Académique Documents

Professionnel Documents

Culture Documents

Projeto de Dutos

Transféré par

paulo_enpjDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Projeto de Dutos

Transféré par

paulo_enpjDroits d'auteur :

Formats disponibles

249

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-1 DUCT MATERIAL ROUGHNESS FACTORS Roughness Category Smooth Absolute Roughness E, mm ft 0.0001 0.03

Duct Material Uncoated carbon steel, clean (Moody 1944) (0.00015 ft) (0.05 mm) PVC plastic pipe (Swim 1982) (0.0003 to 0.00015 ft) (0.01 to 0.05 mm) Aluminum (Hutchinson 1953) (0.00015 to 0.0002 ft) (0.04 to 0.06 mm)

Galvanized steel, longitudinal seams, 4 ft (1200 mm) joints (Griggs 1987) (0.00016 to 0.00032 ft) (0.05 to 0.1 mm) Galvanized steel, spiral seam with 1, 2, and 3 ribs, 12 ft (3600 mm) joints (Jones 1979, Griggs 1987) (0.00018 to 0.00038 ft) (0.05 to 0.12 mm)

Medium Smooth

0.0003

0.09

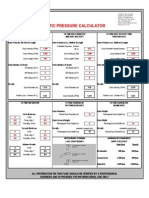

(New Duct Friction Loss Chart)

Hot-dipped galvanized steel, longitudinal seams, 2.5 ft (760 mm) joints (Wright 1945) (0.0005 ft) (0.15 mm) Fibrous glass duct, rigid Fibrous glass duct liner, air side with facing material (Swim 1978) (0.005 ft) (1.5 mm) Fibrous glass duct liner, air side spray coated (Swim 1978) (0.015 ft) (4.5 mm) Flexible duct, metallic, (0.004 to 0.007 ft (1.2 to 2.1 mm) when fully extended) Flexible duct, all types of fabric and wire (0.0035 to 0.015 ft (1.0 to 4.6 mm) when fully extended) Concrete (Moody 1944) (0.001 to 0.01 ft) (0.3 to 3.0 mm)

Old Average

0.0005

0.15

Medium rough

0.003

0.9

Rough

0.01

3.0

14.8

CHAPTER 14

Figure 14-3 DUCT FRICTION LOSS CORRECTION FACTORS

14.9

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-3 CIRCULAR EQUIVALENTS OF RECTANGULAR DUCTS FOR EQUAL FRICTION AND CAPACITY (Metric Units) (2)

Dimensions in mm

14.12

CHAPTER 14

Cont. Table 14-3 CIRCULAR EQUIVALENTS OF RECTANGULAR DUCTS FOR EQUAL FRICTION AND CAPACITY (Metric Units) (2)

Dimensions in mm

Equation for Circular Equivalent of a Rectangular Duct:

De = 1.30 [(ab)0.625/(a + b)0.250]

where a = length of one side of rectangular duct, mm. b = length of adjacent side of rectangular duct, mm. De = circular equivalent of rectangular duct for equal friction and capacity, mm.

14.13

CHAPTER 14

Table 14-5 SPIRAL FLAT-OVAL DUCT (Nominal Sizes-Metric Units) (Diameter of round duct which will have the capacity and friction equivalent to the actual duct size.)

14.15

CHAPTER 14

Table 14-7 VELOCITIESNELOCITY PRESSURES (Metric Units)

Table 14-8 ANGULAR CONVERSION

Degrees 10 20o 30 40 50 60 70 80 90 135 Radians 0.175 0.349 0.524 0.698 0.873 1.05 1.22 1.40 1.57 ( /2) 2.36

180

360

3.14 (

6.28 (2 ) 14.17

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-9 LOSS COEFFICIENTS FOR STRAIGHT-THROUGH FLOW

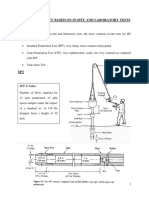

Figure 14-5 AIR DENSITY FRICTION CHART CORRECTION FACTORS When an air distribution system is designed to operate above 2000 feet (610 m) altitude, below 32F

(OC), or above 120F (49C) temperature, the duct

friction loss obtained must be corrected for the air

density. The actual airflow (cfm or I/s) is used to find the duct friction loss which is multiplied by the correction factor or factors from the above chart to obtain the actual friction loss.

