Académique Documents

Professionnel Documents

Culture Documents

Dimensions: Dimension and Tolerance Symbols

Transféré par

jdsa123Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dimensions: Dimension and Tolerance Symbols

Transféré par

jdsa123Droits d'auteur :

Formats disponibles

1.

Dimensions

The boundary dimensions of Spherical Plain Bearings are standardized; dimensions plans are included in DIN and ISO standards. Details are given in the text preceding each table section.

2. Tolerances

In order to guarantee full interchange-ability, SLB Spherical Plain Bearings are made to the dimensional tolerances specified in the following tables, unless otherwise stated. The symbols used in the tables are explained below. The maximum and minimum values quoted for a mean diameter or single width or height are the permissible deviations from the nominal dimensions given in the bearing tables. The tolerances apply to bearings without surface treatment and valid for inch as well as metric sizes. Steel-onsteel Spherical Plain Bearings undergo a special surface treatment to enhance running properties and provide protection against corrosion, so that there may be slight deviations from the tolerance values quoted in the tables. These slight deviations have no influence on the mounting or function of the bearings. Bearings which have fractured have slightly out of round rings as result of the fracturing. When mounted in housings with bores which have accurate dimensions and form, and a sufficient wall thickness, the original roundness will be restored. Consequently, measurements performed on bearings before they are mounted will not give a true picture of the original accuracy of the outer rings.

Dimension and tolerance symbols

d dmp Vdp Vdmp nominal bore diameter mean bore diameter: arithmetical mean of the largest and smallest single bore diameters in one plane bore diameter variation: difference between the largest and smallest bore diameters in one plane mean bore diameter variation: difference between the largest and smallest mean bore diameters of one ring or washer D nominal outside diameter Dmp mean outside diameter: arithmetical mean of the largest and smallest single outside diameters in one plane VDP outside diameter variation: difference between the largest and smallest outside diameters in one plane VDmp mean outside diameter variation: difference between the largest and smallest mean outside diameters of one ring or washer Bs' Cs' single diameter of inner ring and outer ring respectively Ts' Hs' single width ( abutment width ) of an angular contact Spherical Plain Bearing: distance between the back ( seating ) face of the inner ring and the back face of the outer ring, or between the back faces of the shaft and housing washers

181

2.1 Tolerance for radial Spherical P lain Bearings

Please refer to Table 2.1.1 and Table 2.1.2

Table 2.1.1 Inner ring

d ( mm ) incl. over 18 30 18 50 30 80 50 120 80 180 120 250 180 315 250 dmp1) ( m) max. min. 0 -8 0 -10 0 -12 0 -15 0 -20 0 -25 0 -30 0 -35 dmp ( m) max. min. +18 0 +21 0 +25 0 +30 0 +35 0 +40 0 +46 0 0 Vdp ( m) max. 8 10 12 15 20 25 30 35 Vdmp ( m) max. 6 8 9 11 15 19 23 26 Bs1) ( m) min. max. -120 0 -120 0 -120 0 -150 0 -200 0 -250 0 -300 0 -350 0 Bs ( m) min. max. -180 0 -210 0 -250 0 -300 0 -350 0 -400 0 -460 0 -

1) The deviations given in the columns dmp ( corresponding to H7 ) and BS ( corresponding to h1 ) 2) Apply to Spherical Plain Bearings of series GEG

Table 2.1.2 O uter ring

D ( mm ) over 18 30 50 80 120 150 180 250 315 400 incl. 18 30 50 80 120 150 180 250 315 400 500 max. 0 0 0 0 0 0 0 0 0 0 0 Dmp ( m) min. -8 -9 -11 -13 -15 -18 -25 -30 -35 -40 -45 VDp ( m) max. 10 12 15 15 20 24 33 40 47 53 60 VDmp ( m) max. 6 7 8 10 11 14 19 23 26 30 34 Cs ( m) max. 0 0 0 0 0 0 0 0 0 0 0 min. -240 -240 -240 -300 -400 -500 -500 -600 -700 -800 -900

