Académique Documents

Professionnel Documents

Culture Documents

Assignment 4: Question 1 REF Output Calculations: MSC - Str/Ecs 762/seismic Design

Transféré par

Mai OthmanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Assignment 4: Question 1 REF Output Calculations: MSC - Str/Ecs 762/seismic Design

Transféré par

Mai OthmanDroits d'auteur :

Formats disponibles

Msc.

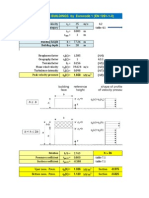

STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 1 OF 9

Made By : MAI

Checked By : DR NORHAYATI

Assignment 4: Question 1

Given data:

Length, L = 10 m

Breadth, b = 250 mm

Depth of beam,h = 400 mm

Effective depth, d = 360 mm

Nominal Cover,c = 25 mm

Dia link, ulink = 8 mm

Inset Comp, d' = 40 mm

Dead Load, gk = 6 kN/m

Live Load, qk = 7 kN/m

Con.strength, fck = 30 N/mm

2

Steel yield, fyk = 500 N/mm

2

EC2

Dead Load factor = 1.35

Live Load factor = 1.5

Ultimate Design Load, W

d

= 1.35 gk + 1.5 qk

= 1.35 x 6 + 1.5 x 7

= 18.6 kN/m

Maximum moment, M

E,d

= (W

d

) L

2

/ 8

= 233 kN-m M

E,d

= 233 kN-m

K = M

E,d

/ (bd

2

fck)

= 233x10

6

/ (250x360

2

x30)

=

K' =

K > K', Hence, beam design as Double Reinforced Beam (DRB) K > K'

DRB

Lever Arm, Z

Z =

= 1.18d

= 1.18 x 360

= 425 mm

0.2397

0.167

ASSIGNMENT #4

RC Beam Design to Eurocode 2

REF OUTPUT CALCULATIONS

(

+ +

134 . 1

25 . 0 5 . 0

K

d

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 2 OF 9

Made By : MAI

Checked By : DR NORHAYATI

Compression Steel required, A's

=

d'/d = 40/360

= < 0.171

fsc = 0.87fyk

= 0.87 x 500

= 435 N/mm

2

A's = (0.2397 - 0.167) x (30) x (250 x 360

2

)

435 (360 - 40)

= mm2

Provide 2 H20 compression bars (A's provided = 628.32 mm

2

) A's prov =

628.32mm

2

Tension Steel required, As

=

= 0.167 x 30 x (250 x 360

2

) + 628

0.87 x 500 x 425

= mm

2

Provide 3 H30 tension bars (As provided = 2120.6 mm

2

) As prov =

2120.6mm

2

OUTPUT

0.11

507.66

1506.02

ASSIGNMENT #4

RC Beam Design to Eurocode 2

REF CALCULATIONS

) ' (

) ' (

2

d d f

bd f K K

sc

ck

s A

Z f

bd f K

yk

ck

'

87 . 0

'

2

+

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 3 OF 9

Made By : MAI

Checked By : DR NORHAYATI

Assignment 4: Question 2

Given data:

Length, L = 6, 4, 6 m

Breadth, b = 350 mm

Depth of beam,h = 550 mm

Effective depth, d = 500 mm

Nominal Cover,c = 40 mm

Main Bar,umain = 25 mm

Dia link, ulink = 10 mm

Inset Comp, d' = 50 mm (assumed)

Dead Load, gk = 25 kN/m

Live Load, qk = 10 kN/m

Con.strength, fck = 30 N/mm

2

Steel yield, fyk = 500 N/mm

2

Slab Thick, t

slab

= 150 mm

Dead Load factor = 1.35

Live Load factor = 1.5

Max Shear Force = 160 kN

Max Hogging

Moment, M

hog

= 147 kN-m

Max Sagging

Moment, M

sag

= 118 kN-m

(a) amount of reinforcement required for maximum sagging moment

K = M

sag

/ (bd

2

f

ck

)

= 118x10

6

/ (350x500

2

x30)

=

K' =

K <K', Hence, beam design as Single Reinforced Beam (SRB)

