Académique Documents

Professionnel Documents

Culture Documents

CAD For Couplings

Transféré par

aymmon8950Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CAD For Couplings

Transféré par

aymmon8950Droits d'auteur :

Formats disponibles

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

Computer Aided Design of Couplings

Adeyeri Michael Kanisuru

Engineering and Engineering Technology//Department of Mechanical Engineering The Federal University of Technology Akure, P.M.B. 704, Akure Ondo State, Nigeria

sademike2003@yahoo.co.uk

Adeyemi Michael Bolaji

Engineering and Engineering Technology//Department of Mechanical Engineering University of Ilorin, Ilorin, P.M.B. 1515, Ilorin, Kwara State, Nigeria

mbadeyemi@yahoo.com

Ajayi Olumuyiwa Bamidele

Engineering and Engineering Technology//Department of Mechanical Engineering Rufus Giwa Polytechnic,Owo Ondo State P.M.B. 1019, Owo, Ondo State, Nigeria

ajayiob@yahoo.com

Abadariki Samson Olaniran

Engineering and Engineering Technology//Department of Mechanical Engineering The Federal University of Technology Akure, P.M.B. 704, Akure Ondo State, Nigeria.

soabadariki@yahoo.com

Abstract The research work explores computer-aided approach to the design of ten different couplings, viz a viz: flange, solid rigid, hollow rigid, old ham/ cross-sliding, pin type flexible, sleeve, seller cone/ compression, split muff, pulley flange and fairbians lap-box couplings. The approach utilizes standard design equations of these couplings and link them together in computer software to determine the design parameters of the couplings. The work reviews the procedural steps involved in the design of couplings and the development of the software package using java as a tool for the design and dratfting of couplings. The design software named COUPLINGCAD combines with sketch template of a single process so as to generate the required parameters of the couplings. The COUPLINGCAD was tested with a number of case studies and the results obtained therein were quite satisfactory. Keywords: Computer Aided design, Couplings, Couplingcad, Equations, Java

1: INTRODUCTION

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power [1]. Couplings do not normally allow disconnection of shafts during operation, though there do exist torque limiting couplings which can slip or disconnect when some torque limit is exceeded [2]. The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both [3]. Shaft couplings are used in machinery for protection against overloads and for power transmission. Most machines are integrated collection of power transmission elements that could be used for the business of moving energy or power from the place where it is generated to where it is to be used. Transmission element in machine tool could be mechanical, hydraulic, pneumatic or electric in

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

313

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

nature. Shaft is one of the most important mechanical transmission element which needs to be coupled properly by the use of shaft couplings. A coupling is mainly to connect two shafts semi permanently. Theoretically, the design and analysis of shaft couplings has been written extensively by several authors and the result put together in textbooks for use by the engineers. SHAFTCAD software was developed through the research work on Computer-Aided design of power transmission shaft.The research establishedthe ease of designing power transmission shaft through various loadings [4]. A software package for the design of special transmission elements in which the various transmission elements such as brakes, power screws, chains and couplings were integrated into a unit package of which the package could only compute the design parameters without the detailed drawings of the machine components [5]. At present, there are no documented software developed for designing couplings except those one designed for spur gears, clutches, flywheel, rolling bearings, helical gears, power screws and chain drives as engineering transmission element [6],[7].

2 : EQUATIONS FOR DESIGN ANALYSIS

The various design equations needed for the design of these categories of couplings are as discussed below: 2.1 Design of Flange Coupling For design purpose, it is to be noted that flange coupling transmit large torque. With reference to Figure 1 [8]. The following are the dimensional parameters to be considered when designing flange coupling; with lettering from figure 1 The appropriate number of bolts, i, is Where d = shaft diameter The average value of the diameter of the bolt circle, D1 in cm D1 = 2d + 5 (2)

i = 0.2d + 3

(1)

FIGURE 1: Flange coupling.

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

314

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

The hub diameter, D2, is The outside diameter of flange, D, is The hub length, L, is The power N is in kilowatt, is Where n = speed (r.p.m),

D 2 = 1.5d + 2.5cm D = 2.5d + 7.5cm L = 1.25 d + 1.875

(3) (4) (5) (6)

d 3n s N= N 1558400

= design shear stress in shaft and

= factor which takes care of the reduced strength due to keyway.

And

= 1+

0.2 x + 1.1 y d

Where: x = width of keyway, cm

and y = depth of keyway, cm

The torque transmitted by the coupling, Mtc, is Where N = Power in Kilowatt Torque transmitted through bolts, Mtb,

M tc =

97400 N

(7)

d12 M tb = i 4

D1 b 2

(8)

Torque capacity based on shear of flange, Mtsf,

M tsf = t (D2 ) f

where

D2 2

(9)

f is the shear stress in flange at the outside hub diameter, kg.

