Académique Documents

Professionnel Documents

Culture Documents

Power System Control

Transféré par

Стоян БанчевCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Power System Control

Transféré par

Стоян БанчевDroits d'auteur :

Formats disponibles

Power Systems Control

Contents SCADA, EMS, DMS Control Room Technology Power Network Telecommunication

Page 7/27/5 7/67/10 7/117/24

SCADA/EMS/DMS

Introduction

The requirements on network control systems are growing as secure and economic energy management is becoming ever more important. Planning and implementation of SCADA systems (Supervisory Control and Data Acquisition), Energy Management Systems (EMS) as well as Distribution Management Systems (DMS) involve coordinating a wide range of engineering tasks. Siemens is in a position to deliver optimum, state-of-the-art solutions in close cooperation with the customers. SINAUT (Siemens Network Automation) is Siemens modern product family for Power Systems Control. It reflects the experience of more than 540 electricity grid control systems installed worldwide since the early sixties. As technological pacemaker Siemens invests considerable funds annually in the further development of the SINAUT product family. Planned for the long term, this user-oriented product line has release compatibility to guarantee that the benefits of tomorrows R&D investments can still be adopted by systems delivered today.

Siemens furthers this strategy by participating in a variety of IEEE, IEC, EPRI, CIGRE and CIRED committees and by enlisting support from active user groups. The quality management certified by DQS according ISO 9001 ensures quality products and a smooth and reliable project implementation within contractual schedule and budget. Siemens Power Systems Control has a large support staff of dedicated experts with power industry experience. With its broad range of products Siemens is able to supply the control systems, all necessary components (communication equipment, control room equipment, uninterruptible power systems, etc.) from one supplier on a turnkey basis.

s s s s

Municipal utilities and Large industries with own networks Regional distribution utilities National and regional generation and transmission utilities

Modular and distributed architecture Each SINAUT Spectrum system consists of individual functional subsystems which are distributed among an optimum number of workstations and servers. Shortest reaction times are achieved by assigning timecritical applications and applications requiring a lot of computation power to dedicated servers (Fig. 1). The database is distributed among the workstations and servers for fast and independent data access with low LAN-loading. The modules of the network control system SINAUT Spectrum are shown in Fig. 3 on page 7/4 and 7/5. Due to its modular and distributed system architecture SINAUT Spectrum offers unlimited horizontal and vertical growth opportunities, e.g. from a small entry-level SCADA system up to a large EMS or combined SCADA/EMS/DMS.

SINAUT Spectrum

General SINAUT Spectrum is the open, modular and distributed control system for electrical networks as well as for gas, water and remote heating networks. Its extensive and modular functionality provides scalable solutions tailored to the needs and budgets of:

Mimic diagram

Communication with other control centers, e.g. ICCP or ELCOM-90

Mimic diagram interface LAN

Administrator, archives, schedules

Operator console

Operator console

Spare

Expert system

Gateway

Data acqusition

SCADA

Network analysis

Power and scheduling applications

Training simulator

Distribution management functions

Bridge

to/from RTUs

Basic components Hot standby

Office LAN

GIS

PC Database

Fig. 1: SINAUT Spectrum system architecture of a large SCADA/EMS/DMS

7/2

Siemens Power Engineering Guide Transmission & Distribution

SCADA/EMS/DMS

SINAUT Data Gateway SINAUT Data Gateway exactly meets the requirements of an integration tool needed for data maintenance. With SINAUT Data Gateway control center data can be maintained with one database instead of maintaining modeling information in several different formats for each application. For the update of an existing control center system, the necessary data can simply be exported in a format recognized by the new control center system.

Available services

Siemens offers services for all important areas: s Studies, planning, engineering s Project implementation s Installation, supervision of installation s Commissioning s Training s Hardware/software maintenance s System upgrading s System migration

Fig. 2: Control room of Northern States Power Company, Minneapolis, MN

Open architecture SINAUT Spectrum is solidly based on industry standards. Therefore the system can be upgraded to take advantage of the rapidly moving technology in the workstation and server market, without losing any of the software investment built up over the years. SINAUT Spectrum runs under a UNIX operating system, strictly adhering to the IEEE POSIX standards, thus providing hardware platform independence. SINAUT Spectrum may be delivered either on SUN or on IBM workstations. The user interface employs a graphical environment that the operator can tailor to his specific tasks and preferences. Based on the X-Window System and OSF/Motif, this user interface provides multiple-window displays, full pan and zoom capabilities and excellent display call-up times. Other standards used in SINAUT Spectrum: s Structured Query Language (SQL) for relational database access s TCP/IP for LAN/WAN communication s IEC 870-5 as well as many other protocols for RTU communication s IEC 870-6 TASE 2 (ICCP), WSCC and ELCOM 90 for communication with other control centers.

Further SINAUT products

SINAUT ACES Accounting, Contracts and Energy Scheduling The volume of wholesale transactions will increase dramatically due to regulatory and economic pressures. SINAUT ACES provides sophisticated software that can manage commodity trading, accounting, billing, monitoring, and contract compliance. SINAUT ACES allows to take full advantage of the growing complexity of contract provisions. SINAUT ACES operates within an open-systems environment that can be fully integrated with SCADA/ EMS/DMS and corporate information systems. SINAUT ICCPNET, SINAUT ICCPNT Communications Products Siemens offers a full range of communication products which support ICCP. The field-proven SINAUT ICCPNET which executes under UNIX, offers a commercial relational database manager to handle configuration and object-set definition with an OSF/Motif operator interface. SINAUT ICCPNT executes on a PC platform and combines a low-cost solution and UCA (Utility Communications Architecture) open-systems technology in order to interconnect utilities.