Lever Arm, Z

Z =

= 1.04d

= 1.04 x 500

= 520 mm

OUTPUT

0.045

0.167

ASSIGNMENT #4

RC Beam Design to Eurocode 2

REF CALCULATIONS

(

+ +

134 . 1

25 . 0 5 . 0

K

d

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 4 OF 9

Made By : MAI

Checked By : DR NORHAYATI

Area of tension reinforcement bar, As

=

= 118x10

6

/ 0.87x500x520

= mm2

Provide 4 H20 tension bars (A's provided = 1256.64 mm

2

) As (sagging)

1256.64mm

2

(b) amount of reinforcement required for maximum hogging moment

K = M

hog

/ (bd

2

f

ck

)

= 147x10

6

/ (350x500

2

x30)

=

K' =

K <K', Hence, beam design as Single Reinforced Beam (SRB)

Lever Arm, Z

Z =

= 1.05d

= 1.05 x 500

= 525 mm

Area of tension reinforcement bar, As

=

= 147x10

6

/ 0.87x500x525

= mm2

Provide 4 H20 tension bars (As provided = 1256.64 mm

2

) As (hogging)

1256.64mm

2

ASSIGNMENT #4

RC Beam Design to Eurocode 2

REF CALCULATIONS OUTPUT

521.66

0.056

0.167

644

Z f

M

yd

sag

(

+ +

134 . 1

25 . 0 5 . 0

K

d

Z f

M

yd

sag

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 1 OF

Made By : MAI

Checked By : DR NORHAYATI

REF CALCULATIONS OUTPUT

ASSIGNMENT #4

RC Beam Design to Eurocode 2

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 5 OF 9

Made By : MAI

Checked By : DR NORHAYATI

( c) If sub-frame structure experiencing the moderate earthquake and the seismic

applied moment on sub-frame is 150 kN-m.

Maximum Hogging Moment, M

E,d

hog

= 297 kN-m

Maximum Sagging Moment, M

E,d

sag

= 268 kN-m

(ci) amount of reinforcement required for maximum sagging moment

K = M

sag

/ (bd

2

f

ck

)

= 268x10

6

/ (350x500

2

x30)

=

K' =

K <K', Hence, beam design as Single Reinforced Beam (SRB)

Lever Arm, Z

Z =

= 1.08d

= 1.08 x 500

= 540 mm

Area of tension reinforcement bar, As

=

= 268x10

6

/ 0.87x500x540

= mm2

Provide 4 H20 tension bars (As provided = 1256.64 mm

2

) As (sagging)

1256.64mm

2

EQ +150 297 kN-m 268 kN-m

OUTPUT

EQ - 150 (-) 3 kN-m (-) 32 kN-m

0.102

147 kN-m 118 kN-m

REF CALCULATIONS

ASSIGNMENT #4

RC Beam Design to Eurocode 2

Load Type Maximum Hogging Moment Maximum Sagging Moment

Gravity

0.167

1141

(

+ +

134 . 1

25 . 0 5 . 0

K

d

Z f

M

yd

sag

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 6 OF 9

Made By : MAI

Checked By : DR NORHAYATI

(cii) amount of reinforcement required for maximum hogging moment

K = M

hog

/ (bd

2

f

ck

)

= 297x10

6

/ (350x500

2

x30)

=

K' =

K <K', Hence, beam design as Single Reinforced Beam (SRB)

Lever Arm, Z

Z =

= 1.11d

= 1.11 x 500

= 555 mm

Area of tension reinforcement bar, As

=

= 297x10

6

/ 0.87x500x555

= mm2

Provide 6 H20 tension bars (As provided = 1885 mm

2

) As (hogging)

1885mm

2

(d) Shear resistance for shorter span of the beam

The maximum sagging moment at the span of 4m is 10 + 150 = 160 kN-m

Maximum Design Shear, V

E,d

max

= Sagging Moment x Effective span/2

= 160x10

6

x 4000 / 2

= 320 kN

Design Shear at face of support, V

E,d

= 320 - (160 x 0.15) --> Half Bearing Length

= 296 kN

REF CALCULATIONS OUTPUT

ASSIGNMENT #4

RC Beam Design to Eurocode 2

0.113

0.167

1230.2

(

+ +

134 . 1

25 . 0 5 . 0

K

d

Z f

M

yd

hog

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 7 OF 9

Made By : MAI

Checked By : DR NORHAYATI

Crushing strength, V

Rd

,

max

of diagonal; strut, assuming u = 22, cot u= 2.5

V

Rd

,

max

= 0.124 b

w

d (1-f

ck

/250)fck

= 0.124 (250)(500)(1-30/250)(30)

