Académique Documents

Professionnel Documents

Culture Documents

Logistics

Transféré par

Murtaza VadiwalaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Logistics

Transféré par

Murtaza VadiwalaDroits d'auteur :

Formats disponibles

SUPPLY CHAIN MANAGEMENT

FUTURE OF LOGISTICS IN WORLD

Supply Chain Management - Group Project

Future Trends in Logistics in world SIMSR

Author: Group 15 Last Updated: 20/12/2012

PAGE 1

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

Table of Contents

1 INTRODUCTION AND NEED OF FUTURE TRENDS...................................................................................................................4 2 FUTURE TRENDS IN LOGISTICS AND SUPPLY CHAIN MANAGEMENT............................................................................5 2.1 INCREASING RESPONSIVENESS .........................................................................................................................................................5 2.1.1 Introduction..............................................................................................................................................................................5 2.1.2 Definition of Responsive Supply Chain (RSC)........................................................................................................................5 2.1.3 A framework for developing a RSC.........................................................................................................................................6 2.1.4 Strategic Planning....................................................................................................................................................................7 2.1.5 Virtual Enterprise.....................................................................................................................................................................8 2.1.6 Knowledge and IT Management..............................................................................................................................................9 2.1.7 Supply Chain Responsiveness Study.....................................................................................................................................10 2.1.8 Recommended Actions...........................................................................................................................................................11 2.1.9 Impact of E-commerce on the supply chain performance.....................................................................................................12 2.2 EXPANDING THE SUPPLY CHAIN....................................................................................................................................................13 2.2.1 The Current State of Data Management................................................................................................................................14 2.2.2 Supply Chain Event Managementa New Era in Working with Trading Partners.............................................................14 2.2.3 Avoiding Information Overload.............................................................................................................................................16 2.2.4 UNDERSTANDING THE EPCGLOBAL NETWORK...........................................................................................................18 2.3 THE GREENING OF SUPPLY CHAIN.................................................................................................................................................20 2.3.1 What is the Green SCM ?.......................................................................................................................................................20 2.3.2 Approach towards Green or Sustainable SCM......................................................................................................................20 2.3.3 Current Best Practices...........................................................................................................................................................21 2.3.4 Long term solutions................................................................................................................................................................21 2.3.5 GSCM Strategies according to Supply Chain Areas:............................................................................................................23 2.3.6 Awareness Programs..............................................................................................................................................................26 2.4 REDUCING SUPPLY CHAIN COST....................................................................................................................................................27 2.4.1 10 tips for reducing supply chain logistics costs...................................................................................................................28 3 REFERENCES....................................................................................................................................................................................29

PAGE 2

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

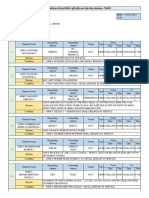

Roll No 59

Name of the Team Member Suraj Vernekar

Contribution Increasing responsiveness of Supply chain Expanding Supply chain Introduction Green Supply Chain Compilation

58 60

Murtuza Vadiwala Anupriya Wagh

61

Parikshit Vashishtha

Reducing cost of the supply chain

PAGE 3

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

1 Introduction and Need of Future Trends

Supply chain is the one management function that connects the inside of an organization to the outside, be it suppliers or customers, and oftentimes represents the most visible corporate activities, various forms of sustainable supply chain management practices have been adopted as organizations strive to be green. Examining their own operational processes and monitoring supplier activities have become important sustainability tasks for many managers. Studying sustainable supply chain management at leading companies, therefore, will help shed light on the current state of sustainability practices and point out the future opportunities for improvement. The practice of the supply chai management is a very recent phenomenon, as many organisations are just beginning to realise the benefits and problems that accompany an integrated supply chain. As competitive situations, product, technology and customer change, the priorities for supply chain must also change, requiring supply chain to respond more quickly to these changes. As we look at most recent practices and future trends of supply chain management, a number of issues present themselves in area that need to be addressed including below, 1. Increasing responsiveness of supply chain 2. Expansion of the supply chain 3. Greening of Supply chain 4. Reducing cost of SCM

PAGE 4

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2 Future trends in Logistics and Supply Chain Management

2.1 Increasing responsiveness 2.1.1 Introduction Companies are undergoing a revolution in terms of implementing new operations strategies and technologies in response to the challenges and demands of the twenty-rst century. Businesses in the twenty-rst century have to overcome the challenges of satisfying the demand of customers for products of a high quality, but low price. To this end, rms need to be responsive to customers unique and rapidly changing needs. Companies are now seriously exploring the potential of the concept of supply chain management (SCM) to improve their revenue growth. In particular, they are attempting to develop agile supply chains to get their product to market faster at a minimum total cost. Effective SCM is an essential strategy for success in the global and e-markets. SCM incorporates the entire exchange of information and movement of goods between suppliers and end customers, including manufacturers, distributors, retailers, and any other enterprises within the extended supply chain. The responsive supply chain (RSC) addresses new ways of running companies to meet these challenges. RSC represents a global industrial paradigm for manufacturing in the twenty-rst century. In a changing and competitive environment, there is a need to develop in a cost effective solutions to organizations and facilities that are highly flexible and responsive to changing market/customer requirements. 2.1.2 Definition of Responsive Supply Chain (RSC) SCM is defined as the coordination of resources and the optimization of activities across the value chain to obtain competitive advantages. SCM facilitates organizational coordination required in an agile/virtual enterprise. An RSC can be defined as, A network of rms that is capable of creating wealth to its stakeholders in a competitive environment by reacting quickly and cost effectively to changing market requirements. There is a need to meet the changing market requirements by developing a suitable network of collaborative rms based on the core-competencies and on leveraging people and information as quickly as possible and in the most costeffective manner. The concept or definition of RSC is illustrated in Fig. 1. There are three major enablers of RSC, namely, value chain or a collaborative network of partners, Information Technology (IT) and systems, and knowledge management. The interaction between these will lead to a supply chain that is responsive and flexible. A supply chain is the basic component of an RSC, wherein suppliers play a major role in performing value-adding

PAGE 5

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

activities. Since a supply chain is primarily developed for lean production with the aim of achieving reductions in cost by eliminating non-value adding activities, it lacks speed and flexibility. Hence, there is a need to devise strategies, methods, and technologies for improving the speed and flexibility of the supply chain. Considering the overall characteristics of the strategies and technologies of AM and SCM, the enablers of RSC can be identified as (i) strategic planning, (ii) virtual enterprise, and (iii) knowledge and IT management. An RSC system requires a level of compatibility and interactivity that will allow the company to cope with the changes and increasingly complex settings of organizations and markets, particularly in a networked economy.

