRESPONDING RELATIVE DENSITY 60/60F TEMP F CORRESPONDING RELATIVE DENSITY 60/60F 90 0.8389 0.8409 0.8429 0.8449 0.8468 0.8488 195 0.9906 0.9926 0.9946 0.9965 0.9985 1.0005 90.5 0.8391 0.8411 0.8431 0.8451 0.847 0.849 195.5 0.9908 0.9928 0.9948 0.9967 0.9987 1.0007 91 0.8393 0.8413 0.8433 0.8453 0.8472 0.8492 196 0.991 0.993 0.995 0.9969 0.9989 1.0008 91.5 0.8395 0.8415 0.8435 0.8455 0.8474 0.8494 196.5 0.9912 0.9932 0.9951 0.9971 0.9991 1.001 92 0.8397 0.8417 0.8437 0.8456 0.8476 0.8496 197 0.9914 0.9933 0.9953 0.9973 0.9992 1.0012 92.5 0.8399 0.8419 0.8439 0.8458 0.8478 0.8498 197.5 0.9916 0.0035 0.9955 0.9975 0.9994 1.0014 24A CRUDE OILS 24B OIL PRODUCTS RELATIVE DENSITY 60/60F RELATIVE DENSITY 60/60F 0.612 0.614 0.616 0.618 0.62 0.622 0.89 0.892 0.894 0.896 0.898 0.9TEMP F CORRESPONDING RELATIVE DENSITY 60/60F TEMP F FACTOR FOR CORRECTING VOLUME TO 60F 75 0.9863 0.9863 0.9864 0.9865 0.9866 0.9867 135 0.9671 0.9672 0.9673 0.9674 0.9675 0.9675 75.5 0.9858 0.9859 0.986 0.9861 0.9862 0.9863 135.5 0.9668 0.9669 0.967 0.9671 0.9672 0.9673 76 0.9853 0.9854 0.9855 0.9856 0.9857 0.9858 136 0.9666 0.9667 0.9668 0.9669 0.967 0.9671 76.5 0.9849 0.985 0.9851 0.9852 0.9853 0.9854 136.5 0.9664 0.9665 0.9666 0.9667 0.9668 0.9669 77 0.9844 0.9845 0.9846 0.9847 0.9848 0.9849 137 0.9662 0.9663 0.9664 0.9665 0.9666 0.9667 77.5 0.984 0.9841 0.9842 0.9843 0.9844 0.9845 137.5 0.966 0.9661 0.9662 0.9663 0.9664 0.9665 53A CRUDE OILS 53B OIL PRODUCTS DENSITY AT OBSERVED TEMPERATURE DENSITY AT OBSERVED TEMPERATURE 950.0 952.0 954.0 956.0 958.0 960.0 997 999.0 1001.0 1003.0 1005.0 1007.0TEMP C CORRESPONDING DENSITY AT 15C TEMP C CORRESPONDING DENSITY AT 15C -18 929.1 931.1 933.1 935.2 937.3 939.3 -0.5 986.9 988.9 990.9 992.9 994.9 996.9 -17.75 929.2 931.3 933.3 935.4 937.4 939.5 -0.25 987.1 989.1 991.1 993.1 995.1 997.1 -17.5 929.4 931.4 933.5 935.5 937.6 939.6 0 987.2 989.2 991.2 993.3 995.3 997.3 -17.25 929.5 931.6 933.6 935.7 937.7 939.8 0.25 987.4 989.4 991.4 993.4 995.4 997.4 -17 929.7 931.7 933.8 935.8 937.9 939.9 0.5 987.6 989.6 991.6 993.6 995.6 997.6 -16.75 929.9 931.9 934 936 938 940.1 0.75 987.7 989.7 991.7 993.7 995.8 997.8 54A CRUDE OILS 54B OIL PRODUCTS DENSITY AT 15 C DENSITY AT 15 C 990 992.0 994.0 996.0 998.0 1000.0 730 732.0 734.0 736.0 738.0 740.0TEMP C FACTOR FOR CORRECTING VOLUME TO 15 C TEMP C CORRESPONDING DENSITY AT 15C 14 1.0006 1.0006 1.0006 1.0006 1.0006 1.0006 40 0.9684 0.9686 0.9687 0.9688 0.969 0.9691 14.25 1.0005 1.0005 1.0005 1.0005 1.0005 1.0005 40.25 0.9681 0.9683 0.9684 0.9685 0.9687 0.9688 14.5 1.0003 1.0003 1.0003 1.0003 1.0003 1.0003 40.5 0.9678 0.9679 0.9681 0.9682 0.9683 0.9685 14.75 1.0002 1.0002 1.0002 1.0002 1.0002 1.0002 40.75 0.9675 0.9676 0.9678 0.9679 0.968 0.9682 15 1 1 1 1 1 1 41 0.9672 0.9673 0.9674 0.9676 0.9677 0.9679 15.25 0.9998 0.9998 0.9998 0.9998 0.9998 0.9998 41.25 0.9669 0.967 0.9671 0.9673 0.9674 0.9675 34. Bunker Delivery Receipt/Bunker Delivery Note:Bunker Delivery Receipt/Bunker Delivery Note:This a standard document originated from the fuel supplier for the purchaser containing necessary and most important information regarding the fuel that has been purchased. The purpose of the Bunker Delivery Receipt (BDR) is to record what has been transferred. Various factors are recorded in this document including: Location and time of transfer Details of product delivered Temperature of product delivered Product density at standard reference temperature Sample seal numbersCare should be taken before signing the BDR. For example, the bunkers should not be signed for in weight form, only for volume at observed temperature. The actual weight can only be calculated after a representative sample of the delivery has been tested for density. IBIA Standard Bunker Delivery Note/Receipt

