Académique Documents

Professionnel Documents

Culture Documents

F50LX Cap 15 (Imp Accensione)

Transféré par

pivarszkinorbertDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

F50LX Cap 15 (Imp Accensione)

Transféré par

pivarszkinorbertDroits d'auteur :

Formats disponibles

15.

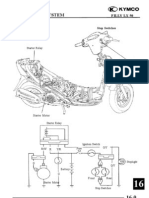

IGNITION SYSTEM

F ILLY LX 50

15

CDI Unit

Ignition Switch

Spark Plug

A.C. Generator Pulser Coil

Ignition Switch

B/Y L/Y

Ignition Coil

Spark Plug

Fuse

Pulser Coil

CDI Unit

Battery

15

15-0

15. IGNITION SYSTEM

SERVICE INFORMATION...................... 15-1 TROUBLESHOOTING ............................ 15-2 CDI UNIT INSPECTION ......................... 15-3

F ILLY LX 50

IGNITION COIL .....................................15-4 PULSER COIL .........................................15-5

SERVICE INFORMATION

GENERAL INSTRUCTIONS Check the ignition system according to the sequence specified in the Troubleshooting. ( 15-2) The ignition system adopts CDI unit and the ignition timing cannot be adjusted. If the timing is incorrect, inspect the CDI unit and A.C. generator and replace any faulty parts. Inspect the CDI unit with a CDI tester Loose connector and poor wire connection are the main causes of faulty ignition system. Check each connector before operation. Use of spark plug with improper heat range is the main cause of poor engine performance. The inspections in this section are focused on maximum voltage. The inspection of ignition coil resistance is also described in this section. Inspect the ignition switch according to the continuity table specified in page 17-3. Inspect the spark plug referring to Section 3. Remove the A.C. generator and pulser coil referring to Section 14. SPECIFICATIONS Standard Standard type (NGK) C7HSA Spark plug Hot type (NGK) C6HSA Cold type (NGK) C8HSA Spark plug gap 0.6_ 0.7mm F mark 13 BTDC Ignition timing Full advance /1,700rpm100RPM 28 BTDC /4,000rpm100RPM Primary coil 0.1_ 1.0W Ignition coil resistance Secondary with plug cap 7_ 12KW (20 ) coil without plug cap 3_ 5KW Pulser coil resistance (20 ) 40_ 300W Ignition coil primary side max. voltage 12V min. Pulser coil max. voltage 2.1V min. TESTING INSTRUMENT Kowa Electric Tester or commercially available electric tester with resistance over 10MW/CDV Item

15-1

15. IGNITION SYSTEM

TROUBLESHOOTING

High voltage too low Weak battery or low engine speed Loose ignition system connection Faulty ignition coil Faulty CDI unit Faulty pulser coil Intermittent high voltage Faulty ignition switch Poorly connected CDI unit coupler Poorly connected or broken CDI ground wire Faulty pulser coil Loose high tension wire connection Faulty CDI unit Normal high voltage but no spark at plug Faulty spark plug Faulty spark plug cap No high voltage Faulty ignition switch Dead battery or faulty regulator/rectifier Faulty charging circuit Faulty ignition coil Faulty CDI unit

F ILLY LX 50

No or intermittent high voltage Faulty ignition coil Weak battery Faulty charging system

15-2

15. IGNITION SYSTEM

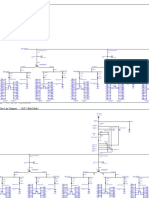

CDI UNIT INSPECTION

Remove the three battery cover screws. Disconnect the CDI coupler and remove the CDI unit. Measure the resistance between the terminals using the electric tester.

F ILLY LX 50

Due to the semiconductor in circuit, it is

necessary to use a specified tester for accurate testing. Use of an improper tester in an improper range may give false readings. Use a Sanwa Electric Tester or Kowa Electric Tester. In this table, Needle swings then returns indicates that there is a charging current applied to a condenser. The needle will then remain at unless the condenser is discharged. Unit: KW

CDI Unit Black

Probe (-)Probe

Black

Black/ Blue/ Yellow Yellow

Green 10~60 5 ~15 40~90 Black/ Yellow Blue/ Green Yellow

Black Black/ Yellow 30~80

1K~

Blue/ 100~25 Yellow 0 Green 10~30

150~40 0

60~200

15-3

15. IGNITION SYSTEM

IGNITION COIL

REMOVAL Remove the met-in box. ( 2-3) Remove the spark plug cap. Disconnect the ignition coil wires and remove the ignition coil bolt and ignition coil.