Fig. 1

2.1.3 A framework for developing a RSC A framework for the development of an RSC is presented in Fig. 2. This framework focuses on three major areas: strategic planning, virtual enterprise, and knowledge and IT management. An integrated system for these

PAGE 6

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

will result in an RSC and, hence, in improved responsiveness and flexibility. For example, strategic planning includes the decentralization of operations to achieve flexibility and speed. Global outsourcing and strategic alliances with partners help reduce the time to market. Also, the system should be proactive.

2.1.4 Strategic Planning Strategic alliances and the integration of complementary core competencies are necessary in developing virtual enterprise for RSC. Therefore, based on the given level of demand along the supply chain, there is a need to select partners based on their involvement in the value-adding chains. The development of a virtual enterprise requires the following: (i) a framework for the process of formulating corporate and business strategies based on

PAGE 7

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

global competitiveness for manufactured goods and services, (ii) a decision support system for selecting suitable partners based on the required core competencies, (iii) an ERP system for controlling operations in a VE, and (iv) a performance measurement system for continuous improvement in RSC. Existing methods and tools can be used to formulate strategies and select partners to develop RSC enterprise. To achieve RSC, several substrategies are needed, including the establishment of a virtual enterprise, the rapid formation of partnerships, the management of knowledge and IT, and the establishment of temporary alliances based on core competencies. Without suitable business and operations strategies, technologies and systems alone are not sufficient to achieve responsiveness in supply chain. Also, RSC can be achieved by forming suitable strategic alliances based on mergers and acquisitions with the objective of obtaining the required services. Other external factors such as the type of market and products, location, government policies, and environmental regulations need to be considered in the strategic planning for the suitability of RSC and its development. With regard to an agile supply chain, the involvement of top management is vital in the effective reengineering of the supply chain and logistics. In agile supply chain environments, relationships with suppliers and interactions between suppliers should be flexible in terms of the delivery of products/services and responsiveness. 2.1.5 Virtual Enterprise Companies are seeking to become more responsive to changing market conditions by streamlining and restructuring their organizations, and making use of virtual enterprises and knowledge work teams. To achieve this responsiveness, a customer-oriented supply chain is required to manage the flow of information within the network of enterprises. To be truly responsive, supply chain partners should be able to move even more quickly with the efficient utilization of existing equipment, existing facilities, and even existing designs. VE is an important concept in manufacturing. The concept of VE is defined somewhat differently from virtual manufacturing, and a VE needs more advanced inter-organizational IT. Furthermore, it also has the same constraints as concurrent engineering. This concept has been used to characterize the global supply chain of a single product in an environment of dynamic networks between companies engaged in many different complex relationships. It is supported by the extensive use of information and communication technology. Considering the role of VE in an RSC, a systemic framework is required for its development. The following steps can be employed for developing a VE: (a) identify the corporate objectives, (b) based on multiple competitive performance objectives, identify the product/service requirements from suppliers, (c) select partners based on the core competencies using a suitable supplier ranking system, (d) use the time scale, which should be rather short, linking all partners as a VE with the help of automation and IT.

PAGE 8

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2.1.6 Knowledge and IT Management Automation and IT play a dominant role in the development of a physically distributed enterprise or VE. The role of automation and IT can be identified in several areas of the development process. The most important elements for them are (i) strategy formulation, (ii) tactical management, (iii) operations control, and (iv) systems. From the review of RSC-enabling technologies, it can be noted that the selection of technologies for RSC depends upon strategies that are selected to meet changing market requirements. For example, JIT may require EDI, FMS may need AGVs, Robots, and NC machine tools, while responsiveness relies heavily on a virtual enterprise or physically distributed manufacturing environments. A good amount of cooperative supported work for prototyping is required to help an engineering team design RSC. The prototype systems should support the following: autonomous inputs, the parallel processing of information, group memory, electronic brainstorming, and consensus building. Suitable algorithms should be developed and tested for the computer supported cooperative work. An RSC organization should possess the capability of a learning organization. For this purpose, IT can be used along with a suitable organizational structure that promotes innovation, training and education. In a global operations environment, the communication should be standardized to improve the cooperative supported work in a VE. This requires standard computer-aided communication systems with suitable changes to suit the local environment such as translation into a different language. Certain challenges from human factors posed by the RSC can be overcome by a series of team meetings during which the team will jointly develop the project plan. Such a plan would involve objectives; strategies for meeting objectives; a detailed task network, schedule, and resources; and funding projections. Information technologies alone are not sufficient to achieve the desired efficiency in communications. If anything, the unfamiliarity of the technologies could impede efficiency in communications Global competition forces companies to opt for an extended enterprise within the framework of supply chain management. ERP systems such as SAP, Oracle, Peoplesoft, BAAN, and JD Edwards can be used to achieve effective integration in RSC. The extended enterprise demands commercially available tools for the integration of applications in a supply chain. This poses a challenge to IT. Hence, the communication industry is to play a major role in achieving responsiveness in a supply chain. In an RSC, information is transmitted via multiple channels depending on its urgency, content, and distribution through phone, voice-mail, fax, e-mail, and http. The workforce should be capable of meeting increasing technological challenges, designing their work places, solving quality related problems, engaging in team-to-team learning, improving the availability of equipment, using mistake proofing processes, dealing with increased complexity of the system and, finally, helping labor unions achieve harmony between their members and the company.

