Académique Documents

Professionnel Documents

Culture Documents

DSC TiO2

Transféré par

nguyengiaohungDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DSC TiO2

Transféré par

nguyengiaohungDroits d'auteur :

Formats disponibles

J Therm Anal Calorim (2011) 103:4957 DOI 10.

1007/s10973-010-1072-6

DSC investigation of nanocrystalline TiO2 powder

Cornelia Marinescu Ancuta Sofronia Cristina Rusti Roxana Piticescu Viorel Badilita Eugeniu Vasile Radu Baies Speranta Tanasescu

AICAT2010 Special Chapter Akademiai Kiado, Budapest, Hungary 2010

Abstract The aim of the article is to investigate the inuence of particle size on titanium dioxide phase transformations. Nanocrystalline titanium dioxide powder was obtained through a hydrothermal procedure in an aqueous media at high pressure (in the range 25100 atm) and low temperature (B200 C). The as-prepared samples were characterized with respect to their composition by ICP (inductive coupled plasma), structure and morphology by XRD (X-ray diffraction), and TEM (transmission electron microscopy), thermal behavior by TG (thermogravimetry) coupled with DSC (differential scanning calorimetry). Thermal behavior of nanostructured TiO2 was compared with three commercial TiO2 samples. The sequence of brookiteanataserutile phase transformation in TiO2 samples was investigated. The heat capacity of anatase and rutile in a large temperature range are reported. Keywords TiO2 Nanomaterial Phase transformation Thermal analysis

Introduction TiO2 is a well-known mineral that occurs in three phases: rutile, anatase, and brookite [1], each having different structures. All the three phases have been studied for their high photocatalitic activity, high dielectric, and semi-conducting properties, good biocompatibility, but also due to their potential as catalyst or active supports [28]. These properties are different relative to the TiO2 phases and are closely related to its crystal structure, which makes phase transformation one of the most important issues in practical application of the compound. Rutile is the most common, stable and well known mineral of the three phases. Anatase and brookite both transform exothermally and irreversibly to rutile upon heating [9]. The transformation sequence and phase stability strongly depend on the initial particle sizes of anatase and/or brookite [10]. In terms of crystal structure, rutile, anatase, and brookite have Ti in an octahedral coordination with respect to O. In all these three crystal structures, Ti4? is present as [TiO6] octahedra which share edges and corners. In brookite the octahedra share both edges and corners, forming an orthorhombic structure, while anatase and rutile crystallize in a tetragonal unit cell. The number of edges shared by the [TiO6] octahedra increases from two in rutile to four in anatase. In rutile there are straight chains of octahedra; in anatase zigzag chains [11]. The TiO bond angle of every [TiO6] octahedron is different in the three structures. Therefore, in the phase transformation process from anatase and brookite to rutile a substantial rearrangement of the structure must occur [12, 13]. The temperature of the phase transition anatase to rutile is in the range between 350 and 1175 C [14]. The brookiterutile transition mainly proceeds in the temperature

C. Marinescu (&) A. Sofronia S. Tanasescu Institute of Physical Chemistry Ilie Murgulescu of the Romanian Academy, 060021 Bucharest, Romania e-mail: alcorina@chimz.icf.ro C. Rusti R. Piticescu V. Badilita National Institute of Research and Development for Non-Ferrous and Rare Metals, 077145 Bucharest, Romania E. Vasile METAVResearch and Development, 020011 Bucharest, Romania R. Baies National Research Institute for Electrochemistry and Condensed Matter, 300224 Timisoara, Romania

123

50

C. Marinescu et al.

range 500600 C [15]. Data regarding the brookite anatase phase transition is rather scarce. It has been reported that the transformation to rutile is affected by the initial particle size, the method of preparation of the sample, the presence of impurities, or additives for the stabilization of the certain modication, and by the atmosphere present during the transformation [4, 5, 1622]. There is, however, some ambiguity regarding the sequences of phase transformation of the TiO2 polymorph phases (anatase, brookite, and rutile) during the heating process. In this article, the stability at high temperature of TiO2 anatase with different particle size was investigated. The role of the brookite phase in the anatase to rutile transition is also of interest to this study. The heat capacity of anatase and rutile in a large temperature range are reported.

Experimental Sample preparation Titanium dioxide (TiO2) was synthesized in hydrothermal conditions starting from soluble salts of titanium (purity grade [99%) and ammonium chloride as mineralize agent. The aqueous precursor suspension was placed in a Cortest, USA autoclave and hydrothermally treated at high pressures (in the range 25100 atm) and low temperatures (B200 C). After the reaction was completed, the as resulted powder was ltered, washed several times with distilled water, and dried in an oven at 100 C. Methods and measurements The nanostructured titanium dioxide thus obtained was characterized from the point of view of composition by inductively coupled plasma analysis (ICP; Spectroame equipment) and microstructure by X ray diffraction analysis (XRD Bruker D8 Advance diffractometer endowed with DIFFRACplus BASIC Evaluation Package, version EVA12, 2006 soft and data base ICDD PDF-2 Release 2006). The sample was morphologically examined by transmission electron microscopy in the bright eld (TEMBF), selected area electron diffraction (SAED), and high resolution transmission electron microscopy (HRTEM), using TECNAI F30 G2 equipment, with a linear resolution of 1 A. For the thermal characterization a simultaneous high temperature thermogravimetry (TG) and differential scanning calorimetry (DSC) was employed. Thermal properties (temperature and enthalpies of transformation, heat capacity, and mass change) of the TiO2 samples were measured by a TG-DSC Setaram Setsys Evolution 17

analyzer, in the temperature range from room temperature to 1200 C. Sample mass for simultaneous TG-DSC measurements was cca 20 mg and for heat capacities measurements of about 100 mg. The thermo analyzer calibration was performed using standard metallic substances in the whole temperature range of the experiment, with 5, 10, and 15 C/min heating rates, with the same type of crucible used for experiments (alumina crucibles) and with the same carrier gas (Ar with high purity). The onset melting point temperatures and heats of fusion of 99.99% purity standard metallic materials (In, Sn, Pb, Zn, Al, Ag, and Au), were used for temperature correction and energy calibration. Heat capacities were determined by performing three consecutive experiments in identical conditions, namely the same heating rate (10 C/min), same gas ow, Ar, at a rate of 16 ml/min, Pt crucibles. The method consists in performing three runs with two vessels: the measuring and the reference vessel. The rst run is done with the two empty vessels (blank test), the second run with reference material with a known heat capacity Cp (in our experimentssapphire) and the third run with sample. Each run consist in a ramp between in the initial temperature and the nal temperature, at a constant heating rate of 10 C/min. Experimental heat capacity was determined for two temperature ranges: 300800 and 7501200 C. To calculate peak temperatures, peaks area and heat capacities (CalistoAKTS) instruments software was used.

