Académique Documents

Professionnel Documents

Culture Documents

Prins Sıvı LPG

Transféré par

Mustafa SofuoğluDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Prins Sıvı LPG

Transféré par

Mustafa SofuoğluDroits d'auteur :

Formats disponibles

World leader in alternative fuel systems

Discover the

Direct LiquiMax system:

Advanced calibration possibilities Optimal integration with the OEM systems

Parallel to the OEM fuel system, the Prins Direct LiquiMax system has been designed for bi-fuel or mono-fuel LPG operation on vehicles with Direct Fuel Injection technology. The Direct LiquiMax system is designed for engines with direct fuel injection systems (GDI), which means that fuel is injected under high pressure [20-200 bar] directly into the cylinder instead of being injected into the manifold (port injection). Taking advantage of the existing OEM-DI components, the Direct LiquiMax performance is equal to that of petrol. With the Direct LiquiMax system the driver will experience no difference between LPG and petrol.

Components

Fuel Module

Multivalve Fuel Module; includes 80% filler restriction, non-return valve, excess flow valve, pressure relief valve, tank level sensor, lock-off valve, remote filler valve connection, fuel supply and return connections Gas tight sealing of tank unit by means of an O-ring LPG Turbine pump; fitted with gas filter to protect the fuel injection system from pollution Swirl pot; which prevents the pump from running dry during dynamic driving behaviour

Important to know:

Adjustable LED colours for integration with dashboard Extensive diagnostic functions, diagnostic software is divided in Basic and Advanced tabs Integrated checklist for switch over procedure, so fast diagnostic Modular Plug & Play wiring loom Freeze frame information of the first 2 errors 32-bits ECU of OEM quality One diagnostic tool for all Prins systems Tank level of LPG tank also visible when driving on petrol No RPM module necessary Sleep current ECU < 1 mA Complies with R67-01 and R115 regulations 2 years warranty

Pump Driver

Controlled by the ECU by means of PWM signal (Pulse Width Modulation) Enables full linear control of the pump Fault code detection and feedback to the ECU Run dry detection Voltage limiter by means of compensation PWM signal Integrated current limiter Reduces the output current when it detects high temperature and turns off when the temperature gets too high

Fuel Supply Unit (FSU)

Makes it possible to switch between LPG and petrol Complete with electronic lock off valve controlled by the ECU Compact design for easy installation

AFC-2

The AFC-2 computer is the heart of the system and controls all the functions of the Direct LiquiMax system for safety, switch over strategy, fuel injection and diagnostics Controls the fuel module, pump driver, boost pump, FSU, FRU and fuel selector switch OEM watertight case with ventilation plug One 81-pins connector for the master wiring loom and a small 40-pins connector for the specific engine configurations wiring loom A number of different communication interfaces for more advanced OEM engine integration. High performance 32-bits automotive controller combined with full diagnostic and self protected

Fuel Return Unit (FRU)

Controls the return of LPG to the LPG tank Makes it possible to switch between LPG and petrol Equipped with electronic lock-off valve controlled by the ECU Lock off valve will shut off the LPG return line during petrol mode Equipped with a pressure sensor Compact design for easy installation

power-output circuits for high reliability and durability Diagnostics, service and parameter-load software operates from Windows XP / Vista / 7 applications

Fuel selector switch

Small and compact design suits all cab interiors Fuel selection via smart touch control. Informs operator of LPG tank contents, audible buzzer to alert low level switching or fault codes plus illuminated fault code warning with LED Self programmable LED colours

Boost Pump

Special petrol turbine pump Installed in series with the OEM petrol fuel pump Multiplying the petrol pressure during switch over procedure above LPG pressure, for smooth switch over High Boost pump capacity Complete with electronic lock-off valve which blocks the petrol flow. Compact design for easy installation

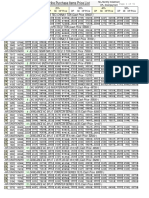

Tank dimensions

Cylindrical and toroidal tanks available: Center Filled Toroidal tanks diameter 600, 630 and 650mm with height of 230, 250-and 270 mm. Cylindrical; tanks with diameter 320, 360 and 450 with different lengths.

