Académique Documents

Professionnel Documents

Culture Documents

Triaxial Test: Consolidated Undrained

Transféré par

Nguyễn HòaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Triaxial Test: Consolidated Undrained

Transféré par

Nguyễn HòaDroits d'auteur :

Formats disponibles

Pavements & Structures

TEST METHOD

WA 151.1

TRIAXIAL TEST: CONSOLIDATED UNDRAINED

SCOPE This method describes the procedure for the determination of the effective shear strength parameters of a soil using the triaxial compression apparatus. APPARATUS 1. A triaxial cell of dimensions appropriate to the size of the specimen to be tested, suitable for use at the highest intended cell pressure and provided with a means of applying additional axial load to the specimen through a loading ram. The cell shall include an end cap of the same diameter as the specimen. The vertical stress due to the top cap shall not exceed 1% of the maximum deviator stress. A cell pressure system for applying, maintaining and measuring the desired pressure of water within the cell to an accuracy of +5kPa. A back pressure system for applying, maintaining and measuring the desired pressure within the specimen to an accuracy of +5 kPa. This system shall also be capable of measuring the volume of water entering or leaving the specimen. A loading machine capable of applying axial compression to the specimen at variable speeds. Rates of speed in the range 0.05mm to 0.5mm per minute are normally satisfactory. The machine shall be capable of applying an axial deformation of approximately one third of the height of the specimen. Apparatus for measuring the additional axial load on the specimen to an accuracy of +5 kPa or 1 percent of the maximum axial load whichever is the greater. Apparatus for measuring the axial deformation of the specimen readable to 0.02mm. A pore pressure monitoring system (transducer type) capable of measuring the expected water pressures within the specimen to an accuracy of +5kPa. Seamless rubber membrane in the form of a tube, open at both ends, of diameter equal to the specimen diameter and of length approximately 50mm greater than the height of the specimen. The membrane thickness should be selected having regard to the nature of the soil to be tested. A thickness of 0.1mm to 0.4mm is normally satisfactory. Membrane stretcher to suit the size of the specimen. Suitable porous discs. Rubber rings to suit the diameter of the end caps. Filter papers cut to the same diameter as the specimen, and also filter papers cut to a suitable pattern to be used as side drains.

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

2. 3.

4.

5. 6. 7. 8.

9. 10. 11. 12.

MAIN ROADS Western Australia T\WA151-1.doc

Page 1 of 9

Pavements & Structures

TEST METHOD

WA 151.1

13. 14. 15. 16. 17.

Suitable equipment for preparing the test sample of the required diameter from undisturbed samples in the laboratory. Moulds and other suitable equipment for preparing remoulded specimens. A balance, of at least 5kg capacity readable to 0.01 grams, with a limit of performance of equal to or less than 0.06g. A thermostatically controlled oven with good air ventilation and capable of maintaining a temperature between 105C and 110C. A stopwatch or other suitable timing device.

PROCEDURE 1. 1.1 Preparation of Test Sample Undisturbed Samples (Note a)

1.1.1 Obtain a test sample taken from a selected position within a core or other sample. 1.1.2 Trim the test sample from an undisturbed sample using a thin walled tube or other suitable sample preparation equipment. 1.1.3 Cut the ends plane and parallel to ensure a right cylindrical specimen of the correct length. 1.1.4 Measure and record the length, diameter and mass of the specimen to the nearest 0.5mm and 0.1g respectively. 1.2 Remoulded Samples

1.2.1 Obtain a test sample taken in accordance with Test Method WA 100.1 or from a selected position within a core or other sample. 1.2.2 Compact the test sample at the required conditions of moisture/density in a suitable split mould. 1.2.3 Cut the ends plane and parallel to ensure a right cylindrical specimen of the correct length. 1.2.4 Measure the length, diameter and mass of the specimen to the nearest 0.5mm and 0.1g respectively.

