Académique Documents

Professionnel Documents

Culture Documents

3 2

Transféré par

jayaarnavTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3 2

Transféré par

jayaarnavDroits d'auteur :

Formats disponibles

Study Material Contents

Function and responsibilities of a senior welding inspector Defects in welds Weld symbol interpretation Interpretation of NDT reports Documentation of welding Approval and certification procedures General principles of supervision Case studies Planning Organisation Interpretation of fractured surfaces Auditing Practice in typical examination questions Course assessments

Low Morale

Monday 31 December 2012 7:43 PM Posted by Cswip Questions , 0 Comments Labels: CSWIP 3.2 , CSWIP 3.2 Question and Answers , cswip 3.2 welding inspector study material , Senior Welding Inspector

IT HAS COME TO YOUR ATTENTION THAT THE MORALE OF YOUR INSPECTION TEAM APPEARS TO BE LOW, a. WHAT COULD YOU HAVE OBSERVED TO DETERMINE THIS? b. WHAT WOULD OCCUR IF THIS WAS NOT RECTIFIED QUICKLY? c. WHAT COULD YOU DO TO LIFT LOW MORALE? Low morale can be identified by the following symptoms 1. lack of diligence 2. taking short cuts 3. ignoring safety procedures 4. not starting work promptly 5. taking long breaks 6. talking in groups and grumbling about minor matters 7. higher levels of absenteeism 8. Negligence (poor record keeping, not inspecting the weld etc..) 9. complaints from TPI/Client Low morale may be result in the following 1. lack of control over production activities from quality point of view 2. poor productivity 3. substandard work output 4. delay in work schedule 5. lack of credibility to the organization

Observing all above, it is imperative that lifting the low morale this can be done as follows 1. Arrange the meeting of entire sub coordinates staff for discussion on the subject matter. 2. From their response I can form a collective opinion for low morale 3. Further to this I may have private discussion with each individual which can help me to zero in on his problems. 4. This problem is then sorted out as general problem and individual problems. 5. As regard to the personal problems I can assure the team that I will do everything possible in my capacity to rectify it. 6. I should bring to the attention of the employees in gentle but firm manner that, their individual problems must not affect the morale. 7. I will try to seek companys help for their personal problem. 8. These they should be noticed that the high morale will reflect in good salary rise, better facilities etc. 9. If low morale continues then the management will be obliged warning letters, demotions and worst case termination also

Signing Off a Prouduct

Monday 31 December 2012 7:39 PM Posted by Cswip Questions , 0 Comments Labels: CSWIP 3.2 , CSWIP 3.2 Question and Answers , cswip 3.2 welding inspector study material , Senior Welding Inspector , Welding Inspector

In an engineering fabrication industry the last activity in the sequence of manufacturing is load out or dispatch. This activity cannot be initiated unless the product is signed off. As a matter of fact signing the product off is assurance of quality which is authenticated by a technically competent person such as Senior Welding Inspector who makes sure that complete manufacturing of product has been carried out in accordance with applicable standard and sound engineering practices. However before signing the documents the senior welding inspector should make enquiry which can give him the in sites of the past while product was being manufactured. Typical questions can be as followed 1. What was the repair rate during production? 2. Whether any difficulties are encountered within the job? 3. Whether any concession or waiver were given, if yes why? 4. How were the weather conditions? 5. Whether there were any safety issues, fatalities, major accidents/incident etc? 6. Whether there were any labour problems? 7. What about the general moral and standard of work amongst the inspection team(s)? Further to this he can start reviewing of documents and he should make sure that he attaches the following documents as a minimum 1. Quality control plan ensure all stages are complete and signed off 2. Inspection check list ensure all stage are completed and signed off 3. Verify material certificates such as mill test certificates, material traceability records etc