= kN

V

Rd

,

max

> V

E,d

OK!

assumed u = 22, cot u= 2.5

Design for shear link

Distance d from face of support,

V

E,d

= 296 - (160 x 0.54)

= kN

A

sw

/s = V

E,d

/ (0.78 d f

yk

cot u)

A

sw

/s = 209.6 / (0.78 x 500 x 500 x 2.5)

A

sw

/s =

Assume 100mm spacing near support,

A

sw

/s =

A

sw

=

Provide 8mm links at 150mm spacing center to center R8~150mm c/c

Minimum Links

A

sw,min

/s = 0.08f

ck

0.5

b

w

/f

yk

= (0.08)(30

0.5

)(300)/500

=

(e) Check for local ductility demand

max =

f

cd

= f

ck

/m

= 30/1.5

REF CALCULATIONS

0.43

0.43

43

0.263

ASSIGNMENT #4

RC Beam Design to Eurocode 2

OUTPUT

409.20

209.6

yd

d

sy o

cd

f

f

c

0018 . 0

'+

Msc.STR/ECS 762/SEISMIC DESIGN

= 20

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 8 OF 9

Made By : MAI

Checked By : DR NORHAYATI

' = As'/Ac

= 2xtx20

2

/4 / (300x550)

=

o = 2q - 1

q = q

o

kw >

1.5 for ou / o1 = 1.3

Table 5.1 q

o

= 3.0 x 1.3

EC8

= 3.9 > 1.5 OK!

o

= 2(3.9) - 1

= 6.8

c

syd

= 0.87f

yk

/Es

= 0.87 x 500 / 200x10

3

=

max = 0.00381 + (0.0018 x 20)

(6.8)(0.0022)(0.87x500)

=

OUTPUT

ASSIGNMENT #4

RC Beam Design to Eurocode 2

REF CALCULATIONS

0.00381

0.0022

0.00934

Msc.STR/ECS 762/SEISMIC DESIGN

Project: Job Ref : ECS762/SD/04

Date : 30/11/2012

Structure: Sheet No : 9 OF 9

Made By : MAI

Checked By : DR NORHAYATI

Cross sectional of the beam at mid length

Cross sectional of the beam at support (column)

OUTPUT REF CALCULATIONS

ASSIGNMENT #4

RC Beam Design to Eurocode 2

Msc.STR/ECS 762/SEISMIC DESIGN

Vous aimerez peut-être aussi

- BS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020Document88 pagesBS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020MohMohkPas encore d'évaluation

- RCCe11 Element DesignDocument8 pagesRCCe11 Element DesignZayyan RomjonPas encore d'évaluation

- SpreadsheetDocument7 pagesSpreadsheetChan Kin CheungPas encore d'évaluation

- Pad Footing Analysis and Design (Bs8110-1:1997)Document6 pagesPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79Pas encore d'évaluation

- RCC62 Retaining WallDocument15 pagesRCC62 Retaining WallRama KrishnaPas encore d'évaluation

- Design of Section According To Eurocode 2Document2 pagesDesign of Section According To Eurocode 23cesPas encore d'évaluation

- Wind EurocodeDocument5 pagesWind EurocodeAntoni Blázquez Boya67% (3)

- Name of Work:-Design of Circular Beam: DegreeDocument25 pagesName of Work:-Design of Circular Beam: DegreeAnirban DeyPas encore d'évaluation

- Design of Free Standing WallsDocument12 pagesDesign of Free Standing Wallssaif.mulla0% (1)

- Retaining wall stability calculationsDocument13 pagesRetaining wall stability calculationsgertjaniPas encore d'évaluation

