Académique Documents

Professionnel Documents

Culture Documents

CMHC1991-Airtightness Testing of Air Barrier Connection Techniques

Transféré par

kulov1592Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CMHC1991-Airtightness Testing of Air Barrier Connection Techniques

Transféré par

kulov1592Droits d'auteur :

Formats disponibles

Airtightness Testing of Air Barrier Connection Techniques (CMHC Canada Mortgage an...

Page 1 of 4

Technical Series 91-202

Airtightness Testing of Air Barrier Connection Techniques

Introduction

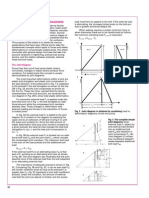

The creation of an effective air barrier requires the creation of an airtight seal between individual elements of the air barrier (for example, individual sheets of gypsum board). This seal must remain intact under temperature and pressure conditions which can vary depending on where the air barrier is located. lf the air barrier is located on the room side of the insulating material, the temperature will remain fairlyconstant at around 20C.If the air barrier is located on the exterior side, however (water-resistant drywall or Tyvek, for example), the temperature may vary from -20C in winter to 65C in summer. Since temperature has a direct effect on strength, adherence and connection creep, it is essential to take this factor into consideration in selecting air barrier materials. Canada Mortgage and Housing Corporation (CMHC) therefore commissioned a study of the behaviour of several air barrier connection techniques when submitted to apressure differential andextremes of temperature over aprolonged period.

Test Program

In all, 23 assemblies were tested. Each was exposed to a pressure differential of 150 Pa for five months. Testing took place at -20C, 20C or 65C, depending on the air barrier in the wall.

Results

The amount of deterioration for each of the assemblies tested is indicated by the increase in air leakage from the beginning of the test to the end. Detailed results appear in the following table. Air leakage, expressed in cubic metres of air per metre length of joint per hour (m3/h-m), was measured under a pressure differential of 75 Pa. None of the samples tested at -20C suffered damage or lost airtightness. At 20C, the test samples with open cell gaskets, sheet type air barriers or mineral wool improved their airtightness due to an accumulation of dust on or within the joints. Test samples with closed cell backer joints and EPDM gap gaskets lost part of their tightness due to greater losses at the joint ends due to shrinkage. At 65C, the spun bounded olefin paper was completely torn off its staples, causing it to completely lose its airtightness. The acrylic sealing joint samples were extensively damaged. All the joints cracked and one of the 12.7 mm (1/2) joints popped out completely over several centimetres. It was not possible to take a final airtightness measurement on this sample.

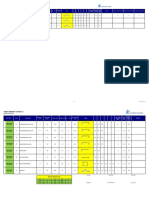

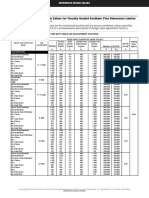

Materials or Assemblies Tested

Air leakage Air leakage before testing after testing m3/h-m* at 75 m3/h-m* at 75 Change in air Pa Pa leakage 0.0756 0.0777 +3% (20C) 0.07437 0.0749 +71% (20C)

No Material Description 1 Closed cell backer rod (initial compression=30%) 2 Closed cell backer rod (initial compression=50%)

http://www.cmhc-schl.gc.ca/publications/en/rh-pr/tech/91202.htm

10/9/2012

Airtightness Testing of Air Barrier Connection Techniques (CMHC Canada Mortgage an...

Page 2 of 4

3 Open cell backer rod (initial compression=50%) Open cell gasket (compression=20%) 4 Open cell gasket (compression=40%) 5 Mineral wool (width=12.7mm [1/21) (low compaction density) 6 Mineral wool (width=12.7mm [1/21) (average compaction density) 7 Mineral wool (width=12.7mm [1/21) (high compaction density) 8 Polyethylene + mineral wool (12.7 mm [1/21) 9 EPDM gap gasket (12.7 mm [1/21) 10 Wood - urethane (12.7 mm [1/21)- aluminium 11 Adhesive tape on water resistant drywall joints (Spacing=12.7 mm [1/21) 12 Adhesive tape on water resistant drywall joints (Spacing=6.35 mm [1/41) 14 Adhesive tape on spun bonded olefin paper joints

23.90 (20C)

21.86

-8.5%

12.75 (20C) 14.11 (20C) 5.232 (20C) 1.706 (20C) 0.5888 (20C) 0.0638 (20C) 0.0602 (20C) (11-1) 0 (-20C) (11-2) 0 (65C) (12-1) 0 (-20C) (12-2) 0 (65C)