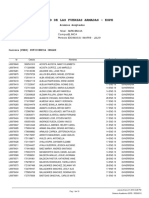

Results and discussion Composition All the samples were investigated for impurities by ICP. Samples have a purity of 99%. Morphological and structural characterization XRD characterization The hydrothermal prepared sample, characterized by X-ray diffraction as a mixture of 88% anatase and 12% brookite (Fig. 1) was compared to commercial TiO2 samples (Table 1). In Fig. 1 is presented the difractogram for a representative S1-A, B sample. Graphical representation of the results by the FPM (Full pattern matching) method consists of: Experimentally measured difractogram (black dotted line; sample);

123

DSC investigation of nanocrystalline TiO2 powder

51

1000

4000

Intensity/cps

Intensity/cps

3000 2000 1000 0

0 20 0 20

S1-A,B S1 -A,B - EVAL

20

30

40 2 /

50

60

30

40

50

60

0

2 /

30 40

S1-A,B - DELTA Anatase (NIST)

50

Brookite (NIST)

60

20

30 S2-A,R S2-A,R - EVAL

40 S2-A,R - DELTA Anatase (NIST)

50 Rutile (NBS)

60

Fig. 1 Graphic representation of the results obtained by FPM method for XRD quantitative phase analysis for S1-A, B sample (anatase (NIST) -03-065-5714 (*) and brookite (NIST) -03-065-2448 (I))

Fig. 2 Graphic representation of the results obtained by FPM method for XRD quantitative phase analysis for S2-A, R sample (Anatase (NIST) -03-065-5714 (*); Rutile (NBS) -00-021-1276 (*))

Table 1 Samples composition and crystallite sizes from X-ray measurements Sample Sample provenience

a

3000

% TiO2 phase composition and crystallite size A 88%: 21.7 nm B 12%: 14.6 nm A 98.2%: 87.7 nm R 1.8%: 91.9 nm A: 74.8 nm R: 106.0 nm

Intensity/cps

2000 1000

S1A, B

Hydrothermal synthesis Commercial Commercial Commercial

0 20 30 40 2 / 20 S3 - A S3 -A - EVAL 30 40 S3 - A - DELTA Anatase (NIST) 50 Rutile (NBS) 60 50 60

S2-A, Ra S3-A S4-R

a

A anatase, B brookite, R rutile

Fig. 3 Graphic representation of the results obtained by FPM method for XRD quantitative phase analysis for S3-A sample (Anatase (NIST) -03-065-5714 (*)

Evaluation difractogram (green; sample-EVAL), obtained by simulation; The diference between the two previous difractograms (orange; sample-DELTA), for evidentiating the simulating quality; Sticks difractograms for compounds that are taken into consideration (identied), according to the PDF references.

Commercially available anatase and rutile mixture (S2-A, R sample), anatase (S3-A), and rutile (S4-R) TiO2 were also characterized for comparison with the hydrothermal synthesized sample (S1-A, B). From X-ray measurements (Figs. 1, 2, 3) the crystallite size of the TiO2 phases were determined (Table 1). Quantitative evaluation and crystallographic characterization of the identied phases was made with the help of the FPM module (contained within the DIFFRACplus BASIC (Bruker AXS) program package). For the S4-R sample a very pronounced preferential increasing of the commercial rutile crystals on [110] direction was observed, for this reason the FMP method

cannot be applied. However, the semi-quantitative composition could be estimated. The criteria used for comparing the simulated difractogram with that measured are the mean reliability RWP: v uP u wi xyobs ycalc 2 i i u RWP u i P 100% t 2 wi xyobs i

i

Other criteria that characterized inevitable discrepancy due to counting statistics R0 is: v uP u wi xyobs i u i R0 u P 2 100% t wi xyobs i

i

in which: yobs intensity in point i from the measured i difractogram, ycalc intensity in point i from the simulated i pictogram, wi mean factor.

123

52 Table 2 Lattice parameters of TiO2 samples Sample TiO2 phase System Space group Z/formula Cell param./A units per cell a b 4 8

C. Marinescu et al.

Cell volume Theoretical Experimental density/g cm-3 density/ g cm-3 [21] 3.90 4.13 3.90 4.27 3.90 4.27 3.88 4.12 3.89 4.25 3.89 4.25

S1-A, B Anatase Brookite S2-A, R Anatase Rutile S3-A S4-R Anatase Rutile

Tetragonal Tetragonal Tetragonal Tetragonal Tetragonal

I41/amd (141)

3.79211 3.79211 9.50566 136.69232 9.18500 5.44700 5.14500 257.40792 3.78508 3.78508 9.51311 136.29271 4.59376 4.59376 2.95850 62.43231 3.78481 3.78481 9.51354 136.27943 4.59395 4.59395 2.95910 62.44996

Orthorhombic Pbca (61)

I41/amd (141) 4 P42/mnm (136) 2 I41/amd (141) 4 P42/mnm (136) 2

The ratio RWP/R0 denes the relative reliability and tends to one for a perfect tting. The relative reliability value for S1-A, B; S2-A, R; and S3-A samples is about 1.67. Lattice parameters of the samples rened by the Rietveld renement method are presented in Table 2. TEM (HRTEM) characterization For morphological characterization of TiO2 powder, small quantities of sample were immersed in ethylic alcohol. The suspension was then homogenized in an ultrasonic bath. Fine particles from the resulted suspension were selected using a copper grid covered with FORMVAR and examined by transmission electron microscopy in the bright eld (TEMBF), selected area electron diffraction (SAED), and high resolution transmission electron microscopy (HRTEM). Electron diffraction image (SAED) in Fig. 5 obtained on a nanoarea of Fig. 4 is typical of a nanocrystalline phase

with randomly oriented small crystallites. Outlined circles correspond to the interplanar distances specied in the left corner of the image Fig. 5. The interplanar distances corresponding crystalline planes visible in Fig. 6 obtained by Fourier transform (Fig. 7) have the following values: 1,2A; 1,3A; 1,5A; 2A; and 2,1A. TEM analysis reveals that the particles are quasi-spheres and are quite uniform in their overall morphology. Thermal analysis Thermal analysis is the study of the relationship between a sample property and its temperature as the sample is heated or cooled in a controlled manner [23]. In this article, thermal analysis refers to differential scanning calorimetry (DSC) and thermogravimetry (TG). Differential scanning calorimetry is a technique used to determine the heat ow in and out of a sample when subjected to a temperature pro-

