Académique Documents

Professionnel Documents

Culture Documents

Plumbing

Transféré par

Niong DavidTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Plumbing

Transféré par

Niong DavidDroits d'auteur :

Formats disponibles

54

ASPE Data Book Volume 3

Table 2-6

Outlet Rating Chart for Medical-Vacuum Piping Systems

Free-Air Allowance, cfm (L/min) at 1 atmosphere Zone Allowances Corridors, Risers, Main Supply Line, Valves Simultaneous Usage Factor (%) Air to Be Transported, cfm (L/min)a

Location of Medical-Surgical Vacuum Outlets Operating rooms: Major A Major B Minor Delivery rooms Recovery room (post anesthesia) and intensive-care units (a minimum of 2 outlets per bed in each such department): 1st outlet at each bed 2nd outlet at each bed 3rd outlet at each bed All others at each bed Emergency rooms Patient rooms: Surgical Medical Nurseries Treatment & examining rooms Autopsy Inhalation therapy, central supply & instructional areas

a Free air at 1 atmosphere.

Per Room

Per Outlet

(Radical, open heart; organ transplant; radical thoracic) (All other major ORs)

3.5 (100) 2.0 1.0 1.0 (60) (30) (30)

100 100 100 100

3.5 (100) 2.0 1.0 (60) (30)

1.0 (30)

(85)

50 50 10 10 100

1.5 0.5 0.1 0.1 1.0

(40) (15) (3) (3) (30)

1.0 (30) 1.0 (30) 1.0 (30) 1.0 (30)

1.0 (30) 1.0 (30) 1.0 (30) 0.5 (15) 2.0 (60) 1.0 (30)

50 10 10 10 20 10

0.5 0.1 0.1 0.05 0.04 0.1

(15) (3) (3) (1) (1) (3)

allow placement of stations in usage groups. These groups can establish demand and simultaneous-use factors (diversities), which are used in the calculation for sizing a particular system. All medical-gas piping systems must be clearly identified using an approved color-coding system similar to that shown in Table 2-8.

Medical-Gas System Dispensing Equipment

Medical-gas outlet/inlet terminals Most manufacturers of medical-gas system equipment offer various types of medical-gas outlets. These medical-gas outlets are available in various gas orders (e.g., 02-N20-Air), center-line spacing, and

Chapter 2 Plumbing Design for Health-Care Facilities

55

Table 2-7 Medical-Vacuum Peak-Demands Chart (Medical-Surgical Vacuum System)

Free-Air Design Flow, scfm (L/min) Area Anesthetizing locations: Specialized surgeries (open heart, organ transplant, etc.) Major operating rooms Cystoscopy Delivery room Emergency operating room Other anesthetizing areas (minor O.R., orthopedic O.R., cardiac catheterization, radiology, induction rooms, etc.) Waste anesthetic gas evacuation Acute care (non-anesthetizing locations): Post-operative recovery room O.B. recovery room Intensive care units (except cardiac) Emergency room Cardiac intensive care Neonatal I.C.U. Subacute patient care areas: Normal nursery Premature nursery Labor / birthing Patient room (surgical) Patient room (medical) Exam & treatment rooms Other areas: Autopsy Central supply Respiratory care department Equipment repair, calibration, and teaching Medical lab 2 (60) 20 10 5 10 10 1 1 (30) (30) 1 1 (30) (30) 10 20 10 50 10 10 3 2 2 1 2 1 (85) (60) (60) (30) (60) (30) 50 50 75 100 50 50 4 (115) 1.5 (40) 100 100 100 100 100 Per Room Per Bed Per Outlet Simultaneous Use Factor (%)

3.5 (100) 2 1 3 (60) (30) (85)

1 1

(30) (30)

50 100

1.5 (40) 1 (30)

1.5 (40) 1.5 (40) 1.5 (40) 1 (30)

56

ASPE Data Book Volume 3

Table 2-8

Gas Intended for Medical Use Oxygen Carbon dioxide Nitrous oxide Cyclopropane Helium Nitrogen Air Vacuum Gas mixtures (other than mixtures of oxygen and nitrogen) Gas mixtures of oxygen and nitrogen 19.5 to 23.5% oxygen All other oxygen concentrations

Color Coding for Piped Medical Gases

United States Color Green Gray Blue Orange Brown Black Yellow* White Canada Color Green on whitea Black on gray Silver on blue Silver on orange Silver on brown Silver on black White and black on black and white Silver on yellowa

Color marking of mixtures shall be a combination of colors corresponding to each component gas. Yellowa Black and green Black and white Pink

Source: Compressed Gas Association, Inc. a Historically, white has been used in the United States and yellow has been used in Canada to identify vacuum systems. Therefore, it is recommended that white not be used in the United States and yellow not be used in Canada as a marking to identify containers for use with any medical gas. Other countries may have differing specific requirements.

