Académique Documents

Professionnel Documents

Culture Documents

345 868 1 PB

Transféré par

Paulo DantasTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

345 868 1 PB

Transféré par

Paulo DantasDroits d'auteur :

Formats disponibles

ISSN 0975 8542

Journal of Global Pharma Technology

Available Online at www.jgpt.co.in

RESEARCH PAPER

FORMULATION DESIGN, DEVELOPMENT AND EVALUATION OF VANCOMYCIN HYDROCHLORIDE TABLETS FOR PSEUDOMEMBRANOUS COLITIS BY DIRECT COMPRESSION METHOD

Gupta M.M. *a, Kedawat Madhulika.b, Srivastava B. c and Saini T.R.d

a b

Jaipur College of Pharmacy, Sitapura, Tonk Road, Jaipur , Rajasthan, India. Dept. of Mathematics and Statistics, Banasthali University, Banasthali , Rajasthan, India, c School of Pharmaceutical Sciences, Jaipur National University, Jaipur,India. d Industrial Pharmacy Lab., Department of Pharmacy, S.G.S.I.T.S., Indore, M.P., India. * For Correspondence: E.Mail- mmingupta@gmail.com Abstract: Conventional dosage form (Tablet) of vancomycin hydrochloride was prepared by direct compression method using Lactose (Direct Compression Lactose-21) as diluent and Avicel 200 as filler disintegrating agent while Kollidon- CL (Crosslinked polyvinyl pyrollidone) was used as superdisintegrant. Tablet prepared by using 10 mm flat punch on single stroke machine. The direct compression method is preferred due to good flow property of powder vancomycin hydrochloride (% Carrs Index 17.5).The drug release profile of tablets was studies in distilled water because drug is freely soluble in water (1 gm in 10 ml). Formula of vancomycin hydrochloride was optimized by varying % of lubricating agent (Magnesium stearate), disintegrating agent (Kollidon CL), hardness of tablets. On increasing the % of magnesium stearate drug release is reduced (delay) as well as increasing in the friability, while as % of disintegrating agent is increases, disintegration time is reduced but again friability was increased that was not desirable. Optimum percentage of magnesium stearate was 1% w/w and 1% w/w kollidon-CL was good regarding drug release and other parameters of tablets. Keywords: Vancomycin hydrochloride, direct compression, Lactose (DCL-21), Avicel-200, Kolidon-CL, Invitro dissolution.

INTRODUCTION Tablets [1] are by far the most popular dosage form for pharmaceutical products for therapeutic use and may be defined as solid pharmaceutical dosage form containing drug substances with or without suitable excipients and prepared by either compression or moulding method.Vancomycin hydrochloride[2] is amphoteric glycopeptide antimicrobial substance produced by the growth of certain strains of Streptomyces orientalis used in the treatment of enterocolitis caused by Staphylococcus aureus, antibiotic associated pseudomembranous colitis caused by C.difficile[3-7]. Drug is poorly absorbed from the gastrointestinal

tract, although absorption may be somewhat greater when the gastrointestinal tract is inflamed. It shows good stability in acidic and alkaline medium and having biological half life between 3-13 hours (average 6 hour). The usual adult daily dose is 500 mg-2 gm administered orally in 3 or 4 divided doses for 7-10 days while for pediatric patients, the usual daily dose is 40 mg/kg in 3 or 4 divided doses for 7 to 10 days [6]. Orally administered vancomycin hydrochloride is only used for enterocolitis and antibiotic associated pseudomembranous colitis and this is not effective for other type of infections [3] .Direct compression method is more suitable for moisture sensitive APIs and less changes in dissolution

2009, JGPT. All Rights Reserved.