PAGE 9

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2.1.7

Supply Chain Responsiveness Study

Hitachi Consulting and AMR Research recently surveyed 164 companies in eight manufacturing segments on what leading companies are doing to be more responsive to customer needs and market conditions while reducing costs. Most companies understand the need for responsiveness to help respond to shorter product lifecycles, increased customer expectations, fluctuating inventory levels and changing costs. But few recognize the impact of that strategy on their supply chain, nor the shifts they will need to make to move from simply being efficient and to becoming truly responsive. This survey was conducted to help clients better understand: The business processes and underlying technologies needed to coordinate a responsive supply chain with the demand signal. Which supply chain business practices lead to real business benefit, are most important to users and which need improvement. The primary reasons driving companies to become more responsive as well as the primary impediments keeping companies from becoming more responsive. Key Findings Mature supply chain organizations do experience benefits. Each four year investment in supply chain excellence represents a 1% improvement in ROA. All industries reported that the key factor driving responsiveness efforts is cost. Given todays economy, that is not surprising. But several previous studies have shown that responsiveness and agility lead to higher ROA than a strict focus on cost reduction. The companies that focus on the other drivers mentioned (increasing customer expectations, unpredictable demand, increasing competition and a more global scope of operations) will improve responsiveness over the longer-term. There is a substantial increase in demand variability. New product launch has the biggest impact on forecast accuracy, followed by changes in market preferences and competition from other products. The opportunity lies in the integration of growth strategies into commercialization excellence.

PAGE 10

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

A focus on Demand/Supply Planning (S&OP) processes and linking Product Lifecycle Management to planning will have the biggest impact on responsiveness capabilities.

Available to Promise technologies while widely hyped, have limited adoption. Those companies with mature ATP processes have a 35% faster order cycle time.

There is a significant need to reduce complexity. Value chain complexity is increasing in the form of increased outsourced volumes, item complexity, SKU proliferation and the length of the supply chain.

2.1.8 Recommended Actions The link between supply chain maturity, agility, and financial success has been proven through previous research. This study asked the question What is stopping companies from making more progress towards becoming responsive? The shift to being responsive calls for fundamental change. Companies that have made this shift have designed their supply chain to deliver a customer experience. They have identified and track the factors that are early indicators of change. And they understand their levers for responding to those changes. It comes down to having visibility and control across the supply chain. To do this, they have invested in: Defining holistic processes and Key Performance Indicators (KPIs) that reward cross-functional, customer-driven metrics. Developing collaborative processes, both within their company and with partners and customers. A World-class Sales and Operations planning to set the tone for the entire supply chain by analyzing and deciding on demand and supply tradeoffs. Transportation Management - One of the quickest ways to impact order-to-delivery times and customer satisfaction, this short-term lever that can have a significant impact on cost. Strategic sourcing to establish capacity, flexibility and expectations with the supply base and provide visibility into landed cost decisions. A mature supply chain network design capability that is responsive to change. Implementing information systems to give them visibility for decision-making.

PAGE 11

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2.1.9 Impact of E-commerce on the supply chain performance E - Commerce has a significant role in re shaping the traditional supply chain and leveraging its performance and efficiency."' Fulfilling e-orders and effecting e-payments, improved prediction and planning, better scheduling, enhanced collaboration and coordination between business partners, reducing delays and shortening response time are some of the supply chain related aspects improved by ecommerce and associated technologies. They have also hastened the advent of mass customization as customer and manufacturer can communicate directly and interactively. In modem business markets, the winners will be firms that are able to recognize the vital connection between the digital commerce and the supply chain. One of the important changes introduced by the modern economy is vigorous competition in volatile markets. One of the main goals of supply chain management (SCM) is to achieve integration of most Total Quality Management (TQM) aspects that convey to higher efficiency in production, improved quality, cost cuts and customer maintenance. These goals, incorporated with Just - in Time (JIT) goals regarding sufficient inventory level for the production of goods needed right away, improved forecasting capability and close coordination with suppliers are the main targets of SCM. The web based commerce and the electronic tools contribute to achieve these goals. E-Commerce and e-marketplaces provide opportunities and efficiencies beyond to those that the traditional tools can offer to the supply chain management. The integration of e-commerce and the SC allows a better flow of information from suppliers to customers and improves the coordination between the SC tiers. Business dynamics, however, makes the SC planning and control processes missions difficult to accomplish. Besides the internet, numerous electronic medium, connected to the e-commerce, affect the supply chain. EAN (European Article Numbering) location and electronic numbers utilized to identify location, barcode scanning; EDI (electronic data interchange), VMI (vendor managed inventory), VANs (value added networks) and LANs (local area networks), extranets and Intranet are the main medium. These tools afford better cognizance of the inventory level and information on logistical activities and sales throughout the entire supply chain. Reorganizing and restructuring processes and technologies is encouraged and supported by e-commerce. Organizational structure, business processes, supplier and customer relationships, operational activities and logistical solutions are being altered by the digital economy. Stable long-term relationships with suppliers and merchants are changing to ad hoc relationships with several partners due to the challenges presented by electronic open markets to the planning of supply chains. Furthermore, e-commerce and the usage of the internet encourages to the development of new and advanced on line business models and concepts and hence contribute to the improvement in SC processes, to the relationships with suppliers, partners and customers.

PAGE 12

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2.2 Expanding the Supply Chain From the advent and implementation of the Universal Product Code (UPC), to modern data applications that streamline production and inventory requirements, supply chain management has saved businesses billions of dollars. As businesses have recognized the ability of supply chain management to deliver significant savings, they continue to search for new ways to achieve competitive advantages through cost savings in the supply chain. While these current systems continue to evolve in order to provide additional sales value through point to-point collaboration and closed loop networks, they face some limitations better resolved by new technologies. Today, the standardization of RFID technologies is largely complete, allowing businesses to succeed in an increasingly competitive environment. Real-time, accurate, and actionable data is available to realize new efficiencies in supply chain event management and to extend the capabilities of existing solutions. Radio Frequency Identification (RFID) tags, in conjunction with Electronic Product Code (EPC) identification technology; offer a practical way of generating detailed supply chain event information. RFID represents the next logical step in a long tradition of reducing costs through improvements to supply chain management.