14.18

CHAPTER 14

B FITTING LOSS TABLES COEFFICIENT

Duct Cross Section to which Coefficient "C" is referenced is at the top of each table. Negative numbers indicate that the static regain exceeds the dynamic pressure loss of the fitting.

Table 14-10 LOSS COEFFICIENTS, ELBOWS Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp A. Elbow, Smooth Radius (Die Stamped), Round(2)

B. Elbow, Round, 3 to 5 pc--90o(2)

C. Elbow, Round, Mitered (15)

U.S. Units For Standard Air:

Re = 8.56 DV

(Metric Units)

(Re = 66.4 DV)

where: D = duct diameter, inches (mm) V = duct velocity, fpm (m/s) For Rectangular Ducts:

14.19

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-10 LOSS COEFFICIENTS, ELBOWS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp D. Elbow, Rectangular, Mitered (15)

E. Elbow, Rectangular, Mitered with Converging or Diverging Flow (15)

F. Elbow, Rectangular, Smooth Radius without Vanes (15)

U.S. Units For Standard Air: Re = 8.56 DV

(Metric Units) (Re = 66.4 DV)

where: D = duct diameter, inches (mm) V = duct velocity, fpm (m/s) For Rectangular Ducts:

14.20

CHAPTER 14

Table 14-10 LOSS COEFFICIENTS, ELBOWS (Cont.) Use the velocity pressure (Vp)of the upstream section. Fitting loss (TP) = C x Vp G. Elbow, Rectangular, Smooth Radius with Splitter Vanes (2)

NOTES FOR THIS FIGURE ONLY: A) See Page 5.14 to calculate splitter vane spacing.

B) CR = Curve Ratio

C) Use correction factors in Note 1 on Page 14.19 for elbows other than 90.

14.21

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-10 LOSS COEFFICIENTS, ELBOWS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp H. Elbow, Rectangular, Mitered with Turning Vanes (See Chapter 5, Sections E and H for additional information and data.)

I. Elbows, 90o,Rectangular, Z-Shaped (15)

U.S. Units For Standard Air: (Metric Units) Re = 8.56 D V (Re = 66.4 DV) where: D = duct diameter, inches (mm) V = duct velocity, fpm (m/s) For Rectangular Ducts:

14.22

CHAPTER 14

Table 14-10 LOSS COEFFICIENTS, ELBOWS (Cont.) Use the velocity pressure (Vp)of the upstream section. Fitting loss (TP) = C x Vp

J. Elbows, 90o,Rectangular in Different Planes (15)

(See Chapter 5, Section Hfor new data on spin-in fittings)

K. Elbows, 30o,Round, Offset (15)

L. Elbows, 90o, Rectangular Wye or Tee Shape

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-11 LOSS COEFFICIENTS, TRANSITIONS (Diverging Flow) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp A. Transition, Round, Conical (15)

U.S. Units = 8.56 DV where: D = Upstream Diameter, inches (mm) V = Upstream Velocity, fpm (m/s) (Metric Units) (Re = 66.4 DV)

Re

B. Transition, Rectangular, Pyramidal (15)

Note 6: A = Area (Entering airstream), A1 = Area (Leaving airstream)

14.24

CHAPTER 14

Table 14-11 LOSS COEFFICIENTS, TRANSITIONS (Diverging Flow) (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp C. Transition, Round to Rectangular (15)

D. Transition, Rectangular to Round (15)

For Figures C and D, compute 0 using the equations and find the coefficient C from Table 14-11B, Transition, Rectangular, Pyramidal.