Fig. 4 Bright eld TEM image. Aggregate of nanoparticles

Fig. 5 Electron diffraction image (SAED) associated with the area of Fig. 4

123

DSC investigation of nanocrystalline TiO2 powder

53

gram in a controlled atmosphere. When heating or cooling a sample, thermal changes in a material are accompanied by an exchange of heat; hence the temperature of these transformations and heat ow can be determined. Thermogravimetry follows the mass changes in a sample subjected to thermal treatment. A thermogravimetric analysis can be recorded as a change in sample mass with temperature and time, and with pressure and gas composition. These techniques are widely employed to provide qualitative, semi-quantitative, and in some cases quantitative measurements of the energetic evolution materials on heating or cooling over a considerable temperature range [24].

Brookite transformation study DSC measurements of the S1-A, B sample were done with three heating rates of 5, 10, and 15 C/min (Fig. 8). To investigate the sequences of phase transformation of the S1-A, B sample (mixture of 88% anatase and 12% brookite) during the heating process at the 10 C/min heating rate in a large temperature range (401100 C), the X-ray measurements have been performed at different stages corresponding to thermal events observed on the DSC curve. In Fig. 8 the following aspects can be revealed: Up to 600 C an exothermic effect without a clear peak can be observed; it corresponds to the decrease in the mass fraction of brookite content without the formation of rutile phase, obtaining a mixture of 96.13% anatase and 3.87% brookite with crystallite size of 24 and 16 nm, respectively. At this stage, the cell parameters of brookite (a = 9.17917, b = 5.42026, c = 5.13299) remain almost unchanged, while those of anatase, both a and c (a = 3.77906, c = 9.48536) slowly decrease, therefore the growth rates in all the crystallographic planes are similar. However, there is no detectable amount of rutile phase in the sample. Up to 600 C, 33.33% of the initial phase of brookite transformed into anatase at a low conversion rate, without any clear peak associated with transformation on the DSC curve being detected. At the same time with brookite transformation, particles growth takes place. The growth rates of the particles of these two phases are almost equal at T \ 600 C, anatase particle growing by 2.3 nm and brookite particle by 1.4 nm. On heating at T [ 600 C, the growth rate of the particles increases and the remaining brookite phase transforms to anatase (Fig. 9) and subsequently anatase to rutile (Fig. 11).

Fig. 6 HRTEM image of TiO2 nanoparticles at high magnication

5 C/min 10 C/min 15 C/min

Heat flow/mW

400

600

800

1000

1200

T/K

Fig. 7 Fast Fourier transform (FFT) corresponding Fig. 6

Fig. 8 Heat ow curves of the S1-A, B sample at 5, 10, and 15 C/min heating rates

123

54

C. Marinescu et al.

Above 600 C the brookiteanatase transformation take place in a narrow temperature range between 600 and 725 C with a maximum rate at the 680 C, visible transformation on heat capacity curve (Fig. 9). The brookiteanatase transition is completed at 800 C when single phase anatase with a crystallite size of 69.7 nm is observed in the X-ray diffraction pattern. Bokhimia and Pedraza [25] pointed out that the transformation of brookite and anatase phases into rutile occurs above 800 C, in good agreement with our experimental results.

The inuence of the heating rate on the phase transformation behavior was also a part of this study. The brookiteanatase transformation is shifted to a higher temperature range when a slow heating rate of 5 C/min is used (Fig. 8). Zhang and Baneld [16, 17] pointed out that the stability of TiO2 polymorphs is crystallite size dependent: anatase is most stable at \11 nm, optimum brookite crystallite size being between 11 and 35 nm, while rutile is favored at sizes greater than 35 nm. Zhang and Baneld [16] also predicted reversible transformations between anatase and brookite in certain size domains (brookite size \11 nm and anatase size [11 nm) where brookite and anatase are metastable. The hydrothermal synthesized TiO2 (S1-A, B sample) has crystallite size of brookite phase of 14.6 nm in the brookite stable region; also, the brookite phase transformation is not reversible, no thermal effect on the DSC cooling curve was observed. As a consequence of the thermodynamic stability and the activation energy dependence of the crystallite size [2628], the brookite phase of S1-A, B sample is thermodynamically stable and the phase transition does not begin when heating until the critical particle size and the activation energy are reached. Xisheng Ye et al. [29] pointed out that the grain growth

rate is small in the range below 780 C. For the heating rate of 5 C/min, in the temperature range of rutile transition, 8001000 C, it is likely that the structural phase transitions brookite to anatase and anatase to rutile co-exist. The lowest transition temperature to rutile and the greatest transition enthalpy obtained for the heating rate of 5 C/ min support the above observation (Table 3). The thermal effect of the irreversible transformation to rutile is more evident with the increasing of heating rate and the transition point is shifted to higher temperatures (Fig. 8). Table 3 presents the rutile transformation peak temperatures, Tp, and transformation energies at different heating rates for S1-A, B sample. The detection of a small fraction of brookite and no rutile phase at 600 C and only anatase phase at 800 C mean that the sequence of the phase transitions of the mixture of 21.7 nm anatase (88%) and 14.6 nm brookite (12%) is: brookite ? anatase ? rutile. Anatase transformation study As the presence of TiO2 anatase or rutile phases is critical for the properties of the materials used in applications [28], many researchers tried to understand and control the anataserutile transition. Crystallite size is one of the most important factors to control the phase stability of TiO2 polymorph phases [16]. In Fig. 10 the DSC curve of the hydrothermal prepared (S1-A, B) sample together the DSC curves of the S2-A, R sample (a mixture of anatase and 1.8% rutile), the S3-A sample (a singular anatase phase), and the S4-R sample (a single rutile phase), respectively, are shown for comparison. The corresponding crystallite sizes are those presented in the Table 4. The presence of 12% brookite in the S1-A, B sample accelerates the transition to rutile, and in the same time, anatase with the 21.7 nm crystallite size not in it stability domain will also contribute at a lower transition temperature. The existence of brookite, therefore, is responsible for the enhancement of the anatase to rutile transition. However, the variation in the transition point is more evident from the heat capacity curves (Fig. 11). To better reect the phase transformation to rutile, heat capacity

