Académique Documents

Professionnel Documents

Culture Documents

Report On Workplace Safety

Transféré par

Anuanuksya AnuDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Report On Workplace Safety

Transféré par

Anuanuksya AnuDroits d'auteur :

Formats disponibles

OUMH 2203

2012

FAKULTI PENDIDIKAN DAN BAHASA SEMESTER SEPTEMBER 2012

OUMH 2203 ENGLISH FOR WORKPLACE COMMUNICATION

NAMA NO. MATRIKULASI NO. KAD PENGENALAN NO. TELEFON E-MEL

: : : : :

KALAIVANI A/P PERUMAL 770906086578002 770906-08-6578 017-4945301 kalaivanimuthu@oum.edu.my INSTITUT PERGURUAN IPOH

PUSAT PEMBELAJARAN :

OUMH 2203

2012

TABLE OF CONTENTS

1) INTRODUCTORY SECTION

Title Page Letter Of Transmittal Table Of Contents

2) THE BODY

Introduction Discussion and Analysis Of Findings Development Of Ideas Conclisions Recommendations

3) FINAL SECTION

References

OUMH 2203

2012

RECOMMENDATIONS TO IMPROVE SAFETY STANDARD

Perepared for Mr.Tan Kim Seng, Managing Director JJ Groups Of Furnitures Pvt.Lmt 64-65,Jalan Kuala Karang 32100 Ipoh

By

Kalaivani Perumal, Occupational Health Manager JJ Groups Of Furnitures Pvt.Lmt 64-65,Jalan Kuala Karang 32100 Ipoh 21 October 2012

OUMH 2203

2012

21 October 2012 Mr.Tan Kim Seng, Managing Director JJ Groups Furniture Pvt.Lmt 64-65,Jalan Kuala Karang 32100 Ipoh

Dear Mr. Tan Kim Seng, I am submitting the attached report entitled Recommendations To Improve The Safety Standard Of Our Operators . This report contains the findings and recommendations of the safety problems that I

discovered during my visit to the Material and Handling department last week. . The drastic changes in ignoring the safety rules by the operators, and the implications of these changes will be discussed. Also discussed are the recommendations and suggestions, and some possible remedies to the problem. I hope this report may lead to an immediate action to protect our workers from an unsafe condition. Thank You.

Sincerely,

( KALAIVANI PERUMAL ) Occupational Health Manager

OUMH 2203

2012

TABLE OF CONTENTS

Title page

Transmittal letter

Introduction, Discussion and Findings

Conclusions and Recommendations

OUMH 2203

2012

A) INTRODUCTION

I am Miss Kalaivani Perumal, the occupational health manager in the company would like to carry the responsibilities of updating the information pertaining to the safety measures of the workers and the company . This report provides information obtained the workers attitude and also

will pay particular attention to overcome the weaknesses by offering some suggestions and recommendations as well .The report will comment on the safety standards of the company workers and make recommendations that would improve the workers current performance.

In order to this matter , I was annoyed to discover that in the Material and Handling Department of our company,the operators were simply ignoring and negotiating the safety regulations which would cause some major damages to the welfare of the factory workers. I have discovered this matter lately due to department. my regular visit and observation every week to the particular

JJ Group of Furniture Private, Limited is one of the best progressing company in this city. We have more than 500 workers working in our factory and it is our main responsibility to provide our workers the proper safety methods to save and protect themselves from unwanted scenarios. We may face any major problem if we failed to find out a quicker remedial action. It was very much annoyed to see that the workers especially those in the material and handling department hesitates safety methods and are not bothered about it .

OUMH 2203

2012

Being an occupational health manager at the said department, I would like to propose the following actions to be taken as soon as possible. Establish an advisory committee immediately to find out the problem faced. The committee should plays an important role in implementing safety standards among the workers and the functions of the committee should be as follows: Promote a culture of safety at work; Act as decision-makers in terms of safety at the Centre of Responsibility Receive, consider complaints and workers problems and make solutions to the problems Provide feedback on the proposals related workers safety Promoting and monitoring compliance to aspects safety at work; Strive to improve the standards of safety at work; Investigate and advise on actions that are not safe at work or the things that can be dangerous; Provide training related to occupational safety and health for the new staffs Always remind and urge the operators the dos and donts in case of neglecting safety method.