MAIN ROADS Western Australia T\WA151-1.doc

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

Page 2 of 9

Pavements & Structures

TEST METHOD

WA 151.1

2. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14

Test Preparation Flush the pore pressure system through with de-aired water to force any trapped air from the system. Flush the cell pressure system through with de-aired water to force any trapped air from the system. Flush the back pressure system including the volume change gauge through with de-aired water to force any trapped air from the system. Set the cell pedestal on the compression machine and connect the cell pressure line, pore pressure line and back pressure line. Place a saturated porous stone disk onto the previously wetted cell pedestal. Locate the saturated filter paper on the porous stone disc. Place the specimen on the filter paper. Saturate the top cap or porous plate if applicable and filter paper and position them onto the specimen. Wrap a saturated filter paper side drain around the specimen and porous disc, and smooth the side drain onto the specimen. Place the rubber membrane around the specimen using the membrane stretcher. Seal the membrane to the cell pedestal by means of rubber rings. Smooth the membrane onto the specimen using the fingers, working lightly up from the base to expel any air which is trapped between the membrane and the specimen. Seal the membrane to the top cap by means of rubber rings. Connect the thin pore pressure tube to the bottom of the pedestal and flush the tube with a small amount of de-aired water ensuring that no air is trapped in the tube. Connect the end of the tube to the top end cap in such a way that the tube coils snugly around the specimen. Assemble the cell, admit the de-aired water (Note b) and secure the loading ram by tightening the gland. Pore Pressure Transducer Calibration Connect a pore pressure transducer into the lower pore water line and the back pressure system in such a way that the transducer can be isolated from the specimen and the back pressure system. Connect the transducer to a suitable power source and readout device.

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

2.15 3. 3.1

3.2

MAIN ROADS Western Australia T\WA151-1.doc

Page 3 of 9

Pavements & Structures

TEST METHOD

WA 151.1

3.3

Isolate the transducer from the specimen, and using the range of pressures between back pressure and maximum cell pressure, prepare a chart comparing transducer output versus pressure. Saturation Stage Activate the back pressure volume change apparatus and ensure that it is at a suitable level to monitor water movement into the specimen. Record the reading on the volume change gauge. Raise the cell pressure and the back pressure in increments of 10kPa in such a way that the cell pressure always remains 5kPa higher than the specimen back pressure (Note c). Monitor the back pressure volume change gauge to ascertain when the specimen appears saturated. Measure the pore pressure of the specimen. Isolate the specimen from the back pressure system and increase the cell pressure by 50kPa. Measure the change in pore pressure. Calculate the pore pressure parameter (B) where: B =

u

4. 4.1 4.2 4.3

4.4 4.5 4.6 4.7 4.8

u 3 = change in pore pressure = change in cell pressure (50 kPa)

where

Saturation is complete when B approaches unity (Note d). 4.9 5. 5.1 5.2 5.3 Repeat the saturation stage if necessary by reducing the cell pressure until it is 5 kPa higher than the back pressure and repeat Procedures 4.1 to 4.8. Consolidation Stage Using the axial deformation measuring apparatus, record the height of the specimen. Increase the cell pressure applied during the saturation stage until the difference between the cell pressure and the back pressure equals the required effective pressure. Allow the pore pressure to dissipate through the back pressure volume change apparatus.

MAIN ROADS Western Australia T\WA151-1.doc

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

Page 4 of 9

Pavements & Structures

TEST METHOD

WA 151.1

5.4 5.5 5.6 5.7 6. 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 6.12

Take readings at pre selected intervals of time (Note e) and record the values of volume change and pore pressure. Plot the volume change cms against the square root of time (min). Continue consolidation until the volume change gauge reading is essentially constant, or dissipation of pore pressure is 95% complete. Determine the height of the specimen. Compression (Shear) Stage Estimate a suitable rate of axial deformation (Note f). Select a suitable proving ring and mount it on the machine. Secure the loading ram to the bottom of the proving ring assembly. Raise the loading ram above the specimen, activate the loading machine, and with the ram moving at the selected test speed, adjust the proving ring to zero. Switch the machine off and manually adjust the loading ram until it is just in contact with the seat on the upper end cap of the specimen. Open the connection between the pore pressure transducer and the specimen and ensure the recording device is operating. Commence compression of the specimen by setting the loading machine into motion. Record simultaneously, readings of axial deformation, pore pressure and proving ring dial gauge at suitable intervals of strain (Note g). Calculate deviator stress and percent strain and plot these values until two consecutive values of the deviator stress are the same (Note h). Terminate axial deformation and raise the loading ram sufficiently to restore the proving ring dial gauge to zero. Carry out Procedures 6.13 - 6.16 if a single stage test or the final stage of a multi-stage test is being performed. Increase the cell pressure to give the next required effective pressure and consolidate the specimen as per procedure 5 if a further stage of the test is being carried out. Repeat Procedures 6.1 to 6.12. Release all pressure systems. Drain and dismantle the cell. Remove the specimen and determine its wet mass.