- Design For Beam Shear - EC2Document1 pageDesign For Beam Shear - EC2thanigai veluPas encore d'évaluation

- CSE 362 Design of Steel Structures Section Properties and CapacitiesDocument19 pagesCSE 362 Design of Steel Structures Section Properties and CapacitiesRufus ChengPas encore d'évaluation

- Design Manual For Structural Stainless Steel Design Example 7 enDocument6 pagesDesign Manual For Structural Stainless Steel Design Example 7 enAl7amdlellah100% (1)

- RC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Document5 pagesRC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Natasha WynePas encore d'évaluation

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79Pas encore d'évaluation

- Wind Loading Based On EC 1991-4 Project: 144 Joo Chiat Terrace Total Building HeightDocument4 pagesWind Loading Based On EC 1991-4 Project: 144 Joo Chiat Terrace Total Building HeightjanethPas encore d'évaluation

- RCC71 Stair Flight & Landing - SingleDocument4 pagesRCC71 Stair Flight & Landing - SingleCioabla BogdanPas encore d'évaluation

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comPas encore d'évaluation

- Punching EC2Document1 pagePunching EC2Win ThanPas encore d'évaluation

- Precast Concrete PilesDocument4 pagesPrecast Concrete PilesnanamallowPas encore d'évaluation

- Pilecap DesignDocument23 pagesPilecap DesignwaikenPas encore d'évaluation

- Cold Form Lipped C Purlin Design Calculations and ChecksDocument8 pagesCold Form Lipped C Purlin Design Calculations and ChecksKTMOPas encore d'évaluation

- Wall CalculationDocument15 pagesWall CalculationAbhijit HazarikaPas encore d'évaluation

- Foundation Pads - MPA - EC2Document1 pageFoundation Pads - MPA - EC2mayphyoPas encore d'évaluation

- Project: ต่อเติมบ้านพักอาศัย Date: Owner: 0 Slap No: Location: 0 FloorDocument13 pagesProject: ต่อเติมบ้านพักอาศัย Date: Owner: 0 Slap No: Location: 0 FloorSurat WaritPas encore d'évaluation

- TCC81 Foundation Pads-1Document21 pagesTCC81 Foundation Pads-1Yap Wei XianPas encore d'évaluation

- STEEL BEAM DESIGNDocument1 pageSTEEL BEAM DESIGNHattori HanzoPas encore d'évaluation

- CALCULATION SHEET FOR 29 RYAN STREET BEAMDocument10 pagesCALCULATION SHEET FOR 29 RYAN STREET BEAMsean edwardsPas encore d'évaluation

- Pe Endorsement For Design of New FCC and Guard House BuildingDocument7 pagesPe Endorsement For Design of New FCC and Guard House Buildingjasekan.dcPas encore d'évaluation

- Corbel Design For Column : ProjectDocument2 pagesCorbel Design For Column : ProjectmayphyoPas encore d'évaluation

- Chapter 24 WexDocument7 pagesChapter 24 WexCiprian VarlanPas encore d'évaluation

- Design A Beams by EurocodeDocument17 pagesDesign A Beams by EurocodeSoubra SenmarecPas encore d'évaluation

- Warehouse Design CalculationsDocument145 pagesWarehouse Design CalculationsCHEA VANNAIPas encore d'évaluation

- Wind Load Calculations According To IS875Document3 pagesWind Load Calculations According To IS875WaelHabibPas encore d'évaluation

- Eccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDocument9 pagesEccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDesign explorer olomizanaPas encore d'évaluation

- Column Foundation ConnectionDocument3 pagesColumn Foundation Connectionmdelacua2Pas encore d'évaluation

- TCC81 Foundation PadsDocument28 pagesTCC81 Foundation PadsMwengei MutetiPas encore d'évaluation

- Basement Wall SPR NewDocument12 pagesBasement Wall SPR NewAnonymous O404LiV4CPas encore d'évaluation

- RC Corbel DesignerDocument1 pageRC Corbel DesignerHari Amudhan IlanchezhianPas encore d'évaluation

- RC Beam Design SummaryDocument3 pagesRC Beam Design SummarymayphyoPas encore d'évaluation