D+d rm = cm 2 Fb = M tc irm

(10)

The mean radius, rm ,

The tension of load in each bolt,

(11)

The preliminary bolt diameter, d1 , is

d1 =

0.5d i

(12)

The allowable or design stress in bolts, b b = Flange thickness,

779200 N

d1 2 inD1

(13)

(14)

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

315

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

Design shear stress,

f =

2M tc D12t

(15)

2.2

Design of Solid Rigid Coupling

Refer figure 2 [8]

FIGURE 2: Solid rigid coupling The parameters for design purposes are: The number of bolts, i, is Flange thickness t, is The diameter of bolt circle, D1, is The outside diameter of flange D, is

i=

1 d +5 3

(16) (17) (18) (19)

t = (0.25d to 0.28d )

D1 = (1.4 d to 1.6 d ) D = D1 + ( 2 d to 3d )

The diameter of bolt, d1, is

d 3 s d1 = 2iD1 b

(20)

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

316

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

2.3

Design of Hollow Rigid Coupling

FIGURE 3: Hollow rigid coupling The parameters for consideration as shown in figure 3 above [8] are as follows: The outside diameter of Hollow rigid, D0, is expressed as

D o = 2.5d + 7.5cm

Minimum number of bolts, i, The diameter of bolt circles, D1,

(21) (22) (23)

4 3

i=

Do 2

D1 = 1.4 Do

The mean diameterw of bolt, d1 is

d1 =

(1 k )D

d Do

2iD1 b

(24)

Where

k=

2.4

Design of Oldham Coupling The length of the boss, L, is The diameter of the boss, D2, is The thickness of flange, t,, is Also diameter of Disc, D, is

L = 1 .75 dcm D2 = 2d t = 0.75 d

(25) (26) (27) (28)

D = 3L

Distance between centre lines of shafts in Oldhams, a,

a = D - 3d )

(29)

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

317

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

Breadth of groove, W, is

W=D

(30)

FIGURE 4: Oldham coupling The thickness of the groove, h1, is

h1 = h=

W 2 W 2

(31)

The thickness of central disc, h, is

(32)

The total pressure on each side of the coupling, F,

F = 1 4 pDh

Where

(33)

p 85kgf / cm2

The torque transmitted on each side of the coupling, Mtc

2 M tc = 2 Fh or M tc = pD h 6

(34)

Power transmitted, N, is

N=

PD 2 hn hp 430000

(35)

N = 1.734 *10 3 PD 2 hn W

Where n = speed in (r.p.m) 2.5 Design of Pin Type Flexible Coupling With reference to figure 5 and its lettering [8] the below formular are derived. The outside diameter, D, is The clearance, b, The hub diameter, D2 is

D = 4d b = 0.1d D2 = 2 d

(36) (37) (38)

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

318

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

The hub length, L, is Diameter of pin at the rock, d1

L = 1.75 d

(39) (40) (41)

d1 = d p cm

i = 0.2d + 3

FIGURE 5: Pin type flexible coupling Force at each Pin, F, is defined as

F = 0.785d p p

(42)

Where p = shear stress in pin = allowable shearing stress kgf/cm2

Bending stress in Pin,

b = F

( l 2 + b)

32 dp

3

(43)

The bearing pressure, Pb kgf / cm , is Where d1= outside diameter of the bush and

Pb =

F Ld 1

(44)

d = d 2 + 0.115d1 + t

Where d2 = diameter of hole for bolt, cm. The torque transmitted, Mtc, is

M tc =

iFD1 2

(45)

2.6 Sleeve Coupling With reference to figure 6 and its lettering [8] the below formular are derived:

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

319

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

The outside diameter of sleeve, The length of the sleeve, L, is The length of the key, l, is

D = 2 d + 1.3cm L = 3.5d l = 3.5d

(46) (47) (48)

FIGURE 6: Sleeve coupling The torque transmitted, Mtc

M tc =

b =

d d 2

144

tc

(49)

The width of keyway, b,

2M

d 2 ld

(50)

Where d 2 = design shear stress in key The thickness of key, h, is

h=

2M tc lb1ld

(51)

Where

1b = design bearing stress for keys

2.7

Seller Cone Coupling The length of the box L, is The outside diameter of the conical sleeve, D1

L=

3.65d + 4d 2

(52)

1.875d + 4d D1 = + 1.25cm 2

(53)

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

320

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

FIGURE 7: Seller cone coupling The outside diameter of the box D2 The length of the conical sleeve, L, is

D 2 = 3d L = 1.5d

(54) (55)

2.8

Design of Split Muff Coupling

Refer Figure 8 [8]

FIGURE 8: Split Muff coupling The outside diameter of the sleeve, D, is The length of the sleeve, L,

D = 2 d + 1.3cm

(56) (57)