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

6.13 6.14 6.15

MAIN ROADS Western Australia T\WA151-1.doc

Page 5 of 9

Pavements & Structures

TEST METHOD

WA 151.1

6.16

Determine the moisture content of the specimen in accordance with Test Method WA 110.1 or 110.2.

CALCULATIONS

1.

Calculate the cross-sectional area for each recorded point of strain on the assumption that the specimen deforms as a right cylinder (Note i). This area at any strain E is given by the equation: A where A =

Ao 1 -

= cross sectional area of the specimen in mm

A o = initial cross sectional area of the specimen in mm

Lo l Lo

where Lo = initial length of the specimen in mm L 2. = length of the specimen in mm at the stage of the test at which the area A is to be determined.

Calculate the deviator stress for each recorded point of strain from the formula (Note j):

( 1 3 )

P x 10 6 A

where ( 1 3 ) = deviator stress in kPa P A 3. 4. = axial load in kN. This value is obtained by multiplying the proving ring factor by dial gauge readings = cross sectional area in mm

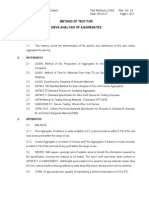

Determine the maximum deviator stress from 6.9 and the corresponding pore pressure (u) from the pore pressure recorder. Obtain effective stress parameters (C and ) by plotting the Mohr effective stress circles for the point of failure in each test stage of a multi-stage test or in each specimen in a series of tests carried out on the sample.

MAIN ROADS Western Australia T\WA151-1.doc

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

Page 6 of 9

Pavements & Structures

TEST METHOD

WA 151.1

The procedure to determine each Mohr circle is as follows: (Note k) 4.1

3 Locate a point at a distance of ( 3 u ) + 1 along a normal stress axis. 2

where u 1 = 1 = = axial stress cell pressure pore pressure

4.2

Using this point as the centre, draw a semi circle of radius:

1 3

2 4.3 4.4 4.5 Draw a tangent of best fit to the circles obtained. Determine the value of the intercept of the tangent on the shear stress axis which represents the effective cohesion (C). Measure the gradient of the line drawn as tangent to the circles which represents the effective angle of internal friction ().

REPORTING

Report the following values and general information if appropriate. 1. 1.1 1.2 1.3 1.4 1.5 2. 2.1 2.2 2.3 2.4 Results. Report the value of maximum deviator stress for each stage of the test to the nearest 5 kPa. Report the corresponding strains and times to failure. Provide Mohr circles and the tangent line of failure. Report effective cohesion to the nearest 5 kPa. Report effective angle of internal friction to the nearest 1. General Information Sample reference numbers, date sampled, location, borehole number and depth. Field description and Unified Soil Classification of the sample. The specimen dimensions. Type of sample (eg undisturbed or remoulded).

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

MAIN ROADS Western Australia T\WA151-1.doc

Page 7 of 9

Pavements & Structures

TEST METHOD

WA 151.1

2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12

NOTES (a)

The initial and final dry density to the nearest 0.001 t/m. The initial and final moisture content to the nearest 0.1%. The cell pressure for each stage to the nearest 5 kPa. The maximum pore pressure for each stage to the nearest 5 kPa. A plot of each consolidation phase. A plot of the stress/strain curves for each stage. A description of the specimen as broken open after the test (Note l). The mode of failure of the specimen (Note m).

