Académique Documents

Professionnel Documents

Culture Documents

Newsletter IE2 Motor Efficiency Standard

Transféré par

babis1980Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Newsletter IE2 Motor Efficiency Standard

Transféré par

babis1980Droits d'auteur :

Formats disponibles

Ref no.

: Date:

No 001-11 01/03/2011

IE2 Motor Efficiency Standard

Introduction

Being energy efficient is something that is more and more becoming part of our daily lives since it allow us to reduce the operating cost of performing a task and it is also beneficial for the environment in the sense that we use our resources more sparingly and generate less pollution. In many case we voluntary buy the more energy efficient products because we would like to reduce our operating cost. In certain other case governments pass laws to set compulsory energy efficient standard to protect the environment and allow us to reduce operating cost. There are pending legislation changes in several countries about the energy efficiency standards for electrical motors. This newsletter provides some background information about the standards; how governments responded to them and how Munters will respond to ensure our customers are supplied by products meeting local regulations. An exact time frame for mentioned changes will be distributed at a later point.

Electrical Motor Efficiency

Electrical motor sizes are determined by energy output capabilities, not by their electrical energy consumption. Therefore a 1.1 kW (1.5 hp) motor is able deliver 1.1 kW (1.5 hp) of mechanical power on the output shaft. Since an electrical motor converts electrical power into mechanical power and no energy conversion processes are 100% efficient, the power input to the motor is always larger than the power output. The degree to which the power input is larger is determined by the overall motor efficiency. Factors that contribute to improving motor efficiency are amongst others magnetic characteristic of steel used in manufacturing rotor and stator as well as overall dimension of rotor and stator; more copper windings inside the motor; tighter tolerances between the windings as well as between the rotor and stator; and the use of bearings with improved tolerances,. All the electrical power that is lost in the conversion process is turned into heat, which means less efficient motors will be much hotter than more efficient motors when operating under the same conditions.

Page 1 of 5

2011 Munters Europe AB

Any energy saving on an electrical motor can easily be transferred into an operating cost saving. Below is a table indicating possible operating cost savings for a variety of different motor efficiencies.

Electrical Power Input [kW]

Motor Efficiency

2 3 Annual Operating Cost [] Efficiency Mechanical Annual Power Consumption [kWh] Power Output 1 Standard [kW] Operating 3,000 Operating 5,000 Operating 3,000 Operating 5,000 hours / year hours / year hours / year hours / year

1.1 1.1 1.1 1.1

Notes 1 2 3

65% 70% 75% 81.4%

IE1 IE2

1.69 1.57 1.47 1.35

5,077 4,714 4,400 4,054

8,462 7,857 7,333 6,757

507.69 471.43 440.00 405.41

846.15 785.71 733.33 675.68

Standards to be discussed later in document Motor operating a specified number of hours per year Electrical cost: 0.10 / kWh

How is energy efficiency measured?

At present there are numerous standards around the world for measuring and classifying motor efficiency. The International Electrotechnical Commission, or IEC, is a non-profit, non-governmental international standards organization that prepares and publishes International Standards. The IEC 60034-30 standard aims to harmonize global motor efficiency standards by defining classes of motor efficiency, known as IE1, IE2 and IE3, and test methods for determining motor efficiency (IEC 60034-2-1). For a motor to be rated in a certain class, it has to meet or exceed a specified efficiency. IE1 has the lowest efficiency, while IE3 has the highest. The efficiency target a motor has to reach is dependant on the motor size and larger motors need to meet higher efficiency standards, as illustrated in the

Page 2 of 5

graph below which applies to 4 pole 50Hz motors.

100

95

90

Motor Efficiency [%]

85

80

IE3 Compliant IE2 Compliant IE1 Compliant

75

70

Below IE standards

65

60

0. 75 18 .5 90 11 0 13 2 15 0 16 0 18 5 30 1. 1. 2. 5. 7. 11 15 22 37 45 55 75 3 4 1 5 2 5 5

Motor Power Output [kW]

To be more specific, the table below summarizes the IE energy efficiency

2011 Munters Europe AB

targets for motor sizes typically used on

fans produced by Munters.

Motor Power kW 0.75 1.1 1.5 hp 1 1.5 2

IE1 Standard efficiency 4 pole motor 50Hz 72.1% 75.0% 77.2% 60Hz 78.0% 79.0% 81.5%

IE2 High efficiency 4 pole motor 50Hz 79.6% 81.4% 82.8% 60Hz 82.5% 84.0% 84.0%

IE3 Premium efficiency 4 pole motor 50Hz 82.5% 84.1% 85.3% 60Hz 85.5% 86.5% 86.5%

What motors are included under these standards?