Siemens Power Systems Control a key to success

Network Control Centers have to operate economically and efficiently over long periods. Therefore Siemens is committed to: s Designing systems that can incorporate new standards and technologies over time to keep the system current s Avoiding dependence on proprietary tools and methods s Using accepted and de facto standards s Meeting the growing need for information management throughout a public utility company The long-term commitments also include:

s s s s s

A full product spectrum Complete turnkey projects Complete spectrum of services An active user group Strong R&D

For further information please contact: Fax: ++49-9 11-4 33 - 8122

Siemens Power Engineering Guide Transmission & Distribution

7/3

SCADA/EMS/DMS

Network Control System

Hardware

Basic system

SCADA functions

Distribution management functions

UNIX server

Database

Data acquisition and processing Supervisory control, control jobs, manual update Report generation system

Data import from a GIS

Spatial control and queries

UNIX workstation

Information management system

Tracing

Jumpers, cuts, grounds

Data acquisition subsystem

User interface

Switching procedure management

Fault location and isolation; service restoration Feeder estimation

Gateway

Computer network management

Dynamic network colouring

Outage management system

Ethernet-LAN

Tools for test and diagnostics

Energy demand control

Load modeling

Online load flow calculation

Communication system

Softbus

Load management

Online short-circuit calculation

Transformer load management

RTU

UNIX operating system

Energy accounting

V/Var control

Cold load pickup

High-level language compiler

Operation optimization for gas and water networks

Archives and schedules

Fig. 3: Modules of the network control system SINAUT Spectrum

7/4

Siemens Power Engineering Guide Transmission & Distribution

SCADA/EMS/DMS

SINAUT Spectrum

Network analysis

Power and scheduling applications

Training simulator

Expert system

Communication

Model update

Network reduction

Automatic generation control

Interchange scheduling

Instructor functions

Intelligent alarm processing

To other control centers (ICCP)

State estimator

Network parameter adaption

Economic dispatch

Reserve monitoring

Complete functionality of the control system User interface of the control system

Disturbance analysis

Geographical information system (GIS)

Dispatcher power flow

Fault calculations

Interchange transaction evaluation (A+B) Unit commitment

Load forecast

Network restoration/ load transfer

Multisite control center operation

Security analysis

Network sensitivity

Hydro scheduling

Process simulation

Other utility IT systems

Optimal power flow

Security checked switching

Hydrothermal coordination

Production costing

Network model

Planning

Voltage scheduler

Study case management

Water worth value calculation

Wheeling loss calculation

Generation model

Maintenance

Security dispatch

Protection model

Billing

Outage scheduler

Siemens Power Engineering Guide Transmission & Distribution

7/5

Control Room Technology

SINAUT Visualization

Introduction With its SINAUT Visualization large-screen rear projection system, the Siemens AG offers the solution for the large-screen display of text or graphics. Thanks to the modular design of SINAUT Visualization with projection modules which can stacked horizontally and vertically without paths, screens of practically any size can be built. The SINAUT Visualization large-screen rear projection system can be used whereever a large-area presentation of computer data is required. For example, in power distribution. SINAUT Visualization can be used in an energy management system as a substitute for or adddition to conventional mosaic panels. All dynamic data, from an overview of topological information about the area supplied to detailed information and special messages for the operators in case of fault, can be visualized so that all operators can read it (Fig. 4). Description Design of SINAUT Visualization-mX The LCD projection technology used in SINAUT Visualization-mX is based on the TFT LCD (thin-film transistor liquid crystal display) light-valve technology. This socalled active matrix LCD has a better contrast and display switching rate than the lower-cost passive LCDs. Each individual red, green and blue color pixel of the LCD is controlled by a transistor that is, in turn, directly linked to the computer electronics of the integrated mX-Terminal*. This eliminates color shift and drift effects because no analog technology is used (Fig. 5). Modularity SINAUT Visualization-mX is a modular system in order to cover different requirements for projection area, resolution and size. Each projection module is an individual rear projection system with a 50"-inch screen and a resolution of 640 x 480 or 1024 x 768 pixels. It has no seam and the edges of the module correspond with the picture borders (Fig. 6). 340 1213

Fig. 4: Control room of Victorian Power Exchange, Australia

VGA, Video, X.11 controller

LCD light valve Mirror, lamp Projection lens Screen Observer

Fig. 5: Principle of rear projection using an LCD

Illumination unit Darkbox Screen module

Screen

750

1000

* mX-Terminal designates the multiscreen-cable x-Terminal from Siemens AG

Fig. 6: Projection module with dimensions in mm

7/6

Siemens Power Engineering Guide Transmission & Distribution

Control Room Technology

Therefore seamless pictures of any size can be built by horizontal and vertical stacking of several modules. Fig. 7 shows an example of a 3 x 2 configuration of modules, offering a resolution of either 1920 x 960 or 3072 x 1536 pixels. The more modules are configured horizontally or vertically, the higher is the resulting resolution. The projection modules can be set up in horizontal direction linear as well as polygonal with an angle of 8 degrees to each other in order to obtain a slightly curved display wall. Other angles are possible on request (Fig. 8). Connectivity as mX-Terminal The mX-Terminal integrated in OVERVIEWmX and the X-server installed on it conform 100% to the internationally standardized protocol definition X window system (X-Windows, X.11.). Up to 4 projection modules can be connected to one mX-Terminal. If they are arranged in a 2 x 2 designs, they provide a resolution of 1280 x 960 or 2048 x 1536 pixels. The system operates like an X-Terminal with all X.11 tool kits such as OSF/Motif and the X-applications based on them. All X-clients can make unrestricted use of the entire projection area of 2 m x 1.5 m (Fig. 9).