2.2 Tolerances for A ngular Contact Spherical P lain Bearings

Please refer to Table 2.2.1 and Table 2.2.2

Table 2.2.1 Inner ring

d ( mm ) over 30 50 80 incl. 30 50 80 120 dmp ( m) max. 0 0 0 0 Vdmp ( m) max. 8 9 11 15 Bs ( m) max. 0 0 0 0 Ts ( m) max. +150 +150 +200 +250

min. -10 -12 -15 -20

min. -100 -120 -150 -200

min. -300 -400 -500 -600

182

Table 2.2.2 O uter ring

D ( mm ) over incl. 30 50 50 80 80 120 120 150 150 180 Dmp ( m) min. max. -11 0 -13 0 -15 0 -18 0 -25 0 VDmp ( m) max. 8 10 11 14 19 Cs ( m) min. max. -240 0 -300 0 -400 0 -500 0 -500 0

Table 2.3 Tolerance for Spherical P lain Thrust Bearings

Please refer to Table 2.3.1 and Table 2.3.2

Table 2.3.1 Shaft w asher

d ( mm ) over 18 30 50 80 100 incl. 18 30 50 80 100 120 max. 0 0 0 0 0 0 dmp ( m) min. -8 -10 -12 -15 -20 -20 max. 0 0 0 0 0 0 Bs ( m) min. -120 -120 -120 -150 -200 -200 max. +150 +150 +200 +250 +300 +350 Hs ( m) min. -300 -400 -500 -600 -700 -800

Table 2.3.2 Housing w asher

D ( mm ) over 30 50 80 120 150 180 incl. 50 80 120 150 180 250 max. 0 0 0 0 0 0 Dmp ( m) min. -11 -13 -15 -18 -25 -30 max. 0 0 0 0 0 0 Cs ( m) min. -240 -300 -400 -500 -500 -600

183

3. Bearing internal clearance

Bearing internal clearance is defined as the total distance through which one ring can be moved radially ( radial internal clearance ) in relation to the other ring under defined measuring load. It is necessary to distinguish between be internal clearance of a bearing before it is mounted and the internal clearance of a mounted bearing when in operation ( operational clearance ). The initial clearance will always be greater than the operational clearance because the rings are expanded or compressed by interference fits and as a result of the differences in thermal expansion of the bearing rings and mating components. The bearing internal clearance referred to as normal has been selected so that when bearings are mounted with the fits generally recommended and operate under normal conditions a suitable operational clearance will be obtained. For other conditions, e.g. where both rings are mounted with an interference fit or where unusual temperatures prevail, bearings with greater or smaller internal clearance than normal may be required. Spherical Plain Bearings have a radial internal clearance which depends on the bearing type and design, values for the internal clearance of the different Spherical Plain Bearing designs will be found in the text section preceding each table section.

3.1 Steel-on-steel Spherical P lain Bearings

Values for the internal clearance of metric and inch-size steel-on-steel spherical plain bearings will be found in the below Fig. 3.1, SLB steel-on-steel Spherical Plain Bearings are manufactured as standard with C2 or C3 clearance can only be supplied from series GE.. E, GE.. ES and GE..ES-2RS; availability should be checked before ordering.

Radial internal clearance

Axial internal clearance

Fig. 3.1

184

3.2 Radial internal clearance of Steel-on-Steel Spherical P lain Bearings

Please refer to Table 3.2.1 and Table 3.2.2

Table 3.2.1 Bearings w ith metric dimensions

Bore diameter d ( mm ) over 12 20 35 60 90 140 240 incl. 12 20 35 60 90 140 240 315 min. 8 10 12 15 18 18 18 18 Radial internal clearance C2 max. 32 40 50 60 72 85 100 110 min. 32 40 50 60 72 85 100 110 Normal max. 68 82 100 120 142 165 192 214

1)

Unit: 0.001 mm

C3 min. 68 82 100 120 142 165 192 214 max. 104 124 150 180 212 245 284 318

1) Bearings of series GEH with bore diameters d=35,60 and 90 have a radial internal clearance.