35. IBIA Standard Bunker Delivery Note/Receipt 36. An Existing Bunker Delivery Note/Receipt Extracted from IBIA Standard Form for comparison 37. Bunker ChecklistBunker Checklist:Bunkering is often carried out when the engineering staff are under pressure in both time and manpower. Key checks are often missed and only come to light when it is too late. A few relevant points are detailed below: 1. The purchaser should obtain specification acceptance from the supplier. 2. Purchaser needs to advise ships Staffs what grade of fuel will be delivered and how transferred. 3. Fuels from different deliveries should be segregated as far as practical. 4. All receiving tanks need to be gauged prior to taking fuel. 5. Dont sign any documentation unless you have witnessed the actual event. 6. Always take up witness offers made by the supplier 7. If the suppliers sampling method is unknown, then sign adding the words for receipt only - source unknown. 8. Always take a fuel sample using a continuous drip method. 9. Take one sample per barge/ delivery 10. Sign the BDR for volume only, if necessary adding the words for volume only - weight to be determined after density tests. 11. Ensure good records are kept throughout the bunkering. 12. Keep accurate engine logs in the event of any subsequent problems 13. Keep fuel samples for at least 12 months. 14. Test all fuel on delivery for Viscosity, Density, Water,Stability, Pour Point and Salt (if water present). 15. Use a laboratory to check results in the event of any discrepancies being indicated by on-site test equipment. 38. MARPOL Annex VI Summery:MARPOL: MARPOL 73/78 is the International Convention for the Prevention of Pollution From Ships, 1973 as modified by the Protocol of 1978. (MARPOL is short form of Marine Pollution and 73/78 short for the years 1973 and 1978)MARPOL Annex VI Summery: Fuel oil purchasers need to advise the ships staff what grade of fuel they will receive and how it will be transferred. Fuels from different deliveries should be segregated as far as is practicable All receiving fuel oil tanks need to be gauged and the results recorded prior to taking delivery of fuel Dont sign any documentation before you have witnessed the actual event Always take up witness offers made by the suppliers representatives. If the origin and method by which the suppliers sample was obtained is unknown then sign for it adding the words for receipt only - source unknown Fuel oil samples should always be taken by continuous-drip method throughout the bunkering. If the fuel oil delivered is supplied by more than one barge, a sample should be taken of each fuel oil from the supplying barges. Sign the bunker delivery receipt only for volume delivered. If the supplier insists on a signature for weight add for volume only - weight to be determined after density testing of representative sample.Comment : Make sure that what you sign for is what you get. Be certain that the bunker receipt reflects the facts as witnessed. Do not sign anything unless you have witnessed it. Always take a representative sample. 39. Guidelines for the Sampling of Fuel Oil for Determination of Compliance with ANNEX VI of MARPOL 73/78Definitions:Suppliers representative: Suppliers representative is the individual from the bunker tanker who isresponsible for the delivery and documentation or, in the case of deliveries direct from the shore to the ship,the person who is responsible for the delivery and documentation.Ships representative: Ships representative is the ships master or officer in charge who is responsible forreceiving bunkers and documentation.Representative Sample: Representative sample is a product specimen having its physical and chemicalcharacteristics identical to the average characteristics of the total volume being sampled.Primary Sample: Primary Sample is the representative sample of the fuel delivered to the ship collectedthroughout the bunkering period obtained by the sampling equipment positioned at the bunker manifoldof the receiving ship.Retained sample: Retained sample is the representative sample in accordance with regulation 18(6) ofAnnex VI to MARPOL 73/78, of the fuel delivered to the ship derived from the primary sample.Sampling Method: The primary sample should be obtained by one of the following methods.1. Manual valve-setting continuous-drip sampler2. Time-Proportional automatic sampler3. Flow-Proportional automatic samplerSampling equipment should be used in accordance with manufacturers instructions or guidelines as appropriate. 40. Guidelines for the Sampling of Fuel Oil for Determination of Compliance with ANNEX VI of MARPOL 73/78 Manual Continuous Drip SamplerAUTOMATIC SAMPLERSampling and Sample Integrity:1. A means should be provided to seal the sampling equipment throughout the period of supply.2. Attention should be given to: a) The form of set up of the sampler b) The form of primary sample container c) The cleanliness and dryness of the sampler and the primary sample container prior to use d) The setting of the means used to control the flow to the sample container e) The method to be used to secure the sample from tampering or contamination during the bunker operation3. The primary sample receiving container should be attached to the sampling equipment and sealed so as to prevent

