Académique Documents

Professionnel Documents

Culture Documents

BGF

Transféré par

Nigin ParambathCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BGF

Transféré par

Nigin ParambathDroits d'auteur :

Formats disponibles

Understanding ASTM D 2000/SAE J200.

Having discussed the properties and uses of the most common elastomer types, the question then becomes: How can these properties be succinctly specified when an existing compound is being selected or when a new compound must be formulated? In order to provide guidance in the selection of vulcanized rubber materials, and to provide a method for specifying these materials by the use of a simple line call-out specification, the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE) established ASTM D 2000 / SAE J200. Though these standards are virtually identical, J200 finds its widest use within the automotive industry. D 2000 is the more common tool among rubber manufacturers. Specifying your elastomer choice via a standardized line call-out is a good idea because it allows the flexibility of using different manufacturers compounds while ensuring that the material quality and performance stay consistent. D 2000 is based on the premise that the properties of all rubber products can be arranged into characteristic material designations. These designations are determined by types, based on resistance to heat aging, and classes, based on resistance to swelling. Here is the line call-out, or specification, for N470, a 70 (Shore A) durometer nitrile:

ASTM D 2000-95 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 Z1 Z2

Specifying your elastomer choice via a standardized line call-out is a good idea because it allows the flexibility of using different manufacturers' compounds while ensuring that the material quality and performance stay consistent.

Call-out

This line call-out contains the following: A. The document name (ASTM D 2000-95). The two-digit number following the hyphen indicates the revision year (in this case, 1995). B. The letter M may or may not be present. Since it is present in our example, the units of measure in

the line call-out (and in any other documentation, such as a test report) are understood to be stated in SI (metric) units. For example, tensile strength is in megapascals (MPa). If the M was not present, English units would be in use. For example, tensile strength would be in pounds per square inch (psi). C. The Grade Number defines specific added test requirements which are desirable in cases where the basic requirements do not always sufficiently ensure an acceptable material. Grade 1 indicates that only the basic requirements are compulsory; no suffix requirements are permitted. All other grades and test requirements are listed in Table 6 of the D 2000 document. In our example, the material is Grade 2. D. The Type is based on changes in tensile strength of not more than 30%, elongation of not more than -50%, and hardness of not more than 15 points after heat aging for 70 hours at a given temperature. The temperatures at which these materials shall be tested for determining type are listed in Table 18. In our example, the material is Type B, which corresponds to a 100 C test temperature. E. The Class is based on the materials resistance to swelling in Industry Reference Material (IRM) 903 Oil (now used in lieu of ASTM Oil # 3, which was discontinued due to requirements by the Occupational Safety and Health Administration). Testing involves immersion for 70 hours at the temperature previously determined from Table 18 (100 C), after which swell is calculated. Limits of swelling for each class are shown in Table 19. In our example, the material is Class G, indicating a maximum swell of 40%. Be aware that ASTM Oil # 3 and IRM 903 Oil are similar but not identical, so complete equivalency among results is not possible. For information on converting ASTM oil swell values to IRM values, please refer to ASTM Emergency Standard ES 27-94. Table 20 below lists the D 2000 material designations (type and class) and the elastomers most often used for each. F. The next three digits (in this case, 714) specify the hardness and tensile strength. The first digit

Table 18

Table 19

Table 20

Table 21

indicates Shore A durometer. For example, 7 for 70 5. The next two numbers indicate the minimum tensile strength, i.e. 14 for 14 MPa. Remember, this will be in SI units if the letter M is in the call-out, and English units if not. To convert to psi, simply multiply the MPa number by 145. In this case, 14 MPa would convert to 2,030 psi MPa X 145 = psi psi / 145 = MPa G. Suffix letters and suffix numbers follow the hardness and tensile strength specifications to provide for additional testing requirements. The meaning of each suffix letter is shown in Table 21. For example, the B of B14 specifies a compression set test. Suffix letters are typically followed by two suffix numbers. The first number always indicates the test method, and the second indicates the test temperature. The suffix numbers are covered by Tables 4 and 5 of the D 2000 document. For example, the 1 specifies a 22-hour compression set test as detailed in D 395 (Method B) for solid test specimens, and the 4 specifies testing at 100 C. Keep in mind that in some cases, the second suffix number may be two digits, which means you might see something like F110. F110 would indicate a 3-minute low temperature resistance test as detailed in ASTM D 2137 (Method A) and conducted at a temperature of -65 C. Thats all there is to understanding the D 2000 / J200 call-out system. It is one of the most versatile specifications in the rubber industry. In addition to helping you specify compounds, familiarity with the system will also help you make sense of material test reports. Lets take a closer look at a sample report next.