Table 3.2.2 Bearings w ith inch dimensions

Bore diameter d over ( mm ) 15.875 50.8 76.2 ( inch ) 0.625 2.0 3.0 ( mm ) 15.875 50.8 76.2 152.4 incl. ( inch ) 0.625 2.0 3.0 6.0 Radial internal clearance min. ( m) 50 80 100 130 max. ( m) 150 180 200 230

3.3 Maintenance-free Spherical P lain Bearings

SLB Maintenance-free Spherical Plain Bearings with the sliding contact surface combinations steel / sinter bronze composite and steel / PFTE fabric ( with bore diameters greater than 90 mm ) have internal clearances as shown in the Tables 3.3.1. Smaller steel / PTFE fabric bearings have a light reload because of their design. The permissible upper limit of the corresponding frictional moment is given in the Table 3.3.2 for these sizes. The outer rings of Maintenance-free Spherical Plain Bearings all have some form of joint, being either fractured, split or having a butt joint. Therefore, the bearing internal clearance or frictional moment can only be measured with the aid of a sleeve. The bore of the measuring sleeve must have the same nominal diameter as the bearing outside diameter; the tolerance limits are 0 /- 0.004 mm.

185

Radial internal clearance of M aintenance-free Spherical P lain Bearings

Please refer to Table 3.3.1 and Table 3.3.2

Table 3.3.1 Steel/ inter bronze composite bearings

Bore diameter d ( mm ) over 12 20 incl. 12 20 30 Radial internal clearance ( m) min. 4 5 6 max. 28 35 44

Table 3.3.2 Steel/ P TFE fabric bearings

Bore diameter d ( mm ) over 17 20 25 35 45 50 60 70 90 140 240 315 incl. 17 20 25 35 45 50 60 70 90 140 240 315 400 Radial internal clearance ( m) min. 85 100 110 135 max. 165 192 214 261 max. 1.0 1.5 2.0 2.5 3.5 4.0 4.5 5.0 6.0 Frictional moment

186

Vous aimerez peut-être aussi

- Bolts ReferencesDocument8 pagesBolts ReferencesvinnuzPas encore d'évaluation

- SKF Double Direction Angular Contact Trust Roller BearingsDocument10 pagesSKF Double Direction Angular Contact Trust Roller BearingsLLPas encore d'évaluation

- Interference Fits and PressureDocument21 pagesInterference Fits and PressurerwmingisPas encore d'évaluation

- BST– 10346 Deflection and cracking limitsDocument15 pagesBST– 10346 Deflection and cracking limitsNelsonDayPas encore d'évaluation

- Catalogo Rotulas IKODocument14 pagesCatalogo Rotulas IKOpedroPas encore d'évaluation

- Connection - Bolt 2022Document80 pagesConnection - Bolt 2022LUGHANO NGAJILOPas encore d'évaluation

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978Pas encore d'évaluation

- Steel Structures Fasteners GuideDocument34 pagesSteel Structures Fasteners GuideEmrePas encore d'évaluation

- My - Spreadsheet - SlabDocument26 pagesMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- Bearing Internal Clearance and PreloadDocument12 pagesBearing Internal Clearance and Preloadmuhamad.badar9285Pas encore d'évaluation

- Jis G4051Document7 pagesJis G4051tnchsgPas encore d'évaluation

- MDR Serie ISO 3320: Guide to Choosing Hydraulic Cylinder Rod DiameterDocument22 pagesMDR Serie ISO 3320: Guide to Choosing Hydraulic Cylinder Rod DiameterMauricio MpintoPas encore d'évaluation

- Angular Contact Bearing SKFDocument26 pagesAngular Contact Bearing SKFjayendrakashyap010% (1)

- SKF Ball Bearing DimensionsDocument44 pagesSKF Ball Bearing Dimensionsmobax1Pas encore d'évaluation

- ARNOLD - Thread Forming ScrewDocument4 pagesARNOLD - Thread Forming ScrewgirishawantiPas encore d'évaluation

- Chapter 3Document5 pagesChapter 3Mahesh SurlaPas encore d'évaluation

- The Most Economical Solution For Drilling!: Indexable DrillDocument20 pagesThe Most Economical Solution For Drilling!: Indexable DrillapulavartyPas encore d'évaluation

- Metric Design Tapered Roller BearingsDocument36 pagesMetric Design Tapered Roller BearingsMohan RajPas encore d'évaluation