E. Transition, Rectangular, Sides Straight (15)

F. Transition, Symmetric at Fan With Duct Sides Straight (15)

Note 6: A = Area (Entering airstream), A1 = Area (Leaving airstream)

14.25

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-11 LOSS COEFFICIENTS, TRANSITIONS (Diverging Flow) (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp G. Transition, Asymmetric at Fan With Duct Sides Straight, Top Level (15)

H. Transition, Asymmetric at Fan With Duct Sides Straight, Top 10 Down (15)

I. Transition, Asymmetric at Fan With Duct Sides Straight, Top 10 Up (15)

J. Transition, Pyramidal at Fan With Duct (15)

Note 6: A = Area (Entering airstream), A, = Area (Leaving airstream)

14.26

CHAPTER 14

Table 14-12 LOSS COEFFICIENTS, TRANSITIONS (Converging Flow) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp A. Contraction, Round and Rectangular, Gradual to Abrupt (15)

Coefficient C (See Note 7)

10 15-40 AA st0 100 15'-40' 50'-60' 2 4 6 10 0.05 0.05 0.05 0.05 0.05 0.04 0.04 0.05 0.06 0.07 0.07 0.08 120

900

150

1200 1500

180

1800

0.12 0.17 0.18 0.19

0.18 0.27 0.28 0.29

0.24 0.35 0.36 0.37

0.26 0.41 0.42 0.43

When O = 180

B. Contraction, Conical, Round and Rectangular (15)

Coefficient C = K Co

0 is major angle for rectangular transition

Note 7: Al = Area (Entering airstream), A = Area (Leaving airstream)

14.27

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-12 LOSS COEFFICIENTS, TRANSITIONS (Converging Flow) (Cont.) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp C. Contraction, Rectangular Slot to Round (15)

Table 14-13 LOSS COEFFICIENTS, CONVERGING JUNCTIONS (Tees, Wyes) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp A. Converging Wye, Round(2)

Note 7: Al = Area (Entering airstream), A = Area (Leaving airstream) Note 8: A = Area, Q = Airflow, V = Velocity

14.28

CHAPTER 14

Table 14-13 LOSS COEFFICIENTS, CONVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp

B. Converging Tee, 90, Round (15)

C. Converging Tee, Round Branch to Rectangular Main

D. Converging Tee, Rectangular Main and Branch

Note 8: A = Area, Q = Airflow, V = Velocity

14.29

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-13 LOSS COEFFICIENTS, CONVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp E. Converging Wye, Conical, Round (2

F. Converging Tee, 45o Entry Branch to Rectangular Main

Note 8: A = Area, Q = Airflow, V = Velocity

14.30

CHAPTER 14

Table 14-13 LOSS COEFFICIENTS, CONVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp)of the downstream section. Fitting loss (TP) = C x Vp

G. Symmetrical Wye, Dovetail, Rectangular (15)

Note 8: A = Area, Q = Airflow, V = Velocity

14.31

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-13 LOSS COEFFICIENTS, CONVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp)of the downstream section. Fitting loss (TP) = C x Vp H. Converging Wye, Rectangular(15)

I. Wye, Rectangular and Round (15)

When:

Alb = A2b Ac = Alb + A2b

Note 8: A = Area, Q = Airflow, V = Velocity

14.32

CHAPTER 14

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Tees, Wyes) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp Round (15) A. Tee or Wye, 30o to 90o,

Note 8: A = Area, Q = Airflow, V = Velocity

14.33

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp B. 90o Conical Tee, Round(2)

C. 45o Conical Wye, Round (2)

D. 90 Tee, Round, Rolled 45o with 45o Elbow, Branch 90o to Main(2)

E. 90 Tee, Round, with 90 Elbow, Branch 90 to Main (2)

Note 8: A = Area, Q = Airflow, V = Velocity

14.34

CHAPTER 14

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp F. 90o Tee, Round, Rolled 45o with 60o Elbow, Branch 45o to Main(2)

G. 90o Conical Tee, Round, Rolled 45o with 45o Elbow, Branch 90o to Main(2)

H. 90o Conical Tee, Round, Rolled 45o with 60o Elbow, Branch 45o to Main(2)

I. 45 Wye, Round, Rolled 45o with 60o Elbow, Branch 90o to Main(2)

Note 8: A = Area, Q = Airflow, V = Velocity

14.35

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp J. 45o Conical Wye, Round, Rolled 45o with 60o Elbow, Branch 90 to Main(2)