PAGE 13

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

Many companies now use RFID to maximize their return on investment (ROI), and the benefits that come with pairing RFID technology and data sharing on the EPC global Network. By providing real-time, secure access to information about each event in the manufacturing and movement of products, the EPC global Network offers the opportunity to significantly improve business efficiencies. 2.2.1 The Current State of Data Management There are two types of data commonly shared between trading partners for business planning and transaction management. RFID creates a new category of information to help drive further improvements to the supply chain. In order to understand how RFID and the EPC global Network influence the future of supply chain management, it is important to discuss the two categories of data that are shared today: master data and transaction-based documents. Master data is the static information that physically defines a product or location. This includes information such as the size and weight of a product. Manufacturers require this information to manage packaging, shipping, and a host of other issues involved in getting products to market. Retailers use the information to determine storage needs and shelving requirements. Additionally, master data can include the address of a required location and its functional role in the supply chain. To ensure the accuracy of master data, the Global Data Synchronization Network (GDSN) was developed. This system leverages EAN.UCC standards to allow data pools to communicate consistently with one another. By leveraging the GDSN, trading partners can be sure that their master data is accurately propagated throughout the supply chain. The second category of data exchanged between supply chain systems is transaction based information. This includes the transfer of necessary business documents including purchase orders, shipping notices, and invoices. Companies have relied heavily on Electronic Data Interchange (EDI) solutions to handle document exchange requirements. EDI was designed to support push-based document exchange and continues to be a highly effective mechanism for supporting relationships with many trading partners. The next level of data sharing requires a new method of exchange-a method that can be achieved through RFID technology and the EPC global Network. These new opportunities for data management will dramatically affect the future of supply chain management. 2.2.2 Supply Chain Event Managementa New Era in Working with Trading Partners The goal of RFID technology and the EPC global Network is to create an environment where every object can be seen from the time it leaves the factory, through shipping and warehousing, and into the retail environment.

PAGE 14

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

This means each and every event in the supply chain can be tracked and recorded. The result is information that can truly enable supply chain visibility. A few important components of RFID technology allow for significant changes to the way supply chain events are recorded and traced. For example, RFID tags are scanned using radio waves, eliminating the current need for line of sight scanning. How does this improve the ability to track products through the supply chain? Line of sight scanning demands significant human interaction. The time and manpower needed for such solutions quickly reach a cost-prohibitive plateau. With the ability to view products via radio frequency technology, products can be cost effectively tracked through every step of the supply chain and errors are virtually eliminated. RFID technology also offers significant advances in the ability to associate an individual object or product with detailed product data. Under the current system, a UPC is attached to a product in the form of a bar code. This code is not specific to each individual unit. In other words, one UPC is used for all units of a product produced by a single supplier. EPC allows product data to be tracked down to the level of each individual product. Each RFID tag includes an EPC that is unique to a single unit. Specific product data is typically not stored directly on the tag. However, product manufacturers can easily associate the EPC with corresponding product information held within the company's databases. Additionally, all trading partners can associate information about the product's Movement through the supply chain with information held in their databases. As all of these databases are connected through an open network, the information becomes instantly available to all authorized parties. But how will these changes benefit business planning and strategy? In the past, supply chain improvements have focused on fi ne-tuning procedures through planning. By implementing detailed plans for managing the supply chain and executing against those plans, companies hoped to create greater efficiencies. However, even the best plans frequently fall victim to human error or to unexpected deviations that occur within real-world settings. An important supply chain contribution of RFID is turning information about the actual events taking place across the extended supply chain into actionable data. RFID delivers visibility to product movement at each and every point along the supply chain. With this knowledge, companies can quickly determine when execution fails to follow the plan and resolve the issues accordingly. Currently, many companies use bulk point-of-sale (POS) data to measure events at an aggregate level and to assist in business planning. This level of information is not practical as a proactive mechanism for identifying exceptions or deviations from supply chain plans. Additionally, these types of systems were not designed to support a high frequency of data transfer between trading partners. The new visibility produced by sharing information about events via the EPC global Network means companies can proactively and more accurately identify problems or concerns in the supply chain and address them faster.

PAGE 15

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

Exchanging data over this open network allows everyone to access the information needed and to make decisions accordingly. No longer are important decisions about responding to supply chain exceptions made in the dark or left to trends and out dated information. This new ability for improved information sharing and decision making is the result of two fundamental capabilities that RFID brings to advanced supply chain management: track and trace. Track capabilities allow companies to know where a product is at any given moment within the supply chain. Manufacturers have the ability to know when a product has been delivered to trading partners. Retailers can better manage inventories and reduce the costs of maintaining large quantities of warehoused merchandise. All trading partners can reduce lost revenues from out-of-stocks. Trace capabilities allow companies to see exactly where a product has been throughout the entire supply chain process. Manufacturers get a big-picture view of how their products move through the supply chain, allowing them to determine where costly delays are taking place or where shrinkage may be occurring within the delivery process. The fundamental information provided by track and trace regarding product location and movement applies to a wide array of business scenarios. Many leading supply chain companies are exploring the possibilities created by this new level of visibility into the supply chain. The result is that businesses are identifying a variety of realworld scenarios that can be addressed by the EPC global Network. These include: Proof of deliverythe ability to track a product's location enables a receiving company to establish proof of receipt as goods are scanned upon entering the building. Inventory accuracyall trading partners can know exactly how much inventory they have at any given moment, streamlining the order process, decreasing safety stock requirements, and improving the number of times a product is on the shelf when a customer wants to buy it. Chain of custodyby identifying which trading partners were in possession of a shipment on its normal path, companies can identify where losses are taking place, guiding important decisions on shipping and partner selection. Product conditionsmanaging expired products and making product recalls become much easier and less costly as the exact products involved can be quickly identified and located. Additionally, physical conditions that impact product integrity, such as temperature, can be tracked and associated with individual products to ensure shipments are enjoying optimal conditions throughout the supply chain process. 2.2.3 Avoiding Information Overload

PAGE 16

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

The impact of implementing RFID across the supply chain for management of data presents some daunting challenges. As RFID achieves the ubiquity currently enjoyed by UPCs, the result will be a networked physical world that will include all traded objects. Such a system will quickly scale to enormous proportions to handle an expected capacity of more than one trillion new unique objects annually.1 If not managed properly, the vast amount of information generated from such a system has the potential to overwhelm the required computer systems. Fortunately, not all companies will want or need every piece of information. To help avoid information overload, only the data that are needed will be moved at any given moment. The EPC global Network delivers only the necessary information that is requested by a company to enable a specifi c business process. A requirement for successfully accomplishing this open system of information exchange is distributed network architecture. Distributed network architectures not only facilitate the easy exchange of information, they also help avoid the problems of information overload. This type of architecture reduces the information processing demands by sharing the workload over many computing processors instead of requiring a single computer to do all the work. Rather than depositing all the required data into a single, centralized system, the information resides on millions of computers throughout the network. Under this system, the manufacturer, as well as all trading partners, create and store their own serialized information about each and every product. The manufacturer will manage and host a database that stores information about the generation of the product. While trading partners manage and host similar databases storing information about the product's movement through the supply chain. Each involved partner will make that information available to all authorized parties over the Internet. Not only does this architecture allow for the management of huge amounts of data, it also delivers other important benefits. Availability of data increases. Consider the current state of the Internet. Large quantities of data are stored locally on millions of servers around the world and are easily accessed through Web browsers connected to the Internet. Similarly, the EPC global Network utilizes the Object Naming Service (ONS). The ONS points to an address on the EPC global Network where information about the product in question is stored. This allows for instantaneous availability of information. The ONS also provides another important benefit: the EPC global Network is loosely coupled to the systems that provide and utilize event information, allowing for added flexibility and scalability. Similarly, the ONS can be adjusted or updated to take into consideration changes in the network. As trading partners move locations, change service providers, or bring new servers online, the revised ONS data will automatically send the appropriate data where it needs to go. As long as an EPC is valid, real-time data exchanges can always be made. The distributed network architecture of the EPC global Network also provides