1.4

Cp/J g1 K1

1.2

1.0

0.8

S1- A, B S2- A, R S3- A S4- R

Table 3 The rutile transformation peak temperatures, Tp, and transformation energies of S1-A, B sample at different heating rates Heating rate/ degree min-1

800

0.6 700 900 1000

Tpeak/C 929 963 969

Transformation energy/kJ mol-1 -0.7147854 -0.6332075 -0.4950604

T/K

5 10 15

Fig. 9 Heat capacity curves of TiO2 samples in the temperature range of 350800 C

123

DSC investigation of nanocrystalline TiO2 powder

20

1.2

55

15

Cp/J g1 K1

S1- A, B S2- A, R S3- A S4- R

0.8 0.4 0.0 0.4

Heat flow/mW

10

5

0.8 S1- A, B S2- A, R S3- A S4- R 1100 1200 1300 1400

1.2

400

600

800

1000

1200

T/K

T/K

Fig. 10 DSC curves of TiO2 samples at heating rate of 10 C/min

Fig. 11 Comparative Cp curves of TiO2 samples at the heating rate of 10 C/min

Table 4 Comparative rutile transformation peak temperatures, Tp at heating rate of 10/min, determinate from Cp curves Sample S1-A, B S2-A, R S3-A Tp/C 963 1040 1027 Initial crystallite size/nm A: 21.7 B: 14.6 A: 87.7 R: 91.9 A: 74.8 [1 lm 166 nm Final rutile crystallite size [1 lm

Cp J/mol K 2:25140 103 13:18299 T 0:0314 T 2 3:67965 105 T 3 2:14453 108 T 4 5:0075 1012 T 5 R2 = 0.99606 Rutile in the temperature range of 6231050 K: Cp J/mol K) 1:42549 103 7:6724 T 0:0157 T 2 1:35781 105 T 3 4:22932 109 T 4 2 R = 0.99768 Rutile in the temperature range of 10671443 K: Cp J/mol K) 1:36879 103 3:74221 T 0:00375 T 2 1:35955 106 T 3 8:62422 1011 T 4 R2 = 0.99946 Water desorption Taking into account the purity grade of the samples (higher than 99%), the major component associated with the mass loss of the sample is water. The enthalpy difference between a nanocrystalline sample and bulk rutile arises from polymorphism, surface energy, and the presence of water [17]. At high temperatures, TiO2 nanoparticles dehydrate and coarsen, the nal stable phase upon grain growth being always rutile. The overall process (phase transformation, water loss, and coarsening) is irreversible. The TiO2 samples contain adsorbed water which has the properties of bulk liquid water and a small fraction bound very tightly, probably in the form of hydroxyl groups [30]. Thermogravimetric analysis of TiO2 powders at the heating rate of 10 C/min (Fig. 12) shows that mass loss occurs mainly up to 600 C.

measurements were performed in the temperature range of 7501200 C. The anatase-to-rutile transformation in nanocrystalline materials is considerate rate limited by rutile nucleation, as opposed to rutile growth [28]. This could explain the higher transition temperature of the S2-A, R sample which contains a small percentage 1.8% of rutile comparative to anatase single phase sample (S3-A) (Table 4). Since the crystallite sizes of the two anatase phases of the above samples are near each other, the result would be only a small variance in the temperatures of anatase to rutile transition (DT % 13 C). Note also that the anatase to rutile transformation occurs with a strong thermal effect, in a wide range of temperature from 800 to 1150 C, which leads to the conclusion that the anatase to rutile transition takes place along with the growth of the already formed rutile particles. The temperature dependences of heat capacity for anatase single phase S3-A and rutile single phase S4-R samples was determined. Cp experimental data at high temperatures are not reported in the literature. Anatase in the temperature range of 6231050 K:

123

56

C. Marinescu et al.

The TG curve of the S1-A, B sample shows that dehydration occurs over a wide range of temperature in two not well dened stages, with maximum rates of desorption of water at 98 and 247 C. The latter two temperatures are clearly observed on dTG curve (inset of Fig. 12). The thermal event at 98 C can be correlated to the DSC endothermic peak which was observed near the same temperature. However, for the greatest mass loss that maximizes at 247 C, there is a sequence of thermal effects corresponding to the DSC curve in the temperature range of 150400 C. The endothermic peak occurring below 100 C corresponds to the weakly adsorbed water removal (0.006 mol of 0.028 mol total water content) and the 1.509% mass loss between 150 and 400 C being attributed to the decomposition of the hydroxyl group; the OH groups were eliminated as water and the TiOTi bond was produced [31]. The mass loss that occurs below 400 C corresponds to desorption of physisorbed water (85% of total mass loss) and the mass loss that occurs above 400 C conrm the existence of some amount of chemically bound water. From thermogravimetric measurements the content of water of TiO2 samples has been calculated. The sample

mass was normalized to obtain 1 mol of sample and x moles of water (Table 5). It can be observed that the smallest sample size of particle, having higher surface energy, can adsorb a larger water quantity to the surface.

Conclusions The thermal behavior of nanocrystalline TiO2 powders using thermogravimetry and differential scanning calorimetry analysis in the temperature range from room temperature to 1200 C has been studied. Experimental results have shown that the anatase to rutile phase transformation depends not only on primary crystallite size, but also on the presence of the brookite phase and adsorbed water. The presence of the brookite phase accelerates the anatase to rutile transformation. Water desorbs over a wide range of temperature (T B 600 C), conrming the existence of some amount of chemically bound water. The brookiteanataserutile transformations are thermodynamically favorable in the large temperature range of 2001150 C. The obtained results will be further used for preparing single phase nanostructured anatase powders in hydrothermal conditions for save energy applications.