Gupta M. M. et al., Journal of Global Pharma Technology. February 2011; 3(2):1-6

profile are likely occur in tablet made from granulation also the drug properties (bulk density, powder flow properties) favours this method In this even primary drug particle is liberated from the tablet mass and is available for dissolution [8,9,10]. As no tablet formulation of vancomycin hydrochloride is manufactured in the world at the time of research we were interested to design and develop such formulation. Our aim was to use less number of readily available raw materials and adopt simple direct compression technique for tablet preparation which avoids many steps result in cost saving, even if used for commercial purpose. Preparation based on direct compression was supposed to fulfill our requirement and therefore, selected for investigation in the present study. MATERIAL AND METHODS Vancomycin hydrochloride USP, lactose (DCL-21), Avicel-200, Kollidon-CL were obtained as a gift samples from Alkem lab Mumbai (India), Aerosil 200 was obtained from Ranbaxy lab. Ltd. Dewas (India) as a gift sample, magnesium stearate was collected from local pharmaceutical industry of pharmaceutical grade. All other chemical were from reagent grade. PREPARATION OF TABLETS Selection of diluents For the formulation of vancomycin hydrochloride tablets lactose (DCL-21) was selected as diluent on the basis of its micromeritic properties, compatibility, inertness, and non-interfering property in the estimation of vancomycin hydrochloride. Avicel-200 [11] was combined with lactose to improve the flow

and compression property of powder blend. Further the bulk density of Avicel200 was 0.45, which is close to the bulk density of vancomycin hydrochloride (bulk density of vancomucin HCl is 0.33) and its presence would therefore minimize the chances of segregation of drug and excipients during tabletting. Selection of disintegrating agent The Kollidon-CL [11] was finally selected as disintegrating agent for vancomycin HCl tablet on the basis of its superior direct compressible and disintegration properties, non-interfering nature in the drug analytical procedure and compatibility with drug. Selection of lubricating agent The magnessium stearate was selected as good lubricating agent [11,12] because its lubricating capacity was found to be the best among all the lubricating studies. Further it did not interfere in the drug analytical procedure and was compatible with drug. Optimization of lubricating agent To optimize the percentage of lubricating agent (Magnesium stearate) different formulation of tablets were prepared according the following composition which shown in table no.1. All the excipients with drug were properly mixed in a polybag and passed through # 30 mesh sieve and reblended in the same polybag. Tablets were compressed using 10 mm flat punch on a single punch machine. The prepared tablets were evaluated employing different evaluation parameters for optimization of excipients (table 2). Theoretical compressed weight per tablet was 350 mg.

Table 1: Formulae of Vancomycin HCl Tablets (Optimization of lubricating agent) Ingredients B.No. L-001 (mg) B.No. L-002 (mg) Vancomycin HCl 128.15* 128.15* Lactose (DCL-21) 128.85 127.10 Avicel-200 86 (24.57%) 86 (24.57%) Kollidon-CL 3.5 (1%) 3.5 (1%)

B.No. L-003 (mg) 128.15* 123.60 86 (24.57%) 3.5 (1%)

2009, JGPT. All Rights Reserved.

Gupta M. M. et al., Journal of Global Pharma Technology. February 2011; 3(2):1-6

Magnessium Stearate 1.75 (05%) 3.5 (1%) Aerosil -200 1.75 (05%) 1.75 (05%) Total Weight 350 350 * 128.15 mg Vancomycin HCl is equivalent to 125 mg Vancomycin Table 2: Evaluation of Vancomycin HCl Tablets (Hardness 8 1Kg/cm2) Parameters B.No. L-001 B.No. L-002 Thickness (mm) 4.0 4.0 Diameter (mm) 10.0 10.0 Friability (%) 0.013 0.22 Disintegration Time 6.18 7.20 (minute) Assay (%) 101.60 101.30 Table 3: Dissolution Study of Batch L-001, L-002, L-003 S.No. Sampling Time Cumulative Drug (Minute) Release (%) Batch L-001 1 0 0 2 5 67.85 3 10 84.18 4 15 88.18 5 30 91.13 6 45 97.38 7 60 100.50

7 (2%) 1.75 (05%) 350

B.No. L-003 4.0 10.0 0.68 9.45 100.40

Cumulative Release (%) Batch L-002 0 32.65 49.54 61.32 94.25 97.38 100.07

Drug

Cumulative Release (%) Batch L-003 0 31.06 40.87 50.96 63.16 78.50 92.98

Drug

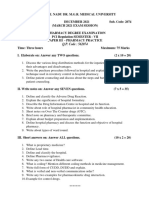

Dissolution study of Batch L-001, L-002, L003 120 100 80 60 40 20 0 0 50 100

Cumulative Drug Relaese (%)

magnesium stearate was considered as optimum lubrication concentration in further studies. Optimization of hardness of vancomycin HCl tablets To optimize the hardness, tablets of vancomycin HCl were prepared according to the formula of L -002, at different compression pressure to get tablet hardness of 61 kg/cm2, 81 kg/ cm2, and 101kg/ cm2,. The tablets were evaluated as earlier for different parameters. The results are recorded in table 4.