OUMH 2203

2012

B) BODY

In recent years, the issue of workplace safety and accidents more frequently dealt whether in print or electronic media, particularly accidents involving in construction and manufacturing sectors due to the workers ignorance of safety regulations. Therefore, to reduce the accidents

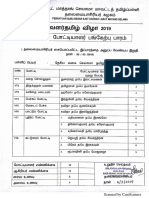

in the workplace, measures have to be taken is to set up the Safety standards in the workplace. Neglecting of workers safety and health in the workplace pose serious implications especially those involving physical. In accordance to that matter, I have identified the following problems in our factory which seems to be severe and needs an immediate action to overcome the serious problem faced by our workers.The bar graph below shows the number of operators who involved in ignoring the safety regulations in the Material and Handling Department.

50 45 40 Number Of Workers 35 30 25 20 15 10 5 0 Smoking Hesitating of Hesitating of Hesitating of Hesitating of wearing wearing wearing wearing masks gloves googles helmets Safety Problems Faced Male workers Female workers Total involved

. Figure 1 : Operators involved in ignoring safety rules.

OUMH 2203

2012

Smoking at the prohibited areas. The most serious problem that annoyed me was, the operators dangerous attitude which is smoking at the prohibited areas .The operators know that it is highly dangerous to smoke at such areas where highly flammable chemicals are kept. Yet they ignore safeties and do things that are prohibited. In our company,more than ten areas are identified as non-smoking zones.Nevertheless, there is still a cigarette smoker in the area listed because I have noticed there are still cigarette butts around the handling and manufacturing department.This means that there are workers who still smoke in non-smoking area. To prove this issue I had my tour to the related department and state the number of workers who involved in the bar graph shown. As we know, wordings and notice boards in big red letter were kept in all the necessary places as warnings such as NO SMOKING .There has been an incident last year where one of our factorys store room was totally destroyed in fire. This was caused by some of the irresponsible workers who threw the unfinished part of cigarette in the room.The workers were identified and were sacked immediately in forty eight hours time for causing a major loss to our factory . Although the operators in the Material and Handling Department aware of the danger ahead, yet they seems to be not bothering the problem faced anymore. Possible safety methods suggested are the follows. Strict enforcement is needed to prohibit the workers who smoke in prohibited area. The operators working in the Material and Handling Department should be checked premises. In case of finding where operators caught on sport keeping cigarettes packets and match boxes should be informed to the authorities concerned immediately. The person should be sacked after giving a third warning . The Investigation officers or supervisors should go around the premises every one hour to watch workers who smokes during working hours. with an alarm system by the guards before entering the factory

OUMH 2203

2012

Negligence in wearing masks

During my visit to the Material and Handling department, another big problem that I came across was negligence in wearing masks. The factory has amended the rule of wearing masks since the opening of our factory and it seems most of our workers avoid wearing the masks due to their comfortable level. .These safety moves were introduced for the safeties of the operators which will protect them from the dusts and chemicals. But it is highly ridiculous to find out that the operators simply ignore because of ignorance. As we know the management also provides the facilities of wearing masks by bearing its costs and the masks were imported from a well known company and are certified by the government. The usage of masks during working hour is highly recommended because the workers

sometimes may have to deal with highly adorable chemicals. A continuous smelling of these chemicals may cause problems in breathing and there is a possibility to face problems in the defunctioning of the lungs. The Occupational Safety and Health Committee had analyzed this earlier and come to a conclusion that wearing mask should be strictly followed. If we go through the data analyzed last year , it shows wearing mask is highly recommended yet there are workers who face problems in breathing and it also shows that fifteen workers had some chronical problem in breathing and were treated in clinics and hospitals. These are the possible suggestions that could be implement to prevent this problem: The operators must be acknowledged about the high risk of health condition that they may face by not wearing the mask. The operators who not wearing masks must not be allowed to continue their job. The operators must also be acknowledged with the problems that the management may face if encountered by the NHD.

OUMH 2203

2012

Hesitating of wearing gloves

Recently, hesitating to wear gloves is also seems to be a problem faced among the operators. As they are dealing with materials which are connected with chemical, electrical and electronics substances , it is very much important and management. to wear gloves which recommended by the

Here I would like to state, that the high cost that the factory has to bear on buying high rated gloves has to be taken in consideration. A famous glove manufacturing company in Singapore is supplying the high grade gloves to our factory every month and the factory has to spend a major proportion on buying the gloves . Without acknowledging the danger, the operators seem to be bare handed while working and the gloves are scattered here and there. During my visit I managed to had some interviews with some of our operators, I come to know that they prevent using gloves because of the following reasons:-

Most of them feel uncomfortable when their hands sweat and they find it uneasy to work by wearing gloves. Some of them complaint that the gloves are slippery and they couldnt finish their work in time.