Prins Autogassystemen B.V. Jan Hilgersweg 22 5657 ES Eindhoven The Netherlands Tel. +31 (0)40 254 77 00 Fax +31 (0)40 254 97 49 www.prinsautogas.com sales@prinsautogas.com

Vous aimerez peut-être aussi

- Cummins ISX Fuel System 02-05Document18 pagesCummins ISX Fuel System 02-05g665013100% (21)

- Komatsu PC160LC 7Document20 pagesKomatsu PC160LC 7Virgil Cenariu100% (3)

- Volvo Penta D7 at GensetDocument4 pagesVolvo Penta D7 at GensetEser75% (4)

- Turbine Fuel SystemDocument66 pagesTurbine Fuel SystemDamon Leong100% (1)

- 722.9 Introduction To MercedesDocument46 pages722.9 Introduction To MercedesThePokeOne89% (9)

- Lab 3 - Measuring Mass of EarthDocument7 pagesLab 3 - Measuring Mass of EarthJacob AltmillerPas encore d'évaluation

- Lolcng WorksDocument5 pagesLolcng WorksAnkit DalalPas encore d'évaluation

- FCMDocument4 pagesFCMMansoor Ahmad100% (1)

- CDS23008 GPR-DI M1 PackageDocument18 pagesCDS23008 GPR-DI M1 PackagehutaPas encore d'évaluation

- CDS23008 GPR DI M1 PackageDocument18 pagesCDS23008 GPR DI M1 PackageDavid SvídaPas encore d'évaluation

- Compressor Drive Allison 501-KB Gas TurbineDocument4 pagesCompressor Drive Allison 501-KB Gas Turbineprabu50% (2)

- I6 4.0 Part 8 - Induction and ExhaustDocument10 pagesI6 4.0 Part 8 - Induction and ExhaustHenrique BelliniPas encore d'évaluation

- CDS23077 GPRP-DI M1 PackageDocument19 pagesCDS23077 GPRP-DI M1 PackageDavid SvídaPas encore d'évaluation

- 500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGDocument7 pages500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGbinstartedPas encore d'évaluation

- CDS23072 GPR M1 PackageDocument10 pagesCDS23072 GPR M1 PackageDavid SvídaPas encore d'évaluation

- Automatic Fuel Oil Transfer Pump Set - DatasheetDocument5 pagesAutomatic Fuel Oil Transfer Pump Set - Datasheetfrankz89Pas encore d'évaluation

- Pump Boss - Intelligent Pump Control PowerpointDocument25 pagesPump Boss - Intelligent Pump Control PowerpointChem-FlowPas encore d'évaluation

- ICE 16 - Computer Controlled Electronic EnginesDocument151 pagesICE 16 - Computer Controlled Electronic EnginesKunal BhatiaPas encore d'évaluation

- CDS23061 GPA M1 PackageDocument10 pagesCDS23061 GPA M1 PackageDavid SvídaPas encore d'évaluation

- PurifierDocument4 pagesPurifierRizal Falevy100% (1)

- Entrenamiento Perkins 1300 CONFIDENCIALDocument40 pagesEntrenamiento Perkins 1300 CONFIDENCIALCe Bayona100% (11)

- CrdiDocument23 pagesCrdiRaja Mukherjee100% (2)

- Bachelor of Maritime Operations: Common Rail Fuel System and Exhaust Valve Actuation With Electronic Injection ControlDocument12 pagesBachelor of Maritime Operations: Common Rail Fuel System and Exhaust Valve Actuation With Electronic Injection ControlGONTONIPas encore d'évaluation

- Vsi CNG EnglishDocument4 pagesVsi CNG Englishbenjohn100Pas encore d'évaluation

- Alfa Laval PurifiersDocument4 pagesAlfa Laval PurifiersNasim AbbasPas encore d'évaluation

- Wartsila 9L20Document9 pagesWartsila 9L20Vikram BaskarPas encore d'évaluation

- SORG EquipmentDocument56 pagesSORG Equipmentl0% (2)

- End-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesDocument6 pagesEnd-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesMuhammad MustafaPas encore d'évaluation

- BRC Plug& PlayDocument8 pagesBRC Plug& PlaydonlukaszPas encore d'évaluation

- CDS23068 GPRP M1 PackageDocument10 pagesCDS23068 GPRP M1 PackageDavid SvídaPas encore d'évaluation