Series1 Series2 Series3

Sampling Time (minute)

Figure1: Dissolution Study of Batch L-001, L002, L-003

The formulation L -002 containing 1 % w/w magnesium stearate exhibited best properties so therefore 1% w/w

Table 4: Comparative account of properties of Vancomycin HCl tablets of different hardness S.No. Evaluation Parameters B.No. -021 B.No. -022 B.No. -023 ( 6 1 Kg/cm2) ( 8 1 Kg/cm2) ( 10 1 Kg/cm2) 1 Diameter (mm) 10.0 10.0 10.0 2 Thickness (mm) 4.1 4.0 3.9 3 Disintegration Time (Minute) 5.41 7.20 11.20 4 Friability 0.86 0.22 0.04 5 Assay (%) 103.20 99.01 102.40

The formulation HL-022 having hardness 81 kg/ cm2, exhibited best tablet characteristic. Therefore, 81 kg/ cm2,

tablet hardness was selected as optimum hardness for vancomycin HCl tablets in further studies.

2009, JGPT. All Rights Reserved.

Gupta M. M. et al., Journal of Global Pharma Technology. February 2011; 3(2):1-6

Optimization of % of disintegration agent Vancomycin HCl tablets were prepared according to the formula of HL -022 of varying hardness 81kg/cm2 with percentage of kollidon-CL (disintegrating

Table 5: Formulae for optimization of disintegration agent S.No. Ingredients B.No. DHL-221 (mg) 1 Vancomycin HCl 128.15 2 Lactose DCL-21 128.85 3 Avicel 200 86 (24.57%) 4 Kollidon-CL 1.75 (0.5%) 5 Magnessium Stearate 3.5 (1%) 6 Aerosil 200 1.75 (0.5%) Total Weight 350

agent). The composition of three formulations (DHL -221, DHL -222, DHL -223) thus devised is shown in table 5. The tablets were evaluated as earlier for different parameters. The evaluations are recorded in table 6 &7.

B.No. DHL-222 (mg) 128.15 127.10 86 (24.57%) 3.5 (1%) 3.5 (1%) 1.75 (0.5%) 350 B.No. DHL-223 (mg) 128.15 123.60 86 (24.57%) 7.0 (2%) 3.5 (1%) 1.75 (0.5%) 350

Table 6: Evaluation of vancomycin HCL Tablets (Optimization of disintegration agent) Evaluation Parameters B.No. DHL-221 B.No. DHL-222 Diameter (mm) 10.0 10.0 Thickness (mm) 4.0 4.0 Hardness ( kg/cm2) 8 1 8 1 Friability (%) 0.14 0.24 Disintegration Time (Minute) 8.15 7.05 Assay (%) 102.10 100.40

B.No. DHL-223 10.0 4.0 8 1 0.69 3.02 101.80

Table 7: Dissolution study5,8,9 of third trial batches (B.No. DHL-221, DHL-222, DHL-223)

S.No. Sampling Time (Minute) Cumulative Drug Release (%) B.No. DHL-221 0 36.51 50.39 61.74 86.16 89.85 99.22 Cumulative Drug Release (%) B.No. DHL-222 0 54.79 90.14 93.82 95.25 96.94 99.78 Cumulative Drug Release (%) B.No. DHL-223 0 42.72 57.62 72.82 92.54 97.80 100.63

1 2 3 4 5 6 7

0 5 10 15 30 45 60

Dissolution study of Third Trial Batch DHL-221,DHL222,DHL-223 120

Cumulative Drug Release (%)

100 80 60 40 20 0 0 20 40 60 80 Sampling Time (Minute) Series1 Series2 Series3

The formulation DHL-222 exhibited most satisfactory tablet properties considering the disintegrating time and friability together. Therefore, the composition of this formulation was selected as optimum for final formulation trials. Formulation of Vancomycin Hydrochloride tablets (Final Formulation Trial, Reproducible Batch)

Figure2: Dissolution Study of Third Trial Batch DHL-221, DHL-222, DHL-223

2009, JGPT. All Rights Reserved.