- M 269-96 (2008) (Turnbuckles and Shackles)Document25 pagesM 269-96 (2008) (Turnbuckles and Shackles)tran_lamPas encore d'évaluation

- Sec Viii d2 Art D-3Document12 pagesSec Viii d2 Art D-3Yuber Rodriguez HPas encore d'évaluation

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckManish542Pas encore d'évaluation

- Bearing Number CodesDocument4 pagesBearing Number CodesDSGPas encore d'évaluation

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- (Tambahan) Tolerances - FitsDocument25 pages(Tambahan) Tolerances - FitsMuhammad Fachry RamadhanyPas encore d'évaluation

- Boundary Dimensions and Bearing Number CodesDocument4 pagesBoundary Dimensions and Bearing Number CodesPutra Kanjeng Romo RomoPas encore d'évaluation

- Ci3503crsi - Column Tie ConfigurationsDocument7 pagesCi3503crsi - Column Tie ConfigurationsNono_geotecPas encore d'évaluation

- Needle Cages and Roller Cages: ConstructionDocument12 pagesNeedle Cages and Roller Cages: ConstructionMohan Kumar MathrubaiPas encore d'évaluation

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9Pas encore d'évaluation

- 5 Strength AnalysisDocument63 pages5 Strength Analysisdan20000Pas encore d'évaluation

- Clearance and PreloadDocument12 pagesClearance and PreloadcuccuaciaPas encore d'évaluation

- Seeger RingDocument3 pagesSeeger Ringjprins7Pas encore d'évaluation

- Pod 2810-097 130 191 1005 PDFDocument2 pagesPod 2810-097 130 191 1005 PDFjeneveuxpasPas encore d'évaluation

- Metric Washer FlatDocument4 pagesMetric Washer Flatjontylee87Pas encore d'évaluation

- Bang Catalog Bac Dan NSKDocument0 pageBang Catalog Bac Dan NSKsariobaoPas encore d'évaluation

- Asme2b sb-160Document8 pagesAsme2b sb-160jsskj12122Pas encore d'évaluation

- Crankshaft: Shutdown SIS Previous ScreenDocument5 pagesCrankshaft: Shutdown SIS Previous Screenariy yuli styawanPas encore d'évaluation

- Boundary Dimensions and Bearing Number CodesDocument4 pagesBoundary Dimensions and Bearing Number Codesps_07inPas encore d'évaluation

- Mold DesigningDocument19 pagesMold Designingmitrofan.dragosPas encore d'évaluation

- Nominal wall thicknesses and pipe sizesDocument2 pagesNominal wall thicknesses and pipe sizesNaveen Chandar Emmer100% (2)

- Blacks Structural Bolts: Fasteners Your Guarantee of Quality Industrial FastenersDocument4 pagesBlacks Structural Bolts: Fasteners Your Guarantee of Quality Industrial FastenersBhartendu PatniPas encore d'évaluation

- Bs en 485-4 1994 Gruix Tolerancies AluminiDocument6 pagesBs en 485-4 1994 Gruix Tolerancies AluminiAlbert Solsona100% (1)

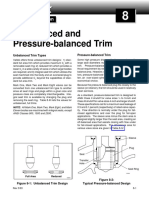

- Unbalanced and Pressure-Balanced Trim: Sizing & SelectionDocument6 pagesUnbalanced and Pressure-Balanced Trim: Sizing & SelectionPratik134Pas encore d'évaluation

- BS en 755-7 1995 TablesDocument6 pagesBS en 755-7 1995 TablesestabejaPas encore d'évaluation

- Design Factors When Using Small Bearings: Part 2: Mounting and FittingDocument11 pagesDesign Factors When Using Small Bearings: Part 2: Mounting and FittingankitsarvaiyaPas encore d'évaluation

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 pagesWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadPas encore d'évaluation

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloPas encore d'évaluation

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyD'EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyPas encore d'évaluation

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- Manual of Engineering Drawing: British and International StandardsD'EverandManual of Engineering Drawing: British and International StandardsÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Design and Analysis of Centrifugal CompressorsD'EverandDesign and Analysis of Centrifugal CompressorsPas encore d'évaluation

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsD'EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Traceable Temperatures - Temp. Measurement and Calibration 2nd Ed.Document435 pagesTraceable Temperatures - Temp. Measurement and Calibration 2nd Ed.jupoc90% (10)