Vous aimerez peut-être aussi

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Understanding ASTM D 2000Document6 pagesUnderstanding ASTM D 2000Murat YankasPas encore d'évaluation

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsD'EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsPas encore d'évaluation

- Astm d2000 İçeri̇kDocument27 pagesAstm d2000 İçeri̇kAhmet HamamcıoğluPas encore d'évaluation

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- 04 Satori Technical Article - ASTM D2000Document3 pages04 Satori Technical Article - ASTM D2000Oscar SupelanoPas encore d'évaluation

- ASTM D 2000: Specification NumberDocument3 pagesASTM D 2000: Specification NumberjanarthananPas encore d'évaluation

- Astm-D2000 How To ReadDocument3 pagesAstm-D2000 How To Readmakineci_67Pas encore d'évaluation

- Astm 890Document3 pagesAstm 890bsnegi111Pas encore d'évaluation

- Asme Sec Viii HighlightsDocument10 pagesAsme Sec Viii HighlightsANILPas encore d'évaluation

- Pressure Vessel Plate RequirementsDocument71 pagesPressure Vessel Plate RequirementsVILLANUEVA_DANIEL2064100% (2)

- NASA guide for heat treating aluminum alloysDocument8 pagesNASA guide for heat treating aluminum alloysmarcoswanPas encore d'évaluation

- How To Read ASTM D2000 Call OutsDocument7 pagesHow To Read ASTM D2000 Call OutsnithyaupscPas encore d'évaluation

- Carbon Steel and Low-Alloy Steel Pressure-Vessel-Component Forgings With Mandatory Toughness RequirementsDocument4 pagesCarbon Steel and Low-Alloy Steel Pressure-Vessel-Component Forgings With Mandatory Toughness RequirementsStanley HallPas encore d'évaluation

- Alloy/Steel Bolting Materials For Low-Temperature ServiceDocument7 pagesAlloy/Steel Bolting Materials For Low-Temperature ServiceJosé Ramón GutierrezPas encore d'évaluation

- D 2116 - 02 - RdixmtyDocument6 pagesD 2116 - 02 - Rdixmtyjamaljamal20Pas encore d'évaluation

- Iso 4632Document4 pagesIso 4632Ruben TejerinaPas encore d'évaluation

- SAE J200 2008 Classification System For Rubber MaterialsDocument62 pagesSAE J200 2008 Classification System For Rubber MaterialsRodrigo Paulo0% (1)

- ASTM Standard for Polyethylene Storage TanksDocument11 pagesASTM Standard for Polyethylene Storage Tanksalex.janeskoPas encore d'évaluation

- As 2885Document21 pagesAs 2885vivek_pandey100% (1)

- ASME Code CalculationsDocument45 pagesASME Code CalculationsPunith Rangegowda100% (12)

- Astm A890 Vs A995Document1 pageAstm A890 Vs A995ok barvePas encore d'évaluation

- Astm D 3159 - 04Document5 pagesAstm D 3159 - 04phaindikaPas encore d'évaluation

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument3 pagesPressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceStanley HallPas encore d'évaluation

- The Current State of Worldwide Standards of Ductile IronDocument8 pagesThe Current State of Worldwide Standards of Ductile IronN.PalaniappanPas encore d'évaluation

- Heat Exchanger Concepts (Att. VIII)Document28 pagesHeat Exchanger Concepts (Att. VIII)Syed M. Imran Ali100% (1)

- A1014Document3 pagesA1014malika_00Pas encore d'évaluation

- Sa 537Document6 pagesSa 537Mauricio Carestia100% (1)

- ASTM A1063 / A1063M - 11aDocument4 pagesASTM A1063 / A1063M - 11avargas35Pas encore d'évaluation

- Maximum Allowable Stress - An Overview - ScienceDirect TopicsDocument15 pagesMaximum Allowable Stress - An Overview - ScienceDirect Topicskloe123Pas encore d'évaluation

- ASME Code Section 8 Guide for Pressure Vessel Design and ConstructionDocument9 pagesASME Code Section 8 Guide for Pressure Vessel Design and Constructionsnehal.deshmukhPas encore d'évaluation

- As 4041Document22 pagesAs 4041vivek_pandey100% (2)

- Astm d2000 Rubber ClasifiactionDocument35 pagesAstm d2000 Rubber Clasifiactionvkms100% (3)

