Académique Documents

Professionnel Documents

Culture Documents

13

Transféré par

Nazim AliDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

13

Transféré par

Nazim AliDroits d'auteur :

Formats disponibles

PRE QUALIFIYING CONSDITIONS FOR

CONSTRUCTION OF WELL FOUNDATIONS AT 3 NO. LOCATIONS ON GARRA RIVER CROSSING FOR . 220 kv Roza Badaun Transmission line , shahjahanpur .

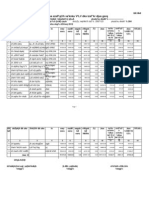

Technical& Financial Qualifications:The desiring tenderer must fulfill the following technical/financial organizational requirements:1- He should be maintaining at least following technical and skilled staff on his own and to be deployed on this work in addition to other skilled and unskilled work as necessary for timely completion of work:SI.No. 1. 1 Category 2. Engineering personals Requirements (Qualified Persons) 3. One Civil Engineering Degree Holder or at lease Diploma Holders having at least 10 Years experience for similar work. One No. Two No. Two No.

2 3 4

Electric Welder (Test welder grade) Well Sinker Fore Man/Supervisor

2- He should have minimum following T&Ps in addition to the other T&Ps norm needed and to be deployed on this work for timely completion of the work. SI. No 1. 1 2 3 Name of Equipment 2. Light Crane of 5 ton Capacity with long boom and grab bucket complete set. Diesel/Electric operated winch 10 ton Capacity with grab bucket complete set. Generator 33 KVA or more capacity, if the well sinking machine is diesel then 15 KVA Generator may be acceptable. Concrete Mixer with hoper (0.4 Cum capacity) Vibrator (400 mm dia needle) Required 3. One No. One No. Two No.

4 5

Two +One No.

Executive Engineer

3- The tenderer must keep the earnest money of required amount in the shape specified in the Notice Inviting Tender without which Part-II of the tender shall not be opened at all. 4- The desiring tenderer shall have the good and reasonable experience of similar works. He must have successfully completed similar work of more than 50% of the cost this tender against one or more agreements in Central/State Govt. Department or public sector undertaking within year during last three years. Certificate to this effect issued by the competent authority (not below the rank of Executive Engineer) giving full details viz. name of work, its nature, contract period, whether completed in time or in extended period, penalty imposed (if any)etc. be submitted. List of all major works executed by the firm within five years shall be given along with the certificates of their successful execution time. In case of Private Limited Companies the certificated should be signed by the person not below the rand of Director (Technical) and annual turn-over of company must not be less than 5.00 Crore. 5- Income Tax clearance certificates/ attested copies of Income Tax Return/Balance Sheets filed for last three years be enclosed along with PAN, TAN issued by income Tax Department. 6- The Solvency certificate of any Nationalized or scheduled Bank, signed by officer not below the rank of Manager of the Bank, indicating the status of the Firm/individual in whose name tender is purchased and to be submitted. 7- Desiring tenderer must have constructed well foundation of all least (6.to9 Meter) outer dia and depth more than 20 Mtr in all types of soil viz. gravel / pebble mix sandy/clayey etc. Tenderer must have enough sets of equipments so that work on all wells could be taken up simultaneously. 8- The tenderer must submit list of technical personals and equipments as stated under point 1 and 2 along with proof/certificates and ownership paper in support. 9- The above information and document shall be kept in the part-I of the bid.