1213

Screen 0

Screen 1

Screen 2 1500

Screen 3 Illumination unit Darkbox Screen module

Screen 4

Screen 5

3000

Fig. 7: 3 x 2 horizontal and vertical stacking of projection modules

Operator

Operator

Fig. 8: Linear or polygonal setup of several SINAUT Visualization-mX projection modules (top view)

SINAUT Visualization-mX projection modules

mX-Terminal

Ethernet, TCP/IP X-Windows

Fig. 9: Integration of SINAUT Visualization-mX into a computer network based on Ethernet, TCP/IP and X-Windows

Siemens Power Engineering Guide Transmission & Distribution

7/7

Control Room Technology

Mosaic-tile systems

24 modules with 3480 x 1920 pixels Introduction Visualization of the electric systems to be controlled and optimization of the working environment are of utmost importance for the control room operators ability to concentrate. By combining the latest ergonomic findings with an appropriate design Siemens provides an environment that allows the operators to work well, even in critical situations. Control boards and mimic displays of mosaic tile design must have a straightforward layout. They must also be costeffective and capable of being shaped to suit customer requirements. It must be possible to modify or extend them quickly, simply and at minimum cost. The ergonomics and design of Siemens control rooms exceed the scope of all DIN and international standards. A broad selection of standard modules and components form the basis of our control rooms. They range from mosaic tile systems and control desks to large-screen rear projection systems, and from optimized mapboards to ergonomically perfect operator workstations. Siemens manufacture of control room technology is certified to ISO 9001. Controlling of the mimic board Control room technology by Siemens has been developed generally over the last few years. Controlling of the mimic board is no longer done by a costly 1:1 wiring system but via an Ethernet bus (SINEC H1) to the PLC (Programmable Logic Controller) system and an internal mimic board bus (SINEC L2). This new idea Mimic Board Controlling (MBA-L2) has been successfully realized in several projects (Fig. 12). LAN-controlled mimic board

Fig. 10: SINAUT Visualization-mX as 6 x 4 setup

Distributed X-Server

6 mX-Terminals as rendering machines

mX-Terminal as central device

Workstations/ Windows NT-PCs

Ethernet TCP/IP, X-Windows

If more than 4 projection modules are required, there is the possibility to have nearly any number of modules as one large display. With the distributed X-Server (1 central device mX-Terminal with keyboard and mouse and several rendering machines) it is possible to control nearly any number of modules as one single display.

This means that both the user and the application software see one single display. Installation, operation and service do not differ from that of a standard X-Terminal (Fig. 10).

The mimic board consists of the following elements: s PLC s Power supply including fuses s Bus terminal s Main module for the control of 32 twincolored LEDs s Extension module for the control of 32 twincolored LEDs s Low consumption diodes s Protocol as per DIN 19245

7/8

Siemens Power Engineering Guide Transmission & Distribution

Control Room Technology

Description The PLC from the S5 automation system consists of:

s Power supply module s Central processing unit (CPU) s Communication processor module

to a host processor

s Communication processor module

The use and the selection of the different types of S5 PLCs depend on the requirements of the controlled LEDs and on the parameters which are to be transmitted from the host processor to the PLC. The communication processor to a host processor is determined by the structure of the protocol and the physical interface (e.g. SINEC H1, L1, L2 and so on).

The bus terminal The bus terminal is designed to connect to the internal LAN one main module and 16 extension modules. In addition to the LAN connections, the following are connected to the bus terminal: power supply, shielding for the cables between bus terminals and modules, and digital input for synchronization of blinking. The bus system, protocol structure The LAN controlling the main module is an RS 485 interface. The protocol is according to DIN 19245 (profibus). This LAN is supplied by a communication processor CP 5430 which supports the protocol DIN 19245 by hardware implementation.

(CP 5430) to internal LAN connection of the mimic board s Eventual memory extensions in case of bigger systems

SINEC H1/Ethernet

PLC

1 2 3 4

Power supply module CPU module CP to SINEC H1 CP to mimic board Ian SINEC L2

1 2 3 4

Fig. 11: Control room of Schluchseewerke AG, Germany

Mimic board

SINEC L2

32

1 LED 32 Main module

SINEC L2

LED 32 Main module 32

PLC

1 RS 485

Online test Parametrizing Commissioning

16

SINEC 1/ Ethernet

Analog output submodule

Display submodule

SINAUT spectrum

Fig. 12: Mimic board wiring with MBA-L2

1234 MW

Fig. 13: Hardware structure of MBA-L2

Siemens Power Engineering Guide Transmission & Distribution

7/9

Control Room Technology

Main module The main module is connected by a 16-pole cable including power supply, LAN connection and synchronizing input. Each main module is a slave partner on the SINEC L2 LAN and is able to control up to 32 twincolored LEDs. The intensity of the LEDs can be controlled via messages from the PLC. Thus the brightness of the indicator lights can be adapted to the light conditions in the control room. The LEDs can be operated in steady-state mode (on/off) or in flashing mode with a frequency of 0.5 to 8 Hz in 5 steps. A red LED on the modules rear side indicates following errors:

s LED failure s Number and color (monocolored,

User software

SINEC H1-Bus

8RS

8RU

8RT

CPU Process and distribution of LED data

Standard interface

twincolored) of LEDs to be used do not match with the number of plug-in LEDs s Failure or error of RAM, EPROM, E2PROM A green LED indicates healthy operation. Errors can be read out and failures can be exactly located. LED failures can be located as well. Thus detection and replacement of defective LEDs are not timeconsuming. A defective LED can also be found by a lamp test message (operation of all LEDs). Each main module can be used to control up to 16 extension modules. Each extension module will be addressed directly over Profibus by a subaddress. Extension module The extension module can control up to 32 twincolored LEDs. As described above, the extension module is addressed by a main module. Each extension module is cyclicly updated by the main module. This message can be interrupted by messages of higher priority. These are:

s Synchronous blinking s Lamp test

Data areas for LED information Data preparation

SINEC L2-Bus

Fig. 14: Software structure of Mimic Board Controlling (MBA-L2)

Fig. 15: 8RU-8RS-8RT mosaic tile systems

Parameteriziation software The menu-driven software allows designing of main and extension modules locally at the module or on line during operation. Features of MBA-L2

s Automatic background LED test,

Mechanical Design The 8RU-8RS-8RT mosaic tile systems are of self-supporting and self-locking design. The tiles are in fact designed to support one another and thus give the finished control board or mimic display a strong structure. No metal supporting grid or any other extra parts are needed for mounting the individual tiles. All the systems can be modified or extended quite simply. Once the board has been erected, mosaic tiles can simply be exchanged or added. The 8RU-8RS-8RT mosaic tile systems have been tested to DIN 40046 seismic requirements and are thus fully able to withstand heavy mechanical loads. For further information please contact: Fax: ++49 - 9 11-4 33 -81 83

faulty LED can be detected at any time

s All errors can be located and transmitted

to host computer system

s Steady-state mode, on/off s Flushing mode, 0.5 up to 8 1/s in

5 steps

s Smooth brightness control s No need for marshalling racks or distri-

bution units

s Reduced number

All further functions of the extension module are the same as described above for the main module.

of cable connections to and inside the mimic board s Simple erection on site, no wiring s Easy extension and modification because of using plug-in technology

7/10

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

Introduction

Safe, reliable and economical energy supply is also a matter of fast, efficient and reliable transmission of information and data. International operation, automation and computer-controlled optimization of network operations, as well as changing communications requirements and the rapid change in technology have considerably increased the demands placed on systems and components of communications networks. The same careful planning and organizing of communications networks are as necessary in the power industry as for the generation and distribution of energy itself. Siemens offers a wide range of systems and network elements specifically designed to solve communications problems in this area. All systems and network elements are adapted to one another in such a way that the power industrys future communications requirements can be satisfied optimally both technically and economically. Siemens is offering advice, planning, production, delivery, installation, operation and training one source for the customer. Providing expertise and commitment as the complexity of the problem requires. Put your trust in the extensive know-how of our specialists and in the solidity of the internationally proven Siemens communications systems. Flexible network configuration with communications systems and network elements The gradual transition from analog to digital information networks in the power industry and other privately operated networks requires a great variety of systems and network elements for widely differing uses. Prior to a decision as to which system could be used for the best technical and economical solution, it is first necessary to clarify such requirements as quantity of speech, data and teleprotection channels to be transmitted, length of transmission link, existing transmission media, infrastructure, reliability, etc. Depending on those clarifications the most cost-efficient and best technical solution can be chosen.

As shown in the block diagram below, we are offering systems and network elements for analog transmission as well as systems for digital transmission. The systems and network elements shown in this survey of products have been specially developed for power industry applications and therefore fulfill the requirements with regard to quality and workmanship as well as reliability and security.

All systems and network elements described meet the relevant international recommendations and are designed, developed and manufactured in accordance with the requirenments of the quality systems of DIN EN ISO 9001.

up to 500 km Line trap PLC CC or CVT AKE

Distance protection 50 ... 2400 Bd 64 kbit/s

SWT F6 FWT

ESB

Hicom O.F. Dig. current comparison and distance protection Data 50 Bd ... n x 64 kbit/s MUX Speech LFH AKE PLC CC CVT SWT F6 FWT ESB Hicom SWT 2 D MUX LFH O.F. Coupling unit Power line carrier communication Coupling capacitor Capacitive voltage transformer Teleprotection signaling system for analog transmission links Telecontrol and data transmission system Power line carrier system ISDN telephone system Teleprotection signaling system for digital transmission links Multiplex system Fiber optic transmission system Optical fiber cable SWT D