- Motion Control HandbookDocument38 pagesMotion Control Handbookvincentttt100% (1)

- Analyze Indeterminate Beam Using Moment Distribution MethodDocument30 pagesAnalyze Indeterminate Beam Using Moment Distribution MethodJovanne LanggaPas encore d'évaluation

- FilestoreDownload AvkDocument16 pagesFilestoreDownload Avkjdsa123100% (1)

- ANSI B16.1 Flanged CatalogDocument20 pagesANSI B16.1 Flanged Catalogjdsa123Pas encore d'évaluation

- FilestoreDownload AvkDocument16 pagesFilestoreDownload Avkjdsa123100% (1)

- Dimensiones de Bridas ASME 125Document3 pagesDimensiones de Bridas ASME 125Pedro SanchezPas encore d'évaluation

- Idas ForjDocument43 pagesIdas ForjJose Luis PintoPas encore d'évaluation

- Ansi B16.1Document6 pagesAnsi B16.1Edison Mauiricio Pulluquitin LaicaPas encore d'évaluation

- Whats Up With FlangesDocument2 pagesWhats Up With FlangesAnwar hussainPas encore d'évaluation

- 04 MomentDistribution PDFDocument88 pages04 MomentDistribution PDFSimran Radheshyam SoniPas encore d'évaluation

- 04 Cross MethodDocument7 pages04 Cross Methodjdsa123Pas encore d'évaluation

- Fire HydrantsDocument4 pagesFire Hydrantsogie_0513100% (1)

- HydrantDocument10 pagesHydrantjdsa123Pas encore d'évaluation

- Tabela - Conv Roscas NPT-BSPDocument1 pageTabela - Conv Roscas NPT-BSPPauloCesarRibeiroPas encore d'évaluation

- Asme b1.20.1 NPT ThreadsDocument1 pageAsme b1.20.1 NPT ThreadsGabriel Arghiriade100% (1)

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Avk Underground Fire Hydrant, Pn16 29/389: Features: OptionsDocument2 pagesAvk Underground Fire Hydrant, Pn16 29/389: Features: Optionsjdsa123100% (1)

- Audels Engineers and Mechanics Guide Volume 5 From WWW Jgokey ComDocument556 pagesAudels Engineers and Mechanics Guide Volume 5 From WWW Jgokey Comjdsa123Pas encore d'évaluation

- Audels Engineers and Mechanics Guide Volume 4 From WWW Jgokey ComDocument488 pagesAudels Engineers and Mechanics Guide Volume 4 From WWW Jgokey Comjdsa123Pas encore d'évaluation

- Pipe Fitting and Piping Handbook GuideDocument231 pagesPipe Fitting and Piping Handbook Guidejuanroman88% (42)

- Audels Engineers and Mechanics Guide Volume 3 From WWW Jgokey ComDocument392 pagesAudels Engineers and Mechanics Guide Volume 3 From WWW Jgokey Comjdsa123Pas encore d'évaluation

- HDS No. 5Document368 pagesHDS No. 5kodiak31Pas encore d'évaluation

- Audels Engineers and Mechanics Guide Volume 2 From WWW Jgokey ComDocument520 pagesAudels Engineers and Mechanics Guide Volume 2 From WWW Jgokey Comjdsa123100% (1)

- Guide Vanes in FrancisturbinesDocument46 pagesGuide Vanes in FrancisturbinesAndika TaufikPas encore d'évaluation

- 2011 HDD SupDocument56 pages2011 HDD Supger80100% (1)

- Audels Engineers and Mechanics Guide Volume 1 From WWW Jgokey ComDocument486 pagesAudels Engineers and Mechanics Guide Volume 1 From WWW Jgokey Comjdsa123100% (2)

- Rockwool Proces ManualDocument199 pagesRockwool Proces ManualArunprasad Murugesan100% (1)

- 010435Document367 pages010435jdsa123Pas encore d'évaluation

- Steam Traps - Engineering Data ManualDocument50 pagesSteam Traps - Engineering Data ManualThitikorn Wassanarpheernphong100% (1)