Executive Engineer

TECHNICAL SPECIFICATIONS FOR WELL FOUNDATIONS WORKS

INTENT OF SPECIFICATION The owner desired to have the contract for complete civil works for construction of Special Foundations for Transmission Towers. The work shall have to be carried out both below and above ground level. Construction of Special Foundations for Transmission Towers of 220 K.V. Double Circuit Transmission Line for Garra River Crossing is to be completed in all respect as per design and drawings provided by UPPTCL. SCOPE OF THE WORK The scope of the work to be performed under the part of contract consists of providing labour, material, plants and equipments including all incidental items not shown or specified but reasonably implied or necessary for proper completion of all civil works in all respects, in accordance with the approved design and drawings provided by UPPTCL for construction of all civil works of Tower Foundations. This also includes contractors supervision in strict accordance with the drawings and speciation or direction of Engineer-in-Charge. 1.2 CONSTRUCTION OF TOWER FOUNDATIONS All work shall be carried out as per I.S. 456:1978 and its subsequent revisions thereof. TOWER FOUNDATION Contruction of tower foundation for 220 KV Double circuit transmission line for Garra river crossing shall consist of and well type foundation as per drawing to issued by UPPTCL. The template for grouting of stub shall be arrange by the transmission wing. The stub shall be set by transmission wing. MEASUREMENTS Details measurements of the works executed by the contractor shall be recorded by UPPTCL. The contractor will execute the work as per the latest I.S. Code 1200 part -23/IRC specification and strictly as per approval drawing provided by UPPTCL. The measurements shall be recorded as per drawing, execution of work at site and with the standard prevalent in UPPTCL and unit rates specified in the agreement. No work shall be measured if it is not executed as per specification is to below specifications or with without proper clearance from UPPTCL. The contractor will do such activities only at his own cost and responsibility. Any sub-standard work shall be demolished by the contractor at his own cost. PAYMENTS 90% running payment shall be released to the contractor on basis of measurements of the work executed in installments commensurate with the progress of work.10% payments shall be retained by the corporation as security deposit which shall be released as per clause no 32 of special condition of specification. The work is to be completed in all respect to the requirement /specification of UPPTCL and it should be functional.

The contractor is advised to study the site condition and should be aware of the quantum of work actually involve. N0 extra claims / payments by the contractor other than specified at the time of award of the work shall be entertained in any circumstances.

PEG MARKING

The Peg Marking of all type of Tower shall be made by the UP Power Transmission Corporation Limited. .

DESIGN AND DRAWINGS

All civil work shall be executed according to the approved drawing of UPPTCL.

1.20 SUBMISSION OF PROGRAMME OF CONSTRUCTION

Contractor shall prepare the Programe for all construction activity (Bar Chart) and submit ,with in period not exceeding 3 days from date of award of contract.

1.21 MATERIALS

1. Ordinary Portland cement 43 grade confirming to latest I.S. and of standard make (J.P. prism/birla or equivalent as decide by Engineer-in-charge) shall only be used. 2. Water to be used shall be clean, potable and free of salts, iron and injurious organic matters. 3. Coarse sand shall be of minimum fneness modulus of 2.25. 4. The cold twisted deformed bars (Fe 415 N/sq.mm) confirming to IS : 1786 shall be used as reinforcement. 5- All aggregates shall confrm to all provisions and test methods of IS : 383 or lS:515.

1.22 TECHNIACL SPECIFICATION FOR EARTH WORK Scope

This shall include all work involved in excavation, dressing of soil, shoring, filling around foundations and trenches, carting of sand or good quality earth if required is filling, disposal of residual earth at a place as directed by the Engineer-In- Charge.Boring and Subsurface data regarding nature of soil, sub-soil water etc.shown on drawings or otherwise furnished to the contractor shall be taken as a guidance only and variation, therefore, shall not affect the term of the contract. The contractor must be satisfy himself of the character and volume of all work under this item and expected surface, sub-surface, and/or Sub-soil water to be encountered. He must also satisfy himself about general conditions of site and ascertain the existing and future obstructions likely to come up during the execution of the contract.

Excavation:

Excavation shall include the removal of all materials required to execute the work properly and shall be made with sufficient clearance to permit the placing, inspection, setting of forms and completion of all works for which the excavation was made.

Disposal of Surplus Earth:

The contractor shall arrange to transport the surplus excavated soil to in/out side the work area as direction of E/l.

Measurement For Excavation:

The unit of measurement shall be cum. Nothing extra would be payable for slope, shoring, strutting etc. irrespective of whatever is provided. The overlapped portion in the case of A adjacent foundation shall be paid only once.

1.23 TECHNFCAL SPECIFICATION FOR CEMENT CONCRETE Scope

This specification deals with Cement concrete plain or reinforced for general use, and covers the requirements for concrete materials, their storage, grading, mix design, strength and quality requirements, pouring at all levels, reinforcement protection, curing, form work, finishing, admixtures, inserts and other miscellaneous works. The provisions of the of IS : 456-2000, shall be complied with unless permitted otherwise and any other Indian Standard Code shall form a part of this specification to the extent it has been referred to for application within this specification.

