Académique Documents

Professionnel Documents

Culture Documents

WPS Gtaw 2G

Transféré par

Sachin S. SalunkheDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WPS Gtaw 2G

Transféré par

Sachin S. SalunkheDroits d'auteur :

Formats disponibles

ANNEX N

AWS D1.1/D1.1M:2010

PWPS

WELDING PROCEDURE SPECIFICATION (WPS) Yes

PREQUALIFIED __________ QUALIFIED BY TESTING __________

or PROCEDURE QUALIFICATION RECORDS (PQR) Yes

UE/WPS/AWS/GMAW/2G/21

Identification # _________________________________

15 Jan. 2013

Sachin

00

Revision _______

Date __________

By ____________

15 Jan. 2013

Ravindra

Rahane

Authorized by __________________ Date __________

TypeManual

Semiautomatic

Mechanized

Automatic

Ultra Engineers.

Company Name _______________________________

GMAW

Welding Process(es) ____________________________

UE/PQR/AWS/GMAW/2G/21

Supporting PQR No.(s) __________________________

JOINT DESIGN USED

Butt Weld

Weld

Type: Butt

Single

Double Weld

Backing: Yes

No

Backing: Backing Material: Non for root pass weld for subsequent passes

2-3mm

2mm max

Root Opening ______

Root Face Dimension ________

-60 ( 5 )

Groove Angle: ___________

Radius (JU) _________

Back Gouging: Yes

No

Method _______

POSITION

2G

NA

Position of Groove: ______________

Fillet: __________

Vertical Progression: Up

Down

for 3G Position

ELECTRICAL CHARACTERISTICS

As per Bellow Table

______________________

Transfer Mode (GMAW)

Short-Circuiting

Globular

Spray

Current: AC

DCEP

DCEN

Pulsed

Power Source: CC

CV

Other ________________________________________

Tungsten Electrode (GTAW)

NA

Size: ______________

NA

Type: ______________

By Grinding , Chipping, Brushing

BASE METALS

ASTM A 36

Material Spec. _________________________________

A36

to A36

Type or Grade _________________________________

25 mm

-Thickness: Groove ____________

Fillet __________

NA

Diameter (Pipe) ________________________________

FILLER METALS

SFA 5.18

AWS Specification______________________________

ER 70S-6

AWS Classification _____________________________

SHIELDING

Argon+CO2

NA

Flux ___________________

Gas _________________

80%+20%

Composition __________

NA

10

to

15 LPM

Electrode-Flux (Class)_____ Flow Rate ____________

NA

______________________ Gas Cup Size _________

TECHNIQUE

Both stringer and weave

Stringer or Weave Bead: _________________________

Multipass

Multi-pass or Single Pass (per side)_________________

Single

Number of Electrodes ___________________________

NA

Electrode Spacing

Longitudinal ____________

NA

Lateral_________________

NA

Angle _________________

15-25

mm

Contact Tube to Work Distance ____________________

NA

Peening ______________________________________

Brushing,Chipping and grinding

Interpass Cleaning: _____________________________

PREHEAT

10C

Preheat Temp., Min. ____________________________

250C

10C

Interpass Temp., Min. ___________

Max. _________

POSTWELD HEAT TREATMENT

NA

Temp. ________________________________________

NA

Time _________________________________________

Wire Diameter 0.8, 1.2mm

WELDING PROCEDURE

Pass or

Weld

Layer(s)

Filler Metals

Process

Class

Diam.

Current

Type &

Polarity

Root Run

GMAW

Subsequent

Run

ER 70S6

1.2mm

Amps or Wire

Feed Speed

Volts

Travel

Speed

180-220 Amp.

18-25 Volts

250-350

mm/min.

180-220 Amp.

18-25 Volts

250-350

mm/min

DCEP

Form N-1 (Front)

354

Joint Details

Vous aimerez peut-être aussi

- Hacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)D'EverandHacking for Beginners: Comprehensive Guide on Hacking Websites, Smartphones, Wireless Networks, Conducting Social Engineering, Performing a Penetration Test, and Securing Your Network (2022)Pas encore d'évaluation

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejPas encore d'évaluation

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

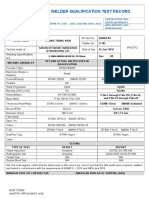

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavPas encore d'évaluation

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniPas encore d'évaluation

- WQTDocument1 pageWQTRamkunwar YadavPas encore d'évaluation

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooPas encore d'évaluation

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONPas encore d'évaluation

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadPas encore d'évaluation

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnPas encore d'évaluation

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraPas encore d'évaluation

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoPas encore d'évaluation

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidPas encore d'évaluation

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaPas encore d'évaluation

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyPas encore d'évaluation

- Draft WPSDocument3 pagesDraft WPSWale OyeludePas encore d'évaluation

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidPas encore d'évaluation

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyPas encore d'évaluation

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessDocument1 pageInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiPas encore d'évaluation

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarPas encore d'évaluation

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSPas encore d'évaluation

- PT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Document2 pagesPT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Wahyu Lailil FaisPas encore d'évaluation

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaPas encore d'évaluation

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielPas encore d'évaluation

- Cajon-001 WPSDocument2 pagesCajon-001 WPSDanem HalasPas encore d'évaluation

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumPas encore d'évaluation

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhPas encore d'évaluation

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaPas encore d'évaluation

- WPS ExampleDocument2 pagesWPS ExampleNur WijiantoPas encore d'évaluation

- QA-R-04 - Visual Inspection ReportDocument1 pageQA-R-04 - Visual Inspection ReportvinothPas encore d'évaluation

- GMAWDocument12 pagesGMAWsushant47Pas encore d'évaluation

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidPas encore d'évaluation

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnPas encore d'évaluation

- 10.LPI. Report FormatDocument1 page10.LPI. Report FormatEr Sumant Kumar SinghPas encore d'évaluation

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Pas encore d'évaluation

- Qualified Welder List Valid Until - 03-12-2019Document2 pagesQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisPas encore d'évaluation

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191Pas encore d'évaluation

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaPas encore d'évaluation

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarPas encore d'évaluation

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviPas encore d'évaluation

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoPas encore d'évaluation

- Sample API 1104 WpsDocument1 pageSample API 1104 Wpsippon_osoto100% (1)

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXPas encore d'évaluation

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PPas encore d'évaluation

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocument1 pageAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkPas encore d'évaluation

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerPas encore d'évaluation

- S 15 PDFDocument1 pageS 15 PDFShirkhanPas encore d'évaluation

- Comparison Chart SA 106 Vs S355J2Document3 pagesComparison Chart SA 106 Vs S355J2Sachin S. SalunkhePas encore d'évaluation

- 10 Procedure For PWHTDocument5 pages10 Procedure For PWHTSachin S. SalunkhePas encore d'évaluation

- Process Flow PDFDocument1 pageProcess Flow PDFSachin S. SalunkhePas encore d'évaluation

- WPS Gtaw 2GDocument1 pageWPS Gtaw 2GSachin S. Salunkhe100% (2)

- Sample WPS For SSDocument2 pagesSample WPS For SSSachin S. SalunkhePas encore d'évaluation

- Process Flow DiagarmDocument1 pageProcess Flow DiagarmSachin S. SalunkhePas encore d'évaluation