K. 45o Wye, Round, Rolled 45o with 30o Elbow, Branch 45o to Main(2)

L. 45o Conical Wye, Round, Rolled 45o with 30o Elbow, Branch 45 to Main(2)

Note 8: A = Area, Q = Airflow, V = Velocity

14.36

CHAPTER 14

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp

M. 45o Wye, Conical Main and Branch with 45o Elbow, Branch 90 to Main (15)

N. Tee, 45 Entry, Rectangular Main and Branch

P. Tee, 45o Entry, Rectangular Main and Branch with Damper

14.37

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp Q. Tee, Rectangular Main and Branch

R. Tee, Rectangular Main and Branch with Damper

S. Tee, Rectangular Main and Branch with Extractor

14.38

CHAPTER 14

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp T. Tee, Rectangular Main to Round Branch

U. Wye, Rectangular (15)

14.39

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp V. Tee Rectangular Main to Conical Branch (2)

W. Wye, Rectangular (15)

X. Symmetrical Wye, Dovetail, Rectangular (15)

14.40

CHAPTER 14

Table 14-14 LOSS COEFFICIENTS, DIVERGING JUNCTIONS (Cont.)

Use the velocity pressure (VP) of the upstream section. Fitting loss (TP) = C x Vp

Y. Wye, Rectangular and Round (15)

Z. Tee, Rectangular Reducing, 45 Entry Branch(2)

Table 14-15 LOSS COEFFICIENTS, ENTRIES

Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp

A. Duct Mounted in Wall, Round and Rectangular (15)

14.41

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-15 LOSS COEFFICIENTS, ENTRIES (Cont.) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp B. Smooth Converging Bellmouth, Round, without End Wall (15)

C. Smooth Converging Bellmouth, Round, with End Wall (15)

D. Conical, Converging Bellmouth, Round and Rectangular without End Wall (15)

14.42

CHAPTER 14

Table 14-15 LOSS COEFFICIENTS, ENTRIES (Cont.)

Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp E. Conical, Converging Bellmouth, Round and Rectangular, with End Wall (15)

F. Intake Hood (15)

G. Hood, Tapered, Flanged or Unflanged(2)

Note 9: With screen in opening at Ds, Cs = C (from table) + C (Screen coef. Table 14-17) As)2 where: A= Area at D; As = Area at Ds

14.43

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-15 LOSS COEFFICIENTS, ENTRIES (Cont.) Use the velocity pressure (Vp) of the downstream section. Fitting loss (TP) = C x Vp H. Hood, Canopy Island or Range

I.

Hood, Slot (Dishwasher)

Table 14-16 LOSS COEFFICIENTS, EXITS Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp A. Exhaust Hood (15)

14.44

CHAPTER 14

Table 14-16 LOSS COEFFICIENTS, EXITS (Cont.).

Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp B. Exit, Conical, Round, with or without a Wall (15)

C. Exit, Plane Diffuser, Rectangular, with or without a Wall (15)

D. Exit, Pyramidal Diffuser, Rectangular, with or without a Wall (15)

14.45

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-16 LOSS COEFFICIENTS, EXITS (Cont.)

Use the velocity pressure (VP) of the upstream section. Fitting loss (TP) = C x Vp E. Exit, Discharge to Atmosphere from a 90o Elbow, Round and Rectangular (15)

A

RECTANGULAR: Coefficient C (See Note 11) R/W Note: In loss coefficient. 0 0.75 1.0 1.5 2.5 L/W 0 3.0 2.2 1.8 1.5 1.2 0.5 3.1 2.2 1.5 1.2 1.1 1.0 3.2 2.1 1,4 1.1 1.1 1.5 3.0 1.8 1,4 1.1 1.0 2.0 2.7 1.7 1.3 1.1 1.0 3.0 2.4 1.6 1.3 1.1 1.0 4.0 2.2 1.6 1.2 1.1 1.0 6.0 2.1 1.5 1.2 1.1 1.0 8.0 2.1 1.5 1.2 1.1 1.0 12.0 2.0 1.5 1.2 1.1 1.0

ROUND: Coefficient C (See Note 10) L/D C 0.9 1.5 1.3 1.4 When: R/D = 1.0 (Round)

F. Exit, Duct Flush with Wall, Flow along Wall (15)

14.46

CHAPTER 14

Table 14-16 LOSS COEFFICIENTS, EXITS (Cont.)

Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp

G. Plane Asymmetric Diffuser at Fan Outlet without Ductwork (15)

H. Pyramidal Diffuser at Fan Outlet without Ductwork (15)

I. Fan, Free Discharge, Plenum

J. Exit, Abrupt, Round and Rectangular, with or without a Wall (15)

14.47

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-17 LOSS COEFFICIENTS, SCREENS AND PLATES Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp A. Screen in Duct, Round and Rectangular (15)

B. Perforated Plate in Duct, Thick, Round and Rectangular (15)

14.48

CHAPTER 14

Table 14-18 LOSS COEFFICIENTS, OBSTRUCTIONS (Constant Velocities) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp A. Damper, Butterfly, Thin Plate, Round(15)

B. Damper, Butterfly, Thin Plate, Rectangular(15)

C. Damper, Gate, Round(15)

14.49

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-18 LOSS COEFFICIENTS, OBSTRUCTIONS (Constant Velocities) (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp D. Damper, Gate, Rectangular(15)

E. Damper, Rectangular, Parallel Blades (2)

F. Damper, Rectangular, Opposed Blades (2)

14.50

CHAPTER 14

Table 14-18 LOSS COEFFICIENTS, OBSTRUCTIONS (Constant Velocities) (Cont.) Use the velocity pressure (Vp)of the upstream section. Fitting loss (TP) = C x Vp G. Damper, Butterfly, Airfoil Blade, Rectangular(15)

H. Obstruction, Smooth Cylinder in Round and Rectangular Ducts(15)

I. Round Duct, Depressed to Avoid an Obstruction

14.51

DUCT

DESIGN

TABLES

AND

CHARTS

Table 14-18 LOSS COEFFICIENTS, OBSTRUCTIONS (Constant Velocities) (Cont.) Use the velocity pressure (Vp) of the upstream section. Fitting loss (TP) = C x Vp J. Rectangular Duct, Depressed to Avoid an Obstruction

K. Rectangular Duct with 4-45 Smooth Radius Ells to Avoid an Obstruction

L. Rectangular Duct with 4-90 Mitered Ells to Avoid an Obstruction

14.52

Vous aimerez peut-être aussi

- Appendix 6 Fitting Loss Coefficient TablesDocument3 pagesAppendix 6 Fitting Loss Coefficient Tablesnewlimpoh100% (7)

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Appendix 6 Fitting Loss Coefficient Tables PDFDocument3 pagesAppendix 6 Fitting Loss Coefficient Tables PDFAshutosh Kumar DubeyPas encore d'évaluation

- Design and Analysis of Centrifugal CompressorsD'EverandDesign and Analysis of Centrifugal CompressorsPas encore d'évaluation

- E DuctulatorDocument8 pagesE DuctulatorMoe KimoPas encore d'évaluation

- Charts: Dr. Ali Hammoud Exam - 2011Document19 pagesCharts: Dr. Ali Hammoud Exam - 2011Rodrigue BarbarPas encore d'évaluation

- Smacna Duct Fitting Loss TableDocument2 pagesSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

- Calculaion PDDocument4 pagesCalculaion PDbhaveshkumar78Pas encore d'évaluation

- Static Pressure CalculatorDocument9 pagesStatic Pressure CalculatorTanveer AzizPas encore d'évaluation

- E Ductulator09Document9 pagesE Ductulator09Carlos SamaniegoPas encore d'évaluation

- Pressure Vessel and Stacks Field Repair ManualD'EverandPressure Vessel and Stacks Field Repair ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- Boilers Chimney Draft and Breeching CalculationDocument15 pagesBoilers Chimney Draft and Breeching Calculationjoabjim8392Pas encore d'évaluation

- Distillation Column DesignDocument27 pagesDistillation Column DesignManisha DeenaPas encore d'évaluation

