Académique Documents

Professionnel Documents

Culture Documents

Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Details

Transféré par

nasar_mahsoodTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Details

Transféré par

nasar_mahsoodDroits d'auteur :

Formats disponibles

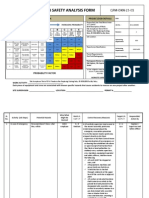

JOB SAFETY ANALYSIS (JSA) WORK SHEET

RISK MATRIX

PROJECT /JOB DETAILS

Project Ref./Job Title/Work Order: Brief Description of Job HEAT TREATMENT INCREASE PROBABILITY

A B Has occurred in industry Low C Has occurred in QP D Occurs several times a year in QP Low E Occurs several times a year at this site Low

DATE JSA No. REVISION Sponsoring Department Performing Department Permit Authority JSA Approved by 004 1

Job Location:

Potential Severity

Hazard Area Classification Permit Requirements: Hot/Cold/Radiography Participant (Parties involve in JSA) Site engineer, supervisor and safety officer All the mitigation measures identified in JSA are in place before starting the activities

People

Asset /Production

Environment

Reputation

Never heard of in industry

No injury Slight injury or health effects Minor injury or health effects Major injury or health effects Single fatality or permanent total disability Multiple fatalities

No damage Slight damage, No disruption to operation Minor damage (=QR 250,000) Local damage (=QR1 300,000) Minor damage (=QR 25,000,000) Extensive (=QR 25,000,000)

No effect

No impact

No Risk

Low

Slight effect

Slight impact Limited impact National effect Regional effect International impact

Low

Low

Low

Low

Low

Minor effect Localized effect

Low

Low

Medium

Medium

Medium

Low

Medium

Medium

Medium

High

Major effect Massive effect

Low

Medium

Medium

High

High

Medium

Medium

High

High

High

Probability Factor

Work Site Supervisor

Page 1 of 4 DOC. NO.: PCES/HSE/ JSA REV.1

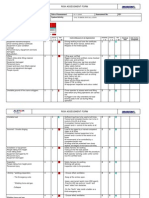

JOB SAFETY ANALYSIS (JSA) WORK SHEET

Sl. No. 1

Activity (Job Steps) Tool box Meeting And JHA Discussion

Potential Hazard

Severity Before Mitigation Medium C

Required Control/Mitigation Measures & Checks

Severity After Mitigation Low C

Action party Site Supervisor and Safety Officer

People Not Understanding What The

Plan Or Hazards Are; People Afraid To Ask Questions Presence of H2S gas and Toxic gas In Work Areas. Presence of chemical or flammable items

Make Sure Everyone Is Involved With The JSA/JHA

Discussion And Understands; Encourage Everyone To Ask Questions And Participate. Don't Make Anyone Feel For Speaking Up Or Questioning Try To Identify These Types Of things In Your Work Areas Before Starting the work; Clear Carefully Work Areas By gas testing and daily site inspection Authorized work permit holders shall ensure obtaining and maintaining valid work permits. The supervisor responsible for this activity has to check the PPE of his staff to ensure that all required items are available and properly used. Inform all people regarding permit conditions before work starts. Supervisors must conduct daily toolbox talk about nature of work and associated potential hazards and their essential precautionary measures. Check gate passes. Drivers /operators must know the rote and location to the job site. Use A Spotter To Back Up And When In Tight Quarters Plan Route; Check Height & Weight Restrictions; Know Height Of Vehicle; Ensure Objects On The Vehicle Are Secured And Not Sticking Out. Watch Turning Radius; Take Wide Turns Drive Defensively and Courteously

Work Permit

Unauthorized commencement of works May result in exposing people and/or

potential to harm or danger.