Fig. 16: General overview

Siemens Power Engineering Guide Transmission & Distribution

7/11

Power Network Telecommunication

Power Line Carrier (PLC) Communication

AKE 100 coupling unit For carrier frequency communication via power lines or via communication circuits subject to interference from power lines, the high-frequency currents from and to the PLC terminals must be fed into or tapped from the lines at chosen points without the operating personnel or PLC terminals being exposed to a high-voltage hazard. The PLC terminals are connected to the power line via coupling capacitors or via capacitive voltage transformers and the coupling unit. In order to prevent the PLC currents from flowing to the power switchgear or in other undesired directions (e. g. spur lines), traps (coils) are used, which are rated for the operating and short-circuit currents of the power installation and which involve no significant loss for the power distribution system. The AKE 100 coupling unit described here, together with a high-voltage coupling capacitor, forms a high-pass filter for the required carrier frequencies, whose lower cut-off frequency is determined by the rating of coupling capacitor and the chosen matching ratio. The AKE 100 coupling unit is supplied in four versions and is used for:

s Phase-to-ground

13 12 11 9 10 1 8 7 6 2

1 Conduit with weather-resistant

PLC cable screw connection

2 Terminal for coupling capacitor 3 Grounding switch with

switch-rod eye Main ground connection External shock hazard protection 1- or 2-pole coarse voltage arrester Drain and tuning coil Isolating capacitor Isolating transformer Resistor for phase-to-phase coupling (balancing resistor) 11 Gas-type surge arrester (optional extra) 12 PLC cable terminals 13 HF hybrid transformer

4 5 6 7 8 9 10

4 3

Fig.17: AKE 100 coupling unit with built-in HF hybrid transformer

A: Phase-to-ground coupling

Line trap CC or CVT AKE 100 PLC System

B: Phase-to-phase coupling

Line trap CC or CVT AKE 100 PLC System

coupling to overhead power lines s Phase-to-phase coupling to overhead power lines s Phase-to-ground coupling to power cables s Phase-to-phase coupling to power cables s Intersystem coupling with two phase-to-ground coupling units The coupling units for phase-to-phase coupling are adaptable for use as phaseto-ground coupling units. The versions for phase-to-ground coupling can be retrofitted for phase-to-phase coupling or can be used for intersystem coupling.

C: Intersystem coupling

Line trap CC or CVT AKE 100 HF hybrid PLC System

Fig. 18: Coupling modes

Line trap

CC or CVT

AKE 100

Coupling mode A: Phase-to-ground coupling B: Phase-to-phase coupling C: Intersystem coupling

Costs

Minimum Twice than A Twice than A

Attenuation

Greater than B&C Minimum Greater than B

Reliability

Minimum Greater than A Maximum

Fig. 19: Comparison of the coupling modes

7/12

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

ESB 2000i power line carrier system

PAX/ PABX MUX

64 kbit/s SDH PDH

DEE Communication system e. g. Hicom

So

64 kbit/s

Line trap Coupling capacitor Coupling unit

LAN PAX/ PABX 2/4-wire E&M V.24/V.28

BMX

64 kbit/s

Remote Service subscriber telephone

Protection relay

Distance protection

SWT 2000 F6

Data Data V.28 up to 2400 Bd or via MODEM

Modem, 19,2 kbits/s

ESB 2000i

Power system control

Data V.28 up to 2400 Bd

FWT 2000i

Service PC

Fig. 20: ESB 2000i power line carrier system

Siemens Power Engineering Guide Transmission & Distribution

7/13

Power Network Telecommunication

ESB 2000i power line carrier system Modern PLC systems must not only take into account the specific characteristics of the high-voltage line but must guarantee first and foremost that they will be economically and technically usable in future digital networks. The ESB 2000i digital PLC system meets these requirements through

s Use of state-of-the-art digital signal pro-

Modulation Interfacemodules Demodulation Digital signal processing Central control

Power amplifier

cessor technology (DSP)

s User-oriented service features, e. g.

automatic line equalization automatic frequency control (AFC) remote supervision/maintenance programming of parameters by PC s Integration of data transmission systems (channel circuits KS 2000 and KS 2000i) s Digital interfaces for transmission up to 64 kbit/s Use of the ESB 2000i PLC system also enables the full advantages of digital transmission to be exploited when employing the high-voltage line as a transmission medium. The ESB 2000i PLC system also satisfies economic requirements such as low investment costs, reduction of expenditure for maintenance and service and technical requirements with respect to security, availability and reliability. Application The ESB 2000i PLC system permits carrier transmission of speech, fax, data, telecontrol and teleprotection signals in the frequency range from 24 kHz to 500 kHz via: s Overhead power lines and s Cables in high- and medium-voltage systems. The information is transmitted using the single-sideband (SSB) method with suppressed carrier. This method permits: s Large ranges due to maximum utilization of the transmitter energy for signal transmission s The smallest possible bandwidth and therefore optimum utilization of the spectrum space of the frequency range permitted for the transmission s Improved privacy due to carrier suppression

Receive selection

Fig. 21: ESB 2000i functional units

Fig. 22: ESB 2000i PLC System with 40 W amplifier

7/14

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

Digital interface of the ESB 2000i PLC System The ESB 2000i PLC system with ITU-T standardized digital interface for transmission rates up to 64 kbit/s significantly increases the possible applications. By using external multiplex systems providing ITU-T standardized interfaces X.21/V.11 or G 703.1, it is possible to adapt the ESB 2000i PLC system more flexibly to the number of transmission channels and the various interfaces for the digital transmission of speech and data.

ESB 2000i

Digital transmission from 1.2 to 64 kbit/s

Digital interface X.21/V.11 or G 703.1 or V.28

SSBmodulator/ demodulator

PLC-lineunit

HFbandwidth 2.5 to 8 kHz

Service channel

Central processor

Service telephone

Service PC network management

Fig. 23: Basic diagram of the ESB 2000i PLC System for digital transmission

19.2 kbit/s

32 kbit/s

40 kbit/s

64 kbit/s

Bandwidth 2.5 kHz

Bandwidth 4 (3.75) kHz

Note: A service channel for remote maintenance and for service telephone is provided in addition to the above nominal bit rates.