GENERAL REQUIREMENTS

The Contractor shall furnish all labour, material and equipment to fonn, place and finish all cement concrete items complete as indicated in the approved drawing and as described there in. All materials, tests, mixing, placing, form work reinforcing and work man ship shall conform to code of practice for plain and reinforced concrete for general building construction IS 456-1978 and other relevant IS Codes.

MATERIALS Cement:

Ordinary Portland Cement 43 grade shall be conforming to latest I.S.

Aggregates:

All aggregates shall conform to provisions of IS: 383, Samples of aggregates proposed to be used shall be submitted free of charge in three bags, each containing 2 cu.ft. of the aggregates, to the Engineer-in-charge for his future reference.

Coarse Aggregates:

The maximum size of coarse aggregates shall be as follows: 1-For Lean concrete of grades M-5, M-7.5 & M-10 40mm size. 2-For concrete of grades M-15, M-20 and higher grades 20mm size (Plane Cement Concrete and Reinforced Cement Concrete) The coarse aggregates to be used shall be graded. The grading of coarse aggregates for a particular size shall generally conform to relevant IS codes and shall also be such as

To produce a dense concrete of the specified proportions and/or strength and consistency that will work readily into position without segregation.

Fine Aggregates:

Coarse sand shall be well-graded within the limits by weight as specified in IS 383. Fineness modulus shall not vary by more than plus or minus 0.20 from that of the approved sample. Fineness modulus for coarse sand should be minimum of 2.25.Washing of aggregates by approved means shall be carried out, if desired by the Engineer-in-charge at no extra cost to the employer. Fine aggregates of zone 1st grading shall not be used for concreting.

Water:

Water shall be clean, fresh and free from organic or other deleterious matters in solution or in suspension in such amounts that may impair the strength or durability of the concrete. Potable water is generally satisfactory. IS : 3025 and 3550 may be followed for testing, if required.

Storage of materials:

Materials shall be as so stored as to prevent deterioration or intrusion of foreign matter, and to ensure the preservation of their quality and fitness for' the work. Any materials, which has deteriorated or has been damaged or as otherwise considered defective by the Engineer-incharge, shall not be used and shall be removed from site immediately, failing which the Engineer-in-charge shall be at liberty to get the materials removed and the cost thereof shall be realized from the contractor's dues. The contractor shall maintain up to date accounts of receipts, issue and balance (stock wise) of all materials. _

Grades of Concrete:

Concrete shall be of grade M-15, M-20, M-25 or as, indicated in the approved drawings /items of the bill of quantity. Workability of Concrete: Ranges of values of workability for different placing condition is suggested as below: Placing Conditions (1) Concreting of shallow sections with vibration Concreting of lightly reinforced section with vibration Concreting of lightly reinforced section without vibration or heavily reinforced section with vibration Concreting of heavily reinforced section without vibration Degree of workability (2) Very low Values of workability (3) 20-10 seconds vee.bee time or 0.75-0.80 compacting factor. 10-5 seconds vee.bee time or 0.80-0.85 compacting factor. 5.2 seconds vee.bee time or 0.85-0.92 compacting factor or 25-75 mm, slump for 20 mm aggregate. Above 0.92, compacting factor or 75-125 mm slump for 20 mm aggregate.

Low

Medium

High

SAMPLING AND TEST OF STRENGTH OF CONCRETE:

Samples from fresh concrete shall be taken as per l.S. ; 1199-1959 and the specimen cubes' shall be made and tested as per I.S. : 516-1959. The preliminary test (compressive strength test at 7 days) are carried out in addition to 28 days compressive strength test only to get a quicker idea of the quality of the concrete which may be expected to give the required strength. But in all cases, 28 days compressive strength specified in IS. : 456-1978 shall alone be the criterion for acceptance or rejection of the concrete. At least one sample shall be taken from each shift. Three test specimen shall be made from each sample for testing at 28 days. Additional cubes may be required to test the concrete at 7 days. The test strength of the sample shall be the average of the strength of the three specimens. The individual variation should not be more than 115% of the average. The cost of all sampling and testing of concrete shall be borne by the contractor.

DURABILITY OF CONCRETE:

Besides ensuring the required strength of the design mix concrete, the concrete must also have and adequate cement content and a low water cement ratio. The minimum cement content and the maximum water cement ratio shall conform to the provisions of clause 7 of I.S. 14561978.