tampering or contamination of the sample throughout the bunker delivery period.Sampling location: For the purpose of these guidelines a sample of the fuel delivered to the ship shouldbe obtained at the receiving ships inlet bunker manifold and should be drawn continuously throughout thebunker delivery period. 41. Guidelines for the Sampling of Fuel Oil for Determination of Compliance with ANNEX VI of MARPOL 73/78Retained sample handling:The retained sample container should be clean and dryImmediately prior to filling the retained sample container, the primary sample quantity should be thoroughlyagitated to ensure that it is homogenousThe retained sample should be sufficient quantity to perform the tests required but should not be less than 400ml. The container should be filled to 90% +/5% capacity and sealed.Sealing of the retained sample: Immediately following collection of the retained sample, a tamper proofsecurity seal with a unique means of identification should be installed by the suppliers representative in thepresence of ships representative. A label containing the following information should be securedTo the retained sample.Location at which, and the method by which the sample was drawnDate of commencement of deliveryName of bunker tanker/installationName and IMO number of the receiving shipSignature over the printed name of suppliers and ships representativeDetails of seal identification, andThe bunker gradeRetained sample storage:The retained sample should be kept in a safe storage location.The retained sample should be stored in a sheltered location where it will not be subject to elevated temperatures,preferably at a cool/ambient temperature, and where it will not be exposed direct sunlight.Pursuant to regulation 18(6) of Annex VI of MARPOL 73/78, the retained sample should be retained under the shipscontrol until the fuel oil is substantially consumed, but in any case for a period of not less than 12 months from the dateof delivery 42. Dubious Practices SummeryDubious Practices Summery: Fuel oil purchasers need to advise the ships staff what grade of fuel they will receive and how it will be transferred. Fuels from different deliveries should be segregated as far as is practicable All receiving fuel oil tanks need to be gauged and the results recorded prior to taking delivery of fuel Dont sign any documentation before you have witnessed the actual event Always take up witness offers made by the suppliers representatives. If the origin and method by which the suppliers sample was obtained is unknown then sign for it adding the words for receipt only - source unknown Fuel oil samples should always be taken by continuous-drip method throughout the bunkering. If the fuel oil delivered is supplied by more than one barge, a sample should be taken of each fuel oil from the supplying barges. Sign the bunker delivery receipt only for volume delivered. If the supplier insists on a signature for weight add for volume only - weight to be determined after density testing of representative sample.Comment : Make sure that what you sign for is what you get. Be certain that the bunker receipt reflects the facts as witnessed. Do not sign anything unless you have witnessed it. Always take a representative sample. 43. Necessary Tools/Documents Required for Bunker Calculation Sounding Tape Thermometer Density Hydrometer Water Finding Paste(For MDO) Bunker Delivery Notes (BDN) ASTM 53B table for density correction ASTM 54B table for VCF calculation ASTM 56D table for weight correction Calculator Sample bottles 44. Pre-Bunker Data Collection in Existing BunkeringMeasuring The Density: To measure the density, a fuel sample is drawn from randomly selectedtank of the tanker. Sometimes average density of multiple tanks are used.Measuring The Temperature: The Temperature is measured using a mercury thermometer.Pre-bunker Tank Gauging/Sounding: Using a suitable sounding tape the soundings of associatedtanks of the tanker are taken and calculate the corresponding volumes from the tankcapacity/calibration tables.Existing Calculation Sheet: Tank Observed Observed Observed Tank No Sounding Volume in Density Temp. cm m3 Kg/m3 o C 1P 301 115.471 1S 299 116.723 2P 333.9 195.201 2S 339 198.752 977.4 26.25 3P 337 117.175 3S 338 118.89 4P 320 129.295 4S 323 132.376 Total Obs. Vol : 1123.883 m3 Observed Density: 977.4 oC Quantity in MT(obs vol. x obs density/1000): 1098.48 MT 45. Existing Bunker Quantity Calculation Flow Chart Sounding of Desired TanksTank Calibration/Capacity Tables Observed Temperature (oC) Observed Volume (m3) Observed Density (Kg/m3) Quantity in (Kg) 1000 Quantity in Metric Tones (MT) 46. IBIA Standard Procedure for Bunker Quantity Calculation Flow Chart Actually, the density of a representative sample at 15oC should be specified in Bunker Delivery Receipt (BDR). If not specified,Observed Density of Representative Sample (Kg/m3) ASTM 53B then use this method to calculate standard density. Density at 15oC (Kg/m3)Observed Temperature of Representative Sample oC ASTM 54B Sounding of Desired Tanks Tank Temperature oC Tank Calibration/Capacity Tables