- Determine basic wind velocity and pressure coefficientsDocument66 pagesDetermine basic wind velocity and pressure coefficientsphamducquangPas encore d'évaluation

- Cantilever FrameDocument3 pagesCantilever FrameNikki RobertsPas encore d'évaluation

- RCC13 Punching ShearDocument10 pagesRCC13 Punching ShearT Satheesh KumarPas encore d'évaluation

- Chequered Plate DesignDocument1 pageChequered Plate DesignAsif AliPas encore d'évaluation

- PF2Document4 pagesPF2nhulugallaPas encore d'évaluation

- Brinch Hansen Lateral CapacityDocument18 pagesBrinch Hansen Lateral CapacityDhimas Surya NegaraPas encore d'évaluation

- Durabilty and Fire ResistanceDocument6 pagesDurabilty and Fire ResistanceMohafisto SofistoPas encore d'évaluation

- Box Culvert Calculation As Per BD3101Document21 pagesBox Culvert Calculation As Per BD3101Pilippenge Asanka Iraj LaknathaPas encore d'évaluation

- SEKOLAH MENENGAH KEBANGSAAN GAMBANG PILE LOAD CALCULATIONDocument3 pagesSEKOLAH MENENGAH KEBANGSAAN GAMBANG PILE LOAD CALCULATIONHasifi LotpiPas encore d'évaluation

- Design For TorsionDocument4 pagesDesign For TorsionChhim RothyPas encore d'évaluation

- Reinforced Concrete Beam Design Calculation SheetsDocument35 pagesReinforced Concrete Beam Design Calculation SheetsPrince Mittal0% (1)

- Chapter 36 WexDocument30 pagesChapter 36 WexCaesarAbdullahPas encore d'évaluation

- Topic 6-Beam DesignDocument73 pagesTopic 6-Beam DesignShahrul Syazwan SalimPas encore d'évaluation

- 6.0 Reka Bentuk Rasuk Disokong MudahDocument22 pages6.0 Reka Bentuk Rasuk Disokong MudahPuteri Buntat Cendawan BiruPas encore d'évaluation

- Rectangular Beam ExampleDocument18 pagesRectangular Beam ExampleNur Syaf FiqahPas encore d'évaluation

- Compression Members ProblemsDocument23 pagesCompression Members ProblemsReyPas encore d'évaluation

- Answer Sceme For Mid Term BAA2213 Sem 1 201314Document5 pagesAnswer Sceme For Mid Term BAA2213 Sem 1 201314Muhammad DulabunPas encore d'évaluation

- LS GILADocument12 pagesLS GILAfyqaePas encore d'évaluation

- Bridge Data Design CalculationsDocument27 pagesBridge Data Design CalculationsPranay ReddyPas encore d'évaluation

- Example Flange Beam PDFDocument17 pagesExample Flange Beam PDFFarhana HussinPas encore d'évaluation

- Mega View Function Layout1Document1 pageMega View Function Layout1Mai OthmanPas encore d'évaluation

- Civil Engineering Faculty: Prepared By: Nadzhatul Syamiru Usmaiza Binti Othman 2011212928 EC771PDocument1 pageCivil Engineering Faculty: Prepared By: Nadzhatul Syamiru Usmaiza Binti Othman 2011212928 EC771PMai OthmanPas encore d'évaluation

- Question 1 (A) Solution: The Idealization of The Shear Frame Is As FollowsDocument10 pagesQuestion 1 (A) Solution: The Idealization of The Shear Frame Is As FollowsMai OthmanPas encore d'évaluation

- Bridge SwayDocument1 pageBridge SwayMai OthmanPas encore d'évaluation

- BridgeDocument4 pagesBridgeMai OthmanPas encore d'évaluation

- Bridge Wih SdofDocument16 pagesBridge Wih SdofMai OthmanPas encore d'évaluation

- Table of Content Eia Pembahagian Tugas1Document2 pagesTable of Content Eia Pembahagian Tugas1Mai OthmanPas encore d'évaluation

- ADA402914Document66 pagesADA402914PhalgunaPas encore d'évaluation

- รายการคำนวณโครง Truss รับประตูม้วนDocument5 pagesรายการคำนวณโครง Truss รับประตูม้วนKanokpon CharoenchaiPas encore d'évaluation