Acknowledgements The nancial support of the National Program IIIDEAS no. 50/2007-2010 Grant and National Program IIPartnership ctr 72-184 are acknowledged.

100

Mass loss/%

99

S1- A, B S2- A, R S3- A S4- R

References

1. Wells AF. Structural inorganic chemistry. 4th ed. Oxford: Clarendon Press; 1975. 2. Dagan G, Tomkiewicz M. Titanium dioxide aerogels for photocatalytic decontamination of aquatic environments. J Phys Chem. 1993;97:126515. 3. Wei ZB, Yan W, Zhang H, Ren T, Xin Q, Li Z. Hydrodesulfurization activity of NiMo/TiO2#Al2O3 catalysts. Appl Catal A Gen. 1998;167:3948. 4. Zhang HZ, Baneld JF. Thermodynamic analysis of phase stability of nanocrystalline titania. J Mater Chem. 1998;8:20736. 5. Gribb AA, Baneld JF. Particle size effects on transformation kinetics and phase stability in nanocrystalline TiO 2. Am Mineral. 1997;82:71728. 6. Matos BR, Arico EM, Linardi M, Ferlauto AS, Santiago EI, et al. Thermal properties of NaonTiO2 composite electrolytes for PEM fuel cell. J Therm Anal Calorim. 2009;97(2):5914. 7. Madarasz J, Braileanu A, Cris an M, Raileanu M, Pokol G. Evolved gas analysis of amorphous precursors for S-doped TiO2 by TG-FTIR and TG/DTA-MS.Part 3. Candidate from thiourea and Ti(IV)-ethoxide. J Therm Anal Calorim. 2009;97(1):26571. 8. Cris an M, Braileanu A, Cris an D, Raileanu M, Dragan N, et al. Thermal behaviour study of some sol-gel TiO2 based materials. J Therm Anal Calorim. 2008;92(1):713. 9. Greenwood, Norman N, Earnshaw A. Chemistry of the elements. Oxford: Pergamon; 1984.

98

S1 - A,B

0.05 dTG/mg min1

97 400 600 800 1000 1200

T/K

Fig. 12 TG curves of TiO2 sample

Table 5 Moles of water corresponding to 1 mol of TiO2 samples Sample TiO2xH2O S1-A, B S2-A, R S3-A S4-R Crystallite size/nm A: 21.7 B: 14.6 A: 87.7 R: 91.9 A: 74.8 R: 106 0.341 0.110 0.01520 0.00478 0.202 0.00890 Weight loss % 2.455 x/moles of water 0.11164

123

DSC investigation of nanocrystalline TiO2 powder 10. Riedel R, Wei I, editors. Ceramics science and technology: properties, vol. 2. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA; 2010. 11. Heald EF, Weiss CW. Kinetics and mechanism of the anatase/ rutile transformation, as catalyzed by ferric oxide and reducing conditions. Am Mineral. 1972;57:1023. 12. Wang Z, Deng X. Al2O3 composite agent effects on phase transformation of nanometer TiO2 powder. Mater Sci Eng B. 2007;140:10913. 13. Huberty J, Xu H. Kinetics study on phase transformation from titania polymorph brookite to rutile. J Solid State Chem. 2008;181:50814. 14. Dabler A, Feltz A, Jung J, Ludwig W, Kaisersberger E. Characterization of rutile and anatase powders by thermal analysis. J Therm Anal Calorim. 1988;33:8039. 15. Li J-G, Ishigaki T. Brookite ? rutile phase transformation of TiO2 studied with monodispersed particles. Acta Mater. 2004;52:514350. 16. Zhang HZ, Baneld JF. Understanding polymorphic phase transformation behavior during growth of nanocrystalline aggregates: insights from Tio2. J Phys Chem B. 2000;104:34817. 17. Ranade MR, Navrotsky A, Zhang HZ, Baneld HZ, Elder SH, Zaban A, Borse PH, Kulkarni SK, Doran GS, Whiteld HJ. Energetics of nanocrystalline TiO2. Proc Natl Acad Sci USA. 2002;99(2):647681. 18. Yoganarasimhan SR, Rao CNR. Mechanism of crystal structure transformations. Part 3.factors affecting the anatase-rutile transformation. Trans Faraday Soc. 1962;58:157989. 19. Shannon RD, Pask JA. Kinetics of the anatase-rutile transformation. J Am Ceram Soc. 1965;48:3918. 20. Gennari FC, Pasquevich DM. Kinetics of the anataserutile transformation in TiO2 in the presence of Fe2O3. J Mater Chem. 1998;33:15718. 21. Arbiol J, Cerda J, Dezanneau G, Cirera A, Peiro F, Cornet A, Morante JR. Effects of Nb doping on the TiO2 anatase-to-rutile phase transition. J Appl Phys. 2002;92:85361.

57 22. Burns A, Hayes G, Li W, Hirvonen J, Demaree JD, Shah SI. Neodymium ion dopant effects on the phase transformation in solgel derived titania nanostructures. Mater Sci Eng B. 2004;111:1505. 23. Gallagher PK. Handbook of thermal analysis and calorimetry vol. 5: Recent advances techniques and applications. In: Brown ME, Gallagher PK, editors; 2008. 24. Navrotsky A. Thermochemistry of nanomaterials. Rev Miner Geochem. 2001;44:73103. 25. Bokhimia X, Pedrazab F. Characterization of brookite and a new corundum-like titania phase synthesized under hydrothermal conditions. J Solid State Chem. 2004;177:245663. 26. Zhang HZ, Baneld JF. Phase transformation of nanocrystalline anatase-to-rutile via combined interface and surface nucleation. J Mater Res. 2000;15:43748. 27. Tanaka K, Iwama S, Mihama K. Crystallization of nanometer sized amorphous sb particles formed by owing gas evaporation technique. Jpn J Appl Phys. 1998;37:L66971. 28. Celine Perego, Renaud Revel, Olivier Durupthy, Sophie Cassaignon, Jean-Pierre Jolivet. Thermal stability of TiO2-anatase: impact of nanoparticles morphology on kinetic phase transformation. Solid State Sci. 2010;12:98995. 29. Ye X, Sha J, Jiao Z, Zhang L. Thermoanalytical characteristic of nanocrystalline brookite-based titanium dioxide. NanoStruct Mater. 1997;8(7):91927. 30. Madras G, McCoy BJ, Navrotsky A. Kinetic model for TiO2 polymorphic transformation from anatase to rutile. J Am Ceram Soc. 2007;90:2505. 31. Nakayama N, Hayashi T. Preparation of TiO2 nanoparticles surface-modied by both carboxylic acid and amine: Dispersibility and stabilization in organic solvents. Colloids Surf A Physicochem Eng Asp. 2008;317:54350.