Observed Volume (m3) Volume Correction Factor (VCF)Standard Volume at 15 oC (m3) Weight Correction Factor (WCF) ASTM 56D Quantity in Metric Tones (MT) 47. Case Study 01:Basic Information Supplied in the Bunker Delivery Receipt.Product Name : Heavy Fuel OilDensity in BDN at 15oC : 989.999 Kg/m3Density of Representative Sample after Bunkering at 15oC = 980.019 Kg/m3 48. Case Study 01:Basic Information Supplied in the Bunker Delivery Receipt.Product Name : Heavy Fuel OilDensity in BDN at 15oC : 989.999 Kg/m3Density of Representative Sample after Bunkering at 15oC = 980.019 Kg/m3 49. Case Study 01:Density of Representative Sample after Bunkering at 15oC = 984.994 Kg/m3Opening Observed Volume (m3) = 1236.76Opening Standard Volume (m3) = 1208.75 (VCF calculated from ASTM 54B)Closing Observed Volume (m3) = 144.949Closing Standard Volume (m3) = 141.826 (VCF calculated from ASTM 54B)Observed Volume Transferred = 1236.76 144.949 = 1091.81 m3Standard Volume Transferred = 1208.75 141.867 = 1066.88 m3The theoretical weight transferred in air: = Density (kg/m3) * Standard volume at 15C(m3) x Factor = kg * kg/1000 = 990.0*1066.88*0.988899/1000 (MT) (The Factor is calculated from ASTM 56D) = 1055.04 MTThe transferred weight of the fuel based on the density provided in Bunker Delivery Receipt(BDR) is = 1055.04 MTAs the density determined from a representative sample of the bunkering is 984.994 kg/m3; the actual weight transferred in air = 980.019 * 1066.88/1000 * 0.978919 = 1044.07 MTIf the density is not determined from a representative sample, the BDR should be signed only for volume. If the supplier insists on a signature for weight, add for volume only - weight to be determined after density testing of a representative sample.Comment: The example calculation given for a fuel delivery changed the actual delivery from: 1055.04 Changes to 1044.07 MT a savings of 10.97 MT or $8776 at $800/MT 50. Bunker Quantity Determination Software TankerCalcThis is the software designed to automate entire bunker calculation process without compromising with any standard. All of the petroleum measurement tables are embedded in this software. Theres no need to carry the ASTM petroleum measurement tables (ASTM 53B, 54B and 56D). The accuracy of the calculation is tested comparing with DNVPS software Bunker Master 2.0 and with Shells BunkerCalc. This software can be used universally to calculate the actual fuel quantity. Additionally this software contains energy calculation tools, density conversion tools, VCF calculation tools, WCF calculation tools, MT calculation tools and much more. 51. Bunker Quantity Determination Software Excel BasedThis is an excel based software designed to automate entire bunker calculation process without compromising with any standard. All of the petroleum measurement tables are embedded in this software. Theres no need to carry the ASTM petroleum measurement tables (ASTM 53B, 54B and 56D). The accuracy of the calculation is also tested comparing with DNVPS software Bunker Master 2.0 and with Shells BunkerCalc. This software can be used universally to calculate the actual fuel quantity in any tanker. 52. Shore Based Fuel Storage System3D layout of a shore based power station fuel storage system. This software can be customized for any tank firm/terminal to automate fuel calculation process. 53. Shore Based Fuel Storage System MonitoringThis is also another automatic fuel storage monitoring system designed to observe the content of individual storage tanks more closely. This is customizable for any liquid storage system Shore Based Fuel Storage Monitoring System 54. Bunker Delivery in Shore TanksIt seems that, bunkering in a shore tank is much easier than that of a ship/barge. The transferred fuel volume (observed volume) is determined from the initial and final tank sounding. The initial and final tank temperatures are not being considered. But the temperature differences influences the entire calculation process. In the software below we will see how the differences in temperature participates on transferred quantity. Bunker delivery in a shore based storage tank 55. Effect of Temperature Variation in BunkeringEffect of Temperature Variation in Bunkering :Average temperature of Shore based fuel storage tanks are maintained around 45 to 50 oC to keep the fuel temperature above their pour point. Another reason of heating is to enhance the transfer process by lowering the viscosity of the oil. Hence, elevated temperature will greatly impart on received quantity during bunkering if the temperature correction is not considered. As the capacities of shore based storage tanks are normally high compared to other storage tanks (like in barge/oil tanker), So the variation in temperature by few degrees will change the entire scenario of bunkering. Please see the subsequent slides regarding volumetric expansion or volumetric shrinkage due to the variation in temperature during bunkering.

