Académique Documents

Professionnel Documents

Culture Documents

Piping Material Specification

Transféré par

ravirawat15Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

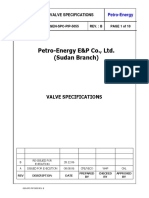

Piping Material Specification

Transféré par

ravirawat15Droits d'auteur :

Formats disponibles

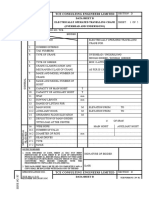

PIPING MATERIAL SPECIFICATION

Project No. Area No. Doc. Classification code Discipline Code + Seq No. Rev. Page

8455001

009

SP

0005

B0

1 OF 36

ATTACHMENT 4 PIPING MATERIAL SPECIFICATIONS -MAIN PLANT

PIPING MATERIAL SPECIFICATION :- CS01

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 CARBON STEEL 1.5 NONE

TEMPERATURE AND PRESSURE RATING 100 -29 to 38 TEMP0C PRESS Kg/cm2G 19.99 18.5

200 14.7

300 10.4

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 205 TEMP0C PRESS Kg/cm2G 12 FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) STEAM CONDENSATE (SC), MEDIUM PRESSURE STEAM (3.5-10 Kg/cm2) (SMT), LOW PRESSURE STEAM (SLT)

NOTES

1 2 3 4 5 6 7 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. WALL THICKNESS CALCULATION FOR SIZES 400NB & ABOVE SHALL BE BASED ON DESIGN CONDITIONS. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No. Area No. Doc. Classification code Discipline Code + Seq No. Rev. Page

8455001

009

SP

0005

B0

2 OF 36

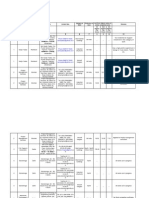

Item Type

PIPE PIPE PIPE PIPE PIPE

Lower Size (mm)

15 50 200 400

Upper Size (mm)

40 150 350 600

Sch/Thk

Design / Dims Standard

ASME B36.10M ASME B36.10M ASME B36.10M ASME B36.10M

Material

Description

Note

80 40 20 20

ASTM A106 GR B ASTM A106 GR B ASTM A106 GR B ASTM A672 GR.B60 CL.12

PE, SMLS BE, SMLS BE, SMLS BE, EFW

FITTINGS ELBOW 90 ELBOW 90 ELBOW 90 ELBOW 45 ELBOW 45 ELBOW 45 TEE EQUAL TEE EQUAL TEE EQUAL TEE RED TEE RED TEE RED RED. COUPLING RED. ECC. RED. ECC. CAP CAP CAP 15 50 400 15 50 400 15 50 400 15 50 400 15 50 400 15 50 400 40 350 600 40 350 600 40 350 600 40 350 600 40 350 600 40 350 600 CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W SW BW, R=1.5D BW, R=1.5D SW BW BW SW BW BW SW BW BW SW BW BW SW BW BW

FULL COUPLING HALF COUPLING

15 15

40 40

CL.3000 CL.3000

ASME B16.11 ASME B16.11

ASTM A105 ASTM A105

SW SW

FLANGES FLANGE SW FLANGE SO 15 50 40 600 CL.150 CL 150 ASME B16.5 ASME B16.5 ASTM A105 ASTM A105 RF RF

BLIND FLANGE

15

600

CL.150

ASME B16.5

ASTM A105

RF

PIPING MATERIAL SPECIFICATION

Project No. Area No. Doc. Classification code Discipline Code + Seq No. Rev. Page

8455001

009

SP

0005

B0

3 OF 36

Item Type

GASKETS GASKET

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15

600

4.5 MM/ CL.150

ASME B16.20

SP.WND SS304+ FLEXIBLE GRAPHITE

4.5 MM THK.,WITH CS OUTER RING

BOLTINGS STUD BOLT NUT 15 15 600 600 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 40 CL. 150 API 602 / MFG STD BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13%CR BODY - ASTM A105, TRIM - 13%CR BODY - ASTM A216 GR.WCB, TRIM - 13%CR BODY - ASTM A105, TRIM - 13%CR BODY - ASTM A216 GR.WCB, TRIM - 13%CR BB, OS&Y, SW, B 16.11

VLV. GATE

50

600

CL. 150

API 600 / ASME B16.10 BS EN ISO 15761/ MFR STD BS 1873 / B-16.10 BS EN ISO 15761/ MFR STD BS 1868/ B-16.10

BB, OS&Y, RF, B16.5

VLV. GLOBE

15

40

CL. 150

BB, OS&Y, SW, B 16.11

VLV. GLOBE

50

600

CL. 150

BB, OS&Y, RF, B16.5 WAFER TYPE,SW, B- 16.11 WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF

VLV.CHECK

15

40

CL. 150

VLV. CHECK

50

600

CL.150

PIPING MATERIAL SPECIFICATION

Project No. Area No. Doc. Classification code Discipline Code + Seq No. Rev. Page

8455001

009

SP

0005

B0

4OF 36

BRANCH CONNECTION TABLE RUN PIPE, NB 500 450 400 350 300 250 200 150 100 80 65 50 40 15 P 20 P 25 P 40 P BRANCH CONNECTION, NB 50 P 65 P 80 P 100 P 150 P 200 P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P RT P P P P P P P P P P P P P P P P P P P P P P P P P P P P 25 20 15

RT RT RT T

RT RT RT T

RT RT RT T

RT RT RT RT T RT RT RT T RT RT T

RT RT RT T

RT RT RT T RT RT T RT T T T : EQUAL TEE

RT RT RT

RT RT RT RT RT RT

RT : REDUCING TEE P : STUB JOINT

250 RT RT P

300 RT RT RT RT T 350 RT RT RT T 400 RT RT T 450 RT T 500 T

CODE DESCRIPTION ST SRT T RT RP P H Socket weld Tee Socket welded Reducing Tee Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch Half coupling

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

5 OF 36

PIPING MATERIAL SPECIFICATION :- CS02

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 CARBON STEEL 1.5 NONE

TEMPERATURE AND PRESSURE RATING -29 to 38 100 TEMP0C PRESS Kg/cm2G 19.99 18.5

200 14.7

300 10.4

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 65 TEMP0C PRESS Kg/cm2G 12.6 FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) ALCOHOL LIQUID (AL), ALCOHOL PRODUCT (AP), DENATURED ALCOHOL (AD), ALCOHOL VAPOUR (AV), DENATURANT LIQUID (DN), DENATURANT VAPOUR (DV).

NOTES

1 2 3 4 5 6 7 8 9 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. WALL THICKNESS CALCULATION FOR SIZES 400NB & ABOVE SHALL BE BASED ON DESIGN CONDITIONS. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX. FULL PORT BALL VALVE SHALL BE USED IF INDICATED ON THE P&ID. THESE VALVES HAVE NO FLANGES BUT ARE INSTALLED BETWEEN LINE FLANGES WITH EXTRA LONG BOLTS.