Gupta M. M. et al., Journal of Global Pharma Technology. February 2011; 3(2):1-6

Table 8: Formula of Final Batch

S.No. 1 2 3 4 5 6 Ingredients Vancomycin HCl Lactose (DCL-21) Avicel 200 Kollidon-CL Magnessium Stearate Aerosil 200 Total Weight Quantity (mg) 128.15 127.10 86 3.5 3.5 1.75 350 % Quantity 36.614 36.314 24.571 1.000 1.000 0.500 100

Table 9: Evaluation of Vancomycin HCl Tablets (Final Formulation)

S. No. 1 2 3 4 5 6 7 8 9 Evaluation Parameters Weight Variation Average tablet weight Appearance Thickness Diameter Hardness Friability Disintegration Time Assay Results Observed is in 5 % acceptable range 347.14 mg White, round shape 4.0 mm 10.0 mm 8 1 kg/cm2 0.24% 7.12 minute 100.4%

Table 10: Dissolution Study of Final Batch S.No. Sampling Time (Minute) 1 2 3 4 5 6 7 8 0 5 10 15 30 45 60 90

Cumulative (mg)

Drug

Release

Cumulative Release

Drug

0 72.92 88.18 96.34 117.89 120.65 125.08 120.47

0 58.34 70.54 77.07 94.31 96.52 100.06 96.38

Dissolution Study of Final Batch 120 100 80 60 40 20 0 0 50 Sampling Time (Minute) 100

Cumulative Drug Release (%)

should be made for oral administration. The developed formula of vancomycin hydrochloride (table 8) can be recommended for the pilot plant and manufacturing scale tablet production after subjecting it to long term stability studies. REFERENCES 1. Ansel H.C., Allen L.V., and Popvich N.G. Pharmaceutical Dosage Forms And Drug Delivery Systems, 7th ed.(1999), Lippincott Williams and wilkins, Philadelphia, USA, 179-228. 2. Rasenack N., and Mullar B.W., Crystal Habit and Tableting Behaviour, International Journal Pharmaceutical, 2002;244: 45-57. 3. www.health.allrefer.com/health/pseudo membranous-colitis-info.html

Figure 3: Dissolution Study of Final Batch

RESULTS AND DISCUSSION The result shows that the properties of tablets of formulation DHL-222 were retained in the bigger size batch. It confirmed the reproducibility of the final formulation (DHL-222) In the light of this research work, it may be concluded that tablets of vancomycin hydrochloride

2009, JGPT. All Rights Reserved.

Gupta M. M. et al., Journal of Global Pharma Technology. February 2011; 3(2):1-6

4. www.cdc.gov/ncidod/hip/gastro/clostri diumDifficileGen.htm 5. www.lilly.com 6. www.viropharma.com 7. www.ascp.com/public/pubs 8. Liberman H.A., Lachman L. and Schwartz J.B. Pharmaceutical Dosage Forms, Tablets Volume- I, Marcel Dekker, Inc., USA, 1-69,108-121,195245. 9. Khan K.A., and Rhodes C.T. The Production of Tablets by Direct Compression, Can. J. Pharm. Sci.1973l; 8:1-5.

10. Shangraw R.F. Compressed Tablets by Direct Compression Granulation Pharmaceutical Dosage Forms: Tablets, Vol.-1, Marcel Dekkar, USA, 2nd ed., (1989), 195-246. 11. Handbook of Pharmaceutical Excipients, Second Edition (1994), ALPA Pharm. Sc.Great Britain, AphA, Washington DC,89-86. 12. Armstrong N.A., Selection of Excipients for Direct Compression Tablet Formulation, Pharm. Technol. Eur. 1997;9:24-30.

2009, JGPT. All Rights Reserved.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Imogen SlidesCarnivalDocument29 pagesImogen SlidesCarnivalZarith Emily Burgoa AguilarPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Buanz 2011Document7 pagesBuanz 2011Paulo DantasPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Silva 2004Document8 pagesSilva 2004Paulo DantasPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Calvo 2016Document33 pagesCalvo 2016Paulo DantasPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- CFG Open2017 Event 17 2 v14-1 PDFDocument6 pagesCFG Open2017 Event 17 2 v14-1 PDFPaulo DantasPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- FDC PRODUCTS MARKET OVERVIEWDocument21 pagesFDC PRODUCTS MARKET OVERVIEWPaulo DantasPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Polina Rio 2017Document8 pagesA Polina Rio 2017Paulo DantasPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- CFG Open2017 Event 17 2 v14-1 PDFDocument6 pagesCFG Open2017 Event 17 2 v14-1 PDFPaulo DantasPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- CFG Open2017 Event 17 3-9sbqi8712bdhsy6344dbs PDFDocument6 pagesCFG Open2017 Event 17 3-9sbqi8712bdhsy6344dbs PDFPaulo DantasPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Research Article Thermal Stability and Decomposition Kinetic Studies of Acyclovir and Zidovudine Drug CompoundsDocument7 pagesResearch Article Thermal Stability and Decomposition Kinetic Studies of Acyclovir and Zidovudine Drug CompoundsSahera Nurhidayah NasutionPas encore d'évaluation

