Académique Documents

Professionnel Documents

Culture Documents

01po WS 1 3 PDF

Transféré par

Marcelo Varejão CasarinDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

01po WS 1 3 PDF

Transféré par

Marcelo Varejão CasarinDroits d'auteur :

Formats disponibles

The 17th World Petroleum Congress

Rio de Janeiro, Brazil, September 1-5, 2002 Reference: Block 1 Forum 3 Excelling in the Exploration and Production of Oil and Gas New Oil and Gas in Mature Provinces: Exploration and Production

Optimisation of Oil Production in the Mature Oil Field of Matzen

Walter Schumi, Herbert Gager, OMV-Aktiengesellschaft, Austria Abstract

The giant multi-pool, multi-layered oil and gas field of Matzen was discovered in 1949. It is the largest oil and gasfield of Central Europe. The production history shows a typical profile of accelerated early production with a yearly peak production of 2.9 million tons (20 MM STB) of oil in 1955, followed by a long decline. Today the field comprises 400 producing units over 70 horizons. Until now some 1410 wells have been drilled and a total of 72 million tons of oil (510 MM STB) and more than 30 billion m (1.2 TCF) of gas have been produced. Current daily production averages 1650 tons (12 M STB) of oil with a water-cut of 92% and 2 million m (72 MMCF) of gas. The average oil recovery-factor of the whole field is about 38% (in some horizons more than 60%). Regarding these facts the Matzen field can truly be considered as a very "mature field". The main oil reservoirs of the field are in the Neogene basin fill of the Vienna Basin and in the triassic basin underground (fractured dolomite) in the eastern part of Austria. Well depths vary from 600 m to 3000 m and oil qualities from 22 to 45 API. Sand problems with unconsolidated reservoirs as well as reservoir souring, corrosion, scaling and paraffin-deposit problems are a big challenge to optimise the oil production of this field. To keep the Matzen field also profitable for the future three main approaches have been made: Modern G&G re-examinations During the late nineties 3D-seismic and sequence stratigraphy were used to re-appraise geological, sedimentological and petrophysical models throughout the main reservoirs of the tertiary basin fill. Based on these models the original hydrocarbon distribution was reevaluated. Using a simplified drainage model in combination with production data allow to draw maps of potential bypassed oil and lead to improved reservoir studies. Not only was by-passed oil found with infill-drilling and workovers but also new surrounding reservoirs. Reservoir management to develop the maximum output from the existing reservoirs Re-design of the waterflood concept due to geological re-evaluation: To further increase oil recovery it has been found useful to split down singular geologic sand layers with defined facies models and to consider these layers individually as well as in connection with the whole horizon. The implementation of an appropriate relocation program of the injectors was started to get a better areal and vertical sweep efficiency. Nitrogen injection to get attic oil from vuggy reservoirs: Engineering studies showed that with nitrogen injection into a dual porosity reservoir a considerable amount of attic oil left in the fractures and matrix could have been produced which could not be recovered by the water flooding process.

Natural gas injection into the gas cap of the main horizon: Production history has shown that with gas injection into the main horizon of the Matzen field not only has the oil recovery improved but also it has confirmed that the reservoir is suitable as a gas storage in order to cover the peak gas demand to further increase profitability. New microbial enhanced-oil-recovery (MEOR) concept: In co-operation with STATOIL considerable efforts have been made to develop a MEOR-method for a field-wide application. Two of three pilots are still continuing and showing promising results. Water-shut-off methods in excessive water producing wells: To minimise water production in wells where the mechanical method of water-shut-off is not applicable, field tests with polymer systems were carried out. As result of the tests it was decided to use the water-glass system because it is economically feasible and easy to use. Hydraulic fracturing: A step to an aggressive frac design has been taken place because high fluid volumes are the main part of the expenditures and should be reduced. The new dynamic frac design shows more tests and prefracs like minifracs with or without sand before the mainfrac.

New suitable technology for stripper well environment Use of new chemicals and change of materials: Great progress has been made in minimising well-failures with sucker-rod wells and in connection with it life-cycle has increased from about 300 days to more than 1000 days within fifteen years. This could have been achieved by massive improvements with sucker-rods, pumps, tubings, couplings, protectors and chemicals. Optimisation of gas-lift design: Improvements of gas-lift performance (continuously lifted wells as well as intermitting gas-lift wells) have helped to reduce the injection gas-liquid ratio from more than 130 m/m (730 SCF/B) to less than 50 m/m (280 SCF/B). Change from the conventional water conditioning plant to a microbial clarification technology: Instead of adding more and more biocides to prevent biofauling of the injected water attempts were made to starve the population by microbiologically clearing the water. This brine clarification offers a cost-effective alternative to conventional chemical treatment and produces stable, biologically inert water with excellent injectivity. Use of a modern production-control system: The implementation of a modern production-control and surveying system has helped to employ the personnel more efficiently and to improve the quality of production metering, the survey of the oilfield facilities and above all the safety of the whole field.