- Calculation of Air Duct Pressure Loss (Circular)Document5 pagesCalculation of Air Duct Pressure Loss (Circular)Phyu Mar Thein KyawPas encore d'évaluation

- Hazen Williams EquationDocument5 pagesHazen Williams Equationprabhjot123100% (1)

- Axial Flow MachinesDocument93 pagesAxial Flow MachinesSaipriya BalakumarPas encore d'évaluation

- NewLecture8 Centrifugal CompressorsDocument126 pagesNewLecture8 Centrifugal CompressorsKhalid Mahmood100% (1)

- 0 - Mains Water Pipe SizingDocument4 pages0 - Mains Water Pipe SizingstarykltPas encore d'évaluation

- Calculation of Blower Air Pipe Pressure Loss (Ave)Document30 pagesCalculation of Blower Air Pipe Pressure Loss (Ave)Phyu Mar Thein Kyaw100% (2)

- Pump Sizing Calculation SheetDocument20 pagesPump Sizing Calculation Sheetvazzoleralex6884100% (1)

- Stability Control ReportDocument15 pagesStability Control Reportvidic971Pas encore d'évaluation

- Fluid Flow Lecture Notes - 9Document13 pagesFluid Flow Lecture Notes - 9Lin Xian Xing100% (1)

- Extraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)Document17 pagesExtraction of Plant Design VIVA VOCE (Updated 08-05-2008 5pm)weeseongPas encore d'évaluation

- 4 - Pipe Fitting LossesDocument4 pages4 - Pipe Fitting LossesstarykltPas encore d'évaluation

- AutomationDocument57 pagesAutomationlalinda100% (4)

- VICTAULIC PipingMethodForAccomodatingPipeOffsetDocument5 pagesVICTAULIC PipingMethodForAccomodatingPipeOffsetJohnny SanchezPas encore d'évaluation

- Eywords: Analytical Models ImpellerDocument11 pagesEywords: Analytical Models ImpellerbaubaumihaiPas encore d'évaluation

- Pipe System DesignDocument64 pagesPipe System DesignRonald GeorgePas encore d'évaluation

- Appendix I.: Install Equation Editor and Double-Click Here To View EquationDocument26 pagesAppendix I.: Install Equation Editor and Double-Click Here To View EquationPhasin ChitutsahaPas encore d'évaluation

- Pressure Loss - Pump House-9bDocument1 pagePressure Loss - Pump House-9bkarthikraja21Pas encore d'évaluation

- Lecture 2. Sewer HydraulicsDocument13 pagesLecture 2. Sewer HydraulicsshamashergyPas encore d'évaluation

- Centrifugal Pump DesignDocument15 pagesCentrifugal Pump Designzakibrant23Pas encore d'évaluation

- Conversion TableDocument6 pagesConversion TableDoctorObermanPas encore d'évaluation

- Ventilation DesignDocument4 pagesVentilation DesignSharon LambertPas encore d'évaluation

- Static Pressure Calculator r3Document1 pageStatic Pressure Calculator r3ehtesham314Pas encore d'évaluation

- 8.8 Pump Head Available (In Bar)Document4 pages8.8 Pump Head Available (In Bar)AnujGargPas encore d'évaluation

- TROX Guidelines PDFDocument32 pagesTROX Guidelines PDFMiguelQuartilhoPas encore d'évaluation

- 7651bc0b3f PDFDocument69 pages7651bc0b3f PDFameer100% (1)

- Equal Friction Method For Duct DesignDocument8 pagesEqual Friction Method For Duct Designimo konsensya100% (1)

- Static Pressure CalculatorDocument9 pagesStatic Pressure CalculatorjairofgfPas encore d'évaluation

- 6 - Axial Flow CompressorsDocument43 pages6 - Axial Flow CompressorsMostafa Abd Almaksoud100% (2)

- Head Loss Due To Pipe FittingDocument6 pagesHead Loss Due To Pipe Fittingmhk00133% (3)

- Exp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctDocument7 pagesExp6 Air Flow Velocity and Pressure Coefficient Around The 90o Rectangular DuctKawar Abid100% (1)