10 SHALL BE USED UPTO 210 DEG C ONLY.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

6 OF 36

Item Type

PIPE PIPE PIPE PIPE PIPE PIPE

Lower Size (mm)

15 50 200 400 500

Upper Size (mm)

40 150 350 450 600

Sch/Thk

80 40 20 10 7.92 mm

Design / Dims Standard

ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M

Material

API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1

Description

PE,SMLS BE,SMLS BE,SMLS BE,EFW BE,EFW

Note

FITTINGS ELBOW 90 ELBOW 90 ELBOW 90 ELBOW 45 ELBOW 45 ELBOW 45 TEE EQUAL TEE EQUAL TEE EQUAL TEE RED TEE RED TEE RED RED. COUPLING RED. ECC. RED. ECC. CAP CAP CAP 15 50 400 15 50 400 15 50 400 15 50 400 15 50 400 15 50 400 40 350 600 40 350 600 40 350 600 40 350 600 40 350 600 40 350 600 CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W SW BW, R=1.5D BW, R=1.5D SW BW BW SW BW BW SW BW BW SW BW BW SW BW BW

FULL COUPLING HALF COUPLING

15 15

40 40

CL.3000 CL.3000

ASME B16.11 ASME B16.11

ASTM A105 ASTM A105

SW SW

FLANGES FLANGE SW FLANGE SO 15 50 40 600 CL.150 CL 150 ASME B-16.5 ASME B-16.5 ASTM A105 ASTM A105 RF RF

BLIND FLANGE

15

600

CL.150

ASME B-16.5

ASTM A105

RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

7 OF 36

Item Type

GASKETS GASKET

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15

600

2 mm / CL.150

ASME B-16.21

NON ASBESTOS FIBER

TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 600 600 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B-18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 40 CL. 150 API 602 / MFG STD BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BB, OS&Y, SW, B 16.11

VLV. GATE

50

600

CL. 150

API 600 / ASME B16.10

BB, OS&Y, RF, B16.5

VLV. GLOBE

15

40

CL. 150

BS EN ISO 15761/ MFR STD

BB, OS&Y, SW, B 16.11

VLV. GLOBE

50

600

CL. 150

BS 1873 / B-16.10

BB, OS&Y, RF, B16.5 WAFER TYPE,SW, B- 16.11 WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF SW, B 16.11

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

600

CL.150

API 594

VLV. BALL

15

40

CL. 800

MFG STD

VLV. BUTTERFLY

50

600

CL. 150

MFG STD

WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

8 OF 36

BRANCH CONNECTION TABLE RUN PIPE, NB 600 15 P 20 P 25 P 40 P 50 P BRANCH CONNECTION, NB 65 P 80 P 100 P 150 P 200 P P P P P P P P P P P 550 500 450 400 350 300 250 200 150 100 P P P P P P P P P P P P P P P P P P P P P P P P P P P RT P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P 80 P P 65 P 50 40 25 20 RT T T 15

RT RT

RT RT RT

RT RT RT T

RT RT RT RT T RT RT RT T RT RT T

RT RT T

RT P

RT RT T T : EQUAL TEE

RT RT RT RT T RT RT RT T RT RT T RT T T

RT RT

RT : REDUCING TEE P : STUB JOINT

250 RT RT 300 RT RT 350 RT RT 400 RT RT 450 RT RT 500 RT RT 550 RT T 600 T

RT RT RT RT RT RT RT RT RT RT RT T RT T T

CODE DESCRIPTION ST SRT T RT RP P H Socket weld Tee Socket welded Reducing Tee Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch Half coupling

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

9 OF 36

PIPING MATERIAL SPECIFICATION :- CS03

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 CARBON STEEL 1.5 NONE

TEMPERATURE AND PRESSURE RATING 120 TEMP0C PRESS Kg/cm2G 8 FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING TEMP0C PRESS Kg/cm2G FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) 5% NaOH SOLUTION

NOTES

1 2 3 4 5 6 7 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. WALL THICKNESS CALCULATION FOR SIZES 400NB & ABOVE SHALL BE BASED ON DESIGN CONDITIONS. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

10 OF 36

Item Type

PIPE PIPE PIPE PIPE PIPE

Lower Size (mm)

15 50 200 400

Upper Size (mm)

40 150 350 600

Sch/Thk

Design / Dims Standard

ASME B36.10M ASME B36.10M ASME B36.10M ASME B36.10M

Material

Description

Note

80 40 20 20

ASTM A106 GR B ASTM A106 GR B ASTM A106 GR B ASTM A672 GR.B60 CL.12

PE, SMLS BE, SMLS BE, SMLS BE, EFW

FITTINGS ELBOW 90 ELBOW 90 ELBOW 90 ELBOW 45 ELBOW 45 ELBOW 45 TEE EQUAL TEE EQUAL TEE EQUAL TEE RED TEE RED TEE RED RED. COUPLING RED. ECC. RED. ECC. CAP CAP CAP 15 50 400 15 50 400 15 50 400 15 50 400 15 50 400 15 50 400 40 350 600 40 350 600 40 350 600 40 350 600 40 350 600 40 350 600 CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W SW BW, R=1.5D BW, R=1.5D SW BW BW SW BW BW SW BW BW SW BW BW SW BW BW

FULL COUPLING HALF COUPLING

15 15

40 40

CL.3000 CL.3000

ASME B16.11 ASME B16.11

ASTM A105 ASTM A105

SW SW

FLANGES FLANGE SW FLANGE SO 15 50 40 600 CL.150 CL 150 ASME B16.5 ASME B16.5 ASTM A105 ASTM A105 RF RF

BLIND FLANGE

15

600

CL.150

ASME B16.5

ASTM A105

RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

11 OF 36

Item Type

GASKETS GASKET

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15

600

2 MM/ CL.150

ASME B16.20

NON ASBESTOS FIBRE

TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 600 600 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 40 CL. 150 API 602 / MFG STD BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13%CR BODY - ASTM A105, TRIM - 13%CR BODY - ASTM A216 GR.WCB, TRIM - 13%CR BODY - ASTM A105, TRIM - 13%CR BODY - ASTM A216 GR.WCB, TRIM - 13%CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BB, OS&Y, SW, B 16.11

VLV. GATE

50

600

CL. 150

API 600 / ASME B16.10

BB, OS&Y, RF, B16.5

VLV. GLOBE

15

40

CL. 150

BS EN ISO 15761/ MFR STD

BB, OS&Y, SW, B 16.11

VLV. GLOBE

50

600

CL. 150

BS 1873 / B-16.10

BB, OS&Y, RF, B16.5 WAFER TYPE,SW, B- 16.11 WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF SW, B 16.11

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

600

CL.150

BS 1868/ B-16.10

VLV. BALL

15

40

CL. 800

MFG STD

VLV. BUTTERFLY

50

600

CL. 150

MFG STD

WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

12 OF 36

BRANCH CONNECTION TABLE RUN PIPE, NB 500 450 400 350 300 250 200 150 100 80 15 P 20 P 25 P 40 P BRANCH CONNECTION, NB 50 P 65 P 80 P 100 P 150 P 200 P P P P P P P P P P RT P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P RT P P P P P P P P P P P P 65 50 40 25 20 P P P 15

RT RT RT T

RT RT RT T

RT RT RT T

RT RT RT RT T RT RT RT T RT RT T

RT RT T RT T T T : EQUAL TEE

RT RT RT

RT RT RT RT RT RT RT RT RT T P RT RT T

RT : REDUCING TEE P : STUB JOINT

250 RT RT 300 RT RT 350 RT RT 400 RT RT 450 RT T 500 T

RT RT T RT T T

CODE DESCRIPTION ST SRT T RT RP P H Socket weld Tee Socket welded Reducing Tee Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch Half coupling

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

13 0F 36

PIPING MATERIAL SPECIFICATION :- CS04

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 CARBON STEEL 1.5 NONE

TEMPERATURE AND PRESSURE RATING -29 to 38 100 TEMP0C PRESS Kg/cm2G 19.99 18.5

200 14.7

300 10.4

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 65 TEMP0C PRESS Kg/cm2G 9.5

FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) WASTE WATER (WW)

NOTES

1 2 3 4 5 6 7 8 9 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. WALL THICKNESS CALCULATION FOR SIZES 400NB & ABOVE SHALL BE BASED ON DESIGN CONDITIONS. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX. THESE VALVES HAVE NO FLANGES BUT ARE INSTALLED BETWEEN LINE FLANGES WITH EXTRA LONG BOLTS. SHALL BE USED UPTO 210 DEG C ONLY.