4. Verify the following procedures which are to be attached and have all been approved a. Welding b. Repair c. NDT d. PWHT e. Hardness f. PMI g. Hydrotest h. Coating/Painting 5. Verify the qualification level and validity of the welder and NDT personnel 6. Verify the inspection reports of following disciplines and ensure that they cover all appropriate joints and structure a. Visual b. NDT c. Dimensional control etc 7. Verify calibration certificates of equipments and instruments such as pressure gauge, inspection tools and welding equipments etc 8. Verify hardness test reports 9. Verify PMI reports 10. Verify PWHT reports 11. Verify Hydrotest reports 12. Verify as built drawings are completed 13. Verify weld maps are available for traceability 14. Verify name plate, rubbing details are available when applicable 15. Verify concession request, NCR, site query etc 16. Verify permit to work 17. Verify painting and coating inspection reports As a part of his own inspection he may be obliged to witness final hydrotest, visual inspection of completed parts. As a matter of quality assurance he may view some radiographs at random and may even conduct radiograph audit. Finally, transit and tie down procedures should all have been approved by the relevant engineer prior to the final acceptance of the product and issue of any signed certificate of conformance.

Vous aimerez peut-être aussi

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Documents - Tips - Cswip 322 Questions PDFDocument37 pagesDocuments - Tips - Cswip 322 Questions PDFJithuJohn83% (6)

- Sbtis Model Question Part 1Document48 pagesSbtis Model Question Part 1ganeshPas encore d'évaluation

- Exam Narative Cswip 3.2Document5 pagesExam Narative Cswip 3.2yuwantoniPas encore d'évaluation

- AWS Qualification Program: Dr. Eng. Hamed A. NagyDocument65 pagesAWS Qualification Program: Dr. Eng. Hamed A. Nagyislamaktham100% (3)

- CSWIP 3.2 LATEST WIS10-Mar-2011Document303 pagesCSWIP 3.2 LATEST WIS10-Mar-2011Mohamed Faris100% (8)

- Cswip 3.2 Senior Welding InspectionDocument1 pageCswip 3.2 Senior Welding Inspectionaajmsae*0% (1)

- Cswip Question and Answers: ResponsibilitiesDocument11 pagesCswip Question and Answers: Responsibilitiesfery0% (1)

- 3.2 TipsDocument6 pages3.2 Tipssamuel100% (2)

- 3.2.2 RI Sup. - Training Booklet 000521Document28 pages3.2.2 RI Sup. - Training Booklet 000521Mathew KurianPas encore d'évaluation

- 17 Multiple Choice Questions: No Answer GivenDocument5 pages17 Multiple Choice Questions: No Answer GivenAkram AlhaddadPas encore d'évaluation

- WISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014Document10 pagesWISS CSWIP Technology Multiple Choice Exam 1 Version A 18 August 2014rinhycraPas encore d'évaluation

- Cswip 3 - 2Document2 pagesCswip 3 - 2Nguyen Quang Hung100% (1)

- Cswip 3.2 Exam TipsDocument9 pagesCswip 3.2 Exam TipsmageshkumarPas encore d'évaluation

- 400 Q PDFDocument91 pages400 Q PDFAhmed FoudaPas encore d'évaluation

- Questions CswipDocument63 pagesQuestions CswipMohamed ElsayedPas encore d'évaluation

- Welding Inspection Questions WisDocument5 pagesWelding Inspection Questions WisBhavani PrasadPas encore d'évaluation

- Top 15 Mechanical Testing - Cswip 3.1 Course Questions and AnswersDocument5 pagesTop 15 Mechanical Testing - Cswip 3.1 Course Questions and AnswersJlkKumar67% (3)

- Twi Cswip 3.1 Set-4b - 1Document5 pagesTwi Cswip 3.1 Set-4b - 1miteshPas encore d'évaluation

- Technology Multiple Choice 3Document10 pagesTechnology Multiple Choice 3Alex KullehPas encore d'évaluation

- Api 510 QB G-IDocument30 pagesApi 510 QB G-IRanaweera AriyamanjulaPas encore d'évaluation