These are the reasons received from the operators and it shows that they are totally are not aware of the problem that they may face if they dont use gloves. The following reasons are should be bared in mind for the important given in wearing gloves.

OUMH 2203

2012

We acknowledge that the operators are dealing with things such as: Sharp tools, Chemicals and Gums The machines that they are handling may cause cuts on their hands. Some of the chemical used may spoil their nails ff their fingers and skin. Most of the nails, sharp needles and screwdrivers are very much harm full.

The implementations of wearing gloves among the workers strictly announced after considering this entire problems by the managing authorities . A stern and strict action on operation neglecting safety regulation will bring changes.

These are the possible suggestions that could be implement to prevent this problem: Acknowledge the operators of the danger they may face by hesitating to wear gloves in their hands. The managements should take deceplinery actions on operators who dont wear gloves. The management would not bear the cost of any injuries of the operators who neglect the safety rules. The operators without gloves will not be allowed to precede their works.

OUMH 2203

2012

Hesitating of wearing safety goggles Every day an unestimated eye injuries occur in workplaces. Our operators totally ignoring their eye protection and they hesitate to wear their safety goggles while handling with machines when doing repairing. They may face accidents from flying or falling objects or sparks striking the eyes. Other accidents which may happen is, by handling objects which is swinging from a fixed or attached position, like ropes, chains, or tools which will be pulled into the eye while the workers are using them.The workers should know that the safety goggles offer the most complete impact protection because they form a seal around the eye area. They are designed to prevent small dust particles and chemical splashes from reaching the eyes. According to our safety and health report of 2011, out of five injured workers were not wearing eye protection at the time of the accident occurred. The majority of our workplace eye injuries are caused by small particles or objects such as wood chips or dust striking or abrading the eye. Injuries also can occur when nails, staples or metal penetrate the eyeball, which can result in a permanent loss of vision. Once again our management is spending thousands of ringgit just to import high quality safety goggles from Japan in concerning the privileges and safety of our workers. Yet, without acknowledging the danger, the operators seem to just ignore the safety regulations while working . During my visit Ive noticed most of the operators whom doing the fixing and repairing work seems to not bother about the safety goggles or any other eye protection tools provided. Reagarding this issue , here are some suggestions to prevent the the problem immediately ; The operators must be acknowledged about the high risk of health condition that they may face by not wearing the safety goggles. The operators who not wearing safety goggles must not be allowed to continue their job.

OUMH 2203

2012

Hesitating to wear helmets. Almost every factory urges their workers to wear the safety helmet for safety conscious. It is one of our factorys regulation that all the operators should wear helmets in order to protect themselves from the danger of any heavy things knocking their head . I also would like to forward to your acknowledge that , recently one of our staff had a major injury on his head and was admitted in the hospital on a severe condition.Unfortunately he is save and still in medical leave. Due to that issue the officers from the National Health Department had also produced a wearing statement to our company on this matter recently.This matter has been informed to all the operators earlier through circulars. Yet the action taken did not produce or shows any good result since some of our workers at the stated department still refuse to wear the safety helmets. Our factory would have to be answerable in case of any miserable happening in future because such matters are seriously taken in consideration by the national health department officers. Last year, I had attend an introductory meeting in Ipoh, which was organized by our local Health Department in Legend Inn Hotel.The safety rules and regulations has been the main topic of the meeting discussed .I have given an in-house course to all of our staffs and workers on 25th of March this year.The following conclusions which were made as an advise to all factory managements have been delivered to all the staffs and workers as well. The management should make sure, all the workers and operators or even staffs provided with helmets which are certified by SIRIM: The company becomes solely responsible for any major problems faced in case of neglecting to obey safety methods at any period.

OUMH 2203

2012

Acknowledging all the problems which will lead to our workers safety and companys image we had to make a quicker move in this matter. The possible remedies are as follows: Stricly advise the operators to wear the helmets throughout the day while working. Produce letters of warning to all the operators working in our company who hesitates to wear safety helmets during working time. Acknowledge the workers about the benefits of wearing helmets and display posters on safety regulations in each department.