- A225 Pressure Vessel Plates, Alloy Steel, Manganese-Vanadium-Nickel PDFDocument2 pagesA225 Pressure Vessel Plates, Alloy Steel, Manganese-Vanadium-Nickel PDFCristhian Solano BazalarPas encore d'évaluation

- ASTM A537 Standard SpecificationDocument4 pagesASTM A537 Standard SpecificationLeon SanchezPas encore d'évaluation

- A 148 - A 148M - 03 Qte0oc9bmtq4tqDocument4 pagesA 148 - A 148M - 03 Qte0oc9bmtq4tqfekihassanPas encore d'évaluation

- ASME Guides WeldCanadaDocument3 pagesASME Guides WeldCanadaSubhan50Pas encore d'évaluation

- Verification of Allowable Stresses in Asme Section Iii, Subsection NH For Grade 91 SteelDocument143 pagesVerification of Allowable Stresses in Asme Section Iii, Subsection NH For Grade 91 SteelHarish TokiPas encore d'évaluation

- Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsDocument2 pagesPressure Vessel Plates, Carbon-Manganese-Silicon Steel, Quenched and Tempered, For Welded Layered Pressure VesselsGustavo SuarezPas encore d'évaluation

- Pressure Vessel Plates, Alloy Steel, Nickel: Standard Specification ForDocument3 pagesPressure Vessel Plates, Alloy Steel, Nickel: Standard Specification Fordoshi78Pas encore d'évaluation

- A 890 - A 890M - 99 Qtg5mc05oq - PDFDocument4 pagesA 890 - A 890M - 99 Qtg5mc05oq - PDFMung Duong XuanPas encore d'évaluation

- Asme Section II A-2 Sa-455 Sa-455mDocument4 pagesAsme Section II A-2 Sa-455 Sa-455mAnonymous GhPzn1xPas encore d'évaluation

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (1)

- QTIWMY9BMJAZTQDocument3 pagesQTIWMY9BMJAZTQquiensabe0077Pas encore d'évaluation

- Heat ExchangersDocument7 pagesHeat ExchangersAgustin Gago LopezPas encore d'évaluation

- ASME Impact Test RequirementDocument7 pagesASME Impact Test RequirementkasimshaikhPas encore d'évaluation

- A 897 - 90 R97 Qtg5ny05mfi5nw - PDFDocument7 pagesA 897 - 90 R97 Qtg5ny05mfi5nw - PDFMung Duong XuanPas encore d'évaluation

- ASME e EN STDDocument23 pagesASME e EN STDmatteo2009Pas encore d'évaluation

- En ASME ComparisonDocument18 pagesEn ASME ComparisonPeterWay100% (1)

- A 148 - A148M - 93b R98 QTE0OC05M0JSOTGDocument3 pagesA 148 - A148M - 93b R98 QTE0OC05M0JSOTGStuartPas encore d'évaluation

- ASME Impact Test RequirementDocument6 pagesASME Impact Test RequirementgaurangPas encore d'évaluation

- Astm A 297Document3 pagesAstm A 297Rahul KhoslaPas encore d'évaluation

- Properties Value: Ug-23 Maximum Allowable Stress ValuesDocument2 pagesProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliPas encore d'évaluation

- AttachmentDocument13 pagesAttachmentBSK entertainmentPas encore d'évaluation

- D2625Document7 pagesD2625rimi7alPas encore d'évaluation

- Astm A765Document5 pagesAstm A765Mostafa HalawaPas encore d'évaluation

- ASTM D 1051 - 02 Rubber Insulating SleevesDocument9 pagesASTM D 1051 - 02 Rubber Insulating Sleevesalin20050% (1)

- Ram PreventerDocument19 pagesRam PreventerNigin Parambath100% (1)

- Mud PumpsDocument16 pagesMud PumpsNigin Parambath100% (1)

- Heavy Wall DP & Drill CollarsDocument13 pagesHeavy Wall DP & Drill CollarsNigin ParambathPas encore d'évaluation

- Jis Gate ValveDocument1 pageJis Gate ValveNigin ParambathPas encore d'évaluation

- DiverterDocument9 pagesDiverterNigin ParambathPas encore d'évaluation

- Stainless Steel Pressure RatingsDocument7 pagesStainless Steel Pressure RatingsNauman KhanPas encore d'évaluation

- DerrickDocument17 pagesDerrickNigin Parambath100% (4)

- Drill PipeDocument14 pagesDrill PipeNigin Parambath100% (2)