123

Vous aimerez peut-être aussi

- Acetaldol MsdsDocument6 pagesAcetaldol Msdsdlr1233Pas encore d'évaluation

- Aspen Physical Property System Physical Property Methods - 2020Document322 pagesAspen Physical Property System Physical Property Methods - 2020Ongki PurwantaPas encore d'évaluation

- Chem 73 PS2 2017 PDFDocument2 pagesChem 73 PS2 2017 PDFImee Kassandra Estomo CachoPas encore d'évaluation

- CN Total New 3837mthdDocument36 pagesCN Total New 3837mthdYean CarlosPas encore d'évaluation

- The Acid Base Titration of A Very Weak Acid: Boric Acid: M. Celeste C. Azevedo and Ana M. V. CavaleiroDocument4 pagesThe Acid Base Titration of A Very Weak Acid: Boric Acid: M. Celeste C. Azevedo and Ana M. V. CavaleiroAitor PastorPas encore d'évaluation

- P - Block Elements 12th (All)Document63 pagesP - Block Elements 12th (All)Kaveeth Ariyha0% (1)

- Iso 731 1 1977Document4 pagesIso 731 1 1977Tahir Nizam100% (1)

- Cryoscopic Constants For Calculation of Freezing Point DepressionDocument1 pageCryoscopic Constants For Calculation of Freezing Point DepressionantonioPas encore d'évaluation

- Prof. M. R. Riazi (FULL CV) : LAST UPDATED ON:: December 25, 2012Document21 pagesProf. M. R. Riazi (FULL CV) : LAST UPDATED ON:: December 25, 2012JamesPas encore d'évaluation

- Tetronic 904 Block Copolymer Surfactant: Technical BulletinDocument1 pageTetronic 904 Block Copolymer Surfactant: Technical BulletinCarmen Linares100% (1)

- Metal Forming Fundamentals and ApplicationsDocument3 pagesMetal Forming Fundamentals and ApplicationsDANIEL DIAZPas encore d'évaluation

- Quiz Show FileDocument18 pagesQuiz Show FileLeaniel SilvaPas encore d'évaluation

- Complejos OrganometálicosDocument14 pagesComplejos OrganometálicosJuan Felipe SanabriaPas encore d'évaluation

- A Modified Uronic Acid Carbazole Reaction Bitter and Muir 1962Document5 pagesA Modified Uronic Acid Carbazole Reaction Bitter and Muir 1962Levon AntonyanPas encore d'évaluation

- Thermal Decomposition Study by DTA-TG-MS of III Acetylacetonate Used As Ceria Thin Film PrecursorDocument5 pagesThermal Decomposition Study by DTA-TG-MS of III Acetylacetonate Used As Ceria Thin Film PrecursorpicuriciPas encore d'évaluation

- A New Simulation Method For Equilibrium Stage Processes PDFDocument4 pagesA New Simulation Method For Equilibrium Stage Processes PDFmurdanetap957Pas encore d'évaluation

- Nonlinear ProgrammingDocument4 pagesNonlinear ProgrammingsolomonPas encore d'évaluation

- Chromatography: The Separation Technique of The 20th CenturyDocument11 pagesChromatography: The Separation Technique of The 20th CenturyAnonymous qOxE6C7kPas encore d'évaluation

- Lab 10 Coefficient of Restitution-SU2017-1Document3 pagesLab 10 Coefficient of Restitution-SU2017-1rayPas encore d'évaluation

- Composición Química de Aleaciones de CobreDocument71 pagesComposición Química de Aleaciones de Cobreitiz2013100% (1)

- ChE 140 1.01 IntroductionDocument30 pagesChE 140 1.01 IntroductionJelor GallegoPas encore d'évaluation

- Manual Phmetro Altronix PDFDocument22 pagesManual Phmetro Altronix PDFMatias OliveraPas encore d'évaluation

- Campus El IncaDocument10 pagesCampus El IncaEddy FernandoPas encore d'évaluation

- TD Quintolubric 888 68 PDFDocument2 pagesTD Quintolubric 888 68 PDFaneesh awasthiPas encore d'évaluation

- Zinc FinalDocument12 pagesZinc Finalamanuel tafesePas encore d'évaluation

- Full Cream Milk Powder SDS enDocument6 pagesFull Cream Milk Powder SDS enNguyễn Thị Diễm MiPas encore d'évaluation

- 1 Liquid-Liquid Equilibrium For The Ternary System Methanol + Acrylonitrile + WaterDocument10 pages1 Liquid-Liquid Equilibrium For The Ternary System Methanol + Acrylonitrile + WatersandraesiqPas encore d'évaluation

- Manual Rotor PDF SK 10Document29 pagesManual Rotor PDF SK 10Compras FQ AnaltecPas encore d'évaluation

- H-068 Thermo. Titr. Application Note No.: Title: Determination of Ferric Ion by Iodometric TitrationDocument3 pagesH-068 Thermo. Titr. Application Note No.: Title: Determination of Ferric Ion by Iodometric TitrationEko Setyo BudiPas encore d'évaluation

- A Novel Reverse Flow Strategy For Ethylbenzene Dehydrogenation in A Packed-Bed ReactorDocument17 pagesA Novel Reverse Flow Strategy For Ethylbenzene Dehydrogenation in A Packed-Bed ReactorMuhammad Akbar FahleviPas encore d'évaluation

- IR and NMR Practice 93Document8 pagesIR and NMR Practice 93Elliot JamesPas encore d'évaluation

- Resolução de Exercícios - Atkins Princípios de Química Cap. 1 (Par) PDFDocument19 pagesResolução de Exercícios - Atkins Princípios de Química Cap. 1 (Par) PDFplemos23Pas encore d'évaluation

- The Rate Law For The Hydrolysis o Ethyl Acetate by Aqueous Sodium Hydroxide at 298 KDocument2 pagesThe Rate Law For The Hydrolysis o Ethyl Acetate by Aqueous Sodium Hydroxide at 298 KJosé Kaisor Angara100% (1)