L = (3.5d or 2.5d ) + 5cm M tc =

The torque transmitted, Mtc, Where d c =

2d c 2 t id

16

(58)

core diameter of the clamping bolts, cm and i = number of bolts

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

321

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

2.8 Design of Pulley Flange Coupling Refer Figure. 9 The parameters for consideration are; The number of bolts, i, is Bolt diameter d1 is,

i = 0.2 d + 3

(59) (60)

d1 =

0.5d i

The width of flange, l1

l1 = 0.5d + 2.5cm

(61)

FIGURE 9: Pulley flange coupling The thickness of the flange, t The hubs length, l, is The hub diameter, D2 is,

t = 0.25d + 0.7cm l = 1.4d + 1.75cm D2 = 1.8d + 1cm

(62) (63) (64)

The average value of the diameter of the bolt circle, D1,

D1 = 2d + 2.5cm

The outside diameter of flange, D f

(65) (66)

D f = 2.5d + 7.5cm

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

322

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

2.10

Design of Fairbains Lap-Box Coupling

FIGURE 10: Fairbains lap-box coupling The outside diameter of sleeve, D, is Length of lap, l, The length of sleeve L, is

D = 2 d + 1.3cm

(67) (68) (69)

l = (0.9d + 0.3)cm

L = 2.25 d + 2c

3.0

METHODOLOGY

Using the above design equations and procedures, a CAD System/Software for determining necessary coupling parameters and generating automatic drawings of the shaft for a particular application was developed. The design sequence shown in figure 11 was adopted for easier programming. The software was developed with JAVA programming language, which is users friendly and readily compatible with Microsoft Windows environment. The development of COUPLINGCAD involves; creating the user interface, setting object properties and writing of codes. And these were later tested to see if the design codes give the right result. If COULINGCAD is installed on any computer system, when it is clicked to be used, the opening screen features that can be seen is shown in figure 12. As the next button on the opening environment is clicked, this bring out the various couplings (see figure 13) which will give room for users to be able to select the intended type to be considered for any given engineering design problems. For example, if flange coupling is clicked, this takes the user to the design environment as shown in Figure 14.

FIGURE 12 : COUPLINGCAD Main Entry Screen

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

323

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

FIGURE 13: COUPLINGCAD Main Menu Globe

FIGURE 14: COUPLINGCAD Main Dimension Menu

4.0

RESULTS AND DISCUSSION

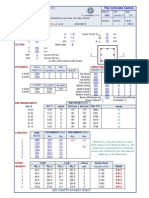

Case studies of samples problems from standard text materials were considered to test or validate the software and by comparing the results got with manually generated solution. Few of these examples are presented below: 4.1 Case Study I Design a flange coupling to connect two shafts each of 55cm diameter transmitting at 350 r.p.m. with allowable shear stress of 40N/cm2. The width and depth of the keyway is 18cm and 6cm respectively. Solution: These values are being input into the package as seen in figure 15. The result is as shown in figure 16

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

324

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

FIGURE 15: Snapshot showing the input parameters for flange coupling

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

325

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

FIGURE 16: Snapshot showing output parameters design values for flange coupling Manually Solved Solution to Case Study I Given parameters are: Diameter, d= 55cm, allowable stress in shaft, keyway, x= 18, Depth of keyway, y= 6cm.

= 40N/cm2, Speed, n= 350 r.p.m, Width of

Using the designed equations spelt above, the following parameters were calculated for. Appropriate number of bolts needed, I = 0 .2 d + 3 = 0.2 55 + 3 = 14 bolts Bolt circle diameter, D1 = 2 d + 5 = 2 55 + 5 = 115cm The hub diameter, D 2 = 1.5d + 2.5cm = 1.5 55 + 2.5 = 85cm Outside diameter of flange, D = 2.5d + 7.5 = 2.5 55 + 7.5 = 145 cm Hub length, L = 1.25 d + 1 .875 = 1.25 55 + 1 .875 = 70 .62 cm Power transmitted, N

d 3 n s 1558400 ,

But,

= factor which takes care of the reduced strength due to keyway.

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

326

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

=1+

N=

0.2 x + 1.1 y 0.2 18 + 1.1 6 =1+ = 1.185 d 55

553 350 1.185 40 = 5566.37 1558400

The torque transmitted by the coupling, Mtc

M tc =

97400 97400 55566.37 N= = 17.5 Ncm n 350

Bolt diameter,

d1 =

0.5d 0.5 55 = = 7.35 i 14

d12 4 D1 b 2

Bolt torque, M tb = i

The allowable or design stress in bolts,

b =

779200 N d1 2 inD1

b =

779200 5566.37 = 45 N cm 2 2 7.33 14 350 115

7.33 2 M tb = 14 4

45 115 = 95627.14 Ncm 2

D2 2

Flange torque, M tsf = t (D2 ) f

Flange thickness, t = 0.25 d = 0.25 55 = 13 .75cm Design shear stress,

f =

2M tc D12t

f =

2 17.5 = 61 N m 2 2 115 13.75 85 = 6241951.9 Ncm 2

M tsf = 13.75( 85)61

The mean radius, rm =

145 + 55 D+d cm = 100cm cm = 2 2

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

327

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

4.2 Case Study II Design a split muff coupling to join two shafts of diameter 35cm, rotating at a speed of 400 r.p.m. and has shear stress of 50N/cm2. The keyways width and depth are 16cm and 4cm respectively. Solution:These values are being input into the package as seen in figure 17. The result is as well shown in figure 18.

