Académique Documents

Professionnel Documents

Culture Documents

ATS Test Report 34

Transféré par

Rami BadranDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ATS Test Report 34

Transféré par

Rami BadranDroits d'auteur :

Formats disponibles

(ATS) AUTOMATIC TRANSFER SWITCH

JOB-NO. CUSTOMER PROJECT DRAWING

Ref. Revision: Date:

EEICQC-F-34 1 March 28, 2011

PANEL TAG NO. NO OF SECTIONS INSPECTION REF: SHOP ORDER NO.

A.

S/N 1. 2. 3. 4.

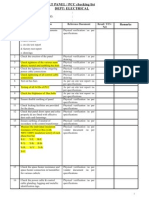

VISUAL TEST

ITEM(S) Check the equipment tag number is correct against the tag number shown on the One Line Diagram and the equipment data sheet. Check the nameplates against, the One Line Diagram and the equipment data sheet. Verify that all internal control and instrumentation terminations are securely and properly connected. Verify that all control wires terminal markings are properly and clearly printed. No visible signs of hand markings. Verify that the number of sections is correct. Verify that all components (e.g. MCB, CT, CPT/VT, relays, fuses, etc.) are installed properly. Verify that the incoming power connections / lugs are properly secured Verify that control wirings are correctly and properly identified. Verify that the cubicle is clean and free from debris. STATUS Not Done

Done

Date

5. 6. 7. 8. 9.

B.

10. 11. 12. 13.

MECHANICAL TEST

Check switch to insure positive interlock between normal and alternate sources. Check tightness of all cable connections and bus joints. Perform manual transfer operation. Verify that all internal control and instrumentation terminations are securely and properly terminated.

C.

14. 15. 16. 17. 18. 19. 20. 21. 22.

ELECTRICAL TEST

Verify continuity of all power and control leads. Verify that the Overload Reset button operates freely and correctly. Carry out Current Transformer (CT) and Voltage Transformer (VT) Tests. ( Attached computer generated test reports affixed with QC stamped) Perform automatic transfer by simulating loss of normal power. Perform automatic transfer by return to normal power. Monitor and verify correct operation and timing Normal Voltage sensing relays. Monitor and verify correct operation and time delay upon transfer. Monitor and verify correct operation and timing of Alternate voltage sensing relays. Monitor and verify correct operation and timing of Automatic transfer operation.

Page 1 of 3

(ATS) AUTOMATIC TRANSFER SWITCH

23. 24. 25.

Ref. Revision: Date:

EEICQC-F-34 1 March 28, 2011

26. 27. 28. 29. 30.

Monitor and verify correct operation and timing of mechanical and electrical interlocks and limit switches Monitor and verify correct operation and timing, of time-delay and Re-transfer upon normal power restoration. Verify that space heaters have been correctly installed operate properly.(if applicable as per customers request or approved data schedule) Carry out Insulation Resistance Test. Carry out Hi-Pot Test. Verify that the Ammeter is accurately calibrated by current injection. Verify that the Voltmeter is accurately calibrated by voltage application. Carry out a complete functional check of the Control Scheme.

* N/A Not Applicable

D.

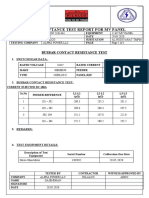

One Minute Insulation Resistance Test

Serial No.: 677 Cal Due Date:

Test Equipment: SEFELEC

Resistance Test Results (Test Voltage = 1000Vdc) Test Description

AB+C+ Ground BA+C+ Ground CA+B+ Ground

PHASE TO PHASE

A - B B - C C - A

Pass / Fail

E.

Over-potential Withstand (Hi-Pot) Test Method and Results

Serial No.: 071325002 Test Voltage ( 2.5 KVac) Time Cal Due Date: Measured Leakage Current PASS / FAIL (Pass if no disruptive charge or flashover)

Test Equipment: BAUR Rated AC Voltage (V)

Description

AB+C+ Ground BA+C+ Ground CA+B+ Ground

Page 2 of 3

(ATS) AUTOMATIC TRANSFER SWITCH

Ref. Revision: Date:

EEICQC-F-34 1 March 28, 2011

Test Voltages and Minimum Acceptable Resistance

(NETA 1990 TABLE 10.1 P.190)

Max Equip Rating (V) 250 600 5000 8000 15000 35000

Minimum Test Voltage (dc) 500 1000 2500 2500 2500 15000

Minimum Acceptable Resistance (M)