Taken together, these approaches have increased the efficiency of OMVs oil and gas production significantly. There has also been a fruitful co-operation of several departments or teams within the exploration and production group of OMV and with external consultants. With these and further technological developments it is realistic to expect another 25 years of profitable oil and gas production in the Matzen field.

Vous aimerez peut-être aussi

- Riopipeline2019 1138 Rio Paper Rev01 PDFDocument11 pagesRiopipeline2019 1138 Rio Paper Rev01 PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1141 - 19 The Use of Optical Sensor To Investigate Dissolved Oxygen in CrudeDocument12 pagesIBP1141 - 19 The Use of Optical Sensor To Investigate Dissolved Oxygen in CrudeMarcelo Varejão CasarinPas encore d'évaluation

- IBP1142 - 19 Offshore Development: Submarine Pipelines-Soil InteractionDocument13 pagesIBP1142 - 19 Offshore Development: Submarine Pipelines-Soil InteractionMarcelo Varejão CasarinPas encore d'évaluation

- IBP1146 - 19 Maintenance Productivity Measurement Study at TranspetroDocument8 pagesIBP1146 - 19 Maintenance Productivity Measurement Study at TranspetroMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1140 Ibp 1140 Nao Intrusivos Final PDFDocument4 pagesRiopipeline2019 1140 Ibp 1140 Nao Intrusivos Final PDFMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1135 Riopipeline2019 t1135 JST Av1Document8 pagesRiopipeline2019 1135 Riopipeline2019 t1135 JST Av1Marcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1120 Ibp1120 19 Transpetro S Worklo PDFDocument9 pagesRiopipeline2019 1120 Ibp1120 19 Transpetro S Worklo PDFMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1124 Worlds First Remote Deepwater PDFDocument10 pagesRiopipeline2019 1124 Worlds First Remote Deepwater PDFMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1127 Article Number Ibp1127 19 PDFDocument10 pagesRiopipeline2019 1127 Article Number Ibp1127 19 PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1111 - 19 Best Alternative For Rigid Offshore Pipelines Decommissioning - A Case StudyDocument13 pagesIBP1111 - 19 Best Alternative For Rigid Offshore Pipelines Decommissioning - A Case StudyMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1137 201906031307ibp1137 19 Increas PDFDocument10 pagesRiopipeline2019 1137 201906031307ibp1137 19 Increas PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1128 - 19 In-Service Welding Hot Tap of Refinary Pipeline With Hydrogen and EthyleneDocument10 pagesIBP1128 - 19 In-Service Welding Hot Tap of Refinary Pipeline With Hydrogen and EthyleneMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1121 201906051235ibp1121 19 Final PDFDocument8 pagesRiopipeline2019 1121 201906051235ibp1121 19 Final PDFMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1126 Article Number Ibp1126 19 PDFDocument11 pagesRiopipeline2019 1126 Article Number Ibp1126 19 PDFMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1113 201906031824ibp Riopipeline 11 PDFDocument10 pagesRiopipeline2019 1113 201906031824ibp Riopipeline 11 PDFMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1117 Ibp1117 19 Versao Final para e PDFDocument8 pagesRiopipeline2019 1117 Ibp1117 19 Versao Final para e PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1123 - 19 Caliper Ili Experience in Offshore Pre-CommissioningDocument10 pagesIBP1123 - 19 Caliper Ili Experience in Offshore Pre-CommissioningMarcelo Varejão CasarinPas encore d'évaluation

- IBP1122 - 19 High Grade Sawl Linepipe Manufacturing and Field Weld Simulation For Harsh EnvironmentsDocument11 pagesIBP1122 - 19 High Grade Sawl Linepipe Manufacturing and Field Weld Simulation For Harsh EnvironmentsMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1112 FM 1112 FinalDocument10 pagesRiopipeline2019 1112 FM 1112 FinalMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1115 201906070716fm 3811 00 Formato PDFDocument13 pagesRiopipeline2019 1115 201906070716fm 3811 00 Formato PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1119 - 19 Internal Corrosion Detection: Conference and Exhibition 2019Document4 pagesIBP1119 - 19 Internal Corrosion Detection: Conference and Exhibition 2019Marcelo Varejão CasarinPas encore d'évaluation

- IBP 1102 - 19 A Gas Routing Identification System On A Pipeline NetworkDocument12 pagesIBP 1102 - 19 A Gas Routing Identification System On A Pipeline NetworkMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1107 201905201751ibp1107 19 Jacques PDFDocument7 pagesRiopipeline2019 1107 201905201751ibp1107 19 Jacques PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1110 - 19 The Relevance of Fuel Transmission Pipelines in BrazilDocument10 pagesIBP1110 - 19 The Relevance of Fuel Transmission Pipelines in BrazilMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1104 201906031512fm 3811 00 Formato PDFDocument11 pagesRiopipeline2019 1104 201906031512fm 3811 00 Formato PDFMarcelo Varejão CasarinPas encore d'évaluation

- IBP1095 - 19 in Flexible Pipes Systems and AncillariesDocument8 pagesIBP1095 - 19 in Flexible Pipes Systems and AncillariesMarcelo Varejão CasarinPas encore d'évaluation