- CSWIP 3.2 ExamDocument1 pageCSWIP 3.2 Examasif712Pas encore d'évaluation

- Welding Inspection, Steels Multi - Choice Question Paper (MFY-007)Document7 pagesWelding Inspection, Steels Multi - Choice Question Paper (MFY-007)Moses_JakkalaPas encore d'évaluation

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDocument4 pagesIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanPas encore d'évaluation

- Welding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedDocument16 pagesWelding Inspection: Multi-Choice Questions Paper 1 Please Return This Paper UnmarkedRobert MichaelrajPas encore d'évaluation

- Cswip Multi Choice Questions With AnswersDocument19 pagesCswip Multi Choice Questions With AnswersNeel Mukherjee0% (1)

- Cswip3.2 Introduction ONLYDocument3 pagesCswip3.2 Introduction ONLYSathishkumar. KPas encore d'évaluation

- Questions Cswip 3.11.1Document11 pagesQuestions Cswip 3.11.1Ralph Laurence Parungao100% (1)

- Api 578-Mock 1 - KeyDocument28 pagesApi 578-Mock 1 - KeysheikmoinPas encore d'évaluation

- CSWIP 3.2 Answer For Msr-Wi-1 To 4Document1 pageCSWIP 3.2 Answer For Msr-Wi-1 To 4Moses_JakkalaPas encore d'évaluation

- Summary Note For CSWIP 3.1Document9 pagesSummary Note For CSWIP 3.1Muhamad ShakyreenPas encore d'évaluation

- Practical Exam Instructions: Canadian Welding BureauDocument4 pagesPractical Exam Instructions: Canadian Welding BureauRajesh KunaPas encore d'évaluation

- Sample CSWIP Questions 1571543456Document42 pagesSample CSWIP Questions 1571543456Evandro Silva50% (2)

- Cswip 3.1 QU MSR WI 4 05Document8 pagesCswip 3.1 QU MSR WI 4 05Luan Nguyen100% (3)

- CSWIP Set QuestionDocument13 pagesCSWIP Set QuestionMuhammad Hannan100% (2)

- Multi - Choice Question Paper (MSR-WI-1)Document8 pagesMulti - Choice Question Paper (MSR-WI-1)Karit Hawichit100% (1)

- Safe Practices For Welding Inspectors: 8/16/2018 AWS-CWI Seminar 1Document30 pagesSafe Practices For Welding Inspectors: 8/16/2018 AWS-CWI Seminar 1Ahmed Shaban KotbPas encore d'évaluation

- Asme Sec 5 QuestionsDocument13 pagesAsme Sec 5 Questionsanasseeksscribd100% (1)

- CSWIPDocument3 pagesCSWIPBox Empty100% (2)

- API 570 Practice Questions PDFDocument147 pagesAPI 570 Practice Questions PDFjasminnee100% (1)

- Model - 5Document26 pagesModel - 5PrabuPas encore d'évaluation

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument63 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23Pas encore d'évaluation

- Questions On Section IxDocument22 pagesQuestions On Section IxNasir JavedPas encore d'évaluation

- Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsDocument18 pagesCswip 3.1 (Welding Inspector) Multiple Choice QuestionsRajkumar APas encore d'évaluation

- API 570 Model Questions-1 PDFDocument4 pagesAPI 570 Model Questions-1 PDFabdulgafoor54Pas encore d'évaluation

- Multiple Choice Question Answering by Meshael SultanDocument89 pagesMultiple Choice Question Answering by Meshael SultanMeshs100% (1)

- API 570 Practise Exam QuestionsDocument7 pagesAPI 570 Practise Exam Questionsjasmineamma100% (1)

- Cswip 3.2 Theory Paper Q&A: 1. Signing Off A ProductDocument40 pagesCswip 3.2 Theory Paper Q&A: 1. Signing Off A ProductMohsen Keramati100% (1)