25 100 1000 2000 5000 100000

Dielectric tests ANSI/IEEE C37.20.2 ANSI/IEEE C37.20.1 & C37.20.3 Metal-Clad, Station-Type Cubical and Metal Enclosed MV Switchgear, C37.23 Bus, Outdoor Circuit Breakers, and ANSI C37.32 Air Switches Power Frequency Field Reference DC Field Test Voltage for 60 seconds Rated Maximum Test Voltage for 60 sec. duration Voltage AC duration 4.76 kVac 14.25 kVac 20.25 kVdc 8.25 kVac 19.5 kVac 27.75 kVdc 15 kVac 27 kVac 37.5 kVdc 15.5 kVac 37.5 kVac 52.5 kVdc 25.8/27 kVac 45 kVac 38.0 kVac 60 kVac 72.5 kVac 120 kVac *Notes: 1.

The presence of the column headed 'dc withstand' does not imply any requirement for a dc withstand test on ac equipment. The column is given as a reference only for those using dc tests and represents values believed to be approximately equivalent to the corresponding power frequency withstand test values specified for each class of bus. Direct current withstand tests are recommended for flexible bus to avoid loss of insulation life that may result from the dielectric heating that occurs with rated frequency withstand testing. Because of the variable voltage distribution encountered when making 'dc withstand tests' and variances in leakage currents associated with various insulation systems, the manufacturer should be consulted for recommendations before applying 'dc withstand tests' to this equipment.

2.

3.

COMMENTS

QUALITY CONTROL ENGINEER

CUSTOMER

DATE

Page 3 of 3

Vous aimerez peut-être aussi

- HT Panel QapDocument2 pagesHT Panel QapAlla Naveen KumarPas encore d'évaluation

- 1 AcdbDocument9 pages1 AcdbmaheshknmPas encore d'évaluation

- Testing and Commissioning of Motor Control Center Method StatementDocument3 pagesTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- Megger Testing Method StatementDocument7 pagesMegger Testing Method StatementRay Agacia0% (1)

- Checklist For Protection Relays General Electrical Tests Rev00Document2 pagesChecklist For Protection Relays General Electrical Tests Rev00Anonymous dH3DIEtz67% (3)

- Check List LT PanelDocument1 pageCheck List LT PanelAnil PatelPas encore d'évaluation

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla Vietor100% (1)

- Electrical Switchboard Test and Commissioning ProcedureDocument4 pagesElectrical Switchboard Test and Commissioning ProcedureAodman4u100% (2)

- Testing and Commissioning of UPS System Method StatementDocument3 pagesTesting and Commissioning of UPS System Method StatementHumaid Shaikh100% (1)

- Checklist For Cable Try Fabrication and EractionDocument2 pagesChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- ATS Testing & Commissioning - Method Statement HQDocument5 pagesATS Testing & Commissioning - Method Statement HQHansika Rajapaksha100% (1)

- Precommissioning Procedures of Testing Commissioning PDFDocument96 pagesPrecommissioning Procedures of Testing Commissioning PDFRatheesh Kumar100% (1)

- Testing & Commissioning ManualDocument37 pagesTesting & Commissioning ManualVenkata Raja Suresh J100% (2)

- Transformer Maintenance Checklist - 5 Must Do Routine ChecksDocument3 pagesTransformer Maintenance Checklist - 5 Must Do Routine Checksmurthy237Pas encore d'évaluation

- Checklist-MV & LV Cable LayingDocument4 pagesChecklist-MV & LV Cable LayingKhalid AwanPas encore d'évaluation

- Power Transformer Testing (25 MVA, 132/33 KV)Document3 pagesPower Transformer Testing (25 MVA, 132/33 KV)Manish Pareek0% (1)

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (1)

- Electrical WIP Test FormDocument28 pagesElectrical WIP Test FormDick Anthony Mabao100% (1)

- FAT Procedure of LV SwitchboardsDocument17 pagesFAT Procedure of LV SwitchboardsWilliam Wong100% (2)

- Type Tests Defined in IEC 61439Document18 pagesType Tests Defined in IEC 61439Mahesh DavePas encore d'évaluation

- Earthpit Resistance Testing RecordsheetDocument1 pageEarthpit Resistance Testing RecordsheetawsomePas encore d'évaluation

- Power and Control Cable Installation ITPDocument1 pagePower and Control Cable Installation ITPkamilPas encore d'évaluation

- Method Statement For Precommissioning & Commissioning of Distribution Boards - DB'sDocument4 pagesMethod Statement For Precommissioning & Commissioning of Distribution Boards - DB'svin ssPas encore d'évaluation