56. Bunker Handler (To determine loss and gain in bunkering) DemoThis is another useful software for bunker handling. It consider all factors related to bunker quantity and use dynamicmaterial balance to determine the volume shrinkage/expansion due to the temperature difference of incoming and receivingvessel. The above picture showing an oil tanker delivering bunker in a shore tank possessing temperature 30oC and afterdelivery the tank temperature increases to say 40 oC. According to the calculation, the receiving vessel will pay for 13.83 MT(Expanded quantity) that they have not received if they ignore the temperature correction. 57. Bunker Handler (To determine loss and gain in bunkering) DemoThis is another useful software for bunker handling. It consider all factors related to bunker quantity and use dynamic material balance to determine the volume shrinkage/expansion due to the temperature difference of incoming and receiving vessel. The above picture showing an oil tanker delivering bunker in a shore tank possessing temperature 40oC and after delivery the tank temperature drops to say 30 oC. According to the calculation, the incoming vessel wont find 13.73 MT (Shrinkage quantity) oil if they ignore the temperature correction. 58. Fuel Management System in a Floating Barge (BargeCalc Pro)Inventory Control Quick Volume ToolsBunker Manager Developed By Md. Moynul Islam Chemical Engineer Expertise in Fuels, Lubricants and Water Treatment mdmoynul@yahoo.com +8801816449869 59. How BargeCalc Pro Works?Input Variables LOAD DATABASE Run 2D-Linear Interpolation ForBarge Drafts Select TRIM Correction Table Given Sounding, TRIM and LIST Select LIST Correction Table ValuesTank SoundingTankTemperature LIST and TRIM Corrected VolumeDensity at15oC Call ASTM 54B Table For VCF Calculation Call ASTM 56D For WCF Calculation Calculate Quantity in Metric Tones 60. How BargeCalc Pro Works? S = 271.7 m T = 0.65 m(AFT) V = 314.73 m3The program calculate the desired volume for given TRIM, LIST and Sounding by invoking 2D-linear interpolation function over the plane 61. Using Flow Meters in BunkeringAn worrying comment made in the Control Engineering article Flow meter seleciton: Right size, right design that Worlds 70% of installed flow meters are either the wrong technology or the wrong size .There are three types of flow meters are commonly used in oil and gas industry. They are the PD (Positive Displacement) flow meter, Ultrasonic Flow meter, and Coriolis Flow meter. None of the above are universal. All of them have some advantages and disadvantages depending on the field of application. Ultrasonic Flow Meter Ultrasonic Flow Meter Ultrasonic Flow Meter Measurement Technology 62. The Coriolis Mass Flow meterAmong the above flow meters, Coriolis Mass Flow meter is the best choice in bunker industry. The main reason is its accuracy in mass measurement and entrained air compensation technology made it unique in flow measurement. It can measure the density, volumetric flow rate and the mass flow rate. 63. Expecting your valuable suggestion about this presentation This presentation is under continuous development. Most of the resources are from internet. Thanks to all who have uploaded the materials/information for the web learner. This presentation is not for any business purpose. Expecting your valuable suggestion/comments about the improvement of this presentation.For more information about the customized bunker fuel calculation software please contact via email mdmoynul@yahoo.com or via mobile +8801816449869