FIGURE 17: Snapshot showing the input parameters for split-muff coupling

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

328

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

FIGURE18: Snapshot showing output parameters design values for split-muff coupling Manually Solved Solution to Case Study II Given parameters are: Shaft diameter, d=35cm, allowable stress in shaft, keyway, x= 16cm, depth of keyway, y= 4cm.

s=50N/cm

, speed, n= 400 r.p.m., width of

Using the designed equations spelt above, the following parameters were calculated for: Appropriate number of bolts needed, I = 0 .2 d + 3 = 0.2 35 + 3 = 10bolts Bolt circle diameter, D1 = 2 d + 5 = 2 35 + 5 = 75cm The sleeve diameter, D 2 = 1.5d + 2.5cm = 1.5 35 + 2.5 = 55cm Outside diameter of sleeve, D = 2 d + 1.3cm = 2 35 + 1.3cm = 71 .3cm Sleeve length, L = 2.5d + 5cm = 2.5 35 + 5 = 92 .5cm Power transmitted, N

d 3 n s 1558400

= factor which takes care of the reduced strength due to keyway.

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

329

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

=1+

N=

0.2 16 + 1.1 4 = 1.217 35

35 3 400 1.217 50 = 2104 Kw 1558400

The torque transmitted by the coupling, Mtc

M tc =

2 d c 2 t id

16

2 d c 2 t 10 35

16

= 46.29 Ncm

Bolt diameter,

d1 =

0.5d 0.5 35 = = 5.53cm i 10

d12 4 D1 b 2

Bolt torque, M tb = i

But, the allowable or design stress in bolts, is

b =

779200 N 779200 2104 = = 57 N cm 2 2 5.532 10 400 75 d1 inD1

57 75 = 97413.92 2

D2 2

5.53 2 M tb = 10 4

Sleeve torque, M tsf = t (D2 ) f

Sleeve thickness, t = 0.25 d = 0.25 35 = 8 .75 cm Design shear stress,

f =

2 M tc

D1 t

2 46.29 = 60 N cm 2 2 75 8.75

M tsf = 8.75( 55)60

The mean radius, rm =

55 = 2078850.76 Ncm 2

71.3 + 35 D+d cm = 53.15cm cm = 2 2

4.3 Comparative View of the Results for Case Study I and Case Study II The means to excellently validate the package developed is to compare the results obtained. From table 1 shown, comparatively, the results got when manually solved or calculated for is same as the results got using the COUPLINGCAD for the various designed parameters for both case study I and case study II. This implies that the COUPLINGCAD is excellently packaged.

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

330

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

Case Study I Design Parameters COUPLING CAD Result Number of bolts Bolt circle diameter Hub diameter Outside diameter Bolt diameter Hub length Power Coupling torque Bolt torque Flange torque Mean radius Flange thickness 14 115.0cm 85.0cm 145.0cm 7.35cm 70.62cm 5566.37Kw 17.5 14 115.0cm 85.0cm 145.0cm 7.35cm 70.62cm 5566.37Kw 17.5 Number of bolts Bolt circle diameter Sleeve diameter Outside diameter Bolt diameter Sleeve length Power Coupling torque Bolt torque Sleeve torque Mean radius Sleeve thickness Manually Solved Result Design Parameters

Case Study II COUPLING CAD Result 10 75.0cm 55.0cm 71.3cm 5.53cm 92.5cm 2104.0Kw 46.29Ncm 10 75.0cm 55.0cm 71.3cm 5.53cm 92.5cm 2104.0Kw 46.29Ncm Manually Solved Result

95627.14 6241951.9

95627.14 6241951.9

97413.92 2078850.76

97413.92 2078850.76

100cm 13.75cm

100cm 13.75cm

53.15cm 8.75cm

53.15cm 8.75cm

TABLE 1: Tabulated results of designed parameters using the COUPLINGCAD and manually solved approach for both Case study I and II

5.0

CONCLUSION

The case studies considered proved that the COUPLINGCAD is excellently packaged and it could be used in solving problems related to the various couplings of choice as discussed. The COUPLINGCAD is quite accurate with high precision. It is noticed that with it, time management is ensured as calculations are done within a short time which is not so with the manually solved approach.