- Checklist of Panels - 00047 NewDocument6 pagesChecklist of Panels - 00047 NewKarthick NatrajanPas encore d'évaluation

- Insulation Test FormDocument1 pageInsulation Test FormDiane Mae Bauzon100% (1)

- LT Panel SOP For Test ProcedureDocument5 pagesLT Panel SOP For Test ProcedureShrikanth Sola100% (2)

- LV Dielectric TestingDocument2 pagesLV Dielectric TestingwaseemsamsodienPas encore d'évaluation

- Quality Assurance PlanDocument2 pagesQuality Assurance PlanSAGARPas encore d'évaluation

- STP-ELECT-DB Distribution Board TestDocument18 pagesSTP-ELECT-DB Distribution Board TestYouwan LeePas encore d'évaluation

- Testing & Commissioning of Telephone Data SystemDocument1 pageTesting & Commissioning of Telephone Data Systemhaytham65Pas encore d'évaluation

- MCC and Panels Maintenance ProcedureDocument15 pagesMCC and Panels Maintenance ProcedureÁlvaro Manterola Lazcano100% (19)

- Bus Bar Contact Resistance TestDocument1 pageBus Bar Contact Resistance TestGajendran Sriram100% (1)

- Testing of Electrical EquipmentsDocument23 pagesTesting of Electrical EquipmentsPrashanth Reddy Gouni100% (5)

- Capacitor TestDocument2 pagesCapacitor TestdineshPas encore d'évaluation

- 06 - Test Format For Insulation ResistanceDocument1 page06 - Test Format For Insulation ResistanceGajendran Sriram100% (1)

- MV Cable Hi-Pot Test ShetDocument1 pageMV Cable Hi-Pot Test ShetAhmad Dagamseh100% (1)

- DC HiPot Testing Guidelines For MV Cables General Cable PDFDocument2 pagesDC HiPot Testing Guidelines For MV Cables General Cable PDFKarim MuhammedPas encore d'évaluation

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanPas encore d'évaluation

- Power Engineering PM Check ListDocument11 pagesPower Engineering PM Check ListSelvn SubramanianPas encore d'évaluation

- QC-143 R2 Distribution Panel ChecklistDocument1 pageQC-143 R2 Distribution Panel ChecklistCamilo Jorquera100% (1)

- Fire Alarm BOQDocument3 pagesFire Alarm BOQalkamishra1984Pas encore d'évaluation

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 pagesCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarPas encore d'évaluation

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDocument3 pagesLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- ITP For Cable Tray - Rev BDocument6 pagesITP For Cable Tray - Rev BDonny Subarja100% (1)

- QAP - LT Panel PDFDocument8 pagesQAP - LT Panel PDFAkshay Ajay100% (2)

- Testing of CTDocument17 pagesTesting of CTsasikumarPas encore d'évaluation

- Emerson Ups ManualDocument73 pagesEmerson Ups Manualvdrizzils100% (2)

- NGCP-CND WTI&OTI Calibration & Test ReportDocument2 pagesNGCP-CND WTI&OTI Calibration & Test Reportedciel100% (1)

- Pre Commissioning ChecklistDocument5 pagesPre Commissioning ChecklistReymart Manablug100% (3)

- Test Procedure - BusbarDocument4 pagesTest Procedure - Busbarmayur dhande100% (2)

- 18002-Int-Fqe-Cl-Pw-001-0 - Checklist-Commissioning of Power Transformer PDFDocument1 page18002-Int-Fqe-Cl-Pw-001-0 - Checklist-Commissioning of Power Transformer PDFVenkataramanan S67% (3)

- CHECKLIST For Installation of Power CablesDocument1 pageCHECKLIST For Installation of Power CablesTHEOPHILUS ATO FLETCHER100% (5)

- MS Conduit InstallationDocument6 pagesMS Conduit InstallationSopi Labu0% (1)

- Transformer Erection ChecklistDocument2 pagesTransformer Erection Checklistmohan babu100% (2)

- ATS Test Report 34Document3 pagesATS Test Report 34ari_pras100% (1)

- Method Statement For AC PANELDocument6 pagesMethod Statement For AC PANELkamilPas encore d'évaluation

- Method Statement For DC PANELDocument6 pagesMethod Statement For DC PANELUtku Can KılıçPas encore d'évaluation

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- SAT PROCEDURE FOR MV SWGR PANELS - PdfToWordDocument4 pagesSAT PROCEDURE FOR MV SWGR PANELS - PdfToWordAmr ElkadyPas encore d'évaluation

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad SwitchgearMohammed MadiPas encore d'évaluation