11.78 14.11 5.05 1.743 0.5647 0.0787 0.0599 (11-1) 0 (11-2) 0 (12-1) 0 (12-1) 0

-8% 0% -3.5% +2% -4% +23% -0.5% -

15 Adhesive tape on perforated polyethylene air barrier joints

16 Interior sealant joints (Acrylic) - width=6.35 mm (1/4) - wood-sealant-aluminium -backer rod 17 interior sealant joints (Acrylic) - width=12.7 mm 0 (200C) 0 (1/2) - wood-sealant-aluminium - backer rod 18 Interior sealant joints (Silicone) - width=6.35 mm (1/4) - wood-sealant-aluminium - backer rod 19 interior sealant joints (Silicone) - width=12.7 mm (1/2") - wood-sealant-aluminium - backer rod 20 Exterior sealant joints (Acrylic) -width=6.35 mm (1/4") - wood-sealant-aluminium - backer rod 21 Exterior sealant joints (Acrylic) -width=12.7 mm (1/2) - wood-sealant-aluminium - backer rod 22 Exterior sealant joints (Silicone) -width=6.35 mm (1/4)

(14-1) 0.0276 0.0252 (20C) 0.0307 (14-2) 0.0315 (- Nil Tightness 20C) (14-3) 0.02586 (65C) (15-1) 0.7740 0.5276 (20C) 0.5257 (15-2) 1.5452 (0.5257 20C) (15-3) 3.1669 (65C) 0 0 (20C) 0 (20C) 0 (20C) 0 (20C) (20-1) 0 (-20C) (20-2) 0 (65C) 0

-9% -2% -

-32% -66% -23%

0 0.9998

(21-1) 0 (-20C) 0 (21-2) 0 (65 C) Nil Tightness (22-1) 0 (-20C) (22-2) 0 (65C) 0 0

http://www.cmhc-schl.gc.ca/publications/en/rh-pr/tech/91202.htm

10/9/2012

Airtightness Testing of Air Barrier Connection Techniques (CMHC Canada Mortgage an...

Page 3 of 4

- wood-sealant-aluminium -backer rod 23 Exterior sealant joints (Acrylic) - width=0 - waferboard - sealant on surface of waferboard 24 Exterior sealant joints (Acrylic) - width=3.18 mm (1/8) - waferboard - sealant - waferboard

(23-1) 0 (-20C) (23-2) 0 (65C) (24-1) 0 (-20C) (24-2) 0 (65C)

0 0 0 0

Conclusions

Silicone base sealant and the adhesive tape showed perfect adherence qualities whatever the conditions. The spun bonded olefin paper and acrylic base sealant should not be used at connections where the temperature may be high. Spun bonded olefin paper should not be attached with staples if it is expected to act as an air barrier. Given their high permeability, open cell gaskets, mineral wool and perforated polyethylene air barrier joints should not be used as air barriers.

Project team: Project Manager:

Jacques Rousseau

Research Report:

Air Tightness Tests on Components Used to Join Different or Similar Materials of the Building Envelope

Research Consultant:

Air-Ins Inc.

Housing Research at CMHC

Under Part IX of the National Housing Act, the Government of Canada provides funds to CMHC to conduct research into the social, economic and technical aspects of housing and related fields, and to undertake the publishing and distribution of the results of this research. For a complete listing of Research and Development Highlights, or for more information on CMHC housing research, please contact: The Canadian Housing Information Centre Canada Mortgage and Housing Corporation 700 Montreal Road, Ottawa, Ontario K1A 0P7 Telephone: (613) 748-2367 Fax: (613) 748-2098

The information in this publication represents the latest knowledge available to CMHC at the time of publication, and has been thoroughly reviewed by experts in the housing field. CMHC, however, assumes no liability for any damage, injury, expense or loss that may result from use of this information.

http://www.cmhc-schl.gc.ca/publications/en/rh-pr/tech/91202.htm

10/9/2012

Airtightness Testing of Air Barrier Connection Techniques (CMHC Canada Mortgage an...