Procedures for the preparation of test specimens vary considerably in detail but the general aim is to produce specimens of required dimensions with a minimum change of soil structure and moisture content. The test is limited to specimens in the form of right cylinders of height approximately equal to twice the diameter of the cylinder.

(b) (c)

To minimise leakage past the loading ram and cell interface, a quantity of oil should be poured onto the water at the top of the cell. A back pressure of approximately 100 kPa is usually sufficient to eliminate trapped air by absorption into the de-aired water. This pressure may be increased if required. Sufficient time should be left between increments to allow pore pressure to stabilise within the specimen. Usually 5-10 minutes is sufficient. From a practical point of view, saturation is considered complete when B has exceeded 0.95. Preferred times for readings are: 7.5, 15 and 30 sec, 1, 2, 4, 8, 16 and 32 min, 1, 2, 4, 8, etc hours. For most clays a test duration of 2-4 hours is adequate. The time chosen must ensure an equalisation of pore pressure within the specimen. The axial deformation at failure can often be estimated by previous experience on similar material. As a guide normally consolidated clays have typical failure strains of 20-24% and heavily over-consolidated clays have typical failure strains of 4-8%. Simultaneous readings should be taken at 0.2mm of axial strain for 38mm and 50mm diameter specimens and 0.4mm axial strain for 75 mm and 100mm diameter specimens. Care should be exercised to ensure that the test is not stopped too early. The general shape of the stress/strain curve should be taken into consideration before a decision is made to stop compression. The formula for calculating the area A assumes negligible volume change in the specimen, ie around 2%. If volume changes larger than this are expected, they should be measured and allowed for. Membrane correction is usually not necessary however on very soft, small diameter specimens, the contribution of the rubber membrane to the measured strength may be significant and should be allowed for. Figure 1 shows the development of Mohr's circles, the Mohr envelope and the determination of C and .

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

(d) (e) (f)

(g) (h) (i) (j)

(k)

MAIN ROADS Western Australia T\WA151-1.doc

Page 8 of 9

Pavements & Structures

TEST METHOD

WA 151.1

(l)

This procedure allows comment to be made regarding the homogeneity of the specimen. Breaking the specimen is preferable to cutting the specimen as structural features are not obscured. As some soils are difficult to break, a partial cut to assist the breaking may be necessary.

(m)

A convenient means of recording the mode of failure is a sketch indicating the position of the failure plane. The angle of the failure plane should be recorded if apparent. The recording should be completed without undue delay to avoid loss of moisture from the specimen.

MAIN ROADS Western Australia T\WA151-1.doc

Triaxial Test: Consolidated Undrainaed Test Method 71/2/151.1 Issue 1 2/88

Page 9 of 9

Vous aimerez peut-être aussi

- Triaxial Test ProcedureDocument7 pagesTriaxial Test ProcedureMuazPas encore d'évaluation

- UU TestDocument7 pagesUU TestVenu Gopal Mudhiraj100% (1)

- STSZ 8Document6 pagesSTSZ 8Edgard GinesPas encore d'évaluation

- Triaxial Compression TestDocument53 pagesTriaxial Compression TestAndyra Jaiz BadduPas encore d'évaluation

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Document10 pagesMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnPas encore d'évaluation

- Soil Mechanics: Triaxial Stress Measurement Test (Uu-Cu-Cd Tests)Document3 pagesSoil Mechanics: Triaxial Stress Measurement Test (Uu-Cu-Cd Tests)Opu DebnathPas encore d'évaluation

- Experiment 7: Field Density (Sand Cone Method)Document8 pagesExperiment 7: Field Density (Sand Cone Method)Thanaa' Marabeh100% (1)

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument12 pagesQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- UU Triaxial TestDocument11 pagesUU Triaxial Testredz00100% (1)

- Percolation TestDocument3 pagesPercolation TestKothiyal MukeshPas encore d'évaluation

- Sieve Analysis ProcedureDocument0 pageSieve Analysis ProcedureAbdul Raheem U LPas encore d'évaluation

- AGGREGATE ABRASION TEST VALUESDocument6 pagesAGGREGATE ABRASION TEST VALUESAbdur RazzakPas encore d'évaluation