- Process Communication Unit PCU400 MR9Document27 pagesProcess Communication Unit PCU400 MR9sahil4INDPas encore d'évaluation

- Checklist Question Support July 2015Document37 pagesChecklist Question Support July 2015Orbán NorbertPas encore d'évaluation

- Inclinimetro Boom RDSR3 BA 09 - BrochDocument3 pagesInclinimetro Boom RDSR3 BA 09 - BrochedgarlimasPas encore d'évaluation

- LW619DM 22 Groups IP CW1 Assign Brief March 23Document4 pagesLW619DM 22 Groups IP CW1 Assign Brief March 23topintechbooks100% (1)

- General Noise Specification: IssueDocument6 pagesGeneral Noise Specification: Issuerony16novPas encore d'évaluation

- Fusebox Gti mk2 VWDocument56 pagesFusebox Gti mk2 VWJuanAlejandroNuñezVazquez100% (4)

- Static vs. DynamicDocument4 pagesStatic vs. Dynamicchetanb39Pas encore d'évaluation

- Voltage Fluctuation Effect On Pumps and MotorsDocument13 pagesVoltage Fluctuation Effect On Pumps and MotorsPratik RaoPas encore d'évaluation

- Furse Lightning Strike Counters: Features & BenefitsDocument2 pagesFurse Lightning Strike Counters: Features & BenefitsLương Quốc ThanhPas encore d'évaluation

- Ifma CFM Candidate Handbook 20210422 - 20210907Document46 pagesIfma CFM Candidate Handbook 20210422 - 20210907aboodyrezqPas encore d'évaluation

- Apache Tomcat File ConfigDocument10 pagesApache Tomcat File Configraj kumarPas encore d'évaluation

- GSM Link BudgetDocument34 pagesGSM Link BudgetJnanendra KhatiwadaPas encore d'évaluation

- Schneider ATV930 ATV950 Installation Manual PDFDocument143 pagesSchneider ATV930 ATV950 Installation Manual PDFRodrigo VidalPas encore d'évaluation

- E202 - Instr Inspection Test Plan Template Rev 00 11.11Document10 pagesE202 - Instr Inspection Test Plan Template Rev 00 11.11Arbaaz Khan100% (1)

- Dräger Babytherm 8000 LDR - User ManualDocument50 pagesDräger Babytherm 8000 LDR - User ManualsangPas encore d'évaluation

- Factories and Machinery Act LiftsDocument65 pagesFactories and Machinery Act LiftsMFaiz RHamiraPas encore d'évaluation

- Goods Lifts: 300 - 2000kg CapacityDocument14 pagesGoods Lifts: 300 - 2000kg CapacityAnton LyakhovPas encore d'évaluation

- Craftsman ChainsawDocument21 pagesCraftsman Chainsawgwrace1Pas encore d'évaluation

- Seeb Vocational College Diploma CourceDocument2 pagesSeeb Vocational College Diploma CourceSiva Agora KarthikeyanPas encore d'évaluation

- 900A Product Guide Imperial PDFDocument16 pages900A Product Guide Imperial PDFRuben Angel RoquePas encore d'évaluation

- Tartarini TM 7 TQ Ball ValvesDocument3 pagesTartarini TM 7 TQ Ball ValvesadrianioantomaPas encore d'évaluation

- Kimber Micro ManualDocument88 pagesKimber Micro Manualcarmelo betncourtPas encore d'évaluation

- Rungta College of Engineering & Technology: Lab Manual CS-322364 (22) : Web TechnologyDocument58 pagesRungta College of Engineering & Technology: Lab Manual CS-322364 (22) : Web TechnologybinzbinzPas encore d'évaluation

- Vikta102 Ecl Modbus OpcDocument10 pagesVikta102 Ecl Modbus OpcTobias AngererPas encore d'évaluation

- Salt WasheryDocument7 pagesSalt WasheryAPas encore d'évaluation

- Electrical SMDB Check ListDocument2 pagesElectrical SMDB Check ListBabu100% (2)

- The ISO27k Standards: Gary HinsonDocument10 pagesThe ISO27k Standards: Gary HinsonKaran DeetPas encore d'évaluation

- A To Z of SAP Ariba With ECCDocument13 pagesA To Z of SAP Ariba With ECCLakka100% (1)

- Preview Only: Malaysian StandardDocument4 pagesPreview Only: Malaysian StandardSyamim kerrrPas encore d'évaluation

- Tumblr Layout 170415Document16 pagesTumblr Layout 170415GlaizaPas encore d'évaluation