- 03 & 04 Duties of SWI and QualityDocument59 pages03 & 04 Duties of SWI and Qualitynagu100% (1)

- The CIH-R7.0Document67 pagesThe CIH-R7.0Erwin MalmsteinPas encore d'évaluation

- AUDITING Final Exam PaperDocument3 pagesAUDITING Final Exam PaperSajid IqbalPas encore d'évaluation

- The Coating Inspectors HandbookR5Document67 pagesThe Coating Inspectors HandbookR5Kumararaja Konikki100% (2)

- General Pre-Qualification QuestionnaiDocument7 pagesGeneral Pre-Qualification QuestionnaisutanuprojectsPas encore d'évaluation

- AISC Shop InspectionDocument19 pagesAISC Shop InspectionkblaxtonPas encore d'évaluation

- Painting Measures and StandartsDocument69 pagesPainting Measures and StandartsNostalgy1981Pas encore d'évaluation

- Specimen Answers To Nebosh IgcDocument32 pagesSpecimen Answers To Nebosh IgcArchie Gh AnkrahPas encore d'évaluation

- The Coating Inspectors HandbookR3.1Document64 pagesThe Coating Inspectors HandbookR3.1Akhter Khan100% (11)

- Coating Inspector HandbookDocument62 pagesCoating Inspector HandbookGerontaki Gerontaki100% (4)

- PMT On The Web InfoDocument14 pagesPMT On The Web InfoRizkhi AldillaPas encore d'évaluation

- Basic NotesDocument347 pagesBasic NoteslynchconPas encore d'évaluation

- Hydrotest Procedure As Per ASME B 31.1 (Power Piping)Document10 pagesHydrotest Procedure As Per ASME B 31.1 (Power Piping)jayaarnav100% (3)

- Mechanical FitterDocument9 pagesMechanical Fitterjayaarnav0% (1)

- Mustapha FfsDocument21 pagesMustapha FfsjayaarnavPas encore d'évaluation

- Titanium Welding Trips and TricksDocument19 pagesTitanium Welding Trips and Tricksjayaarnav100% (2)

- En 473 Level 2 Preparatory Program Schedule For Oct 2013Document1 pageEn 473 Level 2 Preparatory Program Schedule For Oct 2013jayaarnavPas encore d'évaluation

- Steamfitter Pipefitter Practice ExamDocument9 pagesSteamfitter Pipefitter Practice ExamAbo Hasan Abade67% (3)

- Work Instruction On Tube ExpansionDocument40 pagesWork Instruction On Tube Expansionjayaarnav100% (1)

- Open Book For API 653Document10 pagesOpen Book For API 653jayaarnavPas encore d'évaluation

- NORSOK Z-006 - PreservationDocument20 pagesNORSOK Z-006 - Preservationjoaocavti100% (4)

- Approximate RT Calculation For API 650 TankDocument2 pagesApproximate RT Calculation For API 650 Tankjayaarnav100% (6)

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Api 575Document37 pagesApi 575Sakthi Pk100% (3)

- API 570 Question PDFDocument181 pagesAPI 570 Question PDFRamziAhmedPas encore d'évaluation

- Cswip 3.2 Notes 1Document42 pagesCswip 3.2 Notes 1Sisira Chandrasoma100% (7)

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- CWI SCWI Renewal PKG v1Document2 pagesCWI SCWI Renewal PKG v1jayaarnavPas encore d'évaluation

- RTDocument8 pagesRTjayaarnav33% (3)

- RTDocument16 pagesRTjayaarnavPas encore d'évaluation

- Interesting PicturesDocument2 pagesInteresting PicturesjayaarnavPas encore d'évaluation

- CWI SCWI Renewal PKG v1Document2 pagesCWI SCWI Renewal PKG v1jayaarnavPas encore d'évaluation