This standard covers all motors that fall within the following parameters Single-speed, three-phase, 50 and 60 Hz 2, 4 or 6-pole Rated output from 0.75 to 375 kW Rated voltage up to 1000 V Duty type S1 (continuous duty) or S3 (intermittent periodic duty) with a rated cyclic duration factor of 80% or higher Capable of operating direct online 50 and 60 Hz The only exceptions are Motors made solely for operation with an inverter

Motors completely integrated into a machine is such a way that it can not be tested separately from the machine

How are standards applied?

Since the IEC is an independent organization, it is up to local authorities to decide if, and when, they wish enforce such standards. Several countries have passed laws which have set deadlines by which date all motors sold in that country should comply with a specified IE class. The table below gives a summary of the current situation of where governments has chosen to introduce laws or are considering introducing such laws.

Country

Voltage Range 400V 10%, 50Hz 400V 10%, 50Hz 480V 10%, 60Hz 400V / 575V 10%, 50Hz 220V / 380V / 440V / 460V / 480V 10%, 60Hz

Power Range

Poles

Current Status

EU Switzerland USA Canada

0.75 to 375 kW 1 to 400 kW 1 to 200 hp 1 to 200 hp

2 to 6 2 to 6 2 to 6 2 to 6

IE2 Compulsory from 16 June 2011 IE2 Compulsory from 1 July 2011 IE3 Compulsory from 19 December 2010 IE3 Compulsory from 1 January 2011 IE2 Compulsory from 8 December 2009

Brazil

0.75 to 250 kW

2 to 8

Page 3 of 5

2011 Munters Europe AB

Chile

China Hong Kong India Israel

Japan

Korea UAE South Africa Australia

New Zealand Singapore

380V / 400V / 420V / 440V / 460V / 690V 10%, 60Hz 380V 10%, 50Hz 380V 10%, 50Hz 415V / 690V 10%, 50Hz 400V 10%, 50Hz 200V / 220V / 400V / 440V / 10%, 50 / 60Hz Up to 600V 10%, 60Hz 400V 10%, 50Hz 400V / 525V 10%, 50Hz 415 / 690V +10% -6%, 50Hz 415 / 690V +10% -6%, 50Hz 415V 10%, 50Hz

0.75 to 7.5 kW

2 to 6

IE2 Compulsory from 4 January 2011 IE2 Compulsory from 1 July 2011 IE2 Introductory phase since December 2009 IE2 Expected 2013 IE2 Compulsory from 1 February 2008 IE2 Expected

0.55 to 315 kW 0.75 to 375 kW 0.37 to 315 kW 0.75 to 185 kW

2 to 6 2 to 6 2 to 8 2 to 8

0.2 to 160 kW

2 to 6

0.75 to 200 kW 0.75 to 375 kW 0.75 to 375 kW 0.73 to 186 kW

2 to 6 2 to 6 2 to 6 2 to 8

IE2 Compulsory from 1 July 2008 IE2 Recommended from 16 June 2011 IE1 recommended IE2 Compulsory from 1 April 2006, IE3 expected IE2 Compulsory from 1 April 2006, IE3 expected IE2 only on government projects

0.73 to 186 kW 1.1 to 90 kW

2 to 8 2 to 4

How Munters will respond

Due to the pending regulation changes in Europe and China mid 2011, motor manufacturers will be forced to make some alterations their motor line-ups which will have an impact the motor options Munters can offer on fans. The changes that will happen are as follow: 2 New motor options will be introduced that will meet IE2 standards. The cost of these motors will be higher that what we are used to today since they contain more copper and are manufactured with finer tolerances o 0.75 kW (1.0 hp) 400V, 3 phase, 50Hz, IP55, single speed, without cooling fan o 1.1 kW (1.5 hp) 400V, 3 phase, 50Hz, IP55, single speed, without cooling fan

400V, 3 phase, multispeed motors will no longer be available in sizes 0.75 kW (1.0 hp) and 1.1 kW (1.5 hp). Due to the design of these types of motors, they do not meet the IE2 standard All 0.75 kW (1.0 hp) and 1.1 kW (1.5 hp) will be offered without cooling fan only (see note below) The remainder of the options for motor sizes 0.75 kW (1.0 hp) and 1.1 kW (1.5 hp) will still be available as they are today

The changes mentioned above will allow all Munters distributors to have access to the correct motor option in order to comply with local regulations regardless of where the fans are sold. An exact time frame for the implementation of these changes as well as any changes in airflow and prices will be distributed shortly.