- Pressure Loss From FittingsDocument16 pagesPressure Loss From FittingsNoor AiniPas encore d'évaluation

- Centrifugal Pump Design - Rev 2Document11 pagesCentrifugal Pump Design - Rev 2jehadyam100% (1)

- Drilling HydraulicDocument52 pagesDrilling HydraulicHeris Sitompul100% (1)

- Pipe Sizing and Pressure Drop CalculationsDocument14 pagesPipe Sizing and Pressure Drop Calculationsreach_arindomPas encore d'évaluation

- Duct Sizing - ReferenceDocument27 pagesDuct Sizing - ReferenceAnkurPas encore d'évaluation

- Water & Waste Water Engineering 2Document105 pagesWater & Waste Water Engineering 2MA. MATEA MARTINEZ100% (3)

- Effect of Turning Angle On Flow Field Performance of Linear Bowed Stator in Compressor at Low Mach NumberDocument7 pagesEffect of Turning Angle On Flow Field Performance of Linear Bowed Stator in Compressor at Low Mach NumberMoses DevaprasannaPas encore d'évaluation

- Core Ag Engineering Principles - Session 1Document101 pagesCore Ag Engineering Principles - Session 1peagriculturePas encore d'évaluation

- Hydraulic Turbine Design 1Document10 pagesHydraulic Turbine Design 1bikesh032Pas encore d'évaluation

- NASA Tests On 13 Navy Type Model PropellersDocument15 pagesNASA Tests On 13 Navy Type Model PropellersDavid Jiménez MenaPas encore d'évaluation

- Fluid System 04-Centrifugal PumpDocument46 pagesFluid System 04-Centrifugal PumpFuad AlhamidPas encore d'évaluation

- Part Design With CatiaDocument42 pagesPart Design With CatiaBirolC.YakupoğluPas encore d'évaluation

- Icp FM 21-20 ShoDocument46 pagesIcp FM 21-20 Shopaulo_enpjPas encore d'évaluation

- Boiler Installation and SetupDocument30 pagesBoiler Installation and Setupcakhokhe100% (1)

- Forest Bioenergy or Forest Carbon? Assessing Trade-Offs in Greenhouse Gas Mitigation With Wood-Based FuelsDocument7 pagesForest Bioenergy or Forest Carbon? Assessing Trade-Offs in Greenhouse Gas Mitigation With Wood-Based Fuelspaulo_enpjPas encore d'évaluation

- Redwood Canoe PDFDocument6 pagesRedwood Canoe PDFpaulo_enpjPas encore d'évaluation

- A Guide To Tracking People and AnimalsDocument13 pagesA Guide To Tracking People and Animalslearningcurveasia3076Pas encore d'évaluation

- Plywood Touring Canoe PlansDocument14 pagesPlywood Touring Canoe PlansRush Wingate100% (1)

- The Modern Gunsmith Vol 1 (Howe 1941)Document393 pagesThe Modern Gunsmith Vol 1 (Howe 1941)paulo_enpj100% (3)

- The Backyard FoundryDocument54 pagesThe Backyard FoundryOctavio Jesus Dominguez CarrascoPas encore d'évaluation

- Entanglement-Based Secure Quantum Cryptography Over 1,120 KilometresDocument18 pagesEntanglement-Based Secure Quantum Cryptography Over 1,120 KilometresFredy OrjuelaPas encore d'évaluation

- Commercial ComponentsDocument0 pageCommercial ComponentsChevronellePas encore d'évaluation

- Units and Unity in Magnetism: A Call For ConsistencyDocument3 pagesUnits and Unity in Magnetism: A Call For Consistencysiva shankarPas encore d'évaluation

- What Isa Laya CentreDocument9 pagesWhat Isa Laya CentreJohn SkybirdwalkingbearPas encore d'évaluation

- WTC24 W71DAR FD SpecificationDocument4 pagesWTC24 W71DAR FD SpecificationHector Rene Mamani IngalaPas encore d'évaluation

- Qafco 5 RG BoilerDocument156 pagesQafco 5 RG BoilerfakhanPas encore d'évaluation