- Nilai K PDFDocument6 pagesNilai K PDFRisma C. AstariniPas encore d'évaluation

- Modelling Reactors Kinetics PDFDocument65 pagesModelling Reactors Kinetics PDFSachini SarthchandraPas encore d'évaluation

- Oxychlorination Reactor DesignDocument45 pagesOxychlorination Reactor Designhinman714Pas encore d'évaluation

- NaBH4 UlexiteDocument7 pagesNaBH4 UlexiteMichael Ciccarelli IIPas encore d'évaluation

- Water SeerDocument3 pagesWater SeerBagus SadewoPas encore d'évaluation

- Synthesis of Fluorescein From Resorcinol and Phthalic Anhydride - LabmonkDocument4 pagesSynthesis of Fluorescein From Resorcinol and Phthalic Anhydride - LabmonkJuan Agustin Cuadra SotoPas encore d'évaluation

- Estimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsDocument5 pagesEstimating The Permanganate Natural Oxidant Demand of Soil and Aquifer SolidsmickyfelixPas encore d'évaluation

- Sintesis de Metronidazol A Partir de La Etilendiamina PDFDocument3 pagesSintesis de Metronidazol A Partir de La Etilendiamina PDFAstridChoquePas encore d'évaluation

- C01 14PDocument33 pagesC01 14PTiffany LiuPas encore d'évaluation

- Surface Tension of Water From: AlcoholDocument4 pagesSurface Tension of Water From: AlcoholSkandar EverestPas encore d'évaluation

- Book of Abstracts RAA2011Document241 pagesBook of Abstracts RAA2011Vornicu NicoletaPas encore d'évaluation

- Fortran Programming Language For Antoine Equation (Finding Bubble and Dew Point)Document2 pagesFortran Programming Language For Antoine Equation (Finding Bubble and Dew Point)DyahKuntiSuryaPas encore d'évaluation

- RingMethod Zuidema WatersDocument2 pagesRingMethod Zuidema WatersJack Yoseph Martinez OrtegaPas encore d'évaluation

- Electrochemical Noise IntroDocument23 pagesElectrochemical Noise IntroDanie-ElsPas encore d'évaluation

- Orca Manual 4 0 1Document827 pagesOrca Manual 4 0 1Fabio NeryPas encore d'évaluation

- Eat of Solution Data For Aqueous SolutionsDocument2 pagesEat of Solution Data For Aqueous SolutionsJúlio Gabriel Queiroz dos SantosPas encore d'évaluation

- Hydrozirconation - Final 0Document11 pagesHydrozirconation - Final 0David Tritono Di BallastrossPas encore d'évaluation

- ENGRD 221 - Thermodynamics (Prof. N. Zabaras) Prelim IDocument9 pagesENGRD 221 - Thermodynamics (Prof. N. Zabaras) Prelim IMurat TülekPas encore d'évaluation

- C.G. Granqvist Eds. Materials Science For Solar Energy Conversion SystemsDocument208 pagesC.G. Granqvist Eds. Materials Science For Solar Energy Conversion SystemsmedelaidPas encore d'évaluation

- Lycopene and Melatonin: Antioxidant Compounds in Cosmetic FormulationsDocument7 pagesLycopene and Melatonin: Antioxidant Compounds in Cosmetic FormulationsRhenso Victor Albites Condori100% (1)

- ch31 Solution Welty PDFDocument36 pagesch31 Solution Welty PDFDani FernandesPas encore d'évaluation

- Exercícios Resolvidos - Cap. 09 (Pares) - Equilíbrio Químico - Princípios de Química - AtkinsDocument44 pagesExercícios Resolvidos - Cap. 09 (Pares) - Equilíbrio Químico - Princípios de Química - AtkinsPedro HenriquePas encore d'évaluation

- Van Der Waal's Constants For Real Gases: Molecular Formula NameDocument14 pagesVan Der Waal's Constants For Real Gases: Molecular Formula NameDragan PavlovicPas encore d'évaluation

- Mechanism of Spark Plasma SinteringDocument13 pagesMechanism of Spark Plasma Sinteringlakshmikreddy33% (3)

- CH20Document88 pagesCH20Zakria ToorPas encore d'évaluation

- SYNTHESIS AND APPLICATIONS OF TiO2 NANOPARTICLESDocument10 pagesSYNTHESIS AND APPLICATIONS OF TiO2 NANOPARTICLESSoheil MirtalebiPas encore d'évaluation

- Effect of Brookite Phase On The Anatase-Rutile Transition in Titania NanoparticlesDocument6 pagesEffect of Brookite Phase On The Anatase-Rutile Transition in Titania NanoparticlesLucas MarchiniPas encore d'évaluation

- Am 900437 UDocument8 pagesAm 900437 UnguyengiaohungPas encore d'évaluation

- Axit BenzoicDocument52 pagesAxit BenzoicnguyengiaohungPas encore d'évaluation

- Axit BenzoicDocument52 pagesAxit BenzoicnguyengiaohungPas encore d'évaluation

- 9 30Document4 pages9 30nguyengiaohungPas encore d'évaluation

- Preparation and Characterization of nano-TiO2 Powder PDFDocument5 pagesPreparation and Characterization of nano-TiO2 Powder PDFnguyengiaohungPas encore d'évaluation

- Dic To Nary Natural ProdDocument210 pagesDic To Nary Natural ProdSartaj SinghPas encore d'évaluation

- Loai Bo AsenDocument8 pagesLoai Bo AsennguyengiaohungPas encore d'évaluation

- Gold Nanoparticles On Yttrium Modified Titania: Support Properties and Catalytic ActivityDocument10 pagesGold Nanoparticles On Yttrium Modified Titania: Support Properties and Catalytic ActivitynguyengiaohungPas encore d'évaluation

- Fulltext 54Document8 pagesFulltext 54nguyengiaohungPas encore d'évaluation

- Fulltext 44Document17 pagesFulltext 44nguyengiaohungPas encore d'évaluation

- Andronic - Journal of Sol-Gel Science and Technology, Volume 58, Number 1Document8 pagesAndronic - Journal of Sol-Gel Science and Technology, Volume 58, Number 1andronic_lumi2268Pas encore d'évaluation