6.0

[1]

R. N. Peter Childs. Mechanical Design, 1st Edition,NewYorkToronto. John Wiley and Sons Inc 1998, pp.124-143

REFERENCES

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

331

Adeyeri Michael Kanisuru, Adeyemi Michael Bolaji, Ajayi Olumuyiwa Bamidele & Abadariki Samson Olaniran

[2] [3] [4] [5] [6]

R. S.Khurmi and J. K. Gupta.Machine Design, 14th edition,New Delhi EURASIA publishing house,.2005, pp. 481-505 D. N. Reshetor. Machine Design, 1st Edition, Moscow.MIR Publishers, 1978. pp.592-645 T.I. Ogedengbe, 2002. Computer-Aided Design of Power Transmission Shaft M.Eng Thesis, Federal University of Technology, Akure, Nigeria. M.K. Adeyeri Development of Software Package For The Design of Special Transmission Element, M.Eng Thesis, University of Ilorin, Kwara state, Nigeria.2007. M.K. Adeyeri and M.B. Adeyemi.Development of Software package in Designing chain drives as Engineering Transmission Element. Advanced Materials Research, Trans Tech Publication Switzerland, vol 62-64: pp. 655-663,2009.

[7]. J.A. Akpobi,, R.O. Edopia, and M.H. Oladeinde, Computer Aided Design of Power Transmission Screw. 3rd International Conference on Engineering Research & Development: Advances in Engineering Science and Technology, University of Benin, Benin city,Nigeria, Sept. 6th-8th,2010, pp:1191-1221. [8]. K Linguaiah and B. R. Narayana.Machine Design Data Handbook. Jayanagar, Banga, India;1973. pp. 349 375. Suma Publishers

International Journal of Engineering (IJE), Volume (5) : Issue (5) : 2011

332

Vous aimerez peut-être aussi

- Puranmal Lahoti Government Polytechnic Latur: Name of The StudentsDocument11 pagesPuranmal Lahoti Government Polytechnic Latur: Name of The Studentsshankar biradarPas encore d'évaluation

- Puranmal Lahoti Government Polytechnic Latur: Name of The StudentsDocument11 pagesPuranmal Lahoti Government Polytechnic Latur: Name of The Studentsshankar biradarPas encore d'évaluation

- Compound Die PDFDocument4 pagesCompound Die PDFNhan Le100% (1)

- Helical Gear DesignDocument12 pagesHelical Gear DesignRoozbeh PPas encore d'évaluation

- Flange DesignDocument4 pagesFlange DesignJilu Easow RajuPas encore d'évaluation

- Design and Analysis of Composite Structure For Industrial PlatformsDocument8 pagesDesign and Analysis of Composite Structure For Industrial PlatformsIJRASETPublicationsPas encore d'évaluation

- ME 3011D MD1 CouplingsDocument22 pagesME 3011D MD1 Couplingsvivek geddamPas encore d'évaluation

- Fin Irjmets1683986998Document9 pagesFin Irjmets1683986998Yuvraj Singh BhadoriaPas encore d'évaluation

- Winding Design of Induction MotorsDocument7 pagesWinding Design of Induction MotorsKarthik MohankumarPas encore d'évaluation

- MECH68Document8 pagesMECH68GogyPas encore d'évaluation

- Jj513 Engineering DesignDocument9 pagesJj513 Engineering DesignDustin AndersonPas encore d'évaluation

- MECH56Document4 pagesMECH56Rakesh ReddyPas encore d'évaluation

- Report FEADocument15 pagesReport FEAamuPas encore d'évaluation

- Chapter 3 - Design of Mechanical JointDocument26 pagesChapter 3 - Design of Mechanical JointRaj KeeranPas encore d'évaluation

- Design and Analysis of Bushed Pin Flexible Coupling: April 2017Document8 pagesDesign and Analysis of Bushed Pin Flexible Coupling: April 2017Koushik NaganPas encore d'évaluation

- Progressive Tool Design and Analysis For 49 Lever 5 Stage ToolsDocument10 pagesProgressive Tool Design and Analysis For 49 Lever 5 Stage ToolsseventhsensegroupPas encore d'évaluation

- Compound Die Design: A Case Study: Sneha S. Pawar, R. S. DaluDocument4 pagesCompound Die Design: A Case Study: Sneha S. Pawar, R. S. DaluchupchapPas encore d'évaluation

- Design and Analysis of Bushed Pin Flexible Coupling: April 2017Document9 pagesDesign and Analysis of Bushed Pin Flexible Coupling: April 2017DOLSON BUTTI204008Pas encore d'évaluation

- Nan Mudhalvan Project Report Batch 8Document46 pagesNan Mudhalvan Project Report Batch 8Visa Meena2351Pas encore d'évaluation