for exposed and concealed mountings. Outlet types and configurations must meet the requirements of the local jurisdictional authority and NFPA 99. All outlets must be properly identified and confirmed. Care should also be taken to accurately coordinate the various pieces of medical-gas dispensing equipment with the architect and medical staff involved in the given project. If the project is a renovation, the outlet types should match existing equipment. With prefabricated patient headwall units, the medical-gas outlets are generally furnished by the equipment manufacturer, and it is very important that coordination be maintained by the engineer so that unnecessary duplication of work is avoided. Also, with regard to the over-the-bed medical-gas service consoles, these consoles are often specified in the electrical or equipment section of the specification and medical-gas service outlets are specified, furnished, and installed under the mechanical contract.

Gas-outlet sequence, center-line spacing, and multiple-gang-service outlets are some of the considerations to be taken into account when requesting information from the various equipment manufacturers. It is more practical, in terms of both the cost of the equipment and the installation, to specify and select the manufacturers standard outlet(s). Details and specifications regarding the individual standard outlets are usually available from all manufacturers upon request. The existing outlets are compatible with the adapters found on the hospitals anesthesia machines, flow meters, vacuum regulators, etc. Care should be taken to make sure all future expansions in the same facility have compatible equipment. Patient head-wall systems A recent and growing trend in hospital construction is the

Vous aimerez peut-être aussi

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 11-Car ModelsDocument27 pages11-Car ModelsNiong DavidPas encore d'évaluation

- Principles of Exterior DrainageDocument60 pagesPrinciples of Exterior DrainageSeshupower09Pas encore d'évaluation

- Aurora Model 481 Pumps: Single-Stage Fire ServiceDocument1 pageAurora Model 481 Pumps: Single-Stage Fire ServiceNiong DavidPas encore d'évaluation

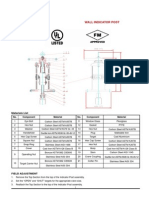

- 6 Rel-Pi-Wall Indicator PostDocument1 page6 Rel-Pi-Wall Indicator PostNiong DavidPas encore d'évaluation

- 08 08.pump Station - IfbDocument35 pages08 08.pump Station - IfbNiong DavidPas encore d'évaluation

- Articles - Elevator Car SizesDocument5 pagesArticles - Elevator Car SizesNiong DavidPas encore d'évaluation

- Electrical EngineeringElevator Safety SystemDocument13 pagesElectrical EngineeringElevator Safety SystemNiong DavidPas encore d'évaluation

- Compressed Air Ref EngDocument118 pagesCompressed Air Ref Engchidambaram kasiPas encore d'évaluation

- FMDS0404NDocument5 pagesFMDS0404NStory LovePas encore d'évaluation

- Basic Elevator Components - Part OneDocument16 pagesBasic Elevator Components - Part OneNiong DavidPas encore d'évaluation

- PSD Ceu 198april13Document16 pagesPSD Ceu 198april13Niong DavidPas encore d'évaluation

- Manual 10 - Irrigation Scheme Operation and MaintenanceDocument55 pagesManual 10 - Irrigation Scheme Operation and MaintenanceNiong DavidPas encore d'évaluation

- Structures For Water Control and DistributionDocument76 pagesStructures For Water Control and Distributionnour100% (2)

- Manual 1 - Introduction To IrrigationDocument152 pagesManual 1 - Introduction To IrrigationNiong DavidPas encore d'évaluation

- Manual 1 - Introduction To IrrigationDocument152 pagesManual 1 - Introduction To IrrigationNiong DavidPas encore d'évaluation

- 43 00 00 - LPG InstallationDocument13 pages43 00 00 - LPG InstallationNiong David100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Community Health Nursing ExamDocument24 pagesCommunity Health Nursing ExamClarisse SampangPas encore d'évaluation

- Inpatient Handbook 2008-2009 UCLADocument275 pagesInpatient Handbook 2008-2009 UCLAartig44Pas encore d'évaluation

- Analisis Sistem Penyelenggaraan Rekam Medis Di Unit Rekam Medis Puskesmas Kota Wilayah Utara Kota KediriDocument7 pagesAnalisis Sistem Penyelenggaraan Rekam Medis Di Unit Rekam Medis Puskesmas Kota Wilayah Utara Kota Kedirikiki naniPas encore d'évaluation

- Study On Functional Outcome of Bimalleolar Ankle FDocument8 pagesStudy On Functional Outcome of Bimalleolar Ankle Fbhushan adhariPas encore d'évaluation