Medium C

Low C

Site Supervisor and Safety Officer

Transportation of

materials to site

Restricted View While Backing or in Tight Quarters Striking Bridges or Low Overpasses Along Path of Travel Taking Turns Too Sharp; Hitting Objects or People Other Vehicles on the Road Driving Unsafely, Creating Hazards For You

Medium C

Low C

Site Supervisor and Safety Officer

HSE check list &Prior to commencing mobilization to site

Lack of safety awareness

Medium C

Site preparation and movement of

Personal injury acquired From damaged tool and equipments

Medium B

Obtain work permits / All personnel shall be H2S trained Comply with all general job requirements mentioned on PTW TBT on possible emergency and response procedure. All safety requirements stated on the work permit must be fulfilled Inspect all tool and equipments Observe proper manual handling techniques

Low C

Site supervisor & safety officer

Low C

Site supervisor & safety

Page 2 of 4 DOC. NO.: PCES/HSE/ JSA REV.1

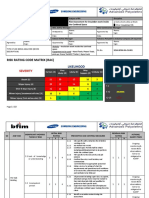

JOB SAFETY ANALYSIS (JSA) WORK SHEET

Manually handling injury Uninspected tools equipments Over exhaustion/extreme weather condition Slips ,trips and falls Sharp object Fire Explosion Spark Touching Hot Metal With Hands, Causing Burns

Medium B

personnel, tools equipments and materials

6-A

Site preparation for heat treatment work

Heating

Touching Hot Metal With Hands, Causing Burns Fire Explosion Spark. Burn. Toxic gases. Slip, trips and falls

Medium B

Burned or split insulation Cable connection points loose screw Lose cable connection Damaged cable

Power tool must in good condition Remove damaged tools Provide adequate amount of cold drinking water Maintain work rest period Remove unnecessary things Suitable access and egress to be provided Wearing of PPE All rubbish to be removed Wear Gloves Be Aware Of Accidental Body Contact With Hot Parts Suitable access and egress to be provided Cover all the existing facilities with approved fire blanket Cover al main hole pits valves near welding area wit fire blanket Make good arrangement around heating area to avoid heat transfer to the other facilities Keep all cables away from the heating area Obtain required permit from control room Obtain gas test regularly. Method of statement Clear Area / Tape Off / Fire Watch Use proper PPE according to hot job. Fire watch must be present at site during hot working. Fire hose charge with water. Fire extinguisher. Skill and certified manpower. Proper housekeeping to be ensured after completion of job. Barricaded the area with warning tape and placed the caution /warning board Remove damaged tools dont us it Equipment check prior to use Dont use damaged cables ,tools or equipments All electrical cables and connection must be inspect regularly

officer

Low C

Site supervisor & safety officer

Low C

Site supervisor & safety officer

Page 3 of 4 DOC. NO.: PCES/HSE/ JSA REV.1

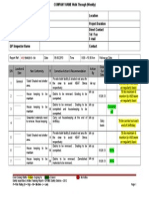

JOB SAFETY ANALYSIS (JSA) WORK SHEET

.heat stress shelters to be provided for workers Make sure Drinking water supply always available Standby vehicle on site for emergency purpose. Heat stress 8

Housekeeping.

Debris causing Slips, trips and falls. Fire risk due to presence of combustible

materials / debris.

Medium C

Infestation of rodents leading to

equipment & materials damage

Regular housekeeping at site shall be performed. Adequate and correct stacking of materials. Regular inspection and immediate corrective action. Keep

always clear of obstruction.

Low C

Regular clearing of work site shall be implemented.

Site Supervisor, Workers and Safety Officer

Engineer (Panorama)

QP Project Engineer

Production Supervisor

Asst.Manager(if Required)

Page 4 of 4 DOC. NO.: PCES/HSE/ JSA REV.1

Vous aimerez peut-être aussi

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterPas encore d'évaluation

- Job Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job DetailsDocument4 pagesJob Safety Analysis (Jsa) Work Sheet: Risk Matrix Project /job Detailsnasar_mahsood100% (1)

- Hydro TestDocument3 pagesHydro TestAnonymous qos47GCByPas encore d'évaluation

- Jsa Radiography ActivitiesDocument4 pagesJsa Radiography Activitiesnasar_mahsood80% (15)