- Part I - Design of Steel MembersDocument91 pagesPart I - Design of Steel MembersAnonymous cuOIjrLIPas encore d'évaluation

- Online 1 PREFABRICATION LOW COST Affordable HousingDocument16 pagesOnline 1 PREFABRICATION LOW COST Affordable HousingSadiya SharminPas encore d'évaluation

- Concrete Mix Design m75Document2 pagesConcrete Mix Design m75nil sutar100% (1)

- Characteristics of asphalt concrete mixtures (AC-WC) using coal fly ash filler variationsDocument23 pagesCharacteristics of asphalt concrete mixtures (AC-WC) using coal fly ash filler variationsArsalia InsyiraaPas encore d'évaluation

- ASD-LRFD For Wood Construction (Provisions For Wind and Seismic)Document33 pagesASD-LRFD For Wood Construction (Provisions For Wind and Seismic)weerapon100% (1)

- Glass Powder and Flyash Replacing CementDocument3 pagesGlass Powder and Flyash Replacing CementaryanPas encore d'évaluation

- Amvic Manual LRDocument374 pagesAmvic Manual LRCarmen BalintPas encore d'évaluation

- RCC Water Tank DesignDocument33 pagesRCC Water Tank DesignSuresh Varma100% (1)

- Shell Structure 1Document1 pageShell Structure 1Altaf Mansoori100% (2)

- Civil HPCDocument14 pagesCivil HPCVivek Raj GuptaPas encore d'évaluation

- 2131 PDFDocument22 pages2131 PDFMohammed Sharif100% (1)

- 1) Design A Large Building WITHOUT Expansion JointDocument7 pages1) Design A Large Building WITHOUT Expansion JointSubinDesarPas encore d'évaluation

- One Joist SlabDocument19 pagesOne Joist SlabMohammad SheaitoPas encore d'évaluation

- BS 8002 2015 Code of Practice For Earth Retaining StructuresDocument104 pagesBS 8002 2015 Code of Practice For Earth Retaining StructuresABHINAY MUVVALAPas encore d'évaluation

- Demolition Works: Particular Qty Unit Rate AmountDocument5 pagesDemolition Works: Particular Qty Unit Rate AmountnaeemPas encore d'évaluation

- Base Shear CheckDocument6 pagesBase Shear CheckDilipPas encore d'évaluation

- Multiple Facets of Cable Supported InfrastructureDocument6 pagesMultiple Facets of Cable Supported InfrastructureStructural SpreadsheetsPas encore d'évaluation

- RC Beam - Singly - NSCP 2015 by RgceDocument4 pagesRC Beam - Singly - NSCP 2015 by RgceJet ToledoPas encore d'évaluation

- Pier DesignDocument16 pagesPier DesignKOUSHIK DATTAPas encore d'évaluation

- Concrete Grade EquivalentDocument3 pagesConcrete Grade EquivalentHoang Duc LocPas encore d'évaluation

- Building A Concrete Spiral StairwayDocument5 pagesBuilding A Concrete Spiral StairwaywalaywanPas encore d'évaluation

- Ar. Raj Rewal: Presentation OnDocument78 pagesAr. Raj Rewal: Presentation OnGurpreetSinghKalsi0% (1)

- Msu NaawanDocument7 pagesMsu NaawanGerry Jr BaldomeroPas encore d'évaluation

- Program control and connectivity tablesDocument87 pagesProgram control and connectivity tablesbenjamin diazPas encore d'évaluation

- Progress-Report Toril 01.30.2020Document1 pageProgress-Report Toril 01.30.2020Fedilino P. FornollesPas encore d'évaluation

- GCW-'UltraTech PPC' Issue Date:14.11.2011Document1 pageGCW-'UltraTech PPC' Issue Date:14.11.2011nanda kishoprePas encore d'évaluation

- Building Construction GuideDocument44 pagesBuilding Construction GuideDanishhadi100% (1)

- Ceramic Roof Tiles: People Look Up To BristileDocument40 pagesCeramic Roof Tiles: People Look Up To BristileEricPas encore d'évaluation