Page 4 of 4

1996-2000, CMHC-SCHL. All rights reserved.

http://www.cmhc-schl.gc.ca/publications/en/rh-pr/tech/91202.htm

10/9/2012

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- ACCA2011-Manual J-Residential Load Calculation-Outdoor Design Conditions PDFDocument52 pagesACCA2011-Manual J-Residential Load Calculation-Outdoor Design Conditions PDFkulov159257% (7)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Sample Termite Treatment Agreement TemplateDocument1 pageSample Termite Treatment Agreement TemplateAllison Gillett100% (2)

- E177 13 Standard Practice For Use of The Terms Precision and Bias in ASTM Test MethodsDocument10 pagesE177 13 Standard Practice For Use of The Terms Precision and Bias in ASTM Test MethodsmatsergyPas encore d'évaluation

- Internal Flow: Mehmet KanogluDocument115 pagesInternal Flow: Mehmet Kanogluizzet9696Pas encore d'évaluation

- WILLIS TOWERpresentation PDFDocument37 pagesWILLIS TOWERpresentation PDFReshanth VangalapudiPas encore d'évaluation

- Polymer DegradationDocument8 pagesPolymer DegradationFayza SyedPas encore d'évaluation

- E112Document3 pagesE112kulov1592Pas encore d'évaluation

- RAiNA2023-Literature Review Report-Rainscreen Performance (RDH-Straube, Smegal)Document67 pagesRAiNA2023-Literature Review Report-Rainscreen Performance (RDH-Straube, Smegal)kulov1592Pas encore d'évaluation

- Qsun and Quv ComparisonDocument16 pagesQsun and Quv Comparisonnikopigni2Pas encore d'évaluation

- Janssen2016-Experimental Study of Dynamic Effects in Moisture Transfer in Building MaterialsDocument13 pagesJanssen2016-Experimental Study of Dynamic Effects in Moisture Transfer in Building Materialskulov1592Pas encore d'évaluation

- Belic2015-HVAC Control Methods - A Review-COOOLDocument8 pagesBelic2015-HVAC Control Methods - A Review-COOOLkulov1592Pas encore d'évaluation

- 03 OsmosisDocument44 pages03 OsmosispankajPas encore d'évaluation

- EPA2008-Indoor Air Vapor Intrusion Mitigation ApproachesDocument49 pagesEPA2008-Indoor Air Vapor Intrusion Mitigation Approacheskulov1592100% (1)

- Bolted Connection DesignDocument25 pagesBolted Connection Designkulov1592Pas encore d'évaluation

- Thermo NotesDocument381 pagesThermo NotespondoraPas encore d'évaluation

- BeyerLeveque1992-Analysis of A One-Dimensional Model For The Immersed Boundary MethodDocument34 pagesBeyerLeveque1992-Analysis of A One-Dimensional Model For The Immersed Boundary Methodkulov1592Pas encore d'évaluation

- Bolt Joint-DiagramsDocument6 pagesBolt Joint-Diagramskulov1592Pas encore d'évaluation

- AC71Document4 pagesAC71kulov1592Pas encore d'évaluation

- Sound PowerDocument12 pagesSound Powerkulov1592Pas encore d'évaluation

- Bolted Connection DesignDocument25 pagesBolted Connection Designkulov1592Pas encore d'évaluation

- CH01-Pressure, Potentials and The GradientDocument20 pagesCH01-Pressure, Potentials and The Gradientkulov1592Pas encore d'évaluation

- Waterhammer-Student Note-COOL PDFDocument8 pagesWaterhammer-Student Note-COOL PDFkulov1592Pas encore d'évaluation

- Boiling Heat Transfer - Annurev - Fluid.30.1Document37 pagesBoiling Heat Transfer - Annurev - Fluid.30.1agnotts09Pas encore d'évaluation

- Cavitation in Valves 7-22-08Document6 pagesCavitation in Valves 7-22-08Keivn SimiyuPas encore d'évaluation

- Cavitation in Valves 7-22-08Document6 pagesCavitation in Valves 7-22-08Keivn SimiyuPas encore d'évaluation

- MTF270-Turbulence Modeling-Large Eddy Simulations PDFDocument29 pagesMTF270-Turbulence Modeling-Large Eddy Simulations PDFkulov1592Pas encore d'évaluation

- Gowri2009-Infiltration Modeling Guidelines For Commercial Building Energy Analysis (USDOE PNNL-18898) PDFDocument24 pagesGowri2009-Infiltration Modeling Guidelines For Commercial Building Energy Analysis (USDOE PNNL-18898) PDFkulov1592Pas encore d'évaluation