- JSA for Night Work at Laydown AreaDocument2 pagesJSA for Night Work at Laydown Areagulryz84100% (9)

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDocument9 pagesJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Example JSA Job Safety AnalysisDocument13 pagesExample JSA Job Safety AnalysisSiti MaisarahPas encore d'évaluation

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriPas encore d'évaluation

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliPas encore d'évaluation

- Safe Work Procedures SWP GuideDocument4 pagesSafe Work Procedures SWP GuideJuanpablo Celis100% (1)

- Risk Assessment FormDocument3 pagesRisk Assessment FormThomas100% (1)

- Tower Crane Work Permit ChecklistDocument1 pageTower Crane Work Permit Checklistfaisal nadeemPas encore d'évaluation

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraPas encore d'évaluation

- Job Hazard Analysis: List The Tasks To Be Performed in Sequence of Execution. #Document2 pagesJob Hazard Analysis: List The Tasks To Be Performed in Sequence of Execution. #Ajay KrishnanPas encore d'évaluation

- Hot Work Procedure, WHSPRO-010 CMDocument3 pagesHot Work Procedure, WHSPRO-010 CMmyo lwinPas encore d'évaluation

- JHA Pressure Washer Gasoline OperatedDocument1 pageJHA Pressure Washer Gasoline OperatedFranz Ryan YbañezPas encore d'évaluation

- 05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EDocument5 pages05.JHA-Site Survey For TR-9702A Transformer Marshalling Box Wiring Verification at Substation EFrancis Enriquez TanPas encore d'évaluation

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Officeriskassess 260109Document1 pageOfficeriskassess 260109api-330763254Pas encore d'évaluation

- Hand Tool Risk AssessmentDocument1 pageHand Tool Risk AssessmentSijo RajanPas encore d'évaluation

- Fabrication Work Shop RADocument4 pagesFabrication Work Shop RASalah Abd Eldayem67% (3)

- Jha - de Spading Activities For N2 PurgingDocument4 pagesJha - de Spading Activities For N2 PurgingNasrullah100% (1)

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezPas encore d'évaluation

- Risk Assessment Form Gaz Turbine InstallationDocument6 pagesRisk Assessment Form Gaz Turbine InstallationRochdi Bahiri100% (1)

- Pregnancy Risk AssessmentDocument6 pagesPregnancy Risk AssessmentSTEVEN DELAHUNTYPas encore d'évaluation

- Risk Assessment For Partition MarkingDocument5 pagesRisk Assessment For Partition Markingkhalid14Pas encore d'évaluation

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelPas encore d'évaluation

- Job Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control MeasuresDocument3 pagesJob Safety Analysis: Work Sequence Potential Hazards Recommended Action / Control Measuresmuhammad imtiaz100% (1)

- JSA For Blower Cyclone and Duct Installation - Revision 004Document8 pagesJSA For Blower Cyclone and Duct Installation - Revision 004WilsonPas encore d'évaluation

- OSH-18 (PTW) Permit To Work System ProcedureDocument3 pagesOSH-18 (PTW) Permit To Work System Procedurerizal azizanPas encore d'évaluation

- HSE guidance on safety devices for rapid roller doorsDocument11 pagesHSE guidance on safety devices for rapid roller doorsmsc920138Pas encore d'évaluation

- Risk Assessment For Generator EquipmentDocument6 pagesRisk Assessment For Generator Equipmentabou bakar0% (1)

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaPas encore d'évaluation

- AB8-ELE-75-HMO - Generator Dismantling For 5 Yearly MaintenanaceDocument2 pagesAB8-ELE-75-HMO - Generator Dismantling For 5 Yearly Maintenanacevikrant911Pas encore d'évaluation

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayPas encore d'évaluation

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriPas encore d'évaluation

- EARTHWORKS SAFETYDocument4 pagesEARTHWORKS SAFETYsatti100% (2)