Connect on LinkedIn Follow us on Twitter Find us on Facebook Find us on Google+ Learn About Us About Careers Our Blog

Press Contact us Help & Support Using SlideShare SlideShare 101 Terms of Use Privacy Policy Copyright & DMCA Community Guidelines SlideShare on mobile Pro & more Go PRO New Business Solutions Advertise on SlideShare Developers & API Developers Section Developers Group Engineering Blog Blog Widgets

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Estimated Project Cost of 5 MW Solar PV Power PlantDocument1 pageEstimated Project Cost of 5 MW Solar PV Power PlantRajeev GargPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Design and Construction of Door Locking Security System Using GSMDocument24 pagesDesign and Construction of Door Locking Security System Using GSMNakkolopPas encore d'évaluation

- Comparion Water ChillingDocument1 pageComparion Water ChillingNakkolopPas encore d'évaluation

- Appendix A of AC10Document3 pagesAppendix A of AC10NakkolopPas encore d'évaluation

- Foto Condition Road Harian Bulan Februari 2017Document1 pageFoto Condition Road Harian Bulan Februari 2017NakkolopPas encore d'évaluation

- Revision History Control Valve Sizing WorksheetsDocument3 pagesRevision History Control Valve Sizing WorksheetsbhuneshwarPas encore d'évaluation

- Performance Formulas For Power PlantDocument1 pagePerformance Formulas For Power Plantmirza_anis100% (1)

- LocationDocument2 pagesLocationNakkolopPas encore d'évaluation

- DrillingDocument9 pagesDrillingHakan ÖzkaraPas encore d'évaluation

- Price Comparison Template 22Document4 pagesPrice Comparison Template 22NakkolopPas encore d'évaluation

- Develve SupportDocument1 pageDevelve SupportNakkolopPas encore d'évaluation

- Cosmic Project Asphalt-1Document1 pageCosmic Project Asphalt-1NakkolopPas encore d'évaluation

- Reinforced Concrete Slab Punching Shear StrengthDocument8 pagesReinforced Concrete Slab Punching Shear StrengthRaju ShresthaPas encore d'évaluation

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopPas encore d'évaluation

- WfbudgetDocument8 pagesWfbudgetNakkolopPas encore d'évaluation

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopPas encore d'évaluation

- Book Wote ClimateDocument47 pagesBook Wote ClimateNakkolopPas encore d'évaluation

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopPas encore d'évaluation

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopPas encore d'évaluation

- PdliceDocument1 pagePdliceNakkolopPas encore d'évaluation

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopPas encore d'évaluation

- Computer Name & IDDocument1 pageComputer Name & IDNakkolopPas encore d'évaluation

- Drop Shipment FlowDocument4 pagesDrop Shipment FlowAmit ChauhanPas encore d'évaluation

- Sun Form 5881 - A (6-14-04) PDFDocument4 pagesSun Form 5881 - A (6-14-04) PDFNakkolopPas encore d'évaluation

- General Flange ChartDocument4 pagesGeneral Flange ChartNakkolopPas encore d'évaluation

- Pdlice SummaryDocument1 pagePdlice SummaryNakkolopPas encore d'évaluation

- PdliceDocument1 pagePdliceNakkolopPas encore d'évaluation

- Sea Water For HydrotestDocument2 pagesSea Water For HydrotestNakkolopPas encore d'évaluation

- Sun Form 5881 - A (6-14-04) PDFDocument4 pagesSun Form 5881 - A (6-14-04) PDFNakkolopPas encore d'évaluation

- CLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFDocument1 pageCLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFCan YıldırımPas encore d'évaluation

- Asme b31.3 InterpretationsDocument18 pagesAsme b31.3 InterpretationsMallela Sampath KumarPas encore d'évaluation

- WS1000-EN Table of ContentsDocument3 pagesWS1000-EN Table of ContentsNeesonPas encore d'évaluation

- Welding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsDocument1 pageWelding Consumable Nominal Chemical Composition, Wt. Pct. Other Designation SystemsLLPas encore d'évaluation

- Equilibrium and Elasticity: Powerpoint Lectures ForDocument16 pagesEquilibrium and Elasticity: Powerpoint Lectures FordeeparPas encore d'évaluation

- Astm A560 A560m - 12Document3 pagesAstm A560 A560m - 12Leandro Dilkin ConsulPas encore d'évaluation

- Calculating Electrical Load and Wire SizingDocument7 pagesCalculating Electrical Load and Wire SizingMarcelo CondinoPas encore d'évaluation

- Civil Engineering MCQDocument19 pagesCivil Engineering MCQSuhail RazaPas encore d'évaluation

- TemperatureDocument6 pagesTemperatureNur Khairiah Daimah SanupinPas encore d'évaluation

- Geology Report Group 6Document19 pagesGeology Report Group 6Muiz Sofi100% (1)

- Zinky-13 Inorganic Zinc Rich Primer Technical Data SheetDocument4 pagesZinky-13 Inorganic Zinc Rich Primer Technical Data SheetppglPas encore d'évaluation

- White Powder GoldDocument28 pagesWhite Powder GoldSpiredon Kayyal57% (7)

- GasesDocument38 pagesGaseshPas encore d'évaluation

- Masterlife Ci 220 v5Document2 pagesMasterlife Ci 220 v5Tech BoyPas encore d'évaluation

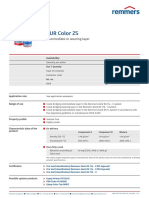

- PUR Color ZS PUR Color ZS: Intermediate or Wearing LayerDocument5 pagesPUR Color ZS PUR Color ZS: Intermediate or Wearing LayerUrsulet SilviuPas encore d'évaluation

- Coal combustion calculationsDocument3 pagesCoal combustion calculationsShane PatulotPas encore d'évaluation

- Matrix Acidizing of SandstonesDocument24 pagesMatrix Acidizing of SandstoneslapinPas encore d'évaluation

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Document13 pagesTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- CAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenDocument10 pagesCAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenlimemPas encore d'évaluation

- Healthcare WasteDocument32 pagesHealthcare WasteEddiemtongaPas encore d'évaluation

- FailureEnvelopesNEW 11Document41 pagesFailureEnvelopesNEW 11Osama AshourPas encore d'évaluation

- ACI 215R - Consideration For Design of Concrete Structures Subjected To Fatigue LoadingDocument24 pagesACI 215R - Consideration For Design of Concrete Structures Subjected To Fatigue LoadingAlbertoPas encore d'évaluation

- Indian Railways MIG Wire Technical RequirementsDocument17 pagesIndian Railways MIG Wire Technical RequirementsJoherPas encore d'évaluation

- MUltis EP 2Document1 pageMUltis EP 2dnoaisapsPas encore d'évaluation

- Figure 1: Basic Design of Fluidized-Bed ReactorDocument3 pagesFigure 1: Basic Design of Fluidized-Bed ReactorElany Whishaw0% (1)

- Memoria Muro Mamposteria Escalera QuickMasonryDocument7 pagesMemoria Muro Mamposteria Escalera QuickMasonryJulio Marcial Ramos QuinteroPas encore d'évaluation

- Astm A-6 PDFDocument1 pageAstm A-6 PDFFrank Berrios GarcesPas encore d'évaluation

- Ascon Design Department: Comparision Based On Value Engineered OptionDocument5 pagesAscon Design Department: Comparision Based On Value Engineered OptionAhmadPas encore d'évaluation

- Advanced Lab Course 50: PhotovoltaicsDocument18 pagesAdvanced Lab Course 50: PhotovoltaicsHamza OuerfelliPas encore d'évaluation

- Pet Bottles Flakes - RoughDocument19 pagesPet Bottles Flakes - RoughSivaraman P. S.100% (1)