- IBP1101 - 19 Element Simulations and Offshore ObservationsDocument13 pagesIBP1101 - 19 Element Simulations and Offshore ObservationsMarcelo Varejão CasarinPas encore d'évaluation

- IBP1099 - 19 Deep Water Pip Installation Using Reel-Lay MethodDocument12 pagesIBP1099 - 19 Deep Water Pip Installation Using Reel-Lay MethodMarcelo Varejão CasarinPas encore d'évaluation

- Riopipeline2019 1093 201905221205final Paper Overpi PDFDocument12 pagesRiopipeline2019 1093 201905221205final Paper Overpi PDFMarcelo Varejão Casarin100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Information Technology and Telecommunications Services Agreement Between County of San Diego and Enterprise Services, LLC ContraDocument106 pagesInformation Technology and Telecommunications Services Agreement Between County of San Diego and Enterprise Services, LLC ContraJackkk FPas encore d'évaluation

- Pca - STATADocument17 pagesPca - STATAAnonymous U5RYS6NqPas encore d'évaluation

- Sub Clause 1.15 Limitation of Liability PDFDocument4 pagesSub Clause 1.15 Limitation of Liability PDFBogdanPas encore d'évaluation

- Presentation - 02 Reliability in Computer SystemsDocument24 pagesPresentation - 02 Reliability in Computer Systemsvictorwu.ukPas encore d'évaluation

- Pablo EscobarDocument21 pagesPablo EscobarTalha WaqasPas encore d'évaluation

- HP Deskjet Printer Supply ChainDocument19 pagesHP Deskjet Printer Supply ChainJose Barnon86% (7)

- Sample Deed of DonationDocument2 pagesSample Deed of DonationMenchie Ann Sabandal Salinas100% (1)

- 6 CHDocument27 pages6 CHjafariPas encore d'évaluation

- Sample Rubrics MakingDocument4 pagesSample Rubrics MakingKerstmis “Scale” NataliaPas encore d'évaluation

- Tata Steel Ratio AnalysisDocument41 pagesTata Steel Ratio AnalysisGourav VallakattiPas encore d'évaluation

- Section 8 33KVDocument13 pagesSection 8 33KVMuna HamidPas encore d'évaluation

- 2 Days Meat Processing Training Program (Kalayaan Laguna)Document2 pages2 Days Meat Processing Training Program (Kalayaan Laguna)Jals SaripadaPas encore d'évaluation

- Land Surveying Chapter 2 Leveling p1Document66 pagesLand Surveying Chapter 2 Leveling p1Azrul ZulwaliPas encore d'évaluation

- Product Sold by APPLE AustraliaDocument1 pageProduct Sold by APPLE AustraliaImran KhanPas encore d'évaluation

- Tactical Radio BasicsDocument46 pagesTactical Radio BasicsJeff Brissette100% (2)

- Social and Prof Issues Module2Document31 pagesSocial and Prof Issues Module2Angelo NebresPas encore d'évaluation

- HSTE User GuideDocument26 pagesHSTE User GuideAnca ToleaPas encore d'évaluation

- Am Bio PhonicsDocument21 pagesAm Bio PhonicsLaura Nataly VillaPas encore d'évaluation

- Session 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)Document52 pagesSession 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)pkumarPas encore d'évaluation

- Autodesk Inventor Practice Part DrawingsDocument25 pagesAutodesk Inventor Practice Part DrawingsCiprian Fratila100% (1)

- Lynette Hawkins, BMG Awesome InsightDocument2 pagesLynette Hawkins, BMG Awesome Insightawesomei100% (1)

- Business Ethics Final Work Brief 2Document6 pagesBusiness Ethics Final Work Brief 2KALIZA TRESSY MEGHANPas encore d'évaluation

- Compt I A Network Plus 008Document902 pagesCompt I A Network Plus 008trainmPas encore d'évaluation

- Ge Washing Machine ManualDocument52 pagesGe Washing Machine Manuallillith1723Pas encore d'évaluation

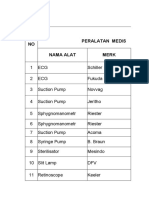

- Daftar Kalibrasi Peralatan MedisDocument34 pagesDaftar Kalibrasi Peralatan Medisdiklat rssnPas encore d'évaluation

- EAU 2022 - Prostate CancerDocument229 pagesEAU 2022 - Prostate Cancerpablo penguinPas encore d'évaluation

- Malik Tcpdump FiltersDocument41 pagesMalik Tcpdump FiltersombidasarPas encore d'évaluation

- Raul C. Cosare v. Broadcom Asia Inc. and Dante ArevaloDocument4 pagesRaul C. Cosare v. Broadcom Asia Inc. and Dante ArevaloRam Migue SaintPas encore d'évaluation

- VLLAR2019Document81 pagesVLLAR2019Christian MallorcaPas encore d'évaluation

- Road Book - MoroccoDocument28 pagesRoad Book - MoroccoCarrie YangPas encore d'évaluation