- Gas Turbine Pump Drive Integrated Control System: Petrotech Home PageDocument4 pagesGas Turbine Pump Drive Integrated Control System: Petrotech Home Pagescribdkhatn100% (1)

- Manual-Motor de Gasolina Cm11 MkiiDocument4 pagesManual-Motor de Gasolina Cm11 MkiiNallely MassoPas encore d'évaluation

- Engines 20 Fuel System PDFDocument36 pagesEngines 20 Fuel System PDFCemalettin öztoprakPas encore d'évaluation

- A E P S T (L1) : Dvanced Ngine Erformance Pecialist ESTDocument24 pagesA E P S T (L1) : Dvanced Ngine Erformance Pecialist ESTeyesaacPas encore d'évaluation

- Milano User Manual.1.45Document28 pagesMilano User Manual.1.45Smarandache ValentinaPas encore d'évaluation

- VSG Compressor: For Natural Gas and Process Gas ApplicationsDocument8 pagesVSG Compressor: For Natural Gas and Process Gas ApplicationsbracioPas encore d'évaluation

- Optilift-GL: Gas Lift Monitoring and OptimizationDocument2 pagesOptilift-GL: Gas Lift Monitoring and OptimizationFabro CoronelPas encore d'évaluation

- DCS Application in Thermal Power PlantDocument30 pagesDCS Application in Thermal Power Plantanjumadhavan50% (2)

- Integrated Controls SolutionDocument21 pagesIntegrated Controls Solutionpredic1100% (1)

- Multipoint Sequential: Injection System With BRC Electro-InjectorDocument6 pagesMultipoint Sequential: Injection System With BRC Electro-Injectorpj_chaudhary3796100% (1)

- Automatic Mains Failure Controller CEA6 - Ing PDFDocument12 pagesAutomatic Mains Failure Controller CEA6 - Ing PDFtecnigenelec80% (5)

- Solar 5.2MVADocument15 pagesSolar 5.2MVAsohaila7Pas encore d'évaluation

- Xtreme X Plug in Ecus PecsDocument6 pagesXtreme X Plug in Ecus Pecsmark chapmanPas encore d'évaluation

- VSSG/VSG Compressor: For Natural Gas and Process Gas ApplicationsDocument8 pagesVSSG/VSG Compressor: For Natural Gas and Process Gas ApplicationsGabriel Zumelzu AltamiranoPas encore d'évaluation

- Gas Turbine Engine: - Fuel SystemDocument45 pagesGas Turbine Engine: - Fuel SystemMoin KhanPas encore d'évaluation

- Texsteam Solar Pump Brochure (04.12)Document12 pagesTexsteam Solar Pump Brochure (04.12)Arman Malik0% (1)

- GPR Package DatasheetDocument11 pagesGPR Package DatasheetVitor SegniniPas encore d'évaluation

- Volvo TAD1250VE Spec SheetDocument2 pagesVolvo TAD1250VE Spec SheetEngine Tuning UpPas encore d'évaluation

- Vilter VSSG VSG Brochure en Us 5411280 PDFDocument8 pagesVilter VSSG VSG Brochure en Us 5411280 PDFCarlos Roberto TamarizPas encore d'évaluation

- Nordic Valve Remote Control System CatalogDocument36 pagesNordic Valve Remote Control System Catalogbinh_duyvuPas encore d'évaluation

- VSSG/VSG Compressor: For Natural Gas and Process Gas ApplicationsDocument8 pagesVSSG/VSG Compressor: For Natural Gas and Process Gas ApplicationsCarlos Roberto TamarizPas encore d'évaluation

- PLTMG Prabumulih 18V34SG Rev.3 OperasiDocument66 pagesPLTMG Prabumulih 18V34SG Rev.3 OperasiOctavianus Harahap100% (2)

- Fuel InjectionDocument93 pagesFuel InjectionCh'ng Jie HanPas encore d'évaluation

- C-PAC Control Philosophy OverviewDocument4 pagesC-PAC Control Philosophy OverviewYan LuzhanskiPas encore d'évaluation

- G3520 Lehe2832 02 PDFDocument6 pagesG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- E SVwhite1Document2 pagesE SVwhite1xianmingPas encore d'évaluation