- Chapter 6 TestDocument5 pagesChapter 6 TesthelloblargPas encore d'évaluation

- Nikola Tesla Lost ManuscriptDocument7 pagesNikola Tesla Lost ManuscriptPANDASKOALA80% (5)

- EnthalpyDocument16 pagesEnthalpyMazen AliPas encore d'évaluation

- Colorimeter 1Document2 pagesColorimeter 1Eng CirroPas encore d'évaluation

- Xii Physics Chapter1-BookDocument25 pagesXii Physics Chapter1-BookChitra KaruppiahPas encore d'évaluation

- Manual Book Microscope CX22 LEDDocument28 pagesManual Book Microscope CX22 LEDtomatPas encore d'évaluation

- ASME - CFD FundamentalsDocument63 pagesASME - CFD FundamentalssebastienschlesserPas encore d'évaluation

- 书单Document45 pages书单Wei LiuPas encore d'évaluation

- 11 HeatDocument11 pages11 Heatapi-185034533Pas encore d'évaluation

- Lecture 1Document8 pagesLecture 1Khang DangPas encore d'évaluation

- Natural RubberDocument16 pagesNatural RubberQoe IooNkPas encore d'évaluation

- Skema 1 PPP Fizik K3 F5 2017Document6 pagesSkema 1 PPP Fizik K3 F5 2017Chan YawPas encore d'évaluation

- Bearing Capacity From Other Methods-KFCDocument14 pagesBearing Capacity From Other Methods-KFCmazharPas encore d'évaluation

- CON4341 - E - Note - 03 PSD, Consistency, DescriptionsDocument22 pagesCON4341 - E - Note - 03 PSD, Consistency, Descriptions123Pas encore d'évaluation

- Final Protocol SuspensionDocument8 pagesFinal Protocol SuspensionCharleen Joyce UsacdinPas encore d'évaluation

- Kaddour Najim Control of Continuous Linear SystemsDocument11 pagesKaddour Najim Control of Continuous Linear SystemsChrislei RizzattiPas encore d'évaluation

- Cleaning and Shaping of The Root Canal System v4 AngolDocument5 pagesCleaning and Shaping of The Root Canal System v4 AngolralszPas encore d'évaluation

- Kerkythea Material Editor Guide 01Document36 pagesKerkythea Material Editor Guide 01sapomasterPas encore d'évaluation

- ESI MS AdductsDocument5 pagesESI MS AdductsSeet TohPas encore d'évaluation

- Harmonic CourseDocument66 pagesHarmonic CourseartzpirationPas encore d'évaluation

- Statistical Mechanics of Hard Ellipsoids. I. Overlap Algorithm and The Contact FunctionDocument8 pagesStatistical Mechanics of Hard Ellipsoids. I. Overlap Algorithm and The Contact FunctionHugo LivasPas encore d'évaluation

- Turbine ModelsDocument4 pagesTurbine Modelsstupid143Pas encore d'évaluation

- Determination of The Electron Specific MassDocument2 pagesDetermination of The Electron Specific MassAdina BlazePas encore d'évaluation

- Marine Structural Design CalculationsD'EverandMarine Structural Design CalculationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresD'EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresÉvaluation : 1 sur 5 étoiles1/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignD'EverandAdvanced Modelling Techniques in Structural DesignÉvaluation : 5 sur 5 étoiles5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignD'EverandTo Engineer Is Human: The Role of Failure in Successful DesignÉvaluation : 4 sur 5 étoiles4/5 (138)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsD'EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsPas encore d'évaluation

- Structural Cross Sections: Analysis and DesignD'EverandStructural Cross Sections: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Pile Design and Construction Rules of ThumbD'EverandPile Design and Construction Rules of ThumbÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingD'EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingPas encore d'évaluation

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesD'EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsD'EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsÉvaluation : 4 sur 5 étoiles4/5 (16)

- Design and Construction of Soil Anchor PlatesD'EverandDesign and Construction of Soil Anchor PlatesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksD'EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksÉvaluation : 3 sur 5 étoiles3/5 (2)