- Optimizing Efficiency of Square Threaded Mechanical Screw Jack by Varying Helix AngleDocument5 pagesOptimizing Efficiency of Square Threaded Mechanical Screw Jack by Varying Helix AnglegrewalgurPas encore d'évaluation

- TCC53 Column Design - 2002-2008Document23 pagesTCC53 Column Design - 2002-2008AnbalaganV100% (3)

- AFDEX Simulation of Connecting RodDocument7 pagesAFDEX Simulation of Connecting RodKumar SatyamPas encore d'évaluation

- Jntuworld: R07 Set No. 2Document9 pagesJntuworld: R07 Set No. 2prk74Pas encore d'évaluation

- The International Journal of Engineering and Science (The IJES)Document6 pagesThe International Journal of Engineering and Science (The IJES)theijes100% (1)

- International Conference On Modeling, Optimization and Computing (ICMOC 2012)Document22 pagesInternational Conference On Modeling, Optimization and Computing (ICMOC 2012)Zain Ul AbideenPas encore d'évaluation

- Knuckle Joints DesignDocument10 pagesKnuckle Joints DesignKvrd Prasad100% (1)

- Timur Choban KhidirJCSgDocument8 pagesTimur Choban KhidirJCSgyash sanwarePas encore d'évaluation

- Modeling and Analysis of Cotter Joint REPORT R20ER055Document21 pagesModeling and Analysis of Cotter Joint REPORT R20ER055Akash AkashPas encore d'évaluation

- Reliability-Based Interaction CurveDocument8 pagesReliability-Based Interaction CurveEnida MataPas encore d'évaluation

- Machine Design Formulas PDFDocument8 pagesMachine Design Formulas PDFCabanes GerluzPas encore d'évaluation

- Fuel From PlasticDocument28 pagesFuel From PlasticAvi SinghPas encore d'évaluation

- IJCRTICGT019Document6 pagesIJCRTICGT019Azeb TeklemariamPas encore d'évaluation

- Knuckle JointDocument20 pagesKnuckle JointROCKY DUBEYPas encore d'évaluation

- Ansys Catia Piston IretDocument12 pagesAnsys Catia Piston IretPranav RajPas encore d'évaluation

- Ecs258 - Lab Report (Co4: Po4) : Faculty of Civil EngineeringDocument10 pagesEcs258 - Lab Report (Co4: Po4) : Faculty of Civil EngineeringSyafwan Hafiz100% (1)

- Design and Analysis of COTTER JOINT Using Autodesk Inventor 2013 and ANSYS WorkbenchDocument22 pagesDesign and Analysis of COTTER JOINT Using Autodesk Inventor 2013 and ANSYS WorkbenchamuPas encore d'évaluation

- Aerospace Engineering, PG. Scholar (Aero), PG. Scholar (Aero), MLR Institute of Technology, Hyderabad, IndiaDocument8 pagesAerospace Engineering, PG. Scholar (Aero), PG. Scholar (Aero), MLR Institute of Technology, Hyderabad, IndiaMasoud doskiPas encore d'évaluation

- Project HelpDocument13 pagesProject HelpVishal MirashiPas encore d'évaluation

- Design and Analysis of Lead Screw For FixtureDocument7 pagesDesign and Analysis of Lead Screw For FixtureA PPPas encore d'évaluation

- CF021504508 PDFDocument5 pagesCF021504508 PDFVignesh vikiPas encore d'évaluation

- KSSC 3 2007 7 4 297 (C)Document13 pagesKSSC 3 2007 7 4 297 (C)ismael.lorandi623Pas encore d'évaluation

- Field Training Report Format22-07Document19 pagesField Training Report Format22-07dhiraj patilPas encore d'évaluation

- Design and Manufacturing of A Non-Standard Chain Parts For A Scraper Chain Conveyor - A Case StudyDocument7 pagesDesign and Manufacturing of A Non-Standard Chain Parts For A Scraper Chain Conveyor - A Case StudyMohammed GamilPas encore d'évaluation

- Bài Giảng Khuôn Dập P1Document34 pagesBài Giảng Khuôn Dập P1xuân quân lêPas encore d'évaluation

- Base Plate Shear Concrete Edge FailureDocument5 pagesBase Plate Shear Concrete Edge FailureJoel Nolan de Carvalho0% (1)

- Buckling Analysis Connecting Rod PDFDocument8 pagesBuckling Analysis Connecting Rod PDFAnonymous NFsIMHyfLtPas encore d'évaluation

- Structural Calculations ST04 AMD 4th FL BEAMDocument35 pagesStructural Calculations ST04 AMD 4th FL BEAMSun PonloeuPas encore d'évaluation

- Knuckle JointDocument10 pagesKnuckle JointRajat MathurPas encore d'évaluation

- Final Mini Project DocDocument31 pagesFinal Mini Project DocVikas FularePas encore d'évaluation