- C 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Document6 pagesC 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Dr Wong Kim YuenPas encore d'évaluation

- Marshall Mix Design Test ProcedureDocument3 pagesMarshall Mix Design Test Procedureshafiqz_4Pas encore d'évaluation

- Determination of Consistency of Standard Cement PasteDocument3 pagesDetermination of Consistency of Standard Cement PasteAfifah FauziPas encore d'évaluation

- Compacting Factor TestDocument3 pagesCompacting Factor TestRahul SharmaPas encore d'évaluation

- L1-Physical Characteristic of SoilDocument78 pagesL1-Physical Characteristic of SoilTAN PANG ZORPas encore d'évaluation

- DETERMINE SOIL DENSITY SAND POURINGDocument5 pagesDETERMINE SOIL DENSITY SAND POURINGGayathri RSPas encore d'évaluation

- Standard Proctor Test - Lab ManualDocument2 pagesStandard Proctor Test - Lab ManualmmPas encore d'évaluation

- Aggregate Angularity NumberDocument5 pagesAggregate Angularity NumberAdnan AhmadPas encore d'évaluation

- Consolidation Test AnalysisDocument26 pagesConsolidation Test AnalysisRajeev Kusugal100% (1)

- Determination of Flakiness and Elongation Index For The Given Aggregate Sample.Document4 pagesDetermination of Flakiness and Elongation Index For The Given Aggregate Sample.Huma AliPas encore d'évaluation

- Direct Shear Test ReprtDocument4 pagesDirect Shear Test ReprtShivaraj SubramaniamPas encore d'évaluation

- Benkelman Beam ApparatusDocument2 pagesBenkelman Beam ApparatusSAIB BRAHIMPas encore d'évaluation

- Asphalt ExtractionDocument4 pagesAsphalt ExtractionOsikur RahamanPas encore d'évaluation

- Unconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsDocument6 pagesUnconsolidated-Undrained Triaxial Compression Test On Cohesive SoilsAle ValbuenaPas encore d'évaluation

- Half-Cell Potential Method for Measuring Reinforcing Bar Corrosion RiskDocument3 pagesHalf-Cell Potential Method for Measuring Reinforcing Bar Corrosion RiskBIPL REPORTPas encore d'évaluation

- The Effect of Excess Water in ConcreteDocument2 pagesThe Effect of Excess Water in ConcreteKevin NacalabanPas encore d'évaluation

- Unconfined Compression TestDocument11 pagesUnconfined Compression TestAmiruddin JSPas encore d'évaluation

- Tittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself ApparatusDocument6 pagesTittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself ApparatusChathura ChamikaraPas encore d'évaluation

- Plastic Limit ReportDocument7 pagesPlastic Limit ReportAngelo John R. JavinezPas encore d'évaluation

- Conrete Mix Design & Making and Curing of Test SpecimenDocument15 pagesConrete Mix Design & Making and Curing of Test SpecimenBlesPas encore d'évaluation

- 2 Ss Unconfined Compression TestDocument10 pages2 Ss Unconfined Compression TestIqi IqahPas encore d'évaluation

- UU Triaxial Test - Lab ManualDocument6 pagesUU Triaxial Test - Lab ManualmmPas encore d'évaluation

- Aashto T307Document27 pagesAashto T307Viviana CruzPas encore d'évaluation

- HMA Mix Design Report-2Document11 pagesHMA Mix Design Report-2yustinokwingwa100% (1)

- Density For Soil by Sand Displacement Method: Scope Is Code ApparatusDocument2 pagesDensity For Soil by Sand Displacement Method: Scope Is Code ApparatusMastani BajiraoPas encore d'évaluation

- Compressive Strength of Hydraulic CementDocument3 pagesCompressive Strength of Hydraulic CementEr Mansoor HussainPas encore d'évaluation

- Open Ended Lab Geotechnic (Constant Head Permeability Test)Document11 pagesOpen Ended Lab Geotechnic (Constant Head Permeability Test)tashadzureen0% (1)