10 SHALL BE USED UPTO 120 DEG C ONLY.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

14 0F 36

Item Type

PIPE PIPE PIPE PIPE PIPE PIPE

Lower Size (mm)

15 50 200 400 500

Upper Size (mm)

40 150 350 450 600

Sch/Thk

Design / Dims Standard

ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M

Material

Description

Note

80 40 20 10 7.92 mm

API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1

PE,SMLS BE,SMLS BE,SMLS BE,ERW BE,ERW

FITTINGS ELBOW 90 ELBOW 90 ELBOW 90 ELBOW 45 ELBOW 45 ELBOW 45 15 50 400 15 50 400 40 350 600 40 350 600 CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W SW BW, R=1.5D BW, R=1.5D SW BW BW

TEE EQUAL TEE EQUAL TEE EQUAL

15 50 400

40 350 600

CL.3000 TO SUIT PIPE TO SUIT PIPE

ASME B16.11 ASME B16.9 ASME B16.9

ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W

SW BW BW

TEE RED TEE RED TEE RED RED. COUPLING

15 50 400 15

40 350 600 40

CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000

ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11

ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105

SW BW BW SW

RED. ECC. RED. ECC. CAP CAP CAP

50 400 15 50 400

350 600 40 350 600

TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE

ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9

ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W

BW BW SW BW BW

FULL COUPLING HALF COUPLING

15 15

40 40

CL.3000 CL.3000

ASME B16.11 ASME B16.11

ASTM A105 ASTM A105

SW SW

FLANGES FLANGE SW FLANGE SO 15 50 40 600 CL.150 CL 150 ASME B-16.5 ASME B-16.5 ASTM A105 ASTM A105 RF RF

BLIND FLANGE

15

600

CL.150

ASME B-16.5

ASTM A105

RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

15 OF 36

Item Type

GASKETS GASKET

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15

600

2 mm / CL.150

ASME B-16.21

NON ASBESTOS FIBER

TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 600 600 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 40 CL. 150 API 602 / MFG STD BODY - ASTM A105, TRIM 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM 13% CR BB, OS&Y, SW, B 16.11

VLV. GATE

50

600

CL. 150

API 600 / ASME B16.10

BB, OS&Y, RF, B16.5

VLV. GLOBE

15

40

CL. 150

BS EN ISO 15761/ MFR STD

BB, OS&Y, SW, B 16.11

VLV. GLOBE

50

600

CL. 150

BS 1873 / B-16.10

BB, OS&Y, RF, B16.5 WAFER TYPE,SW, B- 16.11

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

600

CL.150

API 594

BODY - ASTM A216 GR.WCB, WAFER TYPE, DUEL PLATE, TO SUIT TRIM - 13% CR B 16.5 RF BODY - ASTM A216 GR.WCB, TRIM - 13% CR + EPDM BODY - ASTM A105, TRIM 13% CR WAFER TYPE, TO SUIT B16.5 RF

VLV. BUTTERFLY

50

600

CL. 150

API 609

VLV. BALL

15

40

CL. 800

MFG STD

SW, B 16.11

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

16 OF 36

BRANCH CONNECTION TABLE RUN PIPE, NB 600 15 P 20 P 25 P 40 P 50 P BRANCH CONNECTION, NB 65 P 80 P 100 P 150 P 200 P P P P P P P P P P P 550 500 450 400 350 300 250 200 150 100 P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P RT P P P P P P P P P P P P P P P P P P P P P P P P P P P 80 P P 65 P 50 40 25 20 15

RT RT RT T

RT RT RT T

RT RT RT T

RT RT RT RT T RT RT RT T RT RT T

RT RT T

RT RT T T : EQUAL TEE

RT RT RT

RT RT T RT T T

RT RT RT RT

RT : REDUCING TEE P : STUB JOINT

250 RT RT 300 RT RT 350 RT RT 400 RT RT 450 RT RT 500 RT RT 550 RT T 600 T

RT RT RT RT RT RT RT RT RT T RT RT RT T RT RT T RT T T

CODE DESCRIPTION ST SRT T RT RP P H Socket weld Tee Socket welded Reducing Tee Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch Half coupling

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

17 OF 36

PIPING MATERIAL SPECIFICATION :- CS05

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 CARBON STEEL 1.5 NONE

TEMPERATURE AND PRESSURE RATING -29 to 38 100 TEMP0C PRESS Kg/cm2G 19.99 18.5

200 14.7

300 10.4

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 65 TEMP0C PRESS Kg/cm2G 9.5

FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) COOLING WATER SUPPLY (CWS), COOLING WATER RETURN (CWR), CHILLED WATER SUPPLY (CHWS), CHILLED WATER RETURN (CHWR) PROCESS WATER (PW), FRESH WATER (FW)

NOTES

1 2 3 4 5 6 7 8 9 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. WALL THICKNESS CALCULATION FOR SIZES 400NB & ABOVE SHALL BE BASED ON DESIGN CONDITIONS. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX. MITER BAND SHALL BE USED FOR COOLING WATER SERVICE ONLY. FOR MITER BEND DIMENSIONS REFER ATTACHMENT-2 ATTACHED WITH THIS SPECIFICATION. THESE VALVES HAVE NO FLANGES BUT ARE INSTALLED BETWEEN LINE FLANGES WITH EXTRA LONG BOLTS.