- .Design and Development of Lat Pull Down Machine For Power Generation PDFDocument3 pages.Design and Development of Lat Pull Down Machine For Power Generation PDFMANISH SINGH IET Lucknow StudentPas encore d'évaluation

- Design of Helical Compression Spring in BikeDocument9 pagesDesign of Helical Compression Spring in Bikeraghavendra guptaPas encore d'évaluation

- Problems s8Document4 pagesProblems s8zangue billy jamesPas encore d'évaluation

- Development of Small Injection Moulding Machine For Forming Small Plastic Articles For Small-Scale IndustriesDocument14 pagesDevelopment of Small Injection Moulding Machine For Forming Small Plastic Articles For Small-Scale IndustriesHenry PutraPas encore d'évaluation

- PE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Document33 pagesPE D Vi10 422.023 ME CAL 001 01 E - Calculation Sheet Acc. en 14015 - VAR - 3Virginia Elena Iordache67% (3)

- Design and Analysis of Flyover Bridge Using SAPDocument7 pagesDesign and Analysis of Flyover Bridge Using SAPInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Duong Tien Luan - 20184997 - 124427Document18 pagesDuong Tien Luan - 20184997 - 124427Tien LuanPas encore d'évaluation

- Comparision of Beam by Software and Manual Calculation IrjmetsDocument8 pagesComparision of Beam by Software and Manual Calculation IrjmetsChandini Suman SahooPas encore d'évaluation

- Lift Using Water PumpingDocument46 pagesLift Using Water PumpingPiyush NarkhedePas encore d'évaluation

- KotiranjeDocument22 pagesKotiranjeJosjedankorisniknaskribiduPas encore d'évaluation

- CM A Hollow Core SlabsDocument36 pagesCM A Hollow Core SlabsSulaiman Mohsin AbdulAziz100% (1)

- Mesh SplitDocument9 pagesMesh SplitCesar Lazarte LunaPas encore d'évaluation

- MIT AutomobloxDocument21 pagesMIT Automobloxaymmon8950Pas encore d'évaluation

- SolidWorks For Sheet MetalDocument15 pagesSolidWorks For Sheet MetalCodreanu Petru100% (2)

- Belt ConveyorsDocument361 pagesBelt Conveyorsaymmon8950Pas encore d'évaluation

- 1992 National Waste Processing Conference 05Document9 pages1992 National Waste Processing Conference 05aymmon8950Pas encore d'évaluation

- Prallbrecher EngDocument12 pagesPrallbrecher Engaymmon8950Pas encore d'évaluation

- For The Participants From The Belorussia, Russia and UkraineDocument4 pagesFor The Participants From The Belorussia, Russia and Ukraineaymmon8950Pas encore d'évaluation

- 1992 National Waste Processing Conference 04Document9 pages1992 National Waste Processing Conference 04aymmon8950Pas encore d'évaluation

- 1992 National Waste Processing Conference 01Document8 pages1992 National Waste Processing Conference 01aymmon8950Pas encore d'évaluation

- 1992 National Waste Processing Conference 02Document11 pages1992 National Waste Processing Conference 02aymmon8950Pas encore d'évaluation

- 1992 National Waste Processing Conference 03Document9 pages1992 National Waste Processing Conference 03aymmon8950Pas encore d'évaluation

- Evaluation of Industrial ProjectsDocument151 pagesEvaluation of Industrial Projectsmkumawat20Pas encore d'évaluation

- Mining Machinery V1Document310 pagesMining Machinery V1aymmon8950100% (1)

- Boatbuilding Manual 1999Document246 pagesBoatbuilding Manual 1999aymmon8950Pas encore d'évaluation

- Idustrial MathematicsDocument312 pagesIdustrial Mathematicsaymmon8950Pas encore d'évaluation

- Scalable Electric Power From Solar EnergyDocument19 pagesScalable Electric Power From Solar Energyaymmon8950Pas encore d'évaluation

- Coloring BookDocument8 pagesColoring Bookaymmon8950100% (1)

- Dear All, I Edited and Collected Links For IS Codes, IRC Etc From Following Links On Date 20-March-2009Document16 pagesDear All, I Edited and Collected Links For IS Codes, IRC Etc From Following Links On Date 20-March-2009aymmon8950Pas encore d'évaluation

- Deflection LightDocument4 pagesDeflection Lightaymmon8950Pas encore d'évaluation

- Deflection LightDocument4 pagesDeflection Lightaymmon8950Pas encore d'évaluation

- Is The Most Important Place in The World: All Catalog Prices Are Valid Until June 30, 2008Document372 pagesIs The Most Important Place in The World: All Catalog Prices Are Valid Until June 30, 2008maestrokg100% (1)

- AlternativeConstructionResearchGuide GCCDSDocument161 pagesAlternativeConstructionResearchGuide GCCDSaymmon8950Pas encore d'évaluation