F ILLY LX 50

Ignition Coil

INSPECTION CONTINUITY TEST

The CDI unit is not adjustable.

If the timing is incorrect, inspect the CDI unit, pulser coil and A.C. generator and replace any faulty parts.

Measure the resistance between the ignition coil primary coil terminals. Resistance: 0.1_ 1.0W

Measure the secondary coil resistances with and without the spark plug cap. Resistances: (with plug cap) : 7_ 12KW (without plug cap) : 3_ 5KW

Correctly operate the tester following the

manufacturers instructions.

15-4

15. IGNITION SYSTEM

PULSER COIL

INSPECTION

F ILLY LX 50

This test is performed with the stator

installed in the engine. Remove the frame body cover. ( 2-3) Disconnect the A.C. generator connector.

Pulser Coil Coupler

Measure the pulser coil resistance between the blue/yellow and green wire terminals. Resistance: 80_ 160W Refer to page 14-6 for the A.C. generator removal.

IGNITION TIMING INSPECTION

Timing Hole Cap

The CDI unit is not adjustable.

If the ignition timing is incorrect, inspect the CDI unit, pulser coil and A.C. generator and replace any faulty parts.

Remove the timing hole cap.

Warm up the engine and check the ignition timing with a timing light. When the engine is running at the ignition timing is correct if the F mark aligns with the index mark within 2. Ignition Timing: BTDC28/4000rpm

15-5

F Mark

Vous aimerez peut-être aussi

- AGILITY50 Cap 15 (Imp Accensione)Document6 pagesAGILITY50 Cap 15 (Imp Accensione)api-3759317Pas encore d'évaluation

- F50LX Cap 14 (Imp Ricarica)Document11 pagesF50LX Cap 14 (Imp Ricarica)carbikegePas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- BW125 - 150 Cap 17 (Imp Accensione)Document6 pagesBW125 - 150 Cap 17 (Imp Accensione)Franckie HyacinthePas encore d'évaluation

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaD'EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaPas encore d'évaluation

- Agility 125 Section 14 Battery Charging System AC Generator PDFDocument11 pagesAgility 125 Section 14 Battery Charging System AC Generator PDFdabura1986Pas encore d'évaluation

- Ignition System: General SafetyDocument8 pagesIgnition System: General SafetyJesus ParraPas encore d'évaluation

- 2000-2001 CR250 Ignition Service ManualDocument13 pages2000-2001 CR250 Ignition Service ManualHeidi Hanson0% (1)

- D50 17 Ignition SystemDocument6 pagesD50 17 Ignition SystemcarmechanicPas encore d'évaluation

- A86&A88-chapter 18 (IGNITION SYSTEM)Document8 pagesA86&A88-chapter 18 (IGNITION SYSTEM)Stojanov MarjanPas encore d'évaluation

- GD250 Cap17 (Imp Accensione)Document6 pagesGD250 Cap17 (Imp Accensione)Neagu DanielPas encore d'évaluation

- P250-250S Cap 16 (BATTERYCHARGING SYSTEM)Document7 pagesP250-250S Cap 16 (BATTERYCHARGING SYSTEM)Minh ChuPas encore d'évaluation

- BW125 - 150 Cap 16 (Imp Ricarica)Document8 pagesBW125 - 150 Cap 16 (Imp Ricarica)Franckie HyacinthePas encore d'évaluation

- Yamaha Dynamic Spark Tester Special Tool Ym-34487 90890-06754 PDFDocument5 pagesYamaha Dynamic Spark Tester Special Tool Ym-34487 90890-06754 PDFDr DPas encore d'évaluation

- Volvo Penta d1 30b ElectricalDocument54 pagesVolvo Penta d1 30b ElectricalMišo Vučko75% (4)

- Cp30 Manual Mci300Document201 pagesCp30 Manual Mci300Kalicharan YadavPas encore d'évaluation

- Sharp+Lc c6554u+Difference+Lc 65d64uDocument30 pagesSharp+Lc c6554u+Difference+Lc 65d64uNicholas RileyPas encore d'évaluation

- P250-250S Cap 17 (IGNITION SYSTEM)Document6 pagesP250-250S Cap 17 (IGNITION SYSTEM)Minh ChuPas encore d'évaluation

- Batching Plant CP30-MCI70N MANUAL (Latest)Document180 pagesBatching Plant CP30-MCI70N MANUAL (Latest)DIBNESH PANDITA91% (11)

- Cp30 Mci300 Manual (New)Document213 pagesCp30 Mci300 Manual (New)Er Rakesh Choudhary100% (2)