- Zhou 2018Document12 pagesZhou 2018Paulo DantasPas encore d'évaluation

- Enantiotropically Related Albendazole PolymorphsDocument12 pagesEnantiotropically Related Albendazole PolymorphsPaulo DantasPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Kara Georg Ou 2014Document9 pagesKara Georg Ou 2014Paulo DantasPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Lab 4 DSCDocument7 pagesLab 4 DSCPaulo DantasPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- 3bach - Arioso From Cantata BWV 156 Sheet Music - 8notesDocument1 page3bach - Arioso From Cantata BWV 156 Sheet Music - 8notesPaulo DantasPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- 4 9methodDocument8 pages4 9methodPaulo DantasPas encore d'évaluation

- Bach - Arioso From Cantata BWV 156 Sheet Music - 8notesDocument1 pageBach - Arioso From Cantata BWV 156 Sheet Music - 8notesPaulo DantasPas encore d'évaluation

- Buffer SolutionsDocument6 pagesBuffer SolutionsIrmey Hamidi100% (1)

- 2bach - Arioso From Cantata BWV 156 Sheet Music - 8notesDocument1 page2bach - Arioso From Cantata BWV 156 Sheet Music - 8notesPaulo DantasPas encore d'évaluation

- Bla Jovan 2016Document9 pagesBla Jovan 2016Paulo DantasPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Albendazole FTIRDocument16 pagesAlbendazole FTIRPaulo DantasPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Her Man 2012Document12 pagesHer Man 2012Paulo DantasPas encore d'évaluation

- 0352 51391200145BDocument14 pages0352 51391200145BPaulo DantasPas encore d'évaluation

- It Is Well With My Soul Rec GuitarDocument2 pagesIt Is Well With My Soul Rec GuitarDavid J MoulPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Artigo A1Document13 pagesArtigo A1Paulo DantasPas encore d'évaluation

- Beretta (2013)Document8 pagesBeretta (2013)Paulo DantasPas encore d'évaluation

- Yu 2016Document9 pagesYu 2016Paulo DantasPas encore d'évaluation

- Fandaruff (2014)Document8 pagesFandaruff (2014)Paulo DantasPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- 1 s2.0 S0016236114011831 MainDocument10 pages1 s2.0 S0016236114011831 MainPaulo DantasPas encore d'évaluation

- 1 s2.0 S0008621512004624 MainDocument5 pages1 s2.0 S0008621512004624 MainPaulo DantasPas encore d'évaluation

- Aripiprazole - September 2023Document2 pagesAripiprazole - September 2023LiezelPas encore d'évaluation

- Oral Lipid Based DDSDocument16 pagesOral Lipid Based DDSDyah Ayu NPas encore d'évaluation

- Apr 78Document147 pagesApr 78Quality AssurancePas encore d'évaluation

- LIST OF REGISTERED DRUGS As of December 2012: DR No Generic Brand Strength Form CompanyDocument15 pagesLIST OF REGISTERED DRUGS As of December 2012: DR No Generic Brand Strength Form CompanyBenjamin TantiansuPas encore d'évaluation

- 2012 guidelinesATCDDDpdfDocument288 pages2012 guidelinesATCDDDpdfdrkaranthakkarPas encore d'évaluation

- Manufacturing Address List of Pharma Companies in AnkleshwarDocument11 pagesManufacturing Address List of Pharma Companies in AnkleshwarMeghayu AdhvaryuPas encore d'évaluation

- Pharmacy Practice Question PaperDocument4 pagesPharmacy Practice Question PaperPavithra SurendiranPas encore d'évaluation