10 SHALL BE USED UPTO 210 DEG C ONLY. 11 SHALL BE USED UPTO 120 DEG C ONLY.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

18 OF 36

Item Type

PIPE PIPE PIPE PIPE PIPE PIPE PIPE PIPE

Lower Size (mm)

15 50 200 400 500 700 1000

Upper Size (mm)

40 150 350 450 600 900 1050

Sch/Thk

Design / Dims Standard

ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M ASME B-36.10M

Material

Description

Note

80 40 20 10 7.92 mm 10 STD

API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1 API 5L GR B PSL1

PE,SMLS BE,SMLS BE,SMLS BE,ERW BE,ERW BE,ERW BE,ERW

FITTINGS ELBOW 90 ELBOW 90 MITER BEND 90 ELBOW 45 ELBOW 45 MITER BEND 45 TEE EQUAL TEE EQUAL TEE EQUAL TEE RED TEE RED TEE RED RED. COUPLING 15 50 400 15 50 400 15 50 400 15 50 400 15 40 350 1050 40 350 1050 40 350 1050 40 350 1050 40 CL.3000 TO SUIT PIPE ATTACHMENT-2 CL.3000 TO SUIT PIPE ATTACHMENT-2 CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 ASME B16.11 ASME B16.9 ASME B 31.3 ASME B16.11 ASME B16.9 ASME B 31.3 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASTM A105 ASTM A234 GR. WPB-W API 5L GR B ASTM A105 ASTM A234 GR. WPB-W API 5L GR B ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 SW BW, R=1.5D BW, R=1.5D, 4- PIECE, 3- CUT SW BW BW, R=1.5D, 3- PIECE, 2- CUT SW BW BW SW BW BW SW

RED. ECC. RED. ECC. CAP CAP CAP

50 400 15 50 400

350 1050 40 350 1050

TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE

ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9

ASTM A234 GR. WPB ASTM A234 GR. WPB-W ASTM A105 ASTM A234 GR. WPB ASTM A234 GR. WPB-W

BW BW SW BW BW

FULL COUPLING HALF COUPLING

15 15

40 40

CL.3000 CL.3000

ASME B16.11 ASME B16.11

ASTM A105 ASTM A105

SW SW

FLANGES FLANGE SW FLANGE SO PLATE FLANGE (SO) 15 50 700 40 600 1050 CL.150 CL 150 CL 150 ASME B-16.5 ASME B-16.5 DIMS TO B16.47 SER B ASTM A105 ASTM A105 ASTM A516 GR B60 RF RF RF

BLIND FLANGE BLIND FLANGE

15 700

600 1050

CL.150 CL.150

ASME B-16.5 DIMS TO B16.47 SER B

ASTM A105 ASTM A516 GR B60

RF RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

19 OF 36

Item Type

GASKETS GASKET

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15

600

2 mm / CL.150

ASME B-16.21

NON ASBESTOS FIBER

TO SUIT ASME B16.5 CL.150 RF FLANGES TO SUIT ASME B16.47 SER B, CL.150 RF FLANGES

GASKET

700

1050

2 mm / CL.150

ASME B-16.21

NON ASBESTOS FIBER

BOLTINGS STUD BOLT NUT 15 15 1050 1050 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 40 CL. 150 API 602 / MFG STD BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR + PTFE BODY - ASTM A216 GR.WCB, TRIM - 13% CR + EPDM BODY - ASTM A216 GR.WCB, TRIM - 13% CR + EPDM BB, OS&Y, SW, B 16.11

VLV. GATE

50

800

CL. 150

API 600 / ASME B16.10

BB, OS&Y, RF, B16.5

VLV. GLOBE

15

40

CL. 150

BS EN ISO 15761/ MFR STD

BB, OS&Y, SW, B 16.11

VLV. GLOBE

50

800

CL. 150

BS 1873 / B-16.10

BB, OS&Y, RF, B16.5 WAFER TYPE,SW, B- 16.11 WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF SW, B 16.11

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

800

CL.150

API 594

VLV. BALL

15

40

CL. 800

BS EN 17292

VLV. BUTTERFLY

50

600

CL. 150

API 609

WAFER TYPE, TO SUIT B16.5 RF

VLV. BUTTERFLY

700

1000

CL. 150

API 609

WAFER TYPE, TO SUIT B16.47 SER A RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

1

Page

20 OF 36

BRANCH CONNECTION TABLE RUN PIPE, NB 750 700 650 15 P 20 P 25 P 40 P 50 P 65 P 80 P 100 P 150 P BRANCH CONNECTION, NB 200 P 250 P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P RT 600 550 500 450 P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P RT 400 350 300 250 200 150 100 P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P P 80 65 P P P 50 40 RT RT 25 RT T 20 T 15

RT RT RT

RT RT RT T

RT RT RT RT T RT RT RT T RT RT T

RT RT RT T RT RT T RT T T T : EQUAL TEE

RT RT

RT RT RT RT RT RT RT RT T RT T T

RT RT

RT : REDUCING TEE P : STUB JOINT

RT RT RT RT RT RT RT RT RT RT RT RT RT RT RT T RT RT T RT T T

300 RT RT RT RT 350 RT RT RT RT 400 RT RT RT RT 450 RT RT RT RT 500 RT RT RT RT 550 RT RT RT RT 600 RT RT RT T 650 RT RT T 700 RT T 750 T

CODE DESCRIPTION ST SRT T RT RP P H Socket weld Tee Socket welded Reducing Tee Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch Half coupling

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

21 OF 36

PIPING MATERIAL SPECIFICATION :- CS06

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 CARBON STEEL- GALVANISED 0.0 GALVANISED

TEMPERATURE AND PRESSURE RATING -29 to 38 100 TEMP0C PRESS Kg/cm2G 19.99 18.5 FOR 15 MM THROUGH 100 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING TEMP0C PRESS Kg/cm2G FOR NPS - AND ABOVE SIZE

SERVICE

1) INSTRUMENT AIR (IA), POTABLE WATER (PO), PROCESS AIR (SA), YEAST AIR (YA)

NOTES

1 2 3 4 5 6 7 8 SCREWED TYPE CAP/PLUG SHALL BE USED ONLY FOR THE OUTLET SIDE OF VENT & DRAIN VALVES. UPTO 204 DEG C, THREADED JOINTS SHALL BE MADE WITH 1" WIDTH PTFE JOINING TAPE SURFACES WHERE GALVANISING HAS BEEN DAMAGED SHALL BE WIRE BRUSHED AND COLD GALVANISED WITH ZINC COATING COMPOUND. GALVANISATION SHALL BE HOT DIPPED AS PER ASTM A153. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

22 OF 36

Item Type

PIPE PIPE PIPE

Lower Size (mm)

15 50

Upper Size (mm)

40 100

Sch/Thk

Design / Dims Standard

ASME B36.10M ASME B36.10M

Material

Description

Note

80 40

ASTM A53 GR. B (GALV.) ASTM A53 GR. B (GALV.)

TE TE

FITTINGS ELBOW 90 ELBOW 45 TEE EQUAL TEE RED RED. COUPLING CAP 15 15 15 15 15 15 100 100 100 100 100 100 CL.3000 CL.3000 CL.3000 CL.3000 CL.3000 CL.3000 ASME B16.11 ASME B16.11 ASME B16.11 ASME B16.11 ASME B16.11 ASME B16.11 ASTM A105 (GALV.) ASTM A105 (GALV.) ASTM A105 (GALV.) ASTM A105 (GALV.) ASTM A105 (GALV.) ASTM A105 (GALV.) SCRD SCRD SCRD SCRD SCRD SCRD

FULL COUPLING

15

100

CL.3000

ASME B16.11

ASTM A105 (GALV.)

SCRD

FLANGES FLANGE SCRD 15 100 CL.150 ASME B-16.5 ASTM A105 (GALV.) RF

BLIND FLANGE

15

100

CL.150

ASME B-16.5

ASTM A105 (GALV.)

RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

23 OF 36

Item Type

GASKETS GASKET

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15

100

2 MM / CL.150

ASME B16.21

NON ASBESTOS FIBRE

TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 100 100 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 40 CL. 150 MSS-SP-80 / MFG STD BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A105, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR BODY - ASTM A216 GR.WCB, TRIM - 13% CR + PTFE BODY - ASTM A216 GR.WCB, TRIM - 13% CR + EPDM UB, ISRS, SCRD, B 16.11

VLV. GATE

50

100

CL. 150

API 600 / ASME B16.10

BB, OS&Y, RF, B16.5

VLV. GLOBE

15

40

CL. 150

MSS-SP-80/ MFR STD

UB, ISRS, SCRD, B 16.11

VLV. GLOBE

50

100

CL. 150

BS 1873 / B-16.10

BB, OS&Y, RF, B16.5

VLV.CHECK

15

40

CL. 150

MSS-SP-80/ MFR STD

WAFER TYPE,SCRD, B- 16.11 WAFER TYPE, DUEL PLATE, TO SUIT B 16.5 RF SW, B 16.11

VLV. CHECK

50

100

CL.150

BS 1868/ B-16.10

VLV. BALL

15

40

CL. 800

BS EN 17292

VLV. BUTTERFLY

50

100

CL. 150

API 609

WAFER TYPE, TO SUIT B16.5 RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

24 OF 36

BRANCH PIPE (SIZE IN mm) 15 15 20 25 40 TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT TT 20 25 40 50 80 100

RUN PIPE (SIZE IN mm)

50 80 100

CODE DESCRIPTION TT Threaded Tee Combination of Redusing Tee and reducer/Swage to be used

PIPING MATERIAL SPECIFICATION

PROJECT NO AREA NO DOC. CALSSIFICATION CODE Discipline Code + Seq No. Rev. Page

8455001

009

SP

0005

B0

25 OF 36

PIPING MATERIAL SPECIFICATION :- SS01

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 SS304 (STAINLESS STEEL) 0.0 NONE

TEMPERATURE AND PRESSURE RATING -29 TO 38 50 TEMP0C PRESS Kg/cm2G 19.37 18.66

100 16

150 14.48

200 13.46

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 200 TEMP0C PRESS Kg/cm2G FV / 8 FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) ALCOHOL LIQUID (AL), ALCOHOL VAPOUR (AV), ALCOHOL PRODUCT (AP), PROCESS CONDENSATE (PC), YEAST SLUGE (YS), PROCESS VENT (PV), VENT GAS (VG), ABSOLUTE ALCOHOL LIQUID HOT (AP), CASSAVA SLURRY (CAS), CARBON DIOXIDE (CO2), BIOGAS (BG)

NOTES

1 2 3 4 5 6 7 8 9 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX. SHALL BE USED UPTO 210 DEG C ONLY. WHEREVER REQUIRED BEVELLING TO BE DONE AT SITE AS PER ASME B16.25. THESE VALVES HAVE NO FLANGES BUT ARE INSTALLED BETWEEN LINE FLANGES WITH EXTRA LONG BOLTS.

10 WALL THICKNESS CALCULATION FOR SIZES 400MM & ABOVE SHALL BE BASED ON DESIGN CONDITIONS.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

26 OF 36

Item Type

PIPE PIPE PIPE PIPE

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15 65 250

50 200 800

10S 5S 5S

ASME B36.19M ASME B36.19M ASME B36.19M

ASTM A312 TP 304 ASTM A312 TP 304 ASTM A358 GR 304 CL. 2

BE, WELDED BE, WELDED BE, EFW

FITTINGS ELBOW 90 ELBOW 45 TEE EQUAL TEE RED RED. CONC. RED. ECC. CAP CAP STUB END FULL COUPLING FLANGES FLANGE SO FLANGE LAP JOINT 15 50 40 800 CL.150 CL 150 ASME B16.5 ASME B16.5 ASTM A182 GR F304 ASTM A105 RF RF 15 15 15 15 15 15 15 50 50 15 800 800 800 800 800 800 40 800 800 40 TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A182 GR F304 ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A182 GR F304 BW, R=1.5D BW BW BW BW BW SW BW BW SW

BLIND FLANGE BLIND FLANGE

15 50

40 800

CL.150 CL.150

ASME B16.5 ASME B16.5

ASTM A182 GR F304 ASTM A240 GR 304

RF RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

27 OF 36

Item Type

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

GASKETS GASKET 15 800 2 mm / CL.150 ASME B16.21 NON ASBESTOS FIBER, FLAT RING TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 800 800 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 800 CL. 150 API 602 /API 600 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304+RPTFE BODY - ASTM A351 GR CF8, TRIM - SS304 BB, OS&Y, RF, B 16.5

VLV. GLOBE

15

800

CL. 150

BS EN ISO 15761/ BS 1873

BB, OS&Y, RF, B 16.5 BC,PISTON LIFT,RF, B- 16.5 WAFER TYPE, DUEL PLATE, TO SUIT B16.5 RF REDUCED BORE, RF, B16.5 WAFER TYPE, DUEL PLATE, TO SUIT B16.5 RF

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

800

CL.150

API 594

VLV. BALL

15

40

CL. 800

BS EN 17292

VLV. BUTTERFLY

50

800

CL. 150

API 609

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

28OF 36

BRANCH PIPE (SIZE IN mm) 15 15 20 25 40 T RT RT RT P P P P P P P P P P P T RT T T RT RT P P P P P P P P P T RT T T RT RT RT P P P P P T RT RT RT RT RT P P T RT RT RT RT RT RT T RT RT RT RT RT T RT RT RT RT T RT T T RT T 20 25 40 50 80 100 150 200 250 300 350 400 450 500

RT RT RT RT P P P P P P P P P P P P P P P P P P P P

RUN PIPE (SIZE IN mm)

50 80 100 150 200 250 300 350 400 450 500

RT RT P P P P P P P P RT P P P P P P P

RT RT RT RT

CODE DESCRIPTION T RT RP P Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

29 OF 36

PIPING MATERIAL SPECIFICATION :- SS02

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 SS304 (STAINLESS STEEL) 0.0 NONE

TEMPERATURE AND PRESSURE RATING -29 TO 38 50 TEMP0C PRESS Kg/cm2G 19.37 18.66

100 16

150 14.48

200 13.46

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 200 TEMP0C PRESS Kg/cm2G FV / 8 FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) 98% SULPHURIC ACID (CA), 50% NAOH SOLUTION(CS), DEFOAMING OIL (DO), UREA SOLUTION (UA),GLUCO AMYLASE (GA), LIQUID AMMONIA (LA), ALFA AMYLASE (AA),YEAST AIR

NOTES

1 2 3 4 5 6 7 8 9 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX. SHALL BE USED UPTO 210 DEG C ONLY. WHEREVER REQUIRED BEVELLING TO BE DONE AT SITE AS PER ASME B16.25. THESE VALVES HAVE NO FLANGES BUT ARE INSTALLED BETWEEN LINE FLANGES WITH EXTRA LONG BOLTS.