- TCP IP Protocol Suite Chap-01 IntroDocument13 pagesTCP IP Protocol Suite Chap-01 IntroRahul RajPas encore d'évaluation

- Lecture2 PDFDocument20 pagesLecture2 PDFPinjala AnoopPas encore d'évaluation

- Dust CollectionDocument6 pagesDust Collectionkulov1592Pas encore d'évaluation

- Dust CollectionDocument43 pagesDust Collectionkulov1592100% (1)

- Infiltec-DM4-Dual Digital Micro Manometers PDFDocument3 pagesInfiltec-DM4-Dual Digital Micro Manometers PDFkulov15920% (1)

- CMHC1998-Testing of Air Barrier Systems For Wood Frame WallsDocument4 pagesCMHC1998-Testing of Air Barrier Systems For Wood Frame Wallskulov1592Pas encore d'évaluation

- TECTITE-Explanation of Blower Door Terms and Results PDFDocument6 pagesTECTITE-Explanation of Blower Door Terms and Results PDFkulov1592Pas encore d'évaluation

- BS 00437-2008Document18 pagesBS 00437-2008Rachid TidjaniPas encore d'évaluation

- Char Waste As Road Material: A Case StudyDocument34 pagesChar Waste As Road Material: A Case StudyUmer FarooqPas encore d'évaluation

- Bar Bending Batching PlantDocument3 pagesBar Bending Batching PlantAnonymous 5OUozYPas encore d'évaluation

- CT2 AssignmentDocument16 pagesCT2 AssignmentCHI YAN KONGPas encore d'évaluation

- ZCP Mu13947 PDFDocument36 pagesZCP Mu13947 PDFsugirinPas encore d'évaluation

- Fila TableDocument3 pagesFila TableShafiq ShahrulPas encore d'évaluation

- A Review On Effective Stabilization of Expansive Soils PDFDocument25 pagesA Review On Effective Stabilization of Expansive Soils PDFshabbar abbasPas encore d'évaluation

- Rate Analysis-NormsDocument7 pagesRate Analysis-NormsGajendra Joshi0% (1)

- Strategies in LightDocument32 pagesStrategies in Lightsang_halPas encore d'évaluation

- Boq National Library Timor LesteDocument24 pagesBoq National Library Timor Lestekrisna kingPas encore d'évaluation

- Marco Island Executive Airport Terminal Construction Change of Order #5 - 2021Document5 pagesMarco Island Executive Airport Terminal Construction Change of Order #5 - 2021Omar Rodriguez OrtizPas encore d'évaluation

- NDS 2015 Supplement Table 4B - SYP Material PropertiesDocument1 pageNDS 2015 Supplement Table 4B - SYP Material PropertiesTariqul IslamPas encore d'évaluation

- Ashrae Isbd ReportDocument35 pagesAshrae Isbd ReportLuciano EbangPas encore d'évaluation

- Material Design of Aerated Concrete-An Optimum Performance DesignDocument6 pagesMaterial Design of Aerated Concrete-An Optimum Performance DesignYuliusRiefAlkhalyPas encore d'évaluation

- Exergy AnalysisDocument58 pagesExergy Analysismohammed yaseenPas encore d'évaluation

- ACI318 MNDocument5 pagesACI318 MNhaixdproPas encore d'évaluation

- 2 Plastic DeformationDocument33 pages2 Plastic DeformationpremquilonPas encore d'évaluation

- Dws Info Sheet Braided Well Services Strands FormedDocument1 pageDws Info Sheet Braided Well Services Strands Formederwin atmadjaPas encore d'évaluation

- CVC Thermoset BrochureDocument28 pagesCVC Thermoset BrochureMattPas encore d'évaluation

- WG 325 PDFDocument1 pageWG 325 PDFمحمد مقلدPas encore d'évaluation

- B353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateDocument49 pagesB353 OL3 026-1 - Pres - RevD-02 - Ba - UpdateVraja DasiPas encore d'évaluation

- Astm 524-96Document8 pagesAstm 524-96JOSEPH REFUERZOPas encore d'évaluation

- OKFlux 1062Document10 pagesOKFlux 1062parkkkPas encore d'évaluation

- CargotectureDocument5 pagesCargotecturefitsum tesfayePas encore d'évaluation

- Department of Mechanical Engineering Basic Thermodynamics (B Sec)Document1 pageDepartment of Mechanical Engineering Basic Thermodynamics (B Sec)sutha_me20098282Pas encore d'évaluation