- Servo Adjustment Manual 640mDocument37 pagesServo Adjustment Manual 640malexandre100% (1)

- Crosby G-2130Document1 pageCrosby G-2130AekJayPas encore d'évaluation

- Is 12820 2004Document11 pagesIs 12820 2004kannankrivPas encore d'évaluation

- Design of Machine ElementDocument68 pagesDesign of Machine Elementmanish3247Pas encore d'évaluation

- Rotex CouplingDocument39 pagesRotex CouplingseregePas encore d'évaluation

- Hot Dip Galvanization - FaboryDocument4 pagesHot Dip Galvanization - FaboryBrandon LimPas encore d'évaluation

- PRODUCT NUMBER: 2036-0-57-15-00-00-03-0: Data SheetDocument2 pagesPRODUCT NUMBER: 2036-0-57-15-00-00-03-0: Data SheetPacermann PacermannPas encore d'évaluation

- BS en 10060 2003Document12 pagesBS en 10060 2003VeraPas encore d'évaluation

- Pre Jis B 01702 003 000 2020 e Ed10 CHDocument5 pagesPre Jis B 01702 003 000 2020 e Ed10 CHBabu GnPas encore d'évaluation

- EVRAZ Catalog ENG 2013 PDFDocument114 pagesEVRAZ Catalog ENG 2013 PDFSasi KumarPas encore d'évaluation

- Biodegradability of Alkylbenzene Sulfonates: Standard Test Method ForDocument10 pagesBiodegradability of Alkylbenzene Sulfonates: Standard Test Method ForStuartPas encore d'évaluation

- Reactive and Refractory Metal Clad Plate: Standard Specification ForDocument8 pagesReactive and Refractory Metal Clad Plate: Standard Specification ForraulPas encore d'évaluation

- Lowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationDocument8 pagesLowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationShrikant KajalePas encore d'évaluation

- 4600en 0119fleDocument40 pages4600en 0119fledeni jakaPas encore d'évaluation

- 12 ISO Optical Drawing StandardsDocument28 pages12 ISO Optical Drawing StandardsvishaalPas encore d'évaluation

- ACL Engine BearingsDocument8 pagesACL Engine Bearingsklaus0987654321Pas encore d'évaluation

- 04c - E70 Vertical Dynamics SystemsDocument76 pages04c - E70 Vertical Dynamics SystemsEngine Tuning UpPas encore d'évaluation

- Imo Circulara 776 - Guidelines For The Approval of Equivalent Fixed GasDocument18 pagesImo Circulara 776 - Guidelines For The Approval of Equivalent Fixed GasradugorjPas encore d'évaluation

- Asme B16.1-2020Document49 pagesAsme B16.1-2020Toni71% (7)

- 1003 2 PDFDocument17 pages1003 2 PDFRitesh kumarPas encore d'évaluation

- Testing and CalibrationDocument36 pagesTesting and CalibrationBruno FurukawaPas encore d'évaluation

- ES-03 - PFI - Fabricationg TolerancesDocument5 pagesES-03 - PFI - Fabricationg TolerancesGiám đốc Tín MinhPas encore d'évaluation

- Electrical Insulating Papers GuideDocument28 pagesElectrical Insulating Papers GuideEko SusantoPas encore d'évaluation

- 00 - MAR - IND9D57 - DS - EN SMDocument2 pages00 - MAR - IND9D57 - DS - EN SMErick MelendezPas encore d'évaluation

- Unionocel Big-New enDocument24 pagesUnionocel Big-New encristi_amaPas encore d'évaluation

- Medical Screwdriver Bits: Standard Specification ForDocument4 pagesMedical Screwdriver Bits: Standard Specification ForDanZel DanPas encore d'évaluation

- DIN5480 2006 EnglishDocument34 pagesDIN5480 2006 EnglishAnatolii100% (1)

- Rubric For Pipe BendingDocument4 pagesRubric For Pipe BendingleogarybonPas encore d'évaluation

- Gauge Blocks Reference GaugesDocument32 pagesGauge Blocks Reference GaugesFernando SanezPas encore d'évaluation

- Astm D3139 (1998)Document3 pagesAstm D3139 (1998)Thomas C. Lane100% (1)