Page 4 of 5

2011 Munters Europe AB

Note: Cooling fan In theory a motor equipped with a cooling fan should be better cooled than one without. But theory and practice are not always the same. In practice fans often operate in dusty conditions and under such conditions the cooling fans become an obstacle rather than a solution. Dust tends to accumulate in the cooling fan housing and eventually block all airflow through that part of the motor, which leads the motor to operate at an elevated temperature and cause premature failure. The picture on the right illustrates a scenario frequently seen where the cooling fan housing is completely blocked and the cooling fan rendered ineffective. An additional benefit from eliminating the cooling fan is that the back of the motor is

completely sealed, which eliminates an entry point for water from high pressure cleaners into the motor.

Over the past few years numerous practical test have demonstrated that motors without cooling fans outlast motors with cooling fans, and therefore the decision was taken to standardize on a single solution that improves the overall quality of fans produced by Munters.

Sincerely

Wouter Claassens Global Product Manager Mobile: e-mail: +1 517 899 6849 wouter.claassens@munters.com

Page 5 of 5

2011 Munters Europe AB

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Non-Circular Pressure Vessels SquareDocument27 pagesNon-Circular Pressure Vessels SquareAbhilash Kurian100% (1)

- 4.24 Drains Systems Design PhilosophyDocument8 pages4.24 Drains Systems Design Philosophybabis1980Pas encore d'évaluation

- Blockchain Regulatory ReportDocument264 pagesBlockchain Regulatory Reportsmanley5Pas encore d'évaluation

- Spark 2000 Ul: Instruction ManualDocument65 pagesSpark 2000 Ul: Instruction ManualMárcio Fernandes0% (1)

- Cement plant proposalDocument49 pagesCement plant proposalTesfaye Degefa100% (1)

- ProFlex4 Trainings OverviewDocument16 pagesProFlex4 Trainings Overviewart0928Pas encore d'évaluation

- FUSION MANUAL - Rev IllustrationsDocument36 pagesFUSION MANUAL - Rev IllustrationsMehmet SoysalPas encore d'évaluation

- Ejector BrochureDocument8 pagesEjector Brochurebabis1980Pas encore d'évaluation

- 1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013Document2 pages1220 Butt Fusion Electrofusion and Socket Fusion Welder February 2013babis1980Pas encore d'évaluation

- Plastic Pipe - PE - Chapter01Document9 pagesPlastic Pipe - PE - Chapter01garisa1963Pas encore d'évaluation

- Ati 317Document13 pagesAti 317babis1980Pas encore d'évaluation

- Orifice Plate Flow MetersDocument8 pagesOrifice Plate Flow MetersGaurav Dhiman100% (1)

- FRL SIF 618 CompressedAirDryingDocument36 pagesFRL SIF 618 CompressedAirDryingbabis1980Pas encore d'évaluation

- GF Type 546 BallDocument10 pagesGF Type 546 Ballbabis1980Pas encore d'évaluation

- The Condensate, The Boiler Feed, and Their Auxiliary SystemsDocument70 pagesThe Condensate, The Boiler Feed, and Their Auxiliary Systemsbabis1980100% (1)

- P&IDDocument18 pagesP&IDhectornicolauPas encore d'évaluation

- White Paper RBIDocument12 pagesWhite Paper RBImahesh070Pas encore d'évaluation

- Sa 312Document1 pageSa 312babis1980Pas encore d'évaluation

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- StainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerDocument14 pagesStainlessSteelinWatersGalvanicCorrosionandit PreventionAEBauerbabis1980Pas encore d'évaluation

- PPG Minimizing The Effects of CorrosionDocument9 pagesPPG Minimizing The Effects of Corrosionbabis1980Pas encore d'évaluation

- Brochure ACCDocument8 pagesBrochure ACCbabis1980Pas encore d'évaluation

- Galvanic CorrosionDocument2 pagesGalvanic CorrosionkeronsPas encore d'évaluation

- Veizades Gas Removal Systems Liquid Ring VPDocument3 pagesVeizades Gas Removal Systems Liquid Ring VPVenkatespatange RaoPas encore d'évaluation

- Fundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Document199 pagesFundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Anshul JainPas encore d'évaluation

- Tech Manual Electrical Power Plant DesignDocument135 pagesTech Manual Electrical Power Plant Designd_kabulpuriaPas encore d'évaluation

- Chapter IIIDocument19 pagesChapter IIIghostamirPas encore d'évaluation

- Energy Saving in Steam Systems.Document34 pagesEnergy Saving in Steam Systems.babis1980Pas encore d'évaluation

- What's New in API 610 11th EditionDocument4 pagesWhat's New in API 610 11th Editionshyam_anupPas encore d'évaluation

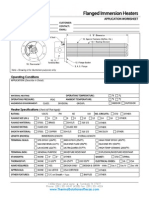

- Flanged Immersion Heaters: Operating ConditionsDocument1 pageFlanged Immersion Heaters: Operating Conditionsbabis1980Pas encore d'évaluation