PAGE 17

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

improved performance. With many machines carrying the workload, traffic bottlenecks are avoided. Data are transferred more efficiently, allowing real time to become a reality. 2.2.4 UNDERSTANDING THE EPCGLOBAL NETWORK The EPC global Network employs EPC and RFID technologies to deliver increased efficiency and accuracy through business automation. The network improves tracking, security and collaboration by providing a standard framework for supply chain event information exchange. Because individual product units can be tracked precisely through the entire supply chain, the EPC global Network offers unprecedented opportunities for supply chain event management. The EPC global Network manages RFID information in three key phases: Discovery, Storage, and Secure Access. VeriSign is a leader in providing services that respond to the needs of each phase. DiscoveryThe ONS directs general requests for specific product information within the network. EPC Discovery Services manage partner specific EPC data, creating the ability to track and trace. StorageEPC Information Services control the storage and retrieval of detailed product information on each unit as it travels through the supply chain. Secure AccessAn EPC Security Framework authenticates user identities, controlling access, and ensuring sensitive information is delivered only to approved entities.

2.2.4.1 BUILDING ON THE BUSINESS BENEFITS OF RFID Many companies are already implementing internal, closed-loop RFID systems. Internal implementations can achieve efficiency benefits whether or not they involve outside trading partners. However, the greatest benefits of RFID technology are realized when products are tracked through the entire supply chain. This is where the EPC global Network becomes an invaluable part of the new supply chain event management. Businesses get real-time views of all products throughout the supply chain, generating efficiency in inventory control, reduced product loss, and improved delivery management.

2.2.4.2 THE EPCGLOBAL NETWORK: AN ESSENTIAL COMPONENT FOR SUPPLY CHAIN EVENT MANAGEMENT The value or RFID technology is significantly increased with the EPC global Network. In order to keep the costs of RFID tags as low as possible, they are designed as a minimal processing chip with an antenna. This limited

PAGE 18

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

computing power means most RFID tags store only an individual EPC. But product data associated with each EPC can be stored on databases across an entire supply chain network. The EPC global Network uses a distributed network architecture to handle the large quantities of data and to make that data accessible to authorized parties.

2.2.4.3 STANDARDIZATION AND THE EPCGLOBAL NETWORK In order for any universal, global system to succeed, standards are essential. The standards process for the EPC global Network is on going. As catalysts of this process, collaborative pilot programs help companies develop a clear vision of the long-term value that RFID offers businesses. Businesses should look for low-risk opportunities to implement pilot programs that require low levels of effort. These programs provide important, practical learning as standards continue to emerge.

PAGE 19

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2.3 The greening of Supply Chain

2.3.1 What is the Green SCM ? Green or sustainable supply chain management is defined as the strategic, transparent, integration and achievement of an organizations social, environmental, and economic objectives in the systemic coordination of key inter-organizational business processes for improving the long-term performance of the firm and its supply chain partners. 2.3.2 Approach towards Green or Sustainable SCM Nowadays, most of the global 500 companies enlist their sustainability practices in their annual reports or standalone sustainability reports. Organizations have been paying attention to environmental preservation since the negative impacts of industrialization were made public by reports and books such as the famous Silent Spring in 1962 (Carson, 1962). Most people are now familiar with the importance of measuring performance in three critical pillars of people, planet, and profit. Since then, many more scholars have studied and documented the impact of corporate activities on the environment. From materials used in manufacturing to locations of vendors along the supply chain to transportation carriers used to the final consumption of the product, supply chain management decisions interact with sustainability in many ways.

PAGE 20

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

2.3.3 Current Best Practices

1.

Choose the right suppliers: This is the first step of the sustainability to choose most environment friendly or most environmentally responsible suppliers.

2. 3. 4.

Put your effort where it will do the most good Collaborate to innovate Use suppliers as force multipliers

2.3.4 Long term solutions 1. Closed-loop supply chain Dan Guide, professor of operations and supply chain management at Penn State, sees the ultimate problem as our consumer culture, which is based on disposable goods. Noting that most of the energy and natural resources associated with a product are consumed during the production phase, when new products are created from raw materials, Guide calls this craving for newness unsustainable. The problem, in his view, is found in our make-use-dispose business model. The solution Guide proposes is a completely new business model based on the concept of a closed-loop supply chain. Xerox, said Guide, is the poster child for this approach, which he calls servicizing. Xerox doesnt sell their machines to companies, he explains. They lease them, and they maintain and service them. So they know exactly what condition that product is in at all times. And when they get it back at the end, they have gained enormously valuable feedback about how the product performs in the field. Using this information, they can then re-use parts from the machines they recover and remanufacture products that are more valuable to customers and far less expensive to produce. While Guide points out that remanufacturing is incredibly profitable, and that Xerox and others are enjoying great success with this business model on the B2B side, he readily admits that the same is not true for products sold to consumers. One challenge is that in order to make the remanufacturing of products efficient, the products need to be initially designed and engineered to have modular parts, some of which can be efficiently recycled, others of which are