- Inside BopDocument5 pagesInside BopNigin Parambath100% (1)

- HookDocument11 pagesHookNigin ParambathPas encore d'évaluation

- B5Document1 pageB5Nigin ParambathPas encore d'évaluation

- Crown BlockDocument6 pagesCrown BlockNigin ParambathPas encore d'évaluation

- ASME B16.5 Ring Joint Facings Table DimensionsDocument1 pageASME B16.5 Ring Joint Facings Table DimensionsNigin ParambathPas encore d'évaluation

- Nuflo Orifice Plate PDFDocument8 pagesNuflo Orifice Plate PDFNigin ParambathPas encore d'évaluation

- Of-Pla NF00074 1001D PDFDocument8 pagesOf-Pla NF00074 1001D PDFNigin ParambathPas encore d'évaluation

- Ori Flo PDFDocument14 pagesOri Flo PDFNigin ParambathPas encore d'évaluation

- Chicken RoastDocument5 pagesChicken RoastNigin ParambathPas encore d'évaluation

- Pfi-Es-44 (1999)Document13 pagesPfi-Es-44 (1999)elangopi89100% (1)

- Chicken GingerDocument1 pageChicken GingerNigin ParambathPas encore d'évaluation

- Boneless Chilly CHICKENDocument5 pagesBoneless Chilly CHICKENNigin ParambathPas encore d'évaluation

- Grundfos White PaperDocument8 pagesGrundfos White PapermishraenggPas encore d'évaluation

- FL4013Document4 pagesFL4013elenic777Pas encore d'évaluation

- Know Your Gym: Exercise SafetyDocument2 pagesKnow Your Gym: Exercise SafetyNigin ParambathPas encore d'évaluation

- Chapter5 - Drive CouplingsDocument90 pagesChapter5 - Drive Couplingsvijay219100% (1)

- KTR Kat99pp01Document0 pageKTR Kat99pp01Nigin ParambathPas encore d'évaluation

- DIN 2566 Threaded Flange PN10 and PN16Document1 pageDIN 2566 Threaded Flange PN10 and PN16Nigin ParambathPas encore d'évaluation

- KTR Pump-Couplings PDFDocument44 pagesKTR Pump-Couplings PDFGeorge_Wabag_2014Pas encore d'évaluation

- Coupling 2Document19 pagesCoupling 2tushar9810080Pas encore d'évaluation

- InspireFitness M2 WallChartDocument1 pageInspireFitness M2 WallChartNigin ParambathPas encore d'évaluation

- Bend Tooling's Tube Bending Tools Set-Up GuideDocument3 pagesBend Tooling's Tube Bending Tools Set-Up GuideNigin ParambathPas encore d'évaluation

- Corrosion-Guide 1 Stainless Steel CategoriesDocument8 pagesCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéPas encore d'évaluation

- Las 9Document14 pagesLas 9HisokaPas encore d'évaluation

- Cassette Inverter (2020) Technical Specification SheetDocument1 pageCassette Inverter (2020) Technical Specification SheetOwais AhmedPas encore d'évaluation

- Cable-Stayed Roof Structure InspectionDocument1 pageCable-Stayed Roof Structure Inspectionbenjamin swokaPas encore d'évaluation

- IPL ListDocument41 pagesIPL Listkapare1209Pas encore d'évaluation

- PDF Standard Construction Productivity Norms ManpowerDocument1 pagePDF Standard Construction Productivity Norms ManpowereldredvongaringPas encore d'évaluation

- Alfa Laval Gphe Catalog 2022Document20 pagesAlfa Laval Gphe Catalog 2022JUAN ANTONIO HERNANDEZ SOSAPas encore d'évaluation

- Tiginox 308H: Classification: ApprovalsDocument1 pageTiginox 308H: Classification: ApprovalsJagannath SahuPas encore d'évaluation

- SS621 TUV Testing Report (Full Permission)Document5 pagesSS621 TUV Testing Report (Full Permission)Christiano RodriguezPas encore d'évaluation

- Practice problems-STEELDocument14 pagesPractice problems-STEELreanPas encore d'évaluation

- CH 06 - Corrosion & ErosionDocument22 pagesCH 06 - Corrosion & ErosionvegaronPas encore d'évaluation

- Torsion of A Circular Cylinder - f06 - RevisedDocument24 pagesTorsion of A Circular Cylinder - f06 - RevisedCrystal WoodwardPas encore d'évaluation