WORKMANSHIP

General: Concrete shall not be placed in any unit of the work until after the forms /centering and shuttering, bracing reinforcing steel and other properties for casting and approval given to proceed with casting. Mixing concrete: Mixing concrete shall conform to IS 456-1978. Mixing shall be continued till materials are distributed uniform colour of the entire mass obtained and each individual particle of the coarse aggregates shows complete coating of mortar containing its proportionate amount of cement. In no case , shall the mixing be done for less than 2 minutes after all ingredients have been put into the mixer. Mixer which have been out of use for more than 30 minutes shall be thoroughly clean before putting in a new batch. Unless otherwise agreed to by the Engineer-in-charge, The first batch of concrete from the mixer shall only two thirds of the normal quantity of coarse aggregates. When hand mixing is permitted by the Engineer-in-charge for concrete to be used in unimportant structure it shall be taken to ensure that mixing is continued until the mass is uniform in color and consistency. In case of hand mixing, extra cement 10% shall be added to each batch at no extra cost to the employer. The workability of the concrete shall be checked at frequent intervals by slump test as required by the Engineer- in-charge Alternatively the compacting factor test in accordance with IS : 1199 shall be carried out.

Transporting, placing compacting & Curing:

The method of transporting and placing concrete shall be approved by Engineer-in-charge. Concrete shall be so transported and placed that there is no contamination and segregation or loss of its constituents materials takes place.

All form work and reinforcement contained in it shall be cleaned and made free from standing water, dust, immediately before placing of concrete. No concrete shall be placed in any part of the structure until the approval of the Engineer-incharge has been obtained. lf concreting is not started within 24 hours of the approval being given, it shall have to be obtained again from the Engineer-in-charge, concreting then shall proceed continuously over area between construction joints, Fresh concrete shall not be placed against concrete which has been in position for more than 3 0 minutes unless a proper construction joint is formed. Concrete when deposited shall have a temperature of not more than 450C and not less than' 38C. It shall be compacted in its final position within 30 minutes of its discharge from mixers unless stirred on properly designed agitators, operating continuously, when this time shall be within 2 hours of the addition of the cement to the mix and within 30 minutes of its discharge from agitator. Except where otherwise agreed to by the Engineer-in-charge, shall be deposited in horizontal layers to a compacted depth of not more than 0.30 meter when internal vibrators are used and not exceeding 0.20 meters in all other cases. Unless otherwise agreed to by the Engineer-in-charge, concrete shall not be dropped into place from a height exceeding 2 meters. When chutes are used, they shall be kept clean and used in a such a way as to avoid segregation. When concreting has to be resumed on a surface which has hardened, it shall be roughened, swept clean, thoroughly wetted, and covered with a 20 mm thick layer of mortar composed of cement and sand in the same ratio as in the concrete mix itself This 20 mm layer of mortar shall be freshly mixed and placed before placing of new concrete. When concrete has not full hardened all laitance shall be removed by scrubbing the wet surface with wire or bristle brushes care being taken to avoid dislodgment of any particles of coarse aggregate. The surface shall then be thoroughly wetted. All free water removed and then coated with neat cement grout. The first layer of concrete to be placed on this surface shall not be exceed 150 mm in thickness, and shall be well rammed against old work. Particular attention being given to corners and close spots. All concrete shall be compacted to produce a dense homogenous mass with assistance of vibrators, unless otherwise permitted by the Engineer-in-charge for exceptional cases. Such as concreting under water where vibrators cannot be used sufficient vibrators in serviceable condition shall be kept at site so that spare equipment is always available in the event of break downs. Internal vibrators shall be capable of producing not less than 10,000 cycles per minute and external or form vibratos not less than -1000 cycles per minute. Vibrators shall not be applied through reinforcement and where vibrators of the immersion type are used contact with reinforcement and all inserts shall be avoided as far as practicable.

Concreting Under water:

When it is necessary to deposit concrete under water the methods, equipment materials and proportions of the mix to be used shall be got approved from the Engineer-in-charge before any work is started. Concrete shall not be placed in water having temperature below 45 0C the temperature of the concrete, when deposited, shall be not less than 16 0 not more.