10 WALL THICKNESS CALCULATION FOR SIZES 400MM & ABOVE SHALL BE BASED ON DESIGN CONDITIONS.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

30 OF 36

Item Type

PIPE PIPE PIPE PIPE

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15 65 250

50 200 800

10S 5S 5S

ASME B36.19M ASME B36.19M ASME B36.19M

ASTM A312 TP 304 ASTM A312 TP 304 ASTM A358 GR 304 CL. 2

BE, WELDED BE, WELDED BE, EFW

FITTINGS ELBOW 90 ELBOW 45 TEE EQUAL TEE RED RED. CONC. RED. ECC. CAP CAP STUB END FULL COUPLING FLANGES FLANGE SO FLANGE LAP JOINT 15 50 40 800 CL.150 CL 150 ASME B16.5 ASME B16.5 ASTM A182 GR F304 ASTM A105 RF RF 15 15 15 15 15 15 15 50 50 15 800 800 800 800 800 800 40 800 800 40 TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A182 GR F304 ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A182 GR F304 BW, R=1.5D BW BW BW BW BW SW BW BW SW

BLIND FLANGE BLIND FLANGE

15 50

40 800

CL.150 CL.150

ASME B16.5 ASME B16.5

ASTM A182 GR F304 ASTM A240 GR 304

RF RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

31 OF 36

Item Type

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

GASKETS GASKET 15 800 2 mm / CL.150 ASME B16.21 NON ASBESTOS FIBER, FLAT RING TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 800 800 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 800 CL. 150 API 602 /API 600 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304+RPTFE BODY - ASTM A351 GR CF8, TRIM - SS304 BB, OS&Y, RF, B 16.5

VLV. GLOBE

15

800

CL. 150

BS EN ISO 15761/ BS 1873

BB, OS&Y, RF, B 16.5 BC,PISTON LIFT,RF, B- 16.5 WAFER TYPE, DUEL PLATE, TO SUIT B16.5 RF REDUCED BORE, RF, B16.5 WAFER TYPE, DUEL PLATE, TO SUIT B16.5 RF

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

800

CL.150

API 594

VLV. BALL

15

40

CL. 800

BS EN 17292

VLV. BUTTERFLY

50

800

CL. 150

API 609

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

32 OF 36

BRANCH PIPE (SIZE IN mm) 15 15 20 25 40 T RT RT RT P P P P P P P P P P P T RT T T RT RT P P P P P P P P P T RT T T RT RT RT P P P P P T RT RT RT RT RT P P T RT RT RT RT RT RT T RT RT RT RT RT T RT RT RT RT T RT T T RT T 20 25 40 50 80 100 150 200 250 300 350 400 450 500

RT RT RT RT P P P P P P P P P P P P P P P P P P P P

RUN PIPE (SIZE IN mm)

50 80 100 150 200 250 300 350 400 450 500

RT RT P P P P P P P P RT P P P P P P P

RT RT RT RT

CODE DESCRIPTION T RT RP P Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

33 0F 36

PIPING MATERIAL SPECIFICATION :- SS03

RATING BASE MATERIAL CORROSION ALLOWANCE (MM) SPECIAL REQUIREMENT

: : : : 150 SS304 (STAINLESS STEEL) 0.0 NONE

TEMPERATURE AND PRESSURE RATING -29 TO 38 50 TEMP0C PRESS Kg/cm2G 19.37 18.66

100 16

150 14.48

200 13.46

FOR 15 MM THROUGH 350 MM (FULL FLANGE RATINGS AS PER ASME B16.5) TEMPERATURE AND PRESSURE RATING 200 TEMP0C PRESS Kg/cm2G 8 FOR NPS 400 MM AND ABOVE SIZE

SERVICE

1) SPENT WASH (SP), WASTE WATER (WW), DM WATER (DW), MASH (MA), SPENT LEESE (LS)

NOTES

1 2 3 4 5 6 7 8 9 WALL THICKNESS FOR BUTTWELDING SHALL BE EQUAL OR GREATER THAN THE NOMINAL WALL THICKNESS OF CONNECTED PIPE. TO BE USED ONLY TO MATCH CLASS 300 RATED FLANGE CONNECTION AT CONTROL VALVE AND SPECIAL EQUIPMENTS. PISTON LIFT CHECK VALVES SHALL BE USED ONLY IN THE HORIZONTAL POSITION FOR SWING CHECK VALVES BONNET COVER SHALL BE UP WHEN INSTALLED IN THE HORIZONTAL POSITION & WHEN INSTALLED IN THE VERTICAL, FLOW DIRECTION SHALL BE UPWARD. SCREWED FITTINGS SHALL BE THREADED TO NPT AS PER ASME B1.20.1 RADIOGRAPHY FOR JOINTS ON SITE SHALL BE DONE AS PER PIPING SPECIFICATION INDEX. SHALL BE USED UPTO 210 DEG C ONLY. WHEREVER REQUIRED BEVELLING TO BE DONE AT SITE AS PER ASME B16.25. THESE VALVES HAVE NO FLANGES BUT ARE INSTALLED BETWEEN LINE FLANGES WITH EXTRA LONG BOLTS.

10 WALL THICKNESS CALCULATION FOR SIZES 400MM & ABOVE SHALL BE BASED ON DESIGN CONDITIONS.

HOLD

SPECIAL NOTES

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

34 0F 36

Item Type

PIPE PIPE PIPE PIPE

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

15 65 250

50 200 800

10S 5S 5S

ASME B36.19M ASME B36.19M ASME B36.19M

ASTM A312 TP 304 ASTM A312 TP 304 ASTM A358 GR 304 CL. 2

BE, WELDED BE, WELDED BE, EFW

FITTINGS ELBOW 90 ELBOW 45 TEE EQUAL TEE RED RED. CONC. RED. ECC. CAP CAP STUB END FULL COUPLING FLANGES FLANGE SO FLANGE LAP JOINT 15 50 40 800 CL.150 CL 150 ASME B16.5 ASME B16.5 ASTM A182 GR F304 ASTM A105 RF RF 15 15 15 15 15 15 15 50 50 15 800 800 800 800 800 800 40 800 800 40 TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE TO SUIT PIPE CL.3000 TO SUIT PIPE TO SUIT PIPE CL.3000 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.9 ASME B16.11 ASME B16.9 ASME B16.9 ASME B16.11 ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A182 GR F304 ASTM A403 GR WP304-W ASTM A403 GR WP304-W ASTM A182 GR F304 BW, R=1.5D BW BW BW BW BW SW BW BW SW

BLIND FLANGE BLIND FLANGE

15 50

40 800

CL.150 CL.150

ASME B16.5 ASME B16.5

ASTM A182 GR F304 ASTM A240 GR 304

RF RF

PIPING MATERIAL SPECIFICATION

Project No.

8455001

Area No.

009

Doc. Classification code

SP

Discipline Code + Seq No.

0005

Rev.