Bandwidth 5 kHz

Bandwidth 8 (7.5) kHz

Fig. 24: Transmission rates of the digital interface of the PLC system according to the available bandwidth

Siemens Power Engineering Guide Transmission & Distribution

7/15

Power Network Telecommunication

SWT 2000 F6 protection signaling system for analog transmission links The task of power system protection equipment in the event of faults in highvoltage installations is to selectively disconnect the defective part of the system within the shortest possible time. In view of constantly increasing power plant capacities and the ever closer meshing of highvoltage networks, superlative demands are placed on power network protection systems in terms of reliability and availability. Network protection systems featuring absolute selectivity therefore need secure and high-speed transmission systems for the exchange of information between the individual substations. The SWT 2000 system for transmission of protection commands provides optimum security and reliability while simultaneously offering the highest possible transmission time. Application The SWT 2000 F6 system is for fast and reliable transmission of one or more protection commands and / or special switching functions in power networks. s Protection Protection commands can be transmitted for the protection of two three-phase systems or one threephase system with individual-phase protection High-voltage circuit-breakers can be actuated either in conjunction with selective protection relays or directly s Special switching functions When the system is used for special switching functions, it is possible to transmit four signals. Each signal is assigned a priority. Transmission paths Depending on the type of supply network, the following transmission paths can be utilized: s High- and medium-voltage overhead lines s High- and medium-voltage cables s Aerial and buried cables s Radio relay links Service PC Alarms 24 ... 60 V dc 110/220 V dc/ac Distance protection IF 4 CLE Electrical line connection

Fig. 25: SWT 2000 F6 teleprotection signal transmission system (stand-alone version)

PU

OMA

Optical line connection

Annunciations

IF 4M PS

Fig. 26: Block diagram of the SWT 2000 F6

7/16

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

FWT 2000i telecontrol and data transmission system for analog/digital transmission links In all areas related to the telemonitoring of systems, automation technology and the control of decentralized equipment, it must be possible to transmit signals and measured values economically and reliably. The new FWT 2000i System for telecontrol and data transmission can be flexibly used to perform the various transmission tasks involved in system management not only in public utility companies, railway companies and refineries, but also in the areas of environmental protection and civil defense, as well as in hydrographic and meteorological services. The following characteristics of the FWT 2000i system make it suitable for meeting users special requirements:

s Safe operating method around s s s s

high-voltage systems High degree of reliability and safety Short process cycle times Easy handling Economical use The FWT 2000i system offers a variety of modules for the widest possible range of transmission tasks. Thanks to the unlimited equipping options of the frame, virtually all system variants necessary for operation can be implemented on a customer-specific basis.

Fig. 27: FWT 2000i telecontrol and data transmission system

Transmitter and receiver as separate modules Separate modules that function only as a receiver or only as a transmitter are available for this operating method. Flexibility By using additional modules the system can be extended for alternative path switching or transmission of the control frequencies of a multistation control system. Fast and easy fault localization A variety of supervisory facilities and automatic fault signaling systems ensure optimum operation and fault-free transmission of data. Transmission media Suitable transmission media are underground cables, grounding conductor aerial cables, aerial cables on crossarms of power line towers, PLC/carrier frequency channels via power lines, carrier links, PCM links and Telecom-owned current paths. The overall concept of the FWT 2000i system meets the stringent demands placed on power supply and distribution networks. The FWT 2000i meets the special requirements with regard to reliable operation and electromagnetic compatibility.

Additional benefits In addition to the system features, the FWT 2000i system provides all users with the cost-effective and technical benefits expected and required when this system is used.

s Economical stocking of spare parts

Universal for all frequencies and transmission rates up to 2400 Bd The KS 2000i channel unit accommodates a transmitter and receiver assembly. All transmission rates from 50 to 2400 Bd can be set in all frequencies within the 30-Hz raster, including in the frequency raster to ITU-T. Transmission in the superimposed frequency band The FWT 2000i System permits transmission in the frequency range from 300 to 7200 Hz. Modularity The modularity of the KS 2000i channel unit is typified by its integration in various other systems, i.e. its use is not limited to the FWT 2000i system. For instance, the channel unit can be integrated in: s The ESB 2000i PLC system s The SWT 2000 F6 protection signaling system s Telecontrol systems.

is possible since, from now on, only one module is needed for all rates and frequencies. s The system can be placed in service quickly and easily thanks to automatic level adjustment and automatic compensation of distortion. s The use of the state-of-the-art digital processors and components ensures that the system will have a long service life and a high rate of availability.