- Casa GrandeDocument6 pagesCasa GrandeXendra AqeylaaPas encore d'évaluation

- Determination of Aggregate CrushingDocument8 pagesDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- Proctor Compaction TestDocument8 pagesProctor Compaction TestIrenePas encore d'évaluation

- Method of Testing Determination of Resistance To FragmentationDocument3 pagesMethod of Testing Determination of Resistance To Fragmentationshahrilzainul77Pas encore d'évaluation

- Direct Shear Box TestDocument4 pagesDirect Shear Box Testarid132Pas encore d'évaluation

- Ultrasonic Pulse VelocityDocument3 pagesUltrasonic Pulse VelocitySougata DasPas encore d'évaluation

- Determining Concrete Workability with Slump TestDocument6 pagesDetermining Concrete Workability with Slump Testjoshdax2Pas encore d'évaluation

- Compressive Strength of ConcreteDocument9 pagesCompressive Strength of ConcreteAmos kiprutoPas encore d'évaluation

- Lay Out of Geo Tech LabDocument15 pagesLay Out of Geo Tech LabKhalid YousafPas encore d'évaluation

- Soil Mechanics TestsDocument9 pagesSoil Mechanics TestsAfifah FauziPas encore d'évaluation

- Aggregate Impact Value TestDocument5 pagesAggregate Impact Value TestMind Rip100% (1)

- Direct Shear TestDocument4 pagesDirect Shear TestNajihaharifPas encore d'évaluation

- OedometerDocument7 pagesOedometerDaniel ShinnickPas encore d'évaluation

- UNCONSOLIDATED UNDRAINED TRIAXIAL TEST (QUICK TESTDocument14 pagesUNCONSOLIDATED UNDRAINED TRIAXIAL TEST (QUICK TESTSi Rerumpai LautPas encore d'évaluation

- CVG3109 - Lab - Consolidated Drained Tests For Sand - 2014Document11 pagesCVG3109 - Lab - Consolidated Drained Tests For Sand - 2014Rhedo.AbdPas encore d'évaluation

- Consolidated triaxial test for soilsDocument9 pagesConsolidated triaxial test for soilsMasriflin TandeanPas encore d'évaluation

- Triaxial Test 2850Document2 pagesTriaxial Test 2850Mostafa MagdyPas encore d'évaluation

- Unconsolidated UndrainedDocument9 pagesUnconsolidated UndrainedMohd Syafiq Akmal100% (2)

- Undrained Triaxial TestDocument7 pagesUndrained Triaxial TestadityatheaaaPas encore d'évaluation

- CEL 321 Unconsolidated Undrained TestDocument5 pagesCEL 321 Unconsolidated Undrained TestAakash Budhiraja100% (2)

- The Ground Reaction Curve Due To Tunnelling Under Drainage ConditionDocument8 pagesThe Ground Reaction Curve Due To Tunnelling Under Drainage ConditionNguyễn HòaPas encore d'évaluation

- Convergence - Confinement MethodDocument0 pageConvergence - Confinement MethodNguyễn HòaPas encore d'évaluation

- Negative Skin Friction - Prof. Poulos PDFDocument29 pagesNegative Skin Friction - Prof. Poulos PDFNguyễn HòaPas encore d'évaluation

- Negative Friction - Canadian F.E.Manual PDFDocument4 pagesNegative Friction - Canadian F.E.Manual PDFNguyễn HòaPas encore d'évaluation

- Fhwa Ed 88 053Document42 pagesFhwa Ed 88 053rshaghayan100% (1)

- Class - 41 Geography (MAJOR INDUSTRIAL REGIONS OF THE WORLD) - 14542941 - 2023 - 04 - 13 - 17 - 54Document26 pagesClass - 41 Geography (MAJOR INDUSTRIAL REGIONS OF THE WORLD) - 14542941 - 2023 - 04 - 13 - 17 - 54Raj GuptaPas encore d'évaluation

- MW Wiretec PVT - LTD.: Quality Assurance Plan Section C' Process Flow Chart-MIG Wire ISO 9001:2015Document7 pagesMW Wiretec PVT - LTD.: Quality Assurance Plan Section C' Process Flow Chart-MIG Wire ISO 9001:2015Våïbhäv Çhåühåñ100% (1)