- Contractor Health, Safety & Environment Management System (CHSEMSDocument150 pagesContractor Health, Safety & Environment Management System (CHSEMSRahul AmbasthaPas encore d'évaluation

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash RaiPas encore d'évaluation

- 2F 5 Radiation Risk AssessmentDocument1 page2F 5 Radiation Risk AssessmentNurul SyaheerahPas encore d'évaluation

- Accident&Incident Reporting FlowchartDocument1 pageAccident&Incident Reporting FlowchartAtika MaulannaPas encore d'évaluation

- Safe Operating Procedures 08 Air CompressorDocument2 pagesSafe Operating Procedures 08 Air CompressorAkbarPas encore d'évaluation

- Job Safety Analysis FormatDocument2 pagesJob Safety Analysis FormatJamil HossainPas encore d'évaluation

- Earthworks Safety AnalysisDocument7 pagesEarthworks Safety AnalysisGeml TrinidadPas encore d'évaluation

- Confine Space at Water TankDocument7 pagesConfine Space at Water TanknaraPas encore d'évaluation

- Safe Work Method Statement WorksheetDocument3 pagesSafe Work Method Statement WorksheetSiti Salwani binti Ab RahimPas encore d'évaluation

- JOB SAFETY ANALYSISDocument21 pagesJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriPas encore d'évaluation

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradPas encore d'évaluation

- Jsa For Tie in of Fuel Gas LineDocument3 pagesJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (1)

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Arc Welding - JSADocument6 pagesArc Welding - JSAdroffilcz27Pas encore d'évaluation

- Typical JHA FormDocument5 pagesTypical JHA FormNasrullah Jan100% (4)

- Jha New Format Painting Revision PDFDocument8 pagesJha New Format Painting Revision PDFNakkolopPas encore d'évaluation

- JSA Cable DisconnectedDocument4 pagesJSA Cable Disconnectedwendypost730% (1)

- JHA For Tie-In at PCR14-02Document7 pagesJHA For Tie-In at PCR14-02Francis Enriquez TanPas encore d'évaluation

- Jsa SKDocument10 pagesJsa SKEngr Tahir UL Haq100% (2)

- JHA FORM CompleteDocument5 pagesJHA FORM Completeangelo177Pas encore d'évaluation

- Job Safety Analysis Work SheetDocument20 pagesJob Safety Analysis Work SheetBarkat Ullah50% (2)

- Safety Analysis Lifting of Plat For Tank WeldingDocument2 pagesSafety Analysis Lifting of Plat For Tank Weldingnasar_mahsood100% (2)

- Monthly Hse Logistics StatisticsDocument3 pagesMonthly Hse Logistics Statisticsnasar_mahsoodPas encore d'évaluation

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Monthly Hse Logistics StatisticsDocument3 pagesMonthly Hse Logistics Statisticsnasar_mahsoodPas encore d'évaluation

- COMPANY LOGO Project HSE Weekly Walk Through ReportDocument1 pageCOMPANY LOGO Project HSE Weekly Walk Through Reportnasar_mahsood100% (1)

- Monthly Hse Logistics StatisticsDocument3 pagesMonthly Hse Logistics Statisticsnasar_mahsoodPas encore d'évaluation

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Job Safety Analysis (14) For Cable Laying and PullingDocument4 pagesJob Safety Analysis (14) For Cable Laying and Pullingnasar_mahsood79% (34)

- Toolbox Talk Grinding and CuttingDocument1 pageToolbox Talk Grinding and Cuttingnasar_mahsoodPas encore d'évaluation

- Hand Tool's For Mechanical WorkDocument1 pageHand Tool's For Mechanical Worknasar_mahsoodPas encore d'évaluation

- Toolbox Talk About PpeDocument3 pagesToolbox Talk About Ppenasar_mahsoodPas encore d'évaluation

- Job Safety Analysis For Scaffolding 1Document3 pagesJob Safety Analysis For Scaffolding 1nasar_mahsood71% (34)