- World Learning Facts FigsDocument2 pagesWorld Learning Facts Figsaymmon8950Pas encore d'évaluation

- VITA Publications - Revised 10.07Document10 pagesVITA Publications - Revised 10.07aymmon8950Pas encore d'évaluation

- WallDocument20 pagesWallaymmon8950Pas encore d'évaluation

- Unit 4 - Grammar - BasicDocument2 pagesUnit 4 - Grammar - BasicvamsrorgePas encore d'évaluation

- LunguP OperaluiA BoldursiDocument30 pagesLunguP OperaluiA BoldursiOxana PostolachiPas encore d'évaluation

- BlackBook of English Vocabulary Updated Till November 2019Document16 pagesBlackBook of English Vocabulary Updated Till November 2019NO ONE100% (1)

- English Las Week 2 English 9 Q4Document8 pagesEnglish Las Week 2 English 9 Q4MON ANTHONY MOLOBOCOPas encore d'évaluation

- EngLish Grammar TVDocument179 pagesEngLish Grammar TVSuvyPas encore d'évaluation

- Form 2 - I WonderDocument32 pagesForm 2 - I WonderTerry J. TimothyPas encore d'évaluation

- Process Analysis EssayDocument5 pagesProcess Analysis EssayrgsmoroniPas encore d'évaluation

- 1.escreva Os Verbos A Seguir No GerúndioDocument3 pages1.escreva Os Verbos A Seguir No Gerúndiopatriciasaires100% (1)

- Brown and Frazer The Acquisition of SyntaxDocument38 pagesBrown and Frazer The Acquisition of SyntaxRobert HutchinsonPas encore d'évaluation

- Kid Innovators Curriculum GuideDocument9 pagesKid Innovators Curriculum GuideQuirk Books100% (1)

- 3 Worksheet On Summary Writing: A I: H T W A SDocument2 pages3 Worksheet On Summary Writing: A I: H T W A SThai ThuyPas encore d'évaluation

- Manythings Handout 2005Document1 pageManythings Handout 2005GyurmedPas encore d'évaluation

- The Virtù of Architectural Invention Rhetoric Ingegno and Imagination in Filaretes Libro Architettonico PDFDocument338 pagesThe Virtù of Architectural Invention Rhetoric Ingegno and Imagination in Filaretes Libro Architettonico PDFroxanaPas encore d'évaluation

- Sacred Books The and Early Literature of The East Vol 6Document416 pagesSacred Books The and Early Literature of The East Vol 6adext100% (1)

- Rutsely Simarra Obeso - Una Muestra de Cultura Palenquera Aproximación A Algunas Formas Léxicas Del Criollo de San BasilioDocument40 pagesRutsely Simarra Obeso - Una Muestra de Cultura Palenquera Aproximación A Algunas Formas Léxicas Del Criollo de San BasilioMICHELL ROJAS GILPas encore d'évaluation

- Chapter 1Document8 pagesChapter 1Keziah VenturaPas encore d'évaluation

- 7th Grade Choice Sheet 2020-21 SampleDocument2 pages7th Grade Choice Sheet 2020-21 Sampleapi-337392771Pas encore d'évaluation

- 3.coding 50QDocument16 pages3.coding 50QKannan Kannan100% (1)

- SuggestionDocument5 pagesSuggestionmari iskandarPas encore d'évaluation

- Intel 8080 Programmers ManualDocument91 pagesIntel 8080 Programmers ManualFlávio Tavares100% (1)

- 15 Minutes - Test 1Document2 pages15 Minutes - Test 1ngaanhc2ngtPas encore d'évaluation

- Transition WordsDocument3 pagesTransition WordsAishath Rifga IbrahimPas encore d'évaluation

- CTCA Logical Fallacies Relevance & Insufficient EvidenceDocument45 pagesCTCA Logical Fallacies Relevance & Insufficient EvidenceHarshil MistryPas encore d'évaluation

- Abilities Chart 1Document4 pagesAbilities Chart 1api-237560763Pas encore d'évaluation

- Politeness Strategies by Shay Patrick CormacDocument14 pagesPoliteness Strategies by Shay Patrick CormacDwi AnugrahPas encore d'évaluation

- LAB - 02 (Reading User Input, Designing Simple Classes)Document6 pagesLAB - 02 (Reading User Input, Designing Simple Classes)green goblinPas encore d'évaluation

- High Score Voc Book FinalDocument122 pagesHigh Score Voc Book Finalkh azimPas encore d'évaluation

- JL & PL SyllabusDocument2 pagesJL & PL SyllabusPrasadPas encore d'évaluation

- Book Thief SyntaxDocument2 pagesBook Thief SyntaxIsabella MontoyaPas encore d'évaluation

- Rubric For SymposiumDocument3 pagesRubric For SymposiumShane Nones100% (1)