- ChargingDocument17 pagesChargingSJElliPas encore d'évaluation

- 74406G U1Document32 pages74406G U1Fendy MPas encore d'évaluation

- Clearwater C Series TroubleshootingDocument28 pagesClearwater C Series TroubleshootingajmanchePas encore d'évaluation

- ATV250-16 (Batteria e Ricarica)Document10 pagesATV250-16 (Batteria e Ricarica)gfgw2pczcwPas encore d'évaluation

- 16sPACE WAGONDocument32 pages16sPACE WAGONrafaelcruzgjaPas encore d'évaluation

- A86&A88-chapter 17 (BATTERY-CHARGING SYSTEM-A.C. GENERATOR)Document14 pagesA86&A88-chapter 17 (BATTERY-CHARGING SYSTEM-A.C. GENERATOR)Stojanov MarjanPas encore d'évaluation

- Service Manual: LC-32D41U LC-32M41U LC-40C32UDocument148 pagesService Manual: LC-32D41U LC-32M41U LC-40C32UkalentoneschatPas encore d'évaluation

- Troubleshooting Guide For Capacitor Excited GeneratorsDocument16 pagesTroubleshooting Guide For Capacitor Excited GeneratorstracypearlPas encore d'évaluation

- Inverter Training 08-BASICDocument91 pagesInverter Training 08-BASICGinguba100% (3)

- Cdi Troubleshooting Guide Johnson EvinrudeDocument35 pagesCdi Troubleshooting Guide Johnson EvinrudeEvan CollinsPas encore d'évaluation

- 2006-2008-Cbf1000-A-19 Ignition SystemDocument8 pages2006-2008-Cbf1000-A-19 Ignition Systemdrkrassas100% (1)

- Sharp PG-D3750W PDFDocument120 pagesSharp PG-D3750W PDFboroda2410Pas encore d'évaluation

- Timers Oscillators CA 555Document6 pagesTimers Oscillators CA 555Thomas A. EDISSONPas encore d'évaluation

- Diagramas Electricos Cruze 1.8Document28 pagesDiagramas Electricos Cruze 1.8Henry Fernendo Pesantez OjedaPas encore d'évaluation

- Venox 16-18Document22 pagesVenox 16-18Fernando HenaoPas encore d'évaluation

- Instrument Panel Analog - Nissan Sentra 1993Document8 pagesInstrument Panel Analog - Nissan Sentra 1993Alessandro BaffaPas encore d'évaluation

- U1149-Lost Communication With Multifunction SwitchDocument4 pagesU1149-Lost Communication With Multifunction SwitchMaster XeotoPas encore d'évaluation

- Elec AlternatorDocument24 pagesElec Alternatordanangharjanto433Pas encore d'évaluation

- Trouble Diagnosis Table: Changed by Effective Date Affected Vin ACTYON SM - 2006.03Document45 pagesTrouble Diagnosis Table: Changed by Effective Date Affected Vin ACTYON SM - 2006.03Mihai DonaPas encore d'évaluation

- Test Report: Serial No.Document9 pagesTest Report: Serial No.imuPas encore d'évaluation

- AlternatorsDocument8 pagesAlternatorsViệt LêPas encore d'évaluation

- Trouble Shooting Guide YorkDocument19 pagesTrouble Shooting Guide YorkMohammed AbbasPas encore d'évaluation

- Engine ElectricalDocument44 pagesEngine ElectricalLuis Ramiro CajasPas encore d'évaluation

- 175 Alternators - KTRv3Document17 pages175 Alternators - KTRv3Quintin Du PlooyPas encore d'évaluation

- Primary Current Injector PCT TrolleyDocument2 pagesPrimary Current Injector PCT TrolleyMohamed RafihPas encore d'évaluation

- KXR50 Cap 14 (Imp Ricarica)Document12 pagesKXR50 Cap 14 (Imp Ricarica)tutifruti649Pas encore d'évaluation

- Johnson/Evinrude 60° 4 Cylinder Optical Ignition (OIS 2000) Carbureted 1995-2006 Model YearsDocument4 pagesJohnson/Evinrude 60° 4 Cylinder Optical Ignition (OIS 2000) Carbureted 1995-2006 Model YearsАлександр КачеишвилиPas encore d'évaluation

- Car Battery ChargerDocument2 pagesCar Battery Chargerasif142Pas encore d'évaluation

- 12k Service ManualDocument68 pages12k Service ManualJ C Quality Woodstoves67% (3)

- 03-Engine Electrical System PDFDocument32 pages03-Engine Electrical System PDFAditiana SukadarusmanPas encore d'évaluation

- Freereportlcd PDFDocument10 pagesFreereportlcd PDFAnthony GonzalesPas encore d'évaluation