PAGE 21

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

designed to be durable enough for multiple uses. Thats easy enough, he said. The hard part is that consumers do not want re-manufactured products; they want new ones. Changing that mindset, conference participants said, will lead to a dramatic change in consumer culture. Guide thinks that marketing, which created the current culture, is a powerful tool for that change. Once the public is sold on the idea of frugality, people will once again value performance over novelty, substance over fashion and long-term quality over disposability. 2. Targeted government action Subsidies, offered by government, can help create the manufacturing and consumer base new technologies need to take off and become self-sustaining. The subsidies give these new green technology companies the ability to stay in business, producing more and more of what they sell, and learning in the process how to produce it both more effectively and less expensively. This is called as the learningby- doing effect. On the consumer side, subsidies encourage more people to use new technologies, which makes more people aware of and comfortable with the new systems, creating a positive feedback loop that helps grow the consumer base. Lobel calls this phenomenon technology diffusion. The result is greater production and increasing economies of scale. Governments that do not model the effects of various subsidy levels before settling on an amount and that make frequent small changes in response to changing market conditions, however well intentioned, are unlikely to accomplish policy goals. Sometimes set subsidies are applied to an entire industry, rather than varying according to purchase price. (Federal tax credits for electric cars are an example) Only by establishing subsidies that are properly structured to motivate the desired behavior, and keeping the subsidies constant enough that people are willing to make long-term decisions based on them, can government create incentives that effectively move consumers, manufacturers and investors. Essentially, they create the negative externalities Orts was alluding to, forcing taxpayers or others to bear the ultimate cost of their actions. Legislation can force companies to pay for the environmental damage they cause, which in turn provides a strong financial incentive for them to change their behavior. Whether cultural changes, government action or growing scarcity helps us become a truly sustainable society or more likely some combination of all three there is no reason to neglect the low-hanging fruit that still abounds.

3. Efficiency based strategy:

PAGE 22

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

This strategy derives environmental benefits for supply chain beyond regulatory compliance through operations based efficiency targets. Much of the benefit arises from manufacturing practices that have been found to give secondary environmental benefits. It has dual economic and environmental benefits and requires the higher levels of engagement from between customers and suppliers. But it lacks the more knowledge intensive environmental activities like product design, innovation or material substitution. 4. Innovation based strategy: Once supply chain begins to consider specialized processes, technologies or complex performance standards, the level of knowledge exchange and investments changes and requires specialized environmental resources. These resources could be used to incorporate innovative environmental planning into specific product designs 2.3.5 GSCM Strategies according to Supply Chain Areas: 3.2.1 Technology: In our age of technology, here is a disconcerting thought more than half of the warehouses in the world still rely on paper rather than an automated system. Essentially,companies lack inventory visibility, suffer operating inefficiencies and waste resources within the supply chain. Leaders in manufacturing and logistics industries should consider an environmentally responsible strategy which not only offers the universal benefits were familiar with, but also financial ones that strengthen their profit margins. Top green SCM best practices include leveraging the tools that you already have, using technology for communication between stakeholders and suppliers, avoiding unnecessary and wasteful activities and encouraging customers to also go green through their purchases. The most beneficial green supply chain technology creates sustainable environmental benefits as well as improves company bottom lines. That's why, across industries, companies are extending CSR and green activities to their suppliers. Manufacturers have a variety of choices when it comes to applying green SCM, including packaging engineering and redesign, materials substitution, certification and logistics optimization.

3.2.2 Design:

PAGE 23

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

From product lifecycle concept, the cycle starts at the designing of product. Green design emphasize both environmentally conscious design and life cycle assessment/analysis. In designing a product, the designing team can change the raw materials or substances used during the manufacturing to be less toxic, more environmental friendly. Some terminologies are related to design for green such as design for environment or EcoDesign. An example of green product is hybrid car. Due to the increasing demand and decreasing amount of petroleum, automobile manufacturers needed to redesign the engine that consumes no or less gas. Hybrid car has been developing from day to day. One article about automobile design is (McAuley, 2003), he discussed the green design of automobile, which tend to change to advanced lightweight materials and fewer materials in vehicle design. In designing a product, the manufacturing company needs a high level of cooperation with their suppliers. An example for the research on supplier-manufacturer cooperation in EcoDesign is (Stevels, 2002). He also presented two examples of successful green supply agenda between manufacturer and suppliers. 3.2.3 Manufacturing Processes: GSCM initiatives ranges from reactive to proactive practices implemented through various Res(..!! (Reduce, Reuse, Rework, Refurbish, Reclaim,Recycle, Remanufacture, Reverse logistics etc.). In manufacturing process, the company can apply green by several methods to reduce the energy and resource consumption. This is where reuse and recycling are referred. Several papers provided green practices such as (Duber-Smith, 2005). He suggested some practices including reducing energy consumption, recycle and reuse, using biodegradable and non-toxic materials, minimize harmful emissions, and minimize or eliminate waste. While transportation carriers are sensitive to energy prices, manufacturers face energy surcharges. This uncertainty along with current economic conditions affects the growth of inventory. The consequences are far reaching since shippers will carry extra inventory or safety stock, and order less frequently, adopting a costreducing strategy to select a cheaper, slower mode of transportation. Companies like Sharp Electronics are shifting their final assembly closer to point of sale, a return to the practices of the 1980s and 90s prior to offshoring becoming a no-choice option for manufacturers to survive.

3.2.4 Distribution and Transportation:

PAGE 24

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

The rising energy prices and limited supply furthers our efforts to adopt alternative solutions. Much talk centers on the expense and complexity of adopting green initiatives, but green business and revenue growth are not mutually exclusive of each other. The most commonly used GSCM transportation practices (such as load maximization) are lowrisk and require minimal capital investment. Applying several transportation GSCM practices in multiple areas can benefit firms and their supply chain partners even. Air and truck transportation are the most agile modes but emit the highest level of CO2 emissions per ton of goods moved per KM. Sophisticated technology boosted supply operations such that Wal-Marts efficient retail stores have become the manifestation of a fast and flawless distribution business. It has adapted the strategy of how to be the low cost operator and low cost leader by focusing on logistics and distribution. It moves the product faster and efficiently and maximizes the use of suppliers and internal distribution lines ensuring that they meet social and environmental standards. E.g. improving fuel mileage efficiency in trucking fleet, Recyclable or Biodegradable packaging, Green colored shelf tags etc. 3.2.5 Suppliers: Further than design and manufacturing, other departments in an organization are involved with the green. Purchasing could become an important agent for change regarding environmental initiatives in the supply chain. In (Walton, 1998) article, he conducted a qualitative study to explore the primary areas for change to increase purchasing impact on environment. Escalating labor costs and ever-increasing government regulation are creating reverse globalization. As the world becomes smaller, moving offshore isnt a cost-effective way to outsource. Instead, companies view outsourcing from a more strategic perspective with a deeper understanding for what the business demands. Pull-based supply chains are again becoming popular, displacing push-based initiatives that encouraged off-shoring manufacturing and other long-lead, long-life transit time strategies to market. Increasingly, companies are asking suppliers to green not just their products but themselves. Volvo, for example, has mandated that its suppliers to go through ISO 14000 or equivalent certification by the year 2000. Few other companies have taken that route so far. Most efforts to improve suppliers' overall eco-performance center

PAGE 25

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

around encouraging compliance with voluntary industry standards, or on participation in such government voluntary programs as the EPA's Green Lights. 3.2.6 Customers: Market demands to improve performance while simultaneously reducing costs is changing the playing field, and highlights the need for technology to support both the agile, energy-efficient supply chain as well as for socially responsible green initiatives. While educating corporate buyers will help, the key to success will come from educating sellers.