Siemens Power Engineering Guide Transmission & Distribution

7/17

Power Network Telecommunication

KS 2000i channel unit The new KS 2000i channel unit is suitable for transmission of asynchronous data on analog media and such forms a complete and versatile VFT modem. Both transmitter and receiver are accomodated on only one plug-in card either to be used as stand-alone unit (seperate frame) or to be integrated in ESB 2000i PLC terminal or in remote terminal unit (RTU). Frequency shift as well as transmission speed are independently adjustable. With a maximum transmission speed of up to 2400 Bd the VFT channel approaches applications traditionally realized with highspeed modems only. Beside others the KS 2000i channel unit provides the following features: s High reliability s High flexibility s Easy detection of faults s Excellent transmission characteristics

Fig. 28: KS 2000i channel unit

7/18

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

Fiber optic communication

The LFH 2000 system Telecommunication requirements in power utilities

Electrical link (CU) Fiber-optic link

OLE 2 SWT MUX

O D F LWL 34 Mbit/s

MDF

Protection

PABX LSA

34 Mbit/s

Energy management system 4 x 2 Mbit/s

Communications network management center 34 Mbit/s 2 Mbit/s

4 x 2 Mbit/s Office

LAN

Communications room

OLE 34 OLE 34 DSMX OLE 8 SWT O O D D F F MUX/CC MUX/CC

2 Mbit/s

2 Mbit/s

MDF PABX PABX

34 Mbit/s 4 x 2 Mbit/s 4 x 2 Mbit/s 4 x 2 Mbit/s

Fig. 29: The LFH 2000 fiber optic transmission system Telecommunication requirements in power utilities

Siemens Power Engineering Guide Transmission & Distribution

7/19

Power Network Telecommunication

LFH 2000 fiber optic transmission system Flexible network configuration and future communications requirements of private network users, such as power companies, call for universal network elements for transmission in digital communications networks. LFH 2000 has been designed and developed on the basis of extensive experience gained with fiber optic transmission systems in public networks and transmission elements specially developed for such systems. It was tailored to the needs of power companies and other private network users. In its basic version LFH 2000 consists of a 19-inch subrack equipped with an optical line terminating unit TRCV2 and a service channel module. Even in its simplest configuration, LFH 2000 offers various types of interfaces for the transmission of speech and data channels such as:

s Line interfaces up to 34 Mbit/s s So-interface for networking digital

The incorporation of the SWT 2000 D digital protection data system provides additional functions required for most applications in power companies. The basic version can be optionally equipped with service telephone units, optical line terminating units with higher transmission speeds or with other service channel modules so that the system can be conveniently adapted to the individual transmission requirements. Further network elements may be connected to LFH 2000 via internationally standardized interfaces if the number of required channels and the types of interfaces, i.e. the capacity of the system, have to be extended. Depending on the number and type of the transmission interfaces required, LFH 2000 can be expanded by connecting flexible multiplex systems.

telephone systems (e.g. Hicom)

s QD 2-interface for network manage-

LFH 2000 is provided with internationally standardized interfaces so that transmission systems of other manufacturers which are also equipped with internationally standardized interfaces can communicate with LFH 2000. This also makes it possible to combine LFH 2000 with digital transmission system of other manufacturers. The incorporation of LFH 2000 with the expansion element e.g. flexible multiplex system into a network hierarchy with differing transmission rates as currently planned and implemented by private network operates can be easily achieved using the compatible network elements available today. The call for a user-friendly network management can be fulfilled by adding the required hardware and software. LFH 2000 meets the requirements of the power companies and private network operators due to its flexibility, availability of internationally standardized interfaces and compatibility with regard to its incorporation into existing private networks.

ment

DPU IF4 OM

Digital processor unit Interface module for distance protection relays Optomodule for connection of digital current comparison protection system Power supply Module for service telephone with DTMF signaling Module for nondialing service telephone Service channel unit protection switching Alarm and event recorder Distance protection or digital current comparison OFC (Fiberoptic cables) DPU IF 4 or OM IF 4 or OM PS TRCV 2 or TRCV 8 or TRCV 34 LWL TRCV 2 or TRCV 8 or TRCV 34 AUX or AUX 1+1 or AUX BUS

PS ST-A ST-B AUX

Service telephone ST-A or ST-B

AUX 1+1 Service channel unit with AUXBUS Bus channel unit TRCV LWL

Optical transceiver Optical fiber

LWL

Telecontrol system PABX

Fig. 30: LFH 2000 fiber optic transmission system

7/20

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

SWT 2000 D protection signaling system for digital communication links In comparison with analog protection signaling the use of digital transmission links provide noise-free communication. Switching operations, atmospheric conditions and other sources of interference on power lines do not impair secure and reliable transmission of protection signals. The SWT 2000 D system for the transmission of protection signals on digital transmission links, mainly fiber optics, provides optimum security and reliability while simultaneously offering the quickest possible transmission speed. Uses SWT 2000 D system is used for fast and secure transmission of one or several independent binary signals for protection and special switching functions in power networks and/or the transmission of serial protection data. The system is avaliable in versions for the transmission of protection data on separate fibers and on 64 kbit/s PCM channels. As an optimized solution between these two possibilities, the system offers transmission of the protection data in the service channel of an optical line termination system (e. g. OLTS, OLTE 8) which ensures maximum independence of the protection data from voice and data transmission despite the common use of fibers in fiber optic cables. Applications

s All types of distance protection

Fig. 31: SWT 2000 D for flush panel mounting with integrated TRCV2 optical line equipment

PCM

2 Mbit/s

40/60 V dc

(permissive tripping, blocking, etc.) s Direct transfer tripping s Special switching functions s Digital current comparison protection (differential protection) with optical serial interface 19.2 kBd (e. g. with 7SD511). Features

s Up to 8 parallel (binary) commands, s s

TRCV Digital longitudinal differential protection (7SD51) O.F. 820 nm n x 64 kbit/s DPU Distance protection IF 4 1300 nm 1500 nm OM X.21/ V.11 G.703

O.F.