Than 380 C. Concrete shall contain 10% more cement than that required for the same mix placed in the dry conditions. The material shall be so proportioned as to produce a concrete having a slump of not less than 100 mm and not more than 150 mm. The slump shall be tested as per IS: 516. , Coffer dams or forms shall be sufficiently to ensure still water conditions if practicable and to reduce the flow of the water to less 3m / minute through the space into which concrete is to be deposited , coffer dams or forms in still water shall be sufficiently tight to prevent loss of mortar through the joints in the walls, Pumping shall not be done while concrete is being placed, or until 24 hours thereafter. Concrete shall be deposited continuously until it has been brought to the required height. While depositing the top surface shall always be kept as nearly leveled as possible and formation of seams avoided. Depositing of concrete may be done by Tremie Pipe or Drop Bottom Bucket.

Curing of Concrete: Immediately after completion concrete shall be protected against harmful effects of weather, including rain, running water, shocks, vibrations, traffic, rapid temperature changes, frost and drying out process. lt shall be covered with wet sacking, Hessian or other similar absorbent material approved by the Engineer-in-Charge soon after initial set, and shall be kept continuously wet for a period not less than 14 days from the date of placement.

Finishing:

Immediately after removal of forms, all exposed bars or bolts passing through the reinforced cement concrete member and used for shuttering or any other purpose shall be cut inside the reinforcement cement concrete members to a depth of at least 25 mm below the surface of concrete and the resulting holes to be closed by cement mortor. All fills caused forms joints all cavities produced by the removal of form tiles and all other holes and depressions, honey comb spots broken edges or corners and other defects shall be thoroughly cleaned saturated with water are carefully pointed and rendered to true with mortor of cement and free aggregates mixed in the proportions used in the grade of concrete that is being finished and to as dry a consistency as is possible to use. Considerable pressure shall be applied in filling and pointing to ensure thorough filling in all voids. Surfaces which have been pointed shall be kept moist for a period of 21 hours. If rock pockets/honey combs in the opinion of the Engineer-in-charge are of such an extent or character as to affect strength of the structure materially to endanger the life of the steel reinforcement, he may declare the concrete defective and required the removal and replacement of the portions of the structure affected.

Measurement of concrete:

Measurement of concrete shall be in cubic meters correct up to seconds place of decimal. Deductions shall be made for all block cuts and openings but not embedment and reinforcement.

Reinforcement:

Reinforcing steel shall be clean and free from loose rust and coats of paints, oil, grease or other coating. Which may impair or reduce bond. It shall conform to the following IS specifications.

i) Mild steel & Medium Tensile Steel Bars and Hard drawn steel wire conforming to IS 280-1978. ii) Cold Twisted Bars conforming to IS: 1786-1979. iii) Structural steel sections conforming to IS-226-1975. All steel reinforcement, including and above 6 mm diameter shall necessarily be of tested quality. The work of providing reinforcement includes cutting of reinforcement bars their Bending and placing them in position as per approved drawing including welding wherever necessary and binding. Binding wire shall be annealed iron wire quality not' less than No. 16 SWG. (1.65 mm dia). Bar support, chairs and bolsters (as approved by Engineer-in-charge) shall be sufficiently strong to support the steel properly. iv) Reinforcement shall be bent and fixed in accordance with procedure specified in lS: 2502 and shall not be straightened in a manner that will injure the material. Bar -I bending schedule as shown in the approved drawing shall be followed for Construction purpose. v) Procedure as specified in IS-456-1978 shall be followed in general unless and otherwise permitted by Engineer-in-charge. vi) As far as possible, bars of full lengths shall be used. In case it is not possible, over lapping of bars shall be done as directed by the Engineer-in-charge. When_ practicable, overlapping bars shall not touch each other and be kept apart by 25 mm of the dia of the bigger bar or 1.25 times the maximum size of the coarse aggregate which ever is greater for easy concreting. Between them. The overlaps shall be staggered for different bars and located at points along the span where neither shear not bending moments maximum. (vii) Welding of mild steel reinforcing bars conforming IS : 432 shall be permitted welding of cold twisted deformed bars conforming to IS: 1786 shall in general be prohibited except in special cases mentioned in I.R.C.21-1987. Test shall be made if directed by the Engineer-incharge to ensure that the joints are of full strength. (viii) Measurement steel work in reinforcement shall be measured in running meters and converted to weight in accordance with the standard sectional unit weight for different diameter bars provided in IS : 1786-1979 or IS :432 (Part I-1966) as the case may be other provisions shall be as per IS : 1200 (Part 8-1971)No allowance shall be made for wastage or no payment shall be made for binding wire. Form Work: General: Form work shall be as per IS : 456-2000. The Form-work shall conform to the shape lines and dimensions as shown as shown in the drawing it shall be composed of steel and/or best quality shuttering wood on non-absorbent timber and shall be free from knots. Hard woods shall be used as caps and wedges under or over posts. Plywood or equivalent shall be used where specified to obtain smooth surfaces for exposed concrete work. Struts shall be generally be mild tubes, and strong sal ballies 150 mm in dia, or above bamboos, small diameters ballies extra shall be not used unless approved by the Engineer-in-charge in specified cases.