An

immediate action, on suggested above will safe both the operators and the managing

department from facing serious problem. The workers safety is the constant concern of our company. Every precaution should be taken to provide a safe workplace to the workers and acknowledge them the impact of safety ignorance.

OUMH 2203

2012

Conclusions Running and maintaining a progressive factory is not a simple task . There are so many good and bad situations, problems as well need to be faced each and every day , which comes from each and every corner of the factory. In relation to that ,maintaining strict regulation on safety measures have also becomes an important factor which has to be handled carefully. Failing in implementing and preparing the occupational and safety standard may end in facing though problem instead. The cooperation of every staff member is necessary to make this entity a safe place in which to work. The ignorance of workers on safety rules and regulations preventing the management to keep up the good safety method and it becomes impossible.

In conclusion I would like to acknowledge the management that, the unsafe conditions in the Material and Handling Department are just because of the workers or operators who are unaware of the high range of problems that would ruin the working systems of the factory both to the management and workers as well. The workers are totally do not understand about how strict is the government considering the health measurer which being amended according to the act of Industries of Malaysia.

I have annoyed that most of the workers take matters simple because lack of proper education and experience as well. Wearing safety helmets, hand gloves, masks and safety goggles are among an important method that should be strictly followed. Nowadays smoking is not allowed in many places due to health conscious but when it comes for factory , it is strictly banned because it may cause damages to highly inflammable equipments and health.There are some modern methods of implements in factories to safeguards the workers.

Aspects of occupational safety and health are very important and should be taken seriously by the management. Performance and organizational productivity will decline if workers always get an industrial accident or health problems. Company's image as a caring employer will be affected.Bearing all these in mind, I hope and make a humble request that as the managing director of the factory you would forward this matter to the authorities concerned. Thank you .

OUMH 2203

2012

Report prepared by,

( KALAIVANI PERUMAL ) Occupational Health Manager

( 3008 words )

OUMH 2203

2012

References Abdul Aziz Hussin, 2000, Aspects of Tort Law in Construction Projects. Penang: Publisher Universiti Sains Malaysia. Factories and Machinery Act, 1967. Guidelines on First-Aid Facilities in the Workplace; Department of Occupational Safety and Health, Malaysia. Maule, K. Expectation of the Principal Constractor Buletin NIOSH September, 1998 Ministry of Human Resources, 1975, the Code of Conduct for Industrial Harmony.Akta Kilang dan Jentera ,1967. Occupational Health and Safety Act, 1994. Press Conference on August 27, 2001, Y.A.B. Prime Minister. The Factories and Machinery (Safety, Health & Welfare), 1970. The Occupational Safety and Health (Safety Committee) Regulations. Department of Occupational Safety and Health, Malaysia.

www.aboutsafety.com/article.cfm?id=850

www.law.cornell.edu/wex/workplace_safety

www.mysafetyandhealth.com/2011/08/law-malaysia-osha-1994.html

www.safetyworksmaine.com/safe_workplace/safety.../index.html

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Borang Valar Tamil Vizha 2019Document1 pageBorang Valar Tamil Vizha 2019Anuanuksya AnuPas encore d'évaluation

- Kod Sek: ABD 6104 No. Tel: 05-8394858 Email: ABD6104@moe - Edu.myDocument1 pageKod Sek: ABD 6104 No. Tel: 05-8394858 Email: ABD6104@moe - Edu.myAnuanuksya AnuPas encore d'évaluation

- Jsu Bahasa Inggeris PemahamanDocument2 pagesJsu Bahasa Inggeris PemahamanAnuanuksya AnuPas encore d'évaluation

- Diognastik TestDocument2 pagesDiognastik TestAnuanuksya AnuPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 7795007957SDS - MS-601 MS Polymer Adhesive SealantDocument6 pages7795007957SDS - MS-601 MS Polymer Adhesive SealantNurulfazilla YusopPas encore d'évaluation

- IMS Objectives Targets 2Document2 pagesIMS Objectives Targets 2FaridUddin Ahmed100% (3)

- Special Effects Job DescriptionsDocument10 pagesSpecial Effects Job Descriptionsemmy1602Pas encore d'évaluation

- Training Loans Are Available For WSH Professional Courses!: Only 6% Per ANNUMDocument2 pagesTraining Loans Are Available For WSH Professional Courses!: Only 6% Per ANNUMGlenden KhewPas encore d'évaluation