- KTM 450 EXC Electric ChecksDocument3 pagesKTM 450 EXC Electric Checksburgerbiter100% (1)

- Royal Enfield BULLET ELECTRICS (Charging) 1999 On PDFDocument2 pagesRoyal Enfield BULLET ELECTRICS (Charging) 1999 On PDFmanri77Pas encore d'évaluation

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsPas encore d'évaluation

- Manual Operación EXPLOSOR REO CD225-2JDocument18 pagesManual Operación EXPLOSOR REO CD225-2JVictor Yucás100% (1)

- Trouble Code Diagnosis: Tcu Diagnostic System OverviewDocument10 pagesTrouble Code Diagnosis: Tcu Diagnostic System OverviewjanocristockPas encore d'évaluation

- 2008 Nissan Teana J32 Service Manual-ChgDocument25 pages2008 Nissan Teana J32 Service Manual-ChgMrihex100% (1)

- Alternator DiagnosticDocument19 pagesAlternator Diagnosticvickers100% (1)

- F50LX Cap 17 (Imp Elettrico)Document6 pagesF50LX Cap 17 (Imp Elettrico)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 16 (Imp Avviamento)Document6 pagesF50LX Cap 16 (Imp Avviamento)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 13 (Ruota Sospensione Post)Document7 pagesF50LX Cap 13 (Ruota Sospensione Post)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 11 (Albero Motore)Document7 pagesF50LX Cap 11 (Albero Motore)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 09 (Trasmissione)Document14 pagesF50LX Cap 09 (Trasmissione)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 06 (Rimozione Motore)Document6 pagesF50LX Cap 06 (Rimozione Motore)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 03 (Manutenzione)Document12 pagesF50LX Cap 03 (Manutenzione)pivarszkinorbertPas encore d'évaluation

- F50LX Cap 02 (Plastiche Marmitta)Document6 pagesF50LX Cap 02 (Plastiche Marmitta)pivarszkinorbertPas encore d'évaluation

- Huf75332P3: N-Channel Ultrafet Power Mosfet FeaturesDocument10 pagesHuf75332P3: N-Channel Ultrafet Power Mosfet FeaturesSabin CostinelPas encore d'évaluation

- 74LS83 PDFDocument5 pages74LS83 PDFKeertanaPas encore d'évaluation

- Surface Mount Triac: SOT223 (Plastic)Document4 pagesSurface Mount Triac: SOT223 (Plastic)Mike BrdnPas encore d'évaluation

- The Idea F System Control: Microcontroller Based Applied Digital Control Dr. Dogan IbrahimDocument21 pagesThe Idea F System Control: Microcontroller Based Applied Digital Control Dr. Dogan Ibrahimنورشان محمدPas encore d'évaluation

- GATE Previous Year Solved Papers ECE PDFDocument276 pagesGATE Previous Year Solved Papers ECE PDFsathisPas encore d'évaluation

- 7UM62 Manual AC V991200 en PDFDocument678 pages7UM62 Manual AC V991200 en PDFJuan100% (1)

- Lecture3. Parallel Circuits-Chapter 6Document35 pagesLecture3. Parallel Circuits-Chapter 6Keshav GopaulPas encore d'évaluation

- Electronic Measurements and Instrumentation QBDocument38 pagesElectronic Measurements and Instrumentation QBSrilekha031Pas encore d'évaluation

- Modeling and Control of A Brushless DC MotorDocument66 pagesModeling and Control of A Brushless DC MotorBalajiKRamPas encore d'évaluation

- Exam Name:: Q.1 Marks: 1 Question IDDocument50 pagesExam Name:: Q.1 Marks: 1 Question IDKumarPas encore d'évaluation

- Buy Surya Led Bulb Neo Prime 40watt Online - GemDocument1 pageBuy Surya Led Bulb Neo Prime 40watt Online - Gemjaio88Pas encore d'évaluation

- RER Lec-2-Solar Energy BT Dr. Farrukh A SiddiquiDocument18 pagesRER Lec-2-Solar Energy BT Dr. Farrukh A SiddiquiAli khan KhanPas encore d'évaluation

- T512-5047 Manual PDFDocument20 pagesT512-5047 Manual PDFelectronico1000Pas encore d'évaluation

- Routine Test Certificate: Unid No. Finish Product Name SO No. ProjectDocument3 pagesRoutine Test Certificate: Unid No. Finish Product Name SO No. ProjectaayushPas encore d'évaluation

- RTMNU-CAPACITOR-DIELECTRICS - B.Sc.-IDocument32 pagesRTMNU-CAPACITOR-DIELECTRICS - B.Sc.-IAhmdPas encore d'évaluation