- Koch 2016Document7 pagesKoch 2016Derri PraPas encore d'évaluation

- ADHD Symptomatology Is Best Conceptualized As A Spectrum: A Dimensional Versus Unitary Approach To DiagnosisDocument82 pagesADHD Symptomatology Is Best Conceptualized As A Spectrum: A Dimensional Versus Unitary Approach To DiagnosisPSIQUIATRÍA HUFAPas encore d'évaluation

- Curriculum Vitae: Career ObjectiveDocument2 pagesCurriculum Vitae: Career ObjectiveRajesh Kumar NayakPas encore d'évaluation

- 2020 Case Report Internasional Short Bowel Sindrom Dan BblserDocument6 pages2020 Case Report Internasional Short Bowel Sindrom Dan Bblserdayu mankPas encore d'évaluation

- UNICEF Sri Lanka Humanitarian Situation Report No. 3 (Economic Crisis 2022), 31 December 2022Document11 pagesUNICEF Sri Lanka Humanitarian Situation Report No. 3 (Economic Crisis 2022), 31 December 2022Ada DeranaPas encore d'évaluation

- NURS FPX 6210 Assessment 2 Strategic PlanningDocument6 pagesNURS FPX 6210 Assessment 2 Strategic Planningjoohnsmith070Pas encore d'évaluation

- Updated Unang Yakap Checklist 1Document3 pagesUpdated Unang Yakap Checklist 1Myrel Cedron TucioPas encore d'évaluation

- Hospiatl Malnut PadangDocument36 pagesHospiatl Malnut PadangElvia DesiPas encore d'évaluation

- HA LEC Notes Jan 16 29Document4 pagesHA LEC Notes Jan 16 29Basty BautistaPas encore d'évaluation

- Fullerton Health Sustainability Report FY2022Document76 pagesFullerton Health Sustainability Report FY2022Michael YiinPas encore d'évaluation

- Occupational Health & Safety ReportDocument18 pagesOccupational Health & Safety Reportargya nareswaraPas encore d'évaluation

- Ellen Lent-Wunderlich RN, MS, CPHQ: HighlightsDocument5 pagesEllen Lent-Wunderlich RN, MS, CPHQ: Highlightsapi-2349150Pas encore d'évaluation

- Contract and Agency LawDocument9 pagesContract and Agency Lawdavid omondiPas encore d'évaluation

- A Review On The Oral Health of Pregnant Women Provided With Basic Oral Health Care (BOHC) in The Province of Davao Oriental: A Local PerspectiveDocument17 pagesA Review On The Oral Health of Pregnant Women Provided With Basic Oral Health Care (BOHC) in The Province of Davao Oriental: A Local PerspectiveAudrey Kristina MaypaPas encore d'évaluation

- Quick Guide To Prescribing, Medicine Supplies and Support From Your PharmacyDocument11 pagesQuick Guide To Prescribing, Medicine Supplies and Support From Your Pharmacyminhmap90_635122804Pas encore d'évaluation

- Management of Hepatitis B in Pregnant Women and Infants: A Multicentre Audit From Four London HospitalsDocument8 pagesManagement of Hepatitis B in Pregnant Women and Infants: A Multicentre Audit From Four London HospitalsXenia Marie Razalo LawanPas encore d'évaluation

- MCN - The Childbearing and Childbearing Family in The CommunityDocument91 pagesMCN - The Childbearing and Childbearing Family in The CommunityAndrea Marie SevillaPas encore d'évaluation

- TDM Exam Study Resources PDFDocument5 pagesTDM Exam Study Resources PDFDrosler MedqsPas encore d'évaluation

- EthicsDocument24 pagesEthicsAME DENTAL COLLEGE RAICHUR, KARNATAKAPas encore d'évaluation

- Guide To Clinical AuditDocument54 pagesGuide To Clinical Auditzenti78100% (1)

- Influence of Psychological Stress On Non-Surgical Periodontal Treatment Outcomes in Patients With Severe Chronic PeriodontitisDocument10 pagesInfluence of Psychological Stress On Non-Surgical Periodontal Treatment Outcomes in Patients With Severe Chronic PeriodontitisAndra AgheorghieseiPas encore d'évaluation

- Nbde Study ResourcesDocument3 pagesNbde Study ResourcesMichael GarciaPas encore d'évaluation

- Chen Et Al (2001)Document7 pagesChen Et Al (2001)ayu pathyaPas encore d'évaluation

- Bio Medical WasteDocument6 pagesBio Medical WastePriscilla SolomonPas encore d'évaluation

- Rubric For Drug StudyDocument2 pagesRubric For Drug StudyMart Juaresa Yambao100% (2)

- Essiac A Native Herbal Cancer Remedy Olsen, Cynthia 9781890941000 Books - Amazon - CaDocument1 pageEssiac A Native Herbal Cancer Remedy Olsen, Cynthia 9781890941000 Books - Amazon - CahkvpchdbtpPas encore d'évaluation