- Artikel 7Document8 pagesArtikel 7Andri PratamaPas encore d'évaluation

- Legend: Add Subject Remove Subject: Student Number Name of StudentDocument32 pagesLegend: Add Subject Remove Subject: Student Number Name of StudentJake ChesterphilPas encore d'évaluation

- Difference Between Forging and CastingDocument2 pagesDifference Between Forging and CastingMOHAMMAD ALIPas encore d'évaluation

- CE ESE-2015 Obj 2Document26 pagesCE ESE-2015 Obj 2rameshPas encore d'évaluation

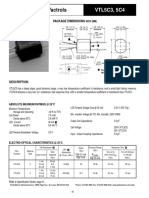

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 pagesLow Cost Axial Vactrols: VTL5C3, 5C4sillyPas encore d'évaluation

- Explicit Dynamics Chapter 6 Explicit MeshingDocument50 pagesExplicit Dynamics Chapter 6 Explicit MeshingAnonymous 0tqzNTWyy100% (4)

- MESCO News January 2016Document4 pagesMESCO News January 2016GoriZakirSalimPas encore d'évaluation

- Xdo XliffloaderDocument7 pagesXdo XliffloaderRenuka ChavanPas encore d'évaluation

- TemperaturaDocument2 pagesTemperaturakamalPas encore d'évaluation

- Chapter ThreeDocument29 pagesChapter ThreeAbel OmweriPas encore d'évaluation

- 5950 Part 1-1990Document120 pages5950 Part 1-1990José Miguel100% (1)

- Interactive CatalogDocument76 pagesInteractive CatalogahmedelhajPas encore d'évaluation

- ACI 308R-16 - Guide o External Curing - PreviewDocument6 pagesACI 308R-16 - Guide o External Curing - PreviewHaniAmin0% (4)

- How To Make AspirinDocument5 pagesHow To Make Aspirincb67Pas encore d'évaluation

- Repair ListDocument36 pagesRepair ListRizky SkrillexPas encore d'évaluation

- RT-161 A1 PDFDocument8 pagesRT-161 A1 PDFRaul Diaz100% (1)

- Installation Main Ten Ace Manual Grasso 10 PDFDocument60 pagesInstallation Main Ten Ace Manual Grasso 10 PDFAhmad HamedPas encore d'évaluation

- Project Management Dashboard TemplateDocument10 pagesProject Management Dashboard Templateindra prasetyaPas encore d'évaluation

- A Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionDocument7 pagesA Mini Unmanned Aerial Vehicle (Uav) : System Overview and Image AcquisitionhougiePas encore d'évaluation

- Position - List - Tank 17 11 2023Document8 pagesPosition - List - Tank 17 11 2023simionalex1987Pas encore d'évaluation

- Air Compressor Anatomy 101Document20 pagesAir Compressor Anatomy 101Rahul ChandrawarPas encore d'évaluation

- Application of Theory of Constraints in Health SystemsDocument10 pagesApplication of Theory of Constraints in Health SystemszafarPas encore d'évaluation

- Safety PrecautionsDocument14 pagesSafety Precautionspavanramana100% (2)

- Sbi Clerk MainsDocument4 pagesSbi Clerk MainspurushothamPas encore d'évaluation

- General Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptDocument3 pagesGeneral Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptNatasha de SilvaPas encore d'évaluation

- Lanko 753 - TdsDocument1 pageLanko 753 - TdskalslingamPas encore d'évaluation

- Adaptive Antenna Systems: Widrow, E. GoodeDocument17 pagesAdaptive Antenna Systems: Widrow, E. GoodeKhal ZeratulPas encore d'évaluation

- Fund PoroDocument97 pagesFund PoroAgustín Ramos LópezPas encore d'évaluation

- HART Tech Short FormDocument9 pagesHART Tech Short FormJediael JuniorPas encore d'évaluation

- Introduction To Igor Programming PDFDocument33 pagesIntroduction To Igor Programming PDFpaulklyuyevPas encore d'évaluation