Where metal forms are used, all bolts and rivets shall be counter-sunk and well grounded to provide smooth and plain finish. The fonns shall be mortar-tight and shall be made sufficiently rigid by the use of ties and bracings to prevent any displacement or sagging. The forms shall be strong enough to withstand all pressures, ramming and vibration without deflection from the prescribed lines. Screw-jacks or hard wood wedges shall be provided where required to make up any settlement in the form work before or during the placing of concrete. Suitable cambers shall bet provided in horizontal members of structures especially in long spans to counteract the effect of any deection. Unless otherwise specified, fillets of size 25mm x 25 mm shall be provided in all edges of form work to avoid sharp corners. Release agents wherever required, shall be applied on the inside surface of the form work except in case of permanent form work strictly in accordance with the manufacturers instructions. Procedure laid down in IS: 456-2000 latest edition) shall be followed for removal of forms. Tolerance: lt shall conform to lS:456-2000.

Mode of measurement:

The rate of R.C.C. / C.C. includes the cost of form work wherever mentioned and no additional payment shall be made for form work in such case.

R.C.C. WORK:

RCC work for well cap chimney raft and similar other works shall be in cement concrete, M-20 with steel reinforcement. PRECAUTIONS OF TAKEN (Ref.Clause 4.13) DURING SINKING OF WELLS 1.CONSTRUCTION OF WELL CURB AND STEINING 1.1.Cutting edge and the top of the well curb shall be placed truly horizontal. 1.2. The methods adopted for placing of the well curb shall depend on the site conditions, and the cutting edge shall be placed on dry bed. 1.3. Well steining shall be built in lifts and the first lift shall be laid after sinking the curb at least partially for stability. 1.4. The steining shall be built in one straight line from bottom to top and shall always be at right angle to the plane of the curb. In no case it shall be built plumb in intermediate stages when the well is tilted. 1.5. In soft strata prone to settlement/creep, the construction of the abutment wells shall be taken up after the approach embankment for a sufficient distance near the abutment has been completed.

1 2. SINKING 1 2.1. A sinking history record be maintained at site. .1 2.2. Efforts shall be made to sink wells true to position in plumb. Tilt and shift shall be within permissible limit as per IS Code 3955 or its subsequent revisions thereof. 2.3. Sumps made by dredging below cutting edge shall referably not be more than half the Internal diameter. 2.4. Boring chart shall be referred to constantly during sinking for taking adequate care while piercing different types of strata by keeping the boring chart at the site and plottmg the soil as obtained for the well staining and comparing it with earlier bore data to take prompt decisions. 2.5. When the wells have to be sunk close to each other and the clear distance is less than the diameter of the wells, they shall normally be sunk in such a manner that the difference in the levels of the sump and the cutting edge in the two wells do not exceed half the clear gap between them. 2.6. When group of wells are near each other, special care is needed that they do not foul in the course of sinking and also do not cause disturbance to wells already sunk. The minimum clearance between the wells shall be half the external diameter. Simultaneous and level dredging shall be carried out in ,\.the dredging holes of all the wells in the group and plugging of all the wells be done together. 2.7. During construction partially suck wells shall be taken to a safe depth below the anticipated scour level to ensure their safely during ensuring floods. 2.8. Dredged material shall not be deposited unevenly around the well. 3. USE OF KENTLEDGE 3.1. Where a well is loaded with kentledge to provide additional sinking effort, such load shall be placed evenly on the loading platform, leaving sufficient space in the middle to remove excavated material. 3.2. Where tilts are present or there is a danger of well developing a tilt, the position of the load shall be regulated in such a manner as to provide greater sinking effort on the higher side of the well. 4. SAND BLOWS IN WELLS .4.1. Dewatering shall be avoided if sand blows are excepted. Any equipment and men working inside the well shall be brought of the well as soon as there are any indications of a sand-blow.