- Alkaloids 1Document4 pagesAlkaloids 1Mr nobodyPas encore d'évaluation

- Alcohols and Halogenoalkanes HLDocument11 pagesAlcohols and Halogenoalkanes HLMary KalamakiPas encore d'évaluation

- Fosroc Conbextra GP2Document4 pagesFosroc Conbextra GP2awsdhnjkklmPas encore d'évaluation

- Technician Manual for Tuttnauer AutoclavesDocument134 pagesTechnician Manual for Tuttnauer AutoclavesIngenieria NemoconPas encore d'évaluation

- Odlaganje OtpadaDocument68 pagesOdlaganje OtpadaEllyOPas encore d'évaluation

- TD Optiflux4000 enDocument44 pagesTD Optiflux4000 enVasilePas encore d'évaluation

- AcetanilideDocument17 pagesAcetanilideAbbas Kazmi100% (1)

- CBF & Pultrusion Basalt Composite Materials Production Project in ArmeniaDocument16 pagesCBF & Pultrusion Basalt Composite Materials Production Project in ArmeniaAnonymous LhmiGjOPas encore d'évaluation

- Iz260 PDFDocument6 pagesIz260 PDFKaRenthLuNaPas encore d'évaluation

- P5 Conjugated DienesDocument52 pagesP5 Conjugated DienesShirl Angelee OcampoPas encore d'évaluation

- N5 Biology 2014Document41 pagesN5 Biology 2014FarooqAhmadLashariPas encore d'évaluation

- CHEMISTRY 12th Sample Paper 2023-24Document15 pagesCHEMISTRY 12th Sample Paper 2023-24Hitesh ChoudharyPas encore d'évaluation

- 1 2714Document1 page1 2714K Mohana PraneshPas encore d'évaluation

- 420kV Reactor - Rev - 08Document83 pages420kV Reactor - Rev - 08Anil Marturi100% (1)

- Reversible Ammonia-Based Hydrogen Storage DavidDocument22 pagesReversible Ammonia-Based Hydrogen Storage Davidkwayneolson6081Pas encore d'évaluation

- Astm d3686 - 13 Covs AireDocument7 pagesAstm d3686 - 13 Covs AirejorgekovachPas encore d'évaluation

- C Difficile DiarrheaDocument12 pagesC Difficile DiarrheaSi vis pacem...Pas encore d'évaluation

- Vendor Development ProcurementDocument3 pagesVendor Development ProcurementVishant GoelPas encore d'évaluation

- Silicon Killed Steel Nozzle CloggingDocument8 pagesSilicon Killed Steel Nozzle CloggingMada TetoPas encore d'évaluation

- Rubber Grades - Aug 09Document6 pagesRubber Grades - Aug 09Raj JogiPas encore d'évaluation

- Concrete-Filled Steel Tubular (CFST) Columns: Mayank Vyas and Ghanishth AgrawalDocument4 pagesConcrete-Filled Steel Tubular (CFST) Columns: Mayank Vyas and Ghanishth AgrawalK RaghuPas encore d'évaluation

- Analysis of Biodigesters and Dehydrators To Manage Organics On-SiteDocument7 pagesAnalysis of Biodigesters and Dehydrators To Manage Organics On-SiteCZCASEZATPas encore d'évaluation

- Life Processes 2Document30 pagesLife Processes 2Generic namePas encore d'évaluation

- CL 2000i 2200iDocument881 pagesCL 2000i 2200iAnonymous GhWU5YK8100% (4)

- Stoichiometry KeynoteDocument104 pagesStoichiometry KeynoteSherlock HolmesPas encore d'évaluation

- Mr. SurfacerDocument4 pagesMr. SurfacerErisiePas encore d'évaluation

- 9802/5800 E3-15-1 Lubricants & FiltersDocument3 pages9802/5800 E3-15-1 Lubricants & FiltersAhmer CamdzicPas encore d'évaluation

- Practical Guidelines On Fluid Therapy 2nd EdDocument395 pagesPractical Guidelines On Fluid Therapy 2nd EdmuarifPas encore d'évaluation