- LG Refridge ServiceManualDocument79 pagesLG Refridge ServiceManualMichael Dianics100% (1)

- RAIS PDA AppDocument8 pagesRAIS PDA Appzaw lin ooPas encore d'évaluation

- 6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHDocument22 pages6-Achs SPMT 210.12.4 G4 6-Axle SPMT 210.12.4 G4: Scheuerle-Fahrzeugfabrik GMBHsrikanthc8550% (2)

- Kinetic and Potential Energy PracticeDocument1 pageKinetic and Potential Energy Practicealchemist2000Pas encore d'évaluation

- FFRT-100: Standard SpecificationsDocument2 pagesFFRT-100: Standard SpecificationsbibhansuPas encore d'évaluation

- Introduction to Concrete Components and ClassificationDocument29 pagesIntroduction to Concrete Components and ClassificationUsama AliPas encore d'évaluation

- Fluid KinematicsDocument49 pagesFluid KinematicsJM Jusay CarabLePas encore d'évaluation

- Projects Oil and Gas BrochureDocument20 pagesProjects Oil and Gas BrochureRussel John RamosPas encore d'évaluation

- The Krebs Cycle ExplainedDocument12 pagesThe Krebs Cycle ExplainedHo Man ChanPas encore d'évaluation

- Solex Adj ProcedureDocument6 pagesSolex Adj Procedureprivate 2Pas encore d'évaluation

- Report 04.02.20Document4 pagesReport 04.02.20Kartik SoniPas encore d'évaluation

- Kaplan Turbine Working As A Propeller CFD InvestigDocument11 pagesKaplan Turbine Working As A Propeller CFD InvestigclaudehackerPas encore d'évaluation

- Energy Manipulation and MeditationDocument6 pagesEnergy Manipulation and Meditationapi-246292178100% (1)

- Measuring Instrument Accuracy LimitsDocument2 pagesMeasuring Instrument Accuracy LimitsDan DanubiusPas encore d'évaluation

- Short and Open Circuit Test On TransformerDocument1 pageShort and Open Circuit Test On TransformerRyan DagsilPas encore d'évaluation

- General Design Considerations for Chemical Plant DesignDocument27 pagesGeneral Design Considerations for Chemical Plant DesignTeddy Ekubay GPas encore d'évaluation

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- Thermal Shock Resistant Neoceram Glass-CeramicDocument2 pagesThermal Shock Resistant Neoceram Glass-CeramicAmândio PintoPas encore d'évaluation

- Dna60 PDFDocument15 pagesDna60 PDFAc IdPas encore d'évaluation

- Flamanville France Nuclear Power Plant WallchartDocument1 pageFlamanville France Nuclear Power Plant WallchartArzu AkarPas encore d'évaluation

- Design and Generating Energy As A Car Alternator TDocument7 pagesDesign and Generating Energy As A Car Alternator TJohnny TestPas encore d'évaluation

- Chlorosorb Ultra Case StudiesDocument5 pagesChlorosorb Ultra Case StudiesWitta Kartika RestuPas encore d'évaluation

- Energy Conservation Oppurtunities in Boiler SystemDocument34 pagesEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- Installation Instructions: Mico Basic 8.6Document2 pagesInstallation Instructions: Mico Basic 8.6Servizio TecnicoPas encore d'évaluation

- The Oil Kings Cooper en 15522 - PDFDocument5 pagesThe Oil Kings Cooper en 15522 - PDFNan EatonPas encore d'évaluation

- E PM 100Document29 pagesE PM 100masoudPas encore d'évaluation

- Transfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualDocument32 pagesTransfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualMesseňger HệŢhốngPas encore d'évaluation

- Boundary Layer ThicknessDocument23 pagesBoundary Layer ThicknessPridhar ThiagarajanPas encore d'évaluation

- 2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSDocument47 pages2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSArhamPas encore d'évaluation

- Installation Manual E-Brick en LoresDocument80 pagesInstallation Manual E-Brick en LoresvideoramirezPas encore d'évaluation