2.3.6 Awareness Programs 1. Education, training, and awareness programs: Consistent with Lueneburger and Goleman (2010), many companies have sustainability training programs for employees and suppliers. FIAT, for example, reports the amount of time spent on employee training in bringing up the sustainability awareness. Quanta and Hon Hai also report on their supplier education initiatives to ensuresustainability in their supply chain members. 2. Supplier risks assessment, auditing, certification: Sustainability certification requirements are becoming increasingly more important for sustainable conscience organizations. Examples can be found among Fortune 500 companies and also in the biofuels/bioenergy (Scarlat, Dallemand, 2011), coffee (Raynolds, Murray, and Heller, 2007), and wine (Berghoef and Dodds, 2011) industries 3. Sustainability KPIs for logistical activities/projects: One of the popular areas for sustainability development is to develop a series of key performance indicators or KPIs. KPIs need to be consistent with organizational goals and objectives (Bai, Sarkis, and Wei, 2010). The results of the present study suggest that many managers believe what is measured gets done. Thus, measuring activities geared to meeting objectives will carry significant weight. Results of our study bear this out where companies have developed auditing and certification tools to assess supply chain risks. For example, in the computer industry, HP and Dell audit their suppliers periodically then certify them for their sustainability levels. Retailers like Wal-mart also have stringent requirements and processes for their suppliers.

PAGE 26

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

4. Environmental Management System: In the past, organizations have been developing methodologies to measure the environmental impact of company activities (Veleva, et al, 2004; Bjorklund, 2010). Companies are developing even more comprehensive systems to manage Environment-related matters the same way they manage production or logistics resources. Deutsche-Bahn, for example, has a system that monitors all of its maintenance activities for environmental issues. 5. Membership in NGOs and professional organizations: Increasingly, social movements scrutiny is focused on multinational companies. As these movements continue to gain global recognition, it becomes more important that they are considered as part organizations strategic environmental calculus (Perez-Aleman, and Sandilands, 2008). The study results show most companies belong to one or more non-profit organizations dedicated to sustainability or environmental preservation. It seems that joining such organizations helps keep companies up to date in sustainability front. Some industry leaders, such as HP, are partnering up with professional associations to develop industry standards. 6. Supply chain coverage: Most companies report a series of activities along the global supply chain. They report having initiatives in the areas of purchasing/procurement, transportation & logistics, product development, production/processes, sales and service, packaging, and even end of life recycling. Manufacturers seem to lead the way in supply chain activities as many of them report monitoring such activities in their own supply chain and for their supply chain partners including carriers and first and second-tier suppliers. 7. Companies also report efforts to cut GHG emission, including the selection of shipping modes and the use of cleaner fuels or alternative energy sources. Some companies, such as Mazda and Michelin report developing newer and cleaner products that help reduce negative environmental impacts. Most companies also report how they reduce, reuse, and recycle packaging materials and production wastes. 2.4 Reducing Supply Chain cost As companies continue to manufacture and source materials from overseas, controlling costs remains a top priority for those involved in international trade. One key factor that should be monitored more closely is logistics management, which covers all activities relating to the procurement, transport, transshipment and storage of goods. Depending on the industry sector, supply chain logistics costs account from 5% to 50% of a products total landed cost.

PAGE 27

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

Some issues effecting logistics costs: Fuel prices remain high and ports continue to experience delays, resulting in higher transportation fees. Increasingly complex international trade laws and security measurements threaten to lengthen delivery times and increase warehousing costs. According to a recent report by TechnologyEvaluation.com, a typical air-freight shipment takes eight to twelve days. Of this, the cargo is en route only 5% of the time. The rest is spent sitting in warehouses waiting for the required documents and compliance checks. 2.4.1 10 tips for reducing supply chain logistics costs Following are 10 Tips on Reducing Supply Chain Logistics Costs: 1. Understand the true costs of sourcing overseas. Calculate freight, duty, brokerage, and inventory carrying costs to support these lengthened supply chains. Also factor in such items as the costs of engineers flying overseas. Once you understand the true total landed cost and total impact to the business, that domestic buy may look a lot better. Sourcing from Ohio to your U.S. plant, distribution center or customer may, in the long run, be more cost effective than sourcing from China. 2. Focus on eliminating the variability out of transit times. The more variable the transit times are, the more likely it is that the receiving party is using more premium freight, building buffers of inventory, or ordering more often and more quantity than necessary to compensate for the uncertainty. Understanding these dynamics can lead to the conclusion that paying higher freight costs to insure higher variability actually saves your company in total costs. 3. Tariff engineering. Strategically source and manufacture products to take advantage of classification duty rates and eligibility for special trade programs such as NAFTA. 4. Consolidate. If you have multiple suppliers in one country, consolidate their goods into one shipment. In addition, if you always have LCL (less than container load) shipments out of one country, try to find another LCL importer of goods from that country. You may be able to partner and consolidate to a more cost-effective FCL (full container load) shipment. 5. Informed decision-making. Provide to the decision-makers/customers of your logistics network the cost of freight for each service level, the reliability of each lane for each service level, and the true cost of carrying inventory so they can make informed decisions. People generally want to be good corporate citizens and will select the less expensive option that still meets their needs. 6. Sometimes insurance doesnt pay. Often when a company has a shipment of premium goods they tend to use the Carriers Insurance. Carriers Insurance is very expensive. If the company is self insured, which most