- ALCE Cable Type Current TransformersDocument7 pagesALCE Cable Type Current TransformersIFeLisTigrisPas encore d'évaluation

- Gek 36378D PDFDocument14 pagesGek 36378D PDFoso0214Pas encore d'évaluation

- Typical SLD Fir Bess in EtapDocument8 pagesTypical SLD Fir Bess in EtapJayson SenoPas encore d'évaluation

- Fortune' Properties For Reference Only: DatasheetDocument6 pagesFortune' Properties For Reference Only: DatasheetKenji WatabePas encore d'évaluation

- HB Stepper Motor EDocument19 pagesHB Stepper Motor Eartpirate003_5420882Pas encore d'évaluation

- Electronic Fuel Viscosity Controller New Model English Tib 771 GB 0215Document50 pagesElectronic Fuel Viscosity Controller New Model English Tib 771 GB 0215irfanWPK100% (2)

- Electrical Matlab/Simulink Projects ListDocument6 pagesElectrical Matlab/Simulink Projects ListAshish PorwalPas encore d'évaluation

- Lab 7 - Simulation of Characteristic Curve of DC Motor On MATLAB (Simulink) PDFDocument7 pagesLab 7 - Simulation of Characteristic Curve of DC Motor On MATLAB (Simulink) PDFAnusha Rehman100% (1)

- LT 1725 PDFDocument28 pagesLT 1725 PDFtallrajPas encore d'évaluation

- 1HSM 9543 32-10en Portable Capacitance Meter CB-2000 EnglishDocument4 pages1HSM 9543 32-10en Portable Capacitance Meter CB-2000 EnglishAnonymous axyNzhPas encore d'évaluation

- Wires and Cables PDFDocument14 pagesWires and Cables PDFRomel Panis88% (8)

- Deep Sea Electronics: Typical Wiring Diagram DSE8660 MKII Installation InstructionsDocument2 pagesDeep Sea Electronics: Typical Wiring Diagram DSE8660 MKII Installation InstructionsElias Herrera Ceron0% (1)

- Introduction To Ac Circuits: Sinusoidal Voltages and CurrentsDocument17 pagesIntroduction To Ac Circuits: Sinusoidal Voltages and Currentsczds6594Pas encore d'évaluation

- Utilization of Non Conventional Sources of Energy With Power Quality Imrovement MLMS by Janesh PaulDocument13 pagesUtilization of Non Conventional Sources of Energy With Power Quality Imrovement MLMS by Janesh PaulPrince Janesh UniquePas encore d'évaluation

- Activity 3.pmdDocument3 pagesActivity 3.pmdMy EMailPas encore d'évaluation

- Electric Motor Control: DC, AC, and BLDC MotorsD'EverandElectric Motor Control: DC, AC, and BLDC MotorsÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceD'EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidencePas encore d'évaluation

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AD'EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&APas encore d'évaluation

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingD'EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingPas encore d'évaluation

- Thermal Power Plant: Design and OperationD'EverandThermal Power Plant: Design and OperationÉvaluation : 4.5 sur 5 étoiles4.5/5 (23)

- Handbook on Battery Energy Storage SystemD'EverandHandbook on Battery Energy Storage SystemÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Solar Energy: Survive Easily on Solar Power Off the GridD'EverandSolar Energy: Survive Easily on Solar Power Off the GridPas encore d'évaluation

- Oil companies and the energy transitionD'EverandOil companies and the energy transitionPas encore d'évaluation

- Global Landscape of Renewable Energy FinanceD'EverandGlobal Landscape of Renewable Energy FinancePas encore d'évaluation

- Renewable Energy Finance: Theory and PracticeD'EverandRenewable Energy Finance: Theory and PracticeÉvaluation : 4 sur 5 étoiles4/5 (1)

- Green Hydrogen Supply: A Guide to Policy MakingD'EverandGreen Hydrogen Supply: A Guide to Policy MakingÉvaluation : 5 sur 5 étoiles5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsD'EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Electric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell VehiclesD'EverandElectric Powertrain: Energy Systems, Power Electronics and Drives for Hybrid, Electric and Fuel Cell VehiclesPas encore d'évaluation

- Life Cycle Assessment: Principles, Practice and ProspectsD'EverandLife Cycle Assessment: Principles, Practice and ProspectsPas encore d'évaluation

- The Homeowner's DIY Guide to Electrical WiringD'EverandThe Homeowner's DIY Guide to Electrical WiringÉvaluation : 5 sur 5 étoiles5/5 (2)