4.2. Sand blowing in wells can often be minimised by keepmg the level of water inside the well higher than the water table and also by adding heavy kentledge. 5. SINKING OF WELLS WITH USE OF DIVERS 5.1. Use of divers may be made in well sinking both for sinking purposes, like removal of obstructions, rock blasting, etc. as also for monsoon. All safety precautions shall be taken as per any acceptable safety code for sinking with divers or any statutory regulations in force. 5.2. Only persons trained for the diving operation shall be employed. They shall work" under expert supervision. The diving and other equipments shall be of an acceptable standard. It shall be well maintained for safe use. 5.3. Arrangement for ample supply of low pressure clean cool air shall be ensured through an armored flexible hose pipe. Stand by compressor plant will have to be provided in case of breakdown. 5.4. Separate high pressure connection for use of pneumatic tools shall be made. Electric lights, where provided, shall be at 50 volts (maximum). The raising of the diver from the bottom of wells shall be controlled so that the decompression rate for rivers conforms to the appropriate rate as laid down in the regulation. 5.5. All men employment for diving purposes shall be certified to be fit certified to be fit for diving by an approved doctor. 6. BLASTING 6.1. Only light charges shall be used under ordinary circumstances and should be fired under water well below the the cutting edge so that there is no change of the curve been damaged. 6.2. There shall be no equipment inside the well nor shall there be any labor in the close vicinity of the well at the time of exploding the charges. 6.3. All safety precautions shall be taken as per IS: 4081 Safety Code for Blasting and related drilling operations to the extent applicable, whenever blasting is resorted to use of large charges 0.7kg or above may not be allowed except under expert direction and with permission from Engineer-in-Charges suitable pattern of charges may be arranged with delay detonators to reduce the number of charges fired at a time. The burden of the charge may be limited to 1 meter and the spacing of holes may normally be kept at 0.5 to 0.6 meter.

6.4. lf rock blasting is to be done for seating of the well, the damage caused by the flying debris should be minimized by provisions of rubber mats covered over the blasting holes before blasting. _ 6.5. After blasting, the steining shall be examined for any cracks and corrective measures shall be taken immediately.

Contractor

Executive Engineer

Vous aimerez peut-être aussi

- Month March 11-2012 C1 NewDocument23 pagesMonth March 11-2012 C1 NewNazim AliPas encore d'évaluation

- Gupta Ji GPFDocument1 pageGupta Ji GPFNazim AliPas encore d'évaluation

- MinitsDocument1 pageMinitsNazim AliPas encore d'évaluation

- Electricity Civil Transmission Division Bareilly. Estimate/Expenditure Done/Fund Required For Various O Going Projects Up To 09/2012Document4 pagesElectricity Civil Transmission Division Bareilly. Estimate/Expenditure Done/Fund Required For Various O Going Projects Up To 09/2012Nazim AliPas encore d'évaluation

- Supply Order of UniformDocument1 pageSupply Order of UniformNazim AliPas encore d'évaluation

- Civil Tran 10-20121111Document5 pagesCivil Tran 10-20121111Nazim AliPas encore d'évaluation

- Cash Fillo 2Document5 pagesCash Fillo 2Nazim AliPas encore d'évaluation

- Pension Gratuity, CPF & GPF 10-2012Document6 pagesPension Gratuity, CPF & GPF 10-2012Nazim AliPas encore d'évaluation

- Bill of Qty. N.C. Sharma, BILSI, BadaunDocument47 pagesBill of Qty. N.C. Sharma, BILSI, BadaunNazim AliPas encore d'évaluation

- Financial Kubar Sen SirDocument2 pagesFinancial Kubar Sen SirNazim AliPas encore d'évaluation