B0

Page

35 0F 36

Item Type

Lower Size (mm)

Upper Size (mm)

Sch/Thk

Design / Dims Standard

Material

Description

Note

GASKETS GASKET 15 800 2 mm / CL.150 ASME B16.21 NON ASBESTOS FIBER, FLAT RING TO SUIT ASME B16.5 CL.150 RF FLANGES

BOLTINGS STUD BOLT NUT 15 15 800 800 CL.150 CL.150 ASME B18.2.1/ ASME B16.5 ASME B18.2.2 ASTM A193 GR.B7 ASTM A194 GR.2H HEAVY HEX SERIES

VALVES VLV. GATE 15 800 CL. 150 API 602 /API 600 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304 BODY - ASTM A351 GR CF8, TRIM - SS304+RPTFE BODY - ASTM A351 GR CF8, TRIM - SS304 BB, OS&Y, RF, B 16.5

VLV. GLOBE

15

800

CL. 150

BS EN ISO 15761/ BS 1873

BB, OS&Y, RF, B 16.5 BC,PISTON LIFT,RF, B- 16.5 WAFER TYPE, DUEL PLATE, TO SUIT B16.5 RF REDUCED BORE, RF, B16.5 WAFER TYPE, DUEL PLATE, TO SUIT B16.5 RF

VLV.CHECK

15

40

CL. 150

BS EN ISO 15761/ MFR STD

VLV. CHECK

50

800

CL.150

API 594

VLV. BALL

15

40

CL. 800

BS EN 17292

VLV. BUTTERFLY

50

800

CL. 150

API 609

PIPING MATERIAL SPECIFICATION

Project No. Area No. Doc. Classification code Discipline Code + Seq No. Rev. Page

8455001

009

SP

0005

B0

36 0F 36

BRANCH PIPE (SIZE IN mm) 15 15 20 25 40 T RT RT RT P P P P P P P P P P P T RT T T RT RT P P P P P P P P P T RT T T RT RT RT P P P P P T RT RT RT RT RT P P T RT RT RT RT RT RT T RT RT RT RT RT T RT RT RT RT T RT T T RT T 20 25 40 50 80 100 150 200 250 300 350 400 450 500

RT RT RT RT P P P P P P P P P P P P P P P P P P P P

RUN PIPE (SIZE IN mm)

50 80 100 150 200 250 300 350 400 450 500

RT RT P P P P P P P P RT P P P P P P P

RT RT RT RT

CODE DESCRIPTION T RT RP P Butt welded Tee Reducing Butt welded Tee Set on branch with reinforced pad Set on branch

Vous aimerez peut-être aussi

- Tie-In List p1Document1 pageTie-In List p1Andreas Schlager100% (1)

- List Mep Contractors Company Dubai6 PDFDocument10 pagesList Mep Contractors Company Dubai6 PDFsojuiype50% (8)

- 18 DrwingsDocument158 pages18 Drwingspandy1604Pas encore d'évaluation

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epPas encore d'évaluation

- Piping Class DatasheetDocument5 pagesPiping Class Datasheetcyno21100% (2)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryD'EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Piping Mat. Specification PDFDocument1 pagePiping Mat. Specification PDFJaved MohammedPas encore d'évaluation

- Material Requisition For Expansion Joint - Rev1Document4 pagesMaterial Requisition For Expansion Joint - Rev1altipatlarPas encore d'évaluation

- Eot Crane Datasheet-BDocument5 pagesEot Crane Datasheet-Bbashok20Pas encore d'évaluation

- Gate Valve DSDocument5 pagesGate Valve DSkhaireddin100% (1)

- 7-12-0018 Rev 5Document1 page7-12-0018 Rev 5cynidePas encore d'évaluation

- MTO ValveDocument2 pagesMTO ValveAgus MarpaungPas encore d'évaluation

- Piping Material Specification Line Class: Doc No.: MBD-SPM-001Document4 pagesPiping Material Specification Line Class: Doc No.: MBD-SPM-001wenny_tpdPas encore d'évaluation

- 493-J1-005-PE-MTO-0001 Piping MTODocument9 pages493-J1-005-PE-MTO-0001 Piping MTOThiên KhánhPas encore d'évaluation

- Ball Valve Data Sheet: Item Requirement NotesDocument1 pageBall Valve Data Sheet: Item Requirement NotesVivi OktaviantiPas encore d'évaluation

- Material Requisition For Expansion Joint - Rev7Document5 pagesMaterial Requisition For Expansion Joint - Rev7altipatlarPas encore d'évaluation

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoPas encore d'évaluation

- SAMSUNG SEM 3074E Piping Design Manual Pump PipingDocument21 pagesSAMSUNG SEM 3074E Piping Design Manual Pump PipingSlobodan AnticPas encore d'évaluation

- Gen-Spc-Pip-5055 - Rev. BDocument10 pagesGen-Spc-Pip-5055 - Rev. BAHMED AMIRAPas encore d'évaluation

- 7-12-0009 Rev 6Document2 pages7-12-0009 Rev 6cynidePas encore d'évaluation

- API Standard Storage Tank Data SheetDocument3 pagesAPI Standard Storage Tank Data Sheetjuanchocazon78Pas encore d'évaluation

- SL No DRG No DescriptionDocument13 pagesSL No DRG No DescriptionRajesh BhadraPas encore d'évaluation

- Steel Line Blanks & Spacer Dimension TableDocument5 pagesSteel Line Blanks & Spacer Dimension TableSeungmin PaekPas encore d'évaluation

- HFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedDocument77 pagesHFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedVignesh Panchabakesan100% (1)

- Piping and Valve Specifications Rev. A PDFDocument28 pagesPiping and Valve Specifications Rev. A PDFYessine RebaiPas encore d'évaluation

- Foot ValvesDocument4 pagesFoot Valveskingathur26681Pas encore d'évaluation

- PIP PCCIP001 Instrument Piping and Tubing Systems CriteriaDocument7 pagesPIP PCCIP001 Instrument Piping and Tubing Systems CriteriaRija Mobin100% (1)

- Piping MaterialsDocument3 pagesPiping MaterialsMurtadda MohammedPas encore d'évaluation

- 7-13-0001 Rev 6Document1 page7-13-0001 Rev 6cynidePas encore d'évaluation

- Spec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportDocument16 pagesSpec No / Name Unsno/ Numeric Norm Form Class Condition: Material Database ReportRafeek ShaikhPas encore d'évaluation

- PIP - Piping Material Specifications Collection - IHSDocument3 pagesPIP - Piping Material Specifications Collection - IHSmontanovillarroelfabiolalourdePas encore d'évaluation

- ENGINEERING STANDARD - Standard Piping Material SpecificationDocument33 pagesENGINEERING STANDARD - Standard Piping Material SpecificationGanesh Eshwar100% (2)

- Boq PipingDocument1 pageBoq PipingRasool Shaik100% (1)

- Option-2-Piping Support Structural BOQDocument12 pagesOption-2-Piping Support Structural BOQMaqsood Ibn Shaikhul ArfeenPas encore d'évaluation

- HDPE Manual: LamasatDocument51 pagesHDPE Manual: LamasatMalay Kar0% (1)

- Pipe Support IndexDocument4 pagesPipe Support IndexxkokarcaxPas encore d'évaluation

- API 602 Forged Steel Valves - Catalog (R1)Document50 pagesAPI 602 Forged Steel Valves - Catalog (R1)Jose Angel GonzalezPas encore d'évaluation

- Larsen & Toubro Limited: Inspection and Test Plan For TankDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For TankABDELKADER BENABDALLAHPas encore d'évaluation

- Compressor Inlet Piping - Compressed Air Best PracticesDocument10 pagesCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadPas encore d'évaluation

- Piping Material EquivalentsDocument1 pagePiping Material EquivalentspejnorozyPas encore d'évaluation

- Common Materilas For CS PipingDocument2 pagesCommon Materilas For CS PipingValiullah SarpanchPas encore d'évaluation

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisPas encore d'évaluation

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresPas encore d'évaluation

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriPas encore d'évaluation

- MS-6.1 Piping SupportsDocument19 pagesMS-6.1 Piping SupportsLe Thanh HaiPas encore d'évaluation