- 7.2 Engine Simulation On PerformanceDocument23 pages7.2 Engine Simulation On PerformancePokya RetroPas encore d'évaluation

- AC-Report Sport HallDocument5 pagesAC-Report Sport HallMohammad IsmailPas encore d'évaluation

- Theorem of Three Moments - Wikipedia, The Free EncyclopediaDocument3 pagesTheorem of Three Moments - Wikipedia, The Free EncyclopediasoulsellPas encore d'évaluation

- Black Holes, Singularities and Information Loss - Richard P DolanDocument5 pagesBlack Holes, Singularities and Information Loss - Richard P DolancolordiamondsPas encore d'évaluation

- E3Document300 pagesE3JuinPas encore d'évaluation

- HPDocument51 pagesHPKhan Basit KhanPas encore d'évaluation

- SWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Document2 pagesSWL 25 MT Padeye at Crosby G-2130 - Extg - MS - 9mm (Hole - Gap - 7mm) (Side - Gap - 9mm) (For 500T GC & AHII)Paulo MoreiraPas encore d'évaluation

- Steam Power Plant LecturesDocument36 pagesSteam Power Plant LecturesKariem Zaki100% (1)

- Navier Stokes PDFDocument22 pagesNavier Stokes PDFKhirupasagar RavibaskarPas encore d'évaluation

- Klima Meat User Manual EngDocument3 pagesKlima Meat User Manual EngAntonioMartinezPas encore d'évaluation

- 6stroke EngineDocument5 pages6stroke EngineMitesh KumarPas encore d'évaluation

- JC2 Physics H2 2018 RafflesDocument88 pagesJC2 Physics H2 2018 RafflesVarshLokPas encore d'évaluation

- Small Amplitude Soliton Propagation in A Weakly Relativistic Magnetized Space Plasma: Electron Inertia ContributionDocument10 pagesSmall Amplitude Soliton Propagation in A Weakly Relativistic Magnetized Space Plasma: Electron Inertia ContributionSukhmander SinghPas encore d'évaluation

- Pneumatic Vulcanizing MachineDocument50 pagesPneumatic Vulcanizing MachineANAND KRISHNANPas encore d'évaluation

- 02 - G12 Powertrain PDFDocument112 pages02 - G12 Powertrain PDFSalisburPas encore d'évaluation

- Tensile TestingDocument17 pagesTensile TestingNanak BatraPas encore d'évaluation

- SC-01 Safety Code On Storage, Handling & Use of Gas CylindersDocument8 pagesSC-01 Safety Code On Storage, Handling & Use of Gas CylindersSandeep ShettyPas encore d'évaluation

- 5.3 Code, Standard and RegulationDocument7 pages5.3 Code, Standard and Regulationandrieysyah2525Pas encore d'évaluation

- Strain Guages ManualDocument48 pagesStrain Guages Manualaishwarya badkulPas encore d'évaluation

- Drillmec DrawworksDocument8 pagesDrillmec DrawworksPrashant Rajput100% (1)

- 10 ASME B31.3 Final Exam ClosedDocument3 pages10 ASME B31.3 Final Exam ClosedMichael Albuquerque100% (1)

- 160 Kva MangrolDocument6 pages160 Kva MangrolrajendranrajendranPas encore d'évaluation

- Arc Welding Process PDFDocument12 pagesArc Welding Process PDFBiswanath RoulPas encore d'évaluation

- Plastic Molding TutorialDocument32 pagesPlastic Molding TutorialSergio RodriguezPas encore d'évaluation

- RC Mini ProjekDocument11 pagesRC Mini ProjekMohd HisbullahPas encore d'évaluation

- Scroll Bending Attachment Model 36621Document26 pagesScroll Bending Attachment Model 36621renspur100% (1)

- Power Generation Using Speed Breaker IJERTV10IS090084Document3 pagesPower Generation Using Speed Breaker IJERTV10IS090084Nilli BilliPas encore d'évaluation

- Valtra T121-T191 EngineDocument29 pagesValtra T121-T191 EngineJakaPas encore d'évaluation

- Pump Primer 2 AssDocument33 pagesPump Primer 2 AssGkou DojkuPas encore d'évaluation

- Iso 3506 1 2020Document46 pagesIso 3506 1 2020Anna BubblegumPas encore d'évaluation