- Fulltext 16Document7 pagesFulltext 16nguyengiaohungPas encore d'évaluation

- Utf-8 - So This Is ChristmasDocument10 pagesUtf-8 - So This Is ChristmasnguyengiaohungPas encore d'évaluation

- Fulltext 75Document15 pagesFulltext 75nguyengiaohungPas encore d'évaluation

- Fulltext 37Document8 pagesFulltext 37nguyengiaohungPas encore d'évaluation

- Photocatalytic Degradation of Rhodamine B by Dye-Sensitized Tio Under Visible-Light IrradiationDocument6 pagesPhotocatalytic Degradation of Rhodamine B by Dye-Sensitized Tio Under Visible-Light IrradiationnguyengiaohungPas encore d'évaluation

- TianDocument10 pagesTiannguyengiaohungPas encore d'évaluation

- Andronic - Journal of Sol-Gel Science and Technology, Volume 58, Number 1Document8 pagesAndronic - Journal of Sol-Gel Science and Technology, Volume 58, Number 1andronic_lumi2268Pas encore d'évaluation

- Bao Hay 1Document10 pagesBao Hay 1nguyengiaohungPas encore d'évaluation

- Polyaniline/Tio Nanocomposite: Enzymatic Synthesis and Electrochemical PropertiesDocument10 pagesPolyaniline/Tio Nanocomposite: Enzymatic Synthesis and Electrochemical PropertiesNguyen Tan LoiPas encore d'évaluation

- Quang Phan HuyDocument18 pagesQuang Phan HuynguyengiaohungPas encore d'évaluation

- Quang Phan HuyDocument18 pagesQuang Phan HuynguyengiaohungPas encore d'évaluation

- Bao Hay Ve TiO2Document23 pagesBao Hay Ve TiO2nguyengiaohungPas encore d'évaluation

- Doping TiO2Document12 pagesDoping TiO2nguyengiaohungPas encore d'évaluation

- Quang Xuc Tac Ban DanDocument20 pagesQuang Xuc Tac Ban DannguyengiaohungPas encore d'évaluation

- Tio 2Document13 pagesTio 2nguyengiaohungPas encore d'évaluation

- Vat Lieu TiO2Document2 pagesVat Lieu TiO2nguyengiaohungPas encore d'évaluation

- Vat Lieu TiO2Document9 pagesVat Lieu TiO2nguyengiaohungPas encore d'évaluation

- Utf-8 - So This Is ChristmasDocument10 pagesUtf-8 - So This Is ChristmasnguyengiaohungPas encore d'évaluation

- MB Biostar P4SDP 3 PDFDocument12 pagesMB Biostar P4SDP 3 PDFEustahije BrzicPas encore d'évaluation

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocument23 pagesInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamPas encore d'évaluation

- 6 - Reasoning PDFDocument5 pages6 - Reasoning PDFAgri CoachigPas encore d'évaluation

- TR33 0298Document4 pagesTR33 0298N APas encore d'évaluation

- Pre Accion PDFDocument8 pagesPre Accion PDFjhoger2012Pas encore d'évaluation

- Argus Dual System Pi enDocument2 pagesArgus Dual System Pi enfahmi1987Pas encore d'évaluation

- Thermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsDocument39 pagesThermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsGregory MacLeodPas encore d'évaluation

- FC-M6100 SM-BB52: DEORE CranksetDocument1 pageFC-M6100 SM-BB52: DEORE CranksetDon JonesPas encore d'évaluation

- Electrical ContactorDocument14 pagesElectrical ContactorRaphael212219Pas encore d'évaluation

- Positector Calibration ProcedureDocument6 pagesPositector Calibration ProcedureluigimasterPas encore d'évaluation

- Specification: CL 21 B 105 K A F N N N EDocument3 pagesSpecification: CL 21 B 105 K A F N N N EcometPas encore d'évaluation

- Kočnice Shimano BR-M422Document1 pageKočnice Shimano BR-M422salecello2113Pas encore d'évaluation

- Dielectric HeatingDocument2 pagesDielectric HeatingPallavi JainPas encore d'évaluation

- (52621001078) DM - DM Half Inch Flex Jumper Spec SheetDocument2 pages(52621001078) DM - DM Half Inch Flex Jumper Spec SheetmicroqualPas encore d'évaluation

- PQP FormatDocument10 pagesPQP FormatMichael TeoPas encore d'évaluation

- Copperacetate Ammonium Nitrate Oxidation of Benzoin To BenzilDocument12 pagesCopperacetate Ammonium Nitrate Oxidation of Benzoin To BenzilDillon TrinhPas encore d'évaluation

- 2003-20 Communication Plan AttachmentDocument6 pages2003-20 Communication Plan Attachmentapi-3731879Pas encore d'évaluation

- Tabl Navegacion Aqua SignalDocument4 pagesTabl Navegacion Aqua SignalNelson Aguirre BravoPas encore d'évaluation

- Servomotor WedgeDocument24 pagesServomotor WedgeAlanPas encore d'évaluation

- ISTJ PersonalityDocument2 pagesISTJ PersonalityMonalisa ChatterjeePas encore d'évaluation

- FORM Inspection Test Plan MMPDocument8 pagesFORM Inspection Test Plan MMPRicky Stormbringer ChristianPas encore d'évaluation

- ITC Guide For Thesis PreparationDocument26 pagesITC Guide For Thesis PreparationPanha MenhPas encore d'évaluation

- 10 - Design of Doubly Reinforced BeamsDocument13 pages10 - Design of Doubly Reinforced BeamsammarnakhiPas encore d'évaluation

- V33500 TVDocument2 pagesV33500 TVgoriath-fxPas encore d'évaluation

- Differential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridDocument13 pagesDifferential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridANURAAGPas encore d'évaluation

- ASWipLL HW Installation Guide-V07-460Document322 pagesASWipLL HW Installation Guide-V07-460Fernando MartinPas encore d'évaluation

- 1233 Pid 03Document11 pages1233 Pid 03Reza AranPas encore d'évaluation

- Structural MembersDocument37 pagesStructural Membersmario gadianoPas encore d'évaluation

- Table 1. Data Set and CalculationDocument5 pagesTable 1. Data Set and CalculationliliPas encore d'évaluation