- Pipeline Stress Analysis With Caesar IIDocument16 pagesPipeline Stress Analysis With Caesar IISathish KumarPas encore d'évaluation

- StainlessSteelBraid (SSB)Document2 pagesStainlessSteelBraid (SSB)phucgenjiPas encore d'évaluation

- Bioinicia: Electrospinning SpecialistDocument4 pagesBioinicia: Electrospinning SpecialistOriana González HernándezPas encore d'évaluation

- ASME B31.3 Straight PipesDocument2 pagesASME B31.3 Straight Pipesjame11inPas encore d'évaluation

- Geyser Mounting Horizontal Vs VerticalDocument1 pageGeyser Mounting Horizontal Vs VerticalRussell Collett0% (1)

- Design of Purlins and TrussesDocument46 pagesDesign of Purlins and TrussesWarrenPresBerdugo100% (1)

- KS3 TestDocument6 pagesKS3 TestVytheeshwaran Vedagiri80% (5)

- Complete EDM Handbook - 14Document12 pagesComplete EDM Handbook - 14soheil gazeranPas encore d'évaluation

- 9.9 Diaphragms-With-Interior-Shearwalls PDFDocument4 pages9.9 Diaphragms-With-Interior-Shearwalls PDFnickPas encore d'évaluation

- Rupture DiscDocument2 pagesRupture Discbigs1303Pas encore d'évaluation

- 12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gDocument1 page12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gKumaresvaranPas encore d'évaluation

- 52 Week PPM Planner Template-15 Jul 14Document26 pages52 Week PPM Planner Template-15 Jul 14safetydellPas encore d'évaluation

- LT2A - 15 - Krisna Surya Pamungkas - SolderDocument2 pagesLT2A - 15 - Krisna Surya Pamungkas - SolderMuhammad Hanif HidayatPas encore d'évaluation

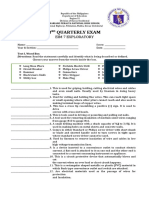

- 3 Quarterly Exam: Eim 7 ExploratoryDocument3 pages3 Quarterly Exam: Eim 7 ExploratoryJulcon Avanceña Araiz100% (1)

- Diagram of The HouseDocument16 pagesDiagram of The HouseBeatriz OliveiraPas encore d'évaluation

- F7az Em12kDocument1 pageF7az Em12kKara WhitePas encore d'évaluation

- Ampt - Advanced Materials Processing TechniquesDocument26 pagesAmpt - Advanced Materials Processing TechniquesIshaan ThakerPas encore d'évaluation

- Multi9 Acti9 Substitution TableDocument530 pagesMulti9 Acti9 Substitution TableKar Keong LewPas encore d'évaluation

- A Place of My Own: The Architecture of DaydreamsD'EverandA Place of My Own: The Architecture of DaydreamsÉvaluation : 4 sur 5 étoiles4/5 (241)

- An Architect's Guide to Construction: Tales from the Trenches Book 1D'EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Pas encore d'évaluation

- Building Construction Technology: A Useful Guide - Part 1D'EverandBuilding Construction Technology: A Useful Guide - Part 1Évaluation : 4 sur 5 étoiles4/5 (3)

- Building Construction Technology: A Useful Guide - Part 2D'EverandBuilding Construction Technology: A Useful Guide - Part 2Évaluation : 5 sur 5 étoiles5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsD'EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedD'EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedÉvaluation : 5 sur 5 étoiles5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- Civil Engineer's Handbook of Professional PracticeD'EverandCivil Engineer's Handbook of Professional PracticeÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsD'EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseD'EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseÉvaluation : 5 sur 5 étoiles5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionD'EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsD'EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsPas encore d'évaluation

- Field Guide for Construction Management: Management by Walking AroundD'EverandField Guide for Construction Management: Management by Walking AroundÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- How to Write Construction Programmes & SchedulesD'EverandHow to Write Construction Programmes & SchedulesÉvaluation : 4 sur 5 étoiles4/5 (9)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsD'EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsÉvaluation : 1 sur 5 étoiles1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideD'Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Estimating With Microsoft ExcelD'EverandEstimating With Microsoft ExcelÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedD'EverandMarkup & Profit: A Contractor's Guide, RevisitedÉvaluation : 5 sur 5 étoiles5/5 (11)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItD'EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItÉvaluation : 4 sur 5 étoiles4/5 (16)

- Estimator's General Construction Manhour ManualD'EverandEstimator's General Construction Manhour ManualÉvaluation : 4.5 sur 5 étoiles4.5/5 (20)