- MSDS - Regal - R&o - 32, 46, 68 - Oils - UsDocument7 pagesMSDS - Regal - R&o - 32, 46, 68 - Oils - UsAustin UdofiaPas encore d'évaluation

- PTS 60.0303Document112 pagesPTS 60.0303Atuk SafizPas encore d'évaluation

- HSSE-D-003 - Health ManagementDocument6 pagesHSSE-D-003 - Health ManagementAHMED AMIRAPas encore d'évaluation

- Cummins PowerBox 20ft 40ft Container Genset Installation ManualDocument28 pagesCummins PowerBox 20ft 40ft Container Genset Installation ManualMohsen Ghorbanzadeh100% (1)

- EHS ManualDocument33 pagesEHS Manualanoushia alviPas encore d'évaluation

- HIRARC - Hazard Identification Risk Assessment and Risk ControlDocument4 pagesHIRARC - Hazard Identification Risk Assessment and Risk ControlRohanPas encore d'évaluation

- 2017 Msds Procion Red Px-5bDocument11 pages2017 Msds Procion Red Px-5bMayank DhawanPas encore d'évaluation

- Seachem Laboratories, Inc. Safety Data SheetDocument9 pagesSeachem Laboratories, Inc. Safety Data SheetJorge Restrepo HernandezPas encore d'évaluation

- Precarious' Non-Standard EmploymentDocument78 pagesPrecarious' Non-Standard Employmentabazamehmet100% (1)

- Integrating Information Technologies Safety Into.22Document3 pagesIntegrating Information Technologies Safety Into.22Raisa PutriPas encore d'évaluation

- Verderflex Dura 45 ManualDocument25 pagesVerderflex Dura 45 ManualTMPas encore d'évaluation

- Hydraulic Oil 68: Safety Data SheetDocument5 pagesHydraulic Oil 68: Safety Data Sheetjerry dauteyPas encore d'évaluation

- Polyurethane Amine Catalysts Guidelines For Safe Handling Amp Disposal English PDFDocument19 pagesPolyurethane Amine Catalysts Guidelines For Safe Handling Amp Disposal English PDFIrelena RomeroPas encore d'évaluation

- OSHJ-GL-16 Permit To Work Version 1 EnglishDocument15 pagesOSHJ-GL-16 Permit To Work Version 1 EnglishsajinPas encore d'évaluation

- Emergency Procedure - PlanDocument10 pagesEmergency Procedure - PlanSiddhesh Kamat Mhamai100% (1)

- TLE 7 (Week 6) TEACHER-MADE MODULESDocument3 pagesTLE 7 (Week 6) TEACHER-MADE MODULESJenicaEilynPas encore d'évaluation

- Block Ladder ReinforcementDocument32 pagesBlock Ladder Reinforcementg3nepsPas encore d'évaluation

- Duties of Prison StaffDocument20 pagesDuties of Prison Staffkvreddy100% (1)

- OSHA's Ergonomics Litigation Record: Three Strikes and It's Out, Cato Policy Analysis No. 370Document17 pagesOSHA's Ergonomics Litigation Record: Three Strikes and It's Out, Cato Policy Analysis No. 370Cato InstitutePas encore d'évaluation

- Chapter 1 (Introduction To Occupational Safety and Health)Document27 pagesChapter 1 (Introduction To Occupational Safety and Health)KinPran100% (2)

- LO 3. Control Hazards and Risks in The Workplace 3.1 Follow Consistently OHS Procedure For Controlling Hazards/risksDocument3 pagesLO 3. Control Hazards and Risks in The Workplace 3.1 Follow Consistently OHS Procedure For Controlling Hazards/risksChristine Joy ValenciaPas encore d'évaluation

- Core 4 TestDocument21 pagesCore 4 TestAlexis RilleraPas encore d'évaluation

- Page 1 of 7Document7 pagesPage 1 of 7Hazim OmarPas encore d'évaluation

- Safety Data Sheet: Tylac®4193Document6 pagesSafety Data Sheet: Tylac®4193Kerron RekhaPas encore d'évaluation

- Green Unikleen 1223 MSDSDocument2 pagesGreen Unikleen 1223 MSDSMurtaza SherwaniPas encore d'évaluation

- Action Plan in Disaster Risk Reduction Management: Division of Cebu ProvinceDocument2 pagesAction Plan in Disaster Risk Reduction Management: Division of Cebu ProvinceCharie P. GraciaPas encore d'évaluation