PAGE 28

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

companies are, they should check their insurance policy to see if it covers shipment of goods. If it does, then they do not need to add the extra cost of Carriers Insurance. 7. Automate compliance processes. Companies that implement software solutions to automate trade compliance are able to speed the cycle times associated with tasks being performed manually, such as document preparation, and eliminate the associated errors. Automated compliance procedures also bring fewer delays at border crossings, resulting in on-time delivery, adequate inventory levels, increased customer satisfaction, and the avoidance of fines. 8. Control your express shipping costs. Typically when a company runs into a supply chain issue, it will have an entire shipment sent on an express/expedited (highest cost) service level basis. Panicking often results in higher costs. If the company would just do a little bit of calculating it can determine the amount of goods that are needed immediately and have that amount sent using express/expedited service level, while the balance of the shipment can be sent using a standard (lower cost) service level. 9. Planes, trains and automobiles. Which is cheapest? In general, rail is more cost-effective than trucking or air. Water is cheaper than air shipment. No matter the mode of delivery, always try to get three quotes for movements. 10. Be aware of non-tariff trade barriers. Companies need to be more aware of the increasing level of non-tariff trade barriers that are in force to reduce sweat shop labor and support human rights and animal welfare issues. These restrictions can bring importers increased liability and compliance costs.

References

Case Study: Hitachi Consulting Study on Supply Chain Responsiveness. Omega International Journal of management Science. Companies without borders: Collaborating to compete. Economist Intelligence Unit. 2006. Unlocking the DNA of the Adaptable Workforce: The Global Human Capital Study 2008. IBM Global Business Services. September 2007.

Web sites http://bx.businessweek.com http://supply-chain.org/ http://www.metrics2.com/blog/2007/02/19/record_182000_new_products_flood_global_cpg_shelve.html

PAGE 29

SUPPLY CHAIN MANAGEMENT

FUTUE OF LOGISTICS IN WORLD

PAGE 30

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Lecture 1 ConstructorDocument28 pagesLecture 1 ConstructorSuraj JeenaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- XLP Interface V4.0Document3 pagesXLP Interface V4.0Anonymous PedQHSMPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Clown - BD v0.81 ChangelogDocument13 pagesClown - BD v0.81 ChangelogFaizurr HartmannPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- MLT526Rev 11-02Document662 pagesMLT526Rev 11-02Razvan Mitru100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- It Era Final ModuleDocument103 pagesIt Era Final ModuleLeonso Visto JrPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Intel Nehalem Core ArchitectureDocument123 pagesIntel Nehalem Core ArchitecturecomplexsplitPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- WAMP Server and PHP ZeroMQ Extension InstallationDocument2 pagesWAMP Server and PHP ZeroMQ Extension InstallationGautambuddha AirportPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Special Topic Presentation: Subject: Wireless Communication Topic: Global System For Mobile CommunicationDocument18 pagesSpecial Topic Presentation: Subject: Wireless Communication Topic: Global System For Mobile Communicationtabish khatriPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Software Engineering: UNIT-3Document41 pagesSoftware Engineering: UNIT-3Jayavarapu Karthik JPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Professional SummaryDocument3 pagesProfessional SummaryVijay LS SolutionsPas encore d'évaluation

- UDF & Powercopy of CATIA V5: About COE Membership Industries Events Content Center Partners ForumsDocument14 pagesUDF & Powercopy of CATIA V5: About COE Membership Industries Events Content Center Partners ForumsRedondela DentalPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- What Is The Difference Between 0.2 and 0.2S Class CTDocument5 pagesWhat Is The Difference Between 0.2 and 0.2S Class CTshaik abdulaleemPas encore d'évaluation

- Bharat Sanchar Nigam Limited: Office of The Executive Engineer (Civil) BSNL Civil Division, Imphal - 795001, ManipurDocument47 pagesBharat Sanchar Nigam Limited: Office of The Executive Engineer (Civil) BSNL Civil Division, Imphal - 795001, Manipurvivekananda sharmaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Read This FirstDocument21 pagesRead This FirstNíkolas BorgesPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Power Decoupling Method For Single Stage Current Fed Flyback Micro InverterDocument41 pagesPower Decoupling Method For Single Stage Current Fed Flyback Micro InverterXavier APas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- GDS-1000B Quick Start Guide ADocument2 pagesGDS-1000B Quick Start Guide Aketab_doostPas encore d'évaluation

- ms880 Car Specific Cable Set - 53985Document11 pagesms880 Car Specific Cable Set - 53985SamuelPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Dr. Nehal Allam: How Technology Trend Change The Nature of HRM Student Name: Mahmoud Mohamed Mahmoud AhmedDocument4 pagesDr. Nehal Allam: How Technology Trend Change The Nature of HRM Student Name: Mahmoud Mohamed Mahmoud AhmedMahmoud MohamedPas encore d'évaluation

- 5 - Handbook On TCAS - An Indigenous ATP System - April 2021Document150 pages5 - Handbook On TCAS - An Indigenous ATP System - April 2021AliveluPas encore d'évaluation

- Commercializing Process TechnologiesDocument11 pagesCommercializing Process TechnologiesBramJanssen76Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- CV NguyenLamTruong EngNew PDFDocument1 pageCV NguyenLamTruong EngNew PDFhoa lePas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Id Motors: Operation and Maintenance ManualDocument64 pagesId Motors: Operation and Maintenance ManualJose Maria Redondo CarsiPas encore d'évaluation

- Er Shutdown For 15.12.21 Rev1Document8 pagesEr Shutdown For 15.12.21 Rev1Gitesh PatelPas encore d'évaluation

- Microchip TimeProvider 4100 Datasheet 20Document7 pagesMicrochip TimeProvider 4100 Datasheet 20Jorge VargasPas encore d'évaluation

- 1st Quarter ICT ReviewerDocument5 pages1st Quarter ICT ReviewerazrielgenecruzPas encore d'évaluation

- eCATT Chaining, Parameterization, Creation of Test Data, Test Configuration, System Data (PART IV)Document18 pageseCATT Chaining, Parameterization, Creation of Test Data, Test Configuration, System Data (PART IV)kalidasmPas encore d'évaluation

- VMX Agy UmDocument165 pagesVMX Agy UmGerardo BocanegraPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Coveo For Sitecore Project Guide Version 2 PDFDocument54 pagesCoveo For Sitecore Project Guide Version 2 PDFmaldonado.ogPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)