- Name of Unit: Electricity Civil Transmission Division Bareilly, Location Code - 264Document2 pagesName of Unit: Electricity Civil Transmission Division Bareilly, Location Code - 264Nazim AliPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CPOC-GS-PI-0001 Rev 0Document34 pagesCPOC-GS-PI-0001 Rev 0PCHAN@TOMPas encore d'évaluation

- Autosar Sws ComDocument216 pagesAutosar Sws ComStefan Ruscanu100% (1)

- GeM Bidding 1847532 PDFDocument2 pagesGeM Bidding 1847532 PDFPalak AgarwalPas encore d'évaluation

- F 1104 - 87 R98 Rjexmdqtoddsotg - PDFDocument2 pagesF 1104 - 87 R98 Rjexmdqtoddsotg - PDFJuanPas encore d'évaluation

- BT 358 ConstructionEstimating and Price AnalysisDocument162 pagesBT 358 ConstructionEstimating and Price Analysisengsam777100% (2)

- JSS 50101 PDFDocument146 pagesJSS 50101 PDFAditya Srivatsav100% (1)

- NSTS v1.0 WebDocument80 pagesNSTS v1.0 Webkaveesh.2011Pas encore d'évaluation

- Nato Quality Assurance Requirements For Design, Development and ProductionDocument21 pagesNato Quality Assurance Requirements For Design, Development and ProductionHilalPas encore d'évaluation

- Lafarge - Gypsum ProductsDocument8 pagesLafarge - Gypsum ProductschojwPas encore d'évaluation

- Zeeshan CV7Document3 pagesZeeshan CV7Zeeshan Ul HassanPas encore d'évaluation

- Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat BarDocument8 pagesAnnealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Baralucard375Pas encore d'évaluation

- Vdmtools: Vdmtools User Manual (VDM++)Document30 pagesVdmtools: Vdmtools User Manual (VDM++)maPas encore d'évaluation

- 50DB Rig SpecificationDocument31 pages50DB Rig Specificationmartahan manurung100% (1)

- Ordinary Pressure Gauges: (Silver M)Document6 pagesOrdinary Pressure Gauges: (Silver M)RofiPas encore d'évaluation

- PPAPDocument116 pagesPPAPevan100% (1)

- Stages in Test Construction: Planning, Preparing, Reviewing/ Revising Test ItemsDocument2 pagesStages in Test Construction: Planning, Preparing, Reviewing/ Revising Test ItemsDini SumadiPas encore d'évaluation

- Aficio SP 4310nDocument224 pagesAficio SP 4310nnewid idPas encore d'évaluation

- TPF 4 Work Plan and Methodology 02-12-15 (Final) ANDREDocument30 pagesTPF 4 Work Plan and Methodology 02-12-15 (Final) ANDREAndrea BroccoliPas encore d'évaluation

- Bsen25817 PDFDocument18 pagesBsen25817 PDFdzat_sudrazat0% (1)

- Spec Sheets Hebden DGB20Document1 pageSpec Sheets Hebden DGB20stefpanPas encore d'évaluation

- Standard Bidding Document: Procurement of Goods Sealed QuotationDocument48 pagesStandard Bidding Document: Procurement of Goods Sealed QuotationMMTS NepalPas encore d'évaluation

- QMS 0803 Quality Management System ManualDocument23 pagesQMS 0803 Quality Management System Manualzae nuddin100% (2)

- Life Cycle Risk Assessment of HPLC InstrumentsDocument13 pagesLife Cycle Risk Assessment of HPLC Instrumentsalexg123100% (1)

- AWS B2 1 1 004 2013 SWPS GMAW ShortDocument22 pagesAWS B2 1 1 004 2013 SWPS GMAW Shortreza acbariPas encore d'évaluation

- 2018 Pub Catalog PublishWEBDocument14 pages2018 Pub Catalog PublishWEBaswayPas encore d'évaluation

- Sizing and Selecting Pressure Relief ValvesDocument70 pagesSizing and Selecting Pressure Relief ValvesSagar Naduvinamani100% (1)

- Java All MergeDocument191 pagesJava All Mergevikranth kalingarayarPas encore d'évaluation

- Spec - Rev TDocument18 pagesSpec - Rev Tgustavo aguilarPas encore d'évaluation

- Sap Fica Sample Resume 1Document5 pagesSap Fica Sample Resume 1NAGARAJU BOJJAGANIPas encore d'évaluation