- POC 2nd Short Important Questions Solution B Pharm 3rd Semester Pharmacy Wala Shahruddin KhanDocument22 pagesPOC 2nd Short Important Questions Solution B Pharm 3rd Semester Pharmacy Wala Shahruddin Khannotech985Pas encore d'évaluation

- Biowaiver Monograph For Immediate-Release Solid Oral Dosage Forms: Acetylsalicylic AcidDocument15 pagesBiowaiver Monograph For Immediate-Release Solid Oral Dosage Forms: Acetylsalicylic AcidPasinduAlwisPas encore d'évaluation

- NIMC Long Stay PDF Kb90Document2 pagesNIMC Long Stay PDF Kb90Marv EfrainPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lecture-09 Dose-Response RelationshipsDocument10 pagesLecture-09 Dose-Response RelationshipsChian WrightPas encore d'évaluation

- Introduction To Nursing PharmacologyDocument7 pagesIntroduction To Nursing Pharmacologyastraeax pandaPas encore d'évaluation

- Sustained Release Suppositories of Metoclopramide HCL Formulation and in Vitro EvaluationDocument7 pagesSustained Release Suppositories of Metoclopramide HCL Formulation and in Vitro EvaluationveniPas encore d'évaluation

- Adverse Drug Reaction: Classification Predisposing Factors MechanismDocument46 pagesAdverse Drug Reaction: Classification Predisposing Factors MechanismSreya SanilPas encore d'évaluation

- Adverse Drug Reaction Reporting Form: - Sr. NoDocument2 pagesAdverse Drug Reaction Reporting Form: - Sr. Nosaadtanvir1256Pas encore d'évaluation

- The "Most Hated CEO" in America: Michael D. Jones, University of CincinnatiDocument10 pagesThe "Most Hated CEO" in America: Michael D. Jones, University of CincinnatiNilüfer DağlıPas encore d'évaluation

- MR Upendra Chauhan (Director)Document4 pagesMR Upendra Chauhan (Director)Lalit NagarPas encore d'évaluation

- Excipient Journal PDFDocument14 pagesExcipient Journal PDFRahmat Nur FitryantoPas encore d'évaluation

- Adme 1: Absorption and DistributionDocument48 pagesAdme 1: Absorption and DistributionAlex LesPas encore d'évaluation

- HSCP - A Brief History of Hepatitis CDocument8 pagesHSCP - A Brief History of Hepatitis CA WeaverPas encore d'évaluation

- Top Chemists in Matunga East, MumbaiDocument6 pagesTop Chemists in Matunga East, MumbaiSubhrajeet TalukdarPas encore d'évaluation

- Brochifar Plus Kap 35664 100 1Document15 pagesBrochifar Plus Kap 35664 100 1rio1995Pas encore d'évaluation

- Rincian Tagihan ObatDocument18 pagesRincian Tagihan Obatganesha trengginasPas encore d'évaluation

- NO Nama Harga Modal (Hna) Harga Jual (Hna)Document48 pagesNO Nama Harga Modal (Hna) Harga Jual (Hna)ressy oliviaPas encore d'évaluation

- Expand Global Pharma's Export Reach into New MarketsDocument14 pagesExpand Global Pharma's Export Reach into New Marketssanjay_gawaliPas encore d'évaluation

- Circular 16 2023 TT BYTDocument31 pagesCircular 16 2023 TT BYTDinh NgocPas encore d'évaluation

- EtoricoxibDocument15 pagesEtoricoxibSree BanPas encore d'évaluation

- Hypodermoclysis: A Literature Review To Assist in Clinical PracticeDocument7 pagesHypodermoclysis: A Literature Review To Assist in Clinical PracticeRaabe AndradePas encore d'évaluation

- 00 - Introduction To PharmacologyDocument19 pages00 - Introduction To PharmacologyChipego NyirendaPas encore d'évaluation

- Right, First Time / Concept: March 2013Document15 pagesRight, First Time / Concept: March 2013ashokjkhannaPas encore d'évaluation

- The Age of Magical Overthinking: Notes on Modern IrrationalityD'EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityÉvaluation : 4 sur 5 étoiles4/5 (13)

- Raising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsD'EverandRaising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Why We Die: The New Science of Aging and the Quest for ImmortalityD'EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- The Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsD'EverandThe Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionD'EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionÉvaluation : 4 sur 5 étoiles4/5 (402)