- Advanced GE CCPPDocument20 pagesAdvanced GE CCPPR Krishna KumarPas encore d'évaluation

- Ideal Bearing Temp LimitsDocument1 pageIdeal Bearing Temp Limitsbabis1980Pas encore d'évaluation

- ATEX Reference GuideDocument2 pagesATEX Reference Guidebabis1980Pas encore d'évaluation

- Introduction To Gas Turbines For Non-EngineersDocument9 pagesIntroduction To Gas Turbines For Non-EngineersKrishna MyakalaPas encore d'évaluation

- Food Processing Machinery - Fixed Deck Oven Loaders - Safety and Hygiene RequirementsDocument50 pagesFood Processing Machinery - Fixed Deck Oven Loaders - Safety and Hygiene RequirementsSantosh IngalePas encore d'évaluation

- Service Manual: Built-In Oven Akp 120 IxDocument6 pagesService Manual: Built-In Oven Akp 120 IxMário CoutoPas encore d'évaluation

- Laura Cooper - ResumeDocument3 pagesLaura Cooper - ResumelaurahubbPas encore d'évaluation

- A 24-Ghz Full-360 ° Cmos Reflection-Type Phase Shifter Mmic With Low Loss-VariationDocument4 pagesA 24-Ghz Full-360 ° Cmos Reflection-Type Phase Shifter Mmic With Low Loss-VariationSàRâh ËłâbïàdPas encore d'évaluation

- Polarity Test of TransformerDocument3 pagesPolarity Test of TransformerdebarshiPas encore d'évaluation

- 9 PMP - ProcurementDocument14 pages9 PMP - Procurementdrsuresh26Pas encore d'évaluation

- PassGuide HP2-H08 V3Document31 pagesPassGuide HP2-H08 V3Kripesh Ramji0% (1)

- Modelling and Simulation PV Station VRTDocument4 pagesModelling and Simulation PV Station VRTDaniel ManjarresPas encore d'évaluation

- F5 Training Lab GuideDocument11 pagesF5 Training Lab GuideBrayan Anggita LinuwihPas encore d'évaluation

- Sentinel LM Programmer/'s Reference ManualDocument474 pagesSentinel LM Programmer/'s Reference ManualAshish JoshiPas encore d'évaluation

- SD Exit Exm Tuto SoLDocument55 pagesSD Exit Exm Tuto SoLTadesse MegersaPas encore d'évaluation

- 2.manual ETR300S V1.0 EngDocument142 pages2.manual ETR300S V1.0 EngAgustinus Phatub KurniawanPas encore d'évaluation

- Gda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Document17 pagesGda Business: Assignment 3 INF10003 Student: Bui Vu Khanh Trang-Swh00554Vũ Khánh Trang BùiPas encore d'évaluation

- Electrical Load Summary - QC-2Document2 pagesElectrical Load Summary - QC-2Nedunuri.Madhav MurthyPas encore d'évaluation

- Measurement of NPK, Temperature, Moisture, Humidity Using WSNDocument6 pagesMeasurement of NPK, Temperature, Moisture, Humidity Using WSNFajar AnugrahPas encore d'évaluation

- D ch07Document50 pagesD ch07mullai03Pas encore d'évaluation

- Aying TechnoDocument2 pagesAying TechnoEvaPas encore d'évaluation

- Ma. Sheryl Mangundayao: Career ObjectiveDocument2 pagesMa. Sheryl Mangundayao: Career ObjectiveMatheo MangundayaoPas encore d'évaluation

- Theoretical PrinciplesDocument2 pagesTheoretical PrinciplesJosef JiaoPas encore d'évaluation

- Mak4462 Machine Tools: Yildiz Technical University Faculty of Mechanical Engineering Department of Mechanical EngineeringDocument12 pagesMak4462 Machine Tools: Yildiz Technical University Faculty of Mechanical Engineering Department of Mechanical EngineeringALPERENPas encore d'évaluation

- World-wide Input Output Power Boost XL120DDocument2 pagesWorld-wide Input Output Power Boost XL120DJavier CastilloPas encore d'évaluation

- Nagachethan - Test ManagerDocument1 pageNagachethan - Test ManagerNagachetan SPPas encore d'évaluation

- Quality Gates Ensure Project SuccessDocument7 pagesQuality Gates Ensure Project Successbelkis rosaPas encore d'évaluation

- AC02 SolDocument135 pagesAC02 SolsfundsPas encore d'évaluation

- If A Pedestrian Is Hit and Lands On The Front of The Car, The Airbag InflatesDocument1 pageIf A Pedestrian Is Hit and Lands On The Front of The Car, The Airbag InflatesYu SunPas encore d'évaluation

- SL Nx-OsDocument676 pagesSL Nx-Osa_salesmanPas encore d'évaluation