- Material Selection Chart Based On Operating TemperatureDocument1 pageMaterial Selection Chart Based On Operating TemperatureVIVEK TIWARIPas encore d'évaluation

- Product Manual PM-1239-pt1-cmd2 PDFDocument12 pagesProduct Manual PM-1239-pt1-cmd2 PDFMohd Masoom AliPas encore d'évaluation

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingalberto rodriguezPas encore d'évaluation

- Bom Storage Tank (M.S.)Document8 pagesBom Storage Tank (M.S.)Varun MalhotraPas encore d'évaluation

- Duplex Material PDFDocument4 pagesDuplex Material PDFmengelito almontePas encore d'évaluation

- KITZ Bronze Brass Valves E-101-11Document0 pageKITZ Bronze Brass Valves E-101-11uyab1989Pas encore d'évaluation

- Basic PipingDocument48 pagesBasic Pipingmackoi BalaresPas encore d'évaluation

- 4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsDocument48 pages4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsZain Ali100% (1)

- Specification For Fire Water HydrantDocument5 pagesSpecification For Fire Water HydrantThiru AnanthPas encore d'évaluation

- Brosur Reckat 2017 PDFDocument12 pagesBrosur Reckat 2017 PDFRidwanda HimawanPas encore d'évaluation

- Index of Revisions: Material RequisitionDocument23 pagesIndex of Revisions: Material RequisitionLANKAPALLISURIPas encore d'évaluation

- Xcpipe PDFDocument6 pagesXcpipe PDFalberto rodriguezPas encore d'évaluation

- Navco b2 BrochureDocument16 pagesNavco b2 Brochurejorge28csPas encore d'évaluation

- Piping SpecificationsDocument10 pagesPiping SpecificationssmithallenPas encore d'évaluation

- Piping ComponentsDocument39 pagesPiping Componentsbvenky991100% (1)

- Tech. Spec. For VesselsDocument6 pagesTech. Spec. For Vesselssanjay421Pas encore d'évaluation

- Problems On SFD & BMDDocument43 pagesProblems On SFD & BMDmal201182% (11)

- Data Bank Consult LoadingDocument151 pagesData Bank Consult Loadingravirawat15Pas encore d'évaluation

- Ibr FormsDocument117 pagesIbr Formsshivabtowin3301Pas encore d'évaluation

- Jigs and Fixtures: A Basic LookDocument16 pagesJigs and Fixtures: A Basic Lookravirawat15Pas encore d'évaluation

- IBRDocument37 pagesIBRravirawat15Pas encore d'évaluation

- UsfdaDocument10 pagesUsfdaravirawat15Pas encore d'évaluation

- Caesar II TrainingDocument61 pagesCaesar II TrainingReaderRRGHT86% (7)

- Team BMM Presents! Greetings SMS!Document6 pagesTeam BMM Presents! Greetings SMS!ravirawat15Pas encore d'évaluation

- Jesper Kyd - Flight Over Venice (Assassin's Creed II)Document9 pagesJesper Kyd - Flight Over Venice (Assassin's Creed II)Aldert de VriesPas encore d'évaluation

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDocument6 pagesGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellPas encore d'évaluation

- Ipcrf Core Values 2019 - FinalDocument23 pagesIpcrf Core Values 2019 - FinalFrendelyn p. Gador100% (4)

- Flotech Corporate FlyerDocument6 pagesFlotech Corporate FlyerPrasetyo PNPPas encore d'évaluation

- SK AccBro CI Update - FABIA - Unpriced - SEPT 2023 AW v4Document34 pagesSK AccBro CI Update - FABIA - Unpriced - SEPT 2023 AW v4Vlad TiurinPas encore d'évaluation

- University of Central Punjab: Object Oriented ProgrammingDocument3 pagesUniversity of Central Punjab: Object Oriented ProgrammingChoudhary MuneebPas encore d'évaluation

- Approaches To Curriculum DesigningDocument20 pagesApproaches To Curriculum DesigningCristel CatapangPas encore d'évaluation

- ISO IEC 11801-5 - IT - Generic Cabling For Data CentreDocument63 pagesISO IEC 11801-5 - IT - Generic Cabling For Data Centreshazwanshaiful1Pas encore d'évaluation

- Module 4 - Community Health AssessmentDocument8 pagesModule 4 - Community Health AssessmentSteffi100% (1)

- 3PM - Project Management Method - Sales MessagingDocument5 pages3PM - Project Management Method - Sales Messagingberuang kutubPas encore d'évaluation

- 120-21 TM RF HandbookDocument164 pages120-21 TM RF HandbookbaymanPas encore d'évaluation

- Komatsu Wheel Loaders Wa250pz 5 Shop ManualDocument20 pagesKomatsu Wheel Loaders Wa250pz 5 Shop Manualmarcia100% (48)

- CSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamDocument57 pagesCSE 473 Pattern Recognition: Instructor: Dr. Md. Monirul IslamNadia Anjum100% (1)

- Digital Album On Prominent Social ScientistsDocument10 pagesDigital Album On Prominent Social ScientistsOliver Antony ThomasPas encore d'évaluation

- Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationDocument8 pagesHydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationINOPETRO DO BRASILPas encore d'évaluation

- BSBPMG632 Manage Program RiskDocument221 pagesBSBPMG632 Manage Program RiskgurpreetPas encore d'évaluation

- Plaquette-Costronic en 2020Document2 pagesPlaquette-Costronic en 2020Jun OrtizPas encore d'évaluation

- Audio Level Meter - ProjectDocument4 pagesAudio Level Meter - ProjectMircea PanzariuPas encore d'évaluation

- T. Murugan: Post Applied For Well Testing OperatorDocument5 pagesT. Murugan: Post Applied For Well Testing Operatorjohn MPas encore d'évaluation

- Breuer - Sun & Shadow (Inglés) PDFDocument18 pagesBreuer - Sun & Shadow (Inglés) PDFccorrea74Pas encore d'évaluation

- Ped 5 FTDocument39 pagesPed 5 FTJoy Grace TablantePas encore d'évaluation

- P16mba7 1Document4 pagesP16mba7 1Vishalatchi MPas encore d'évaluation

- Refraction Experiment-PekaDocument8 pagesRefraction Experiment-PekaA. Suhaimi100% (3)

- Robit Forepoling Catalogue ENG 03-2015Document36 pagesRobit Forepoling Catalogue ENG 03-2015Purwadi Eko SaputroPas encore d'évaluation

- 5S For Service Organizations and OfficesDocument28 pages5S For Service Organizations and OfficesSilviaPas encore d'évaluation

- SITRUST Brochure PDFDocument8 pagesSITRUST Brochure PDFÐôùxBébê Ðê MãmäñPas encore d'évaluation

- Avanti II 04-05Document137 pagesAvanti II 04-05Donald SimsPas encore d'évaluation

- 48 Sociology: B.A./B.Sc.: Elective and OptionalDocument4 pages48 Sociology: B.A./B.Sc.: Elective and OptionalMPas encore d'évaluation

- METR3210 Clausius ClapeyronDocument28 pagesMETR3210 Clausius Clapeyronshubhang2392Pas encore d'évaluation