O.F.

s s s s

bi-directional Up to 2 serial protection data, bi-directional Simultaneous transmission of serial protection data and up to 4 binary protection commands High-performance microcontroller Permanent self-supervision Automatic loop testing Event recorder with real-time clock (readable via hand-held terminal or PC).

Alternative route IF 4 PS

Service PC

24 ... 60 V dc Alarms 110/220 V dc/ac

Fig. 32: Block diagramm SWT 2000 D

Siemens Power Engineering Guide Transmission & Distribution

7/21

Power Network Telecommunication

Flexible Multiplexer (FMX) Depending on the number and type of the transmission interfaces required, the LFH 2000 optical fiber transmission system can be extended by connecting the flexible multiplex system (FMX). The FMX multiplexer is based on a flexible design which is considerably different from normal PCM systems. For terminal operation, it contains a central unit CU, CUAD or CUDI unit and, for branch operation, a CUDI central unit as well as the withdrawable channels. Thanks to the software-controlled configuration and parametrization of the multiplexers they can be integrated quickly and easily into the network. The 19'' inset has sockets for two central units (CU, CUAD, CUDI), twelve channel units, a supervision unit and two power supply units.

User Interfaces (see Fig. 33) The LFH 2000 System overview (see Fig. 34 on page 7/23)

ISDN Basic access unit I4SO

4x

S0 interface

I4UK4 NTP I4UK4 LTP

4x

UK0 interface, 2B1Q or 4B3T, NT-mode or LT-mode n x 64 kbit /s G.703 codirectional or n x 64 kbit /s G.703 contradirectional or centralized clock X.21or V.24/V.28 bis (switchable)

DSC6-nx64G

6x

DSC2-nx64

2x

DSC8x21

8x

X.21/ V.11 64 kbit/s V.35 64 kbit/s or V.36 64 kbit/s Central unit, standard, or central unit for add/drop operation or central unit for ADPCM

DSC4V35 or DSC4V36

4x

CU or CUDI or CUAD

DSC8V24

8x

V.24/ V.28 < 64 kbit/s

DSC104CO

10 x

64 kbit /s G.703 co-directional

SLB62

6x

2-wire LB subscriber

SLX62

6x

Exchange, 2-wire

SUB62

6x

Subscriber, 2-wire

SEM106 or SEM108

10 x

2-wire NF and 2 E&M or 4-wire NF and 2 E&M Central unit, standard, or central unit for add/drop operation or central unit for ADPCM

CU or CUDI or CUAD

Fig. 33: FMX interfaces

7/22

Siemens Power Engineering Guide Transmission & Distribution

Power Network Telecommunication

The LFH 2000 System Overview

SDH 155 Mbit/s 2,5 Gbit/s

EMOS QD2 Network management system EMS Energy management system SDH 155/622 Mbit/s Remote subscriber External and/or internal exchange PABX Substation control and protection system Data interfaces e.g. X.21, V.24, LAN Data and voice of PLC links Distance protection or digital current comparison protection 4 x 2 Mbit/s Protection RTU

34 Mbit/s

34 Mbit/s

34 Mbit/s

34 Mbit/s

2 Mbit/s

2 Mbit/s

4x2 Mbit/s

4x2 Mbit/s

Data

V.11 V.11 Speech four-wire + E&M Speech four-wire + E&M V.28 V.28 Service telephone Speech, two-wire

Protection

PABX

Data RTU 2 Mbit/s 2 Mbit/s

34 Mbit/s

4 x 2 Mbit/s 4 x 2 Mbit/s PLC n x 64 kbit/s

TRCV

SMUQ

Service channel

MUX

Cross connect

Fig. 34: The LFH 2000 System Overview

Siemens Power Engineering Guide Transmission & Distribution

7/23

Power Network Telecommunication

Conclusion

The described digital and analog network elements are, of course, only a small selection from the multitude of network elements which Siemens has on hand for the implementation of transmission networks. We have focused on those products which have been specifically developed for the transmission of information in power utilities and which are indispensable for the operation of such companies. It has also been our intention to show the uses for our products and how they can be integrated in transmission networks with varying network elements and network configurations. The great variety of products in the field of digital transmission systems and the different requirements of our customers with regard to the implementation of digital transmission networks make customerspecific planning, advice and selection of network elements an absolute necessity. Detailed descriptions of all products can be sent to you upon request. For further information please contact: Fax: ++49 - 89-7 22-2 44 53 or ++49 - 89-7 22-4 19 82

7/24

Siemens Power Engineering Guide Transmission & Distribution

Vous aimerez peut-être aussi

- Coordinated Voltage Control in Power SystemsDocument203 pagesCoordinated Voltage Control in Power SystemsSalma AzzamPas encore d'évaluation

- Siemens Distribution Feeder AutomationDocument18 pagesSiemens Distribution Feeder Automationpithoon ungnaparatPas encore d'évaluation

- PSSE Intro Stabilty InstructionsDocument4 pagesPSSE Intro Stabilty Instructionspuja_shinde9Pas encore d'évaluation

- DN P 3 Introduction HorsDocument64 pagesDN P 3 Introduction Horsvrallam007Pas encore d'évaluation

- How To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFDocument35 pagesHow To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFCaroline NobrePas encore d'évaluation

- S7 Communication Between S7-300 and S7-400 Via Profibus With BSEND / BRECEIVEDocument33 pagesS7 Communication Between S7-300 and S7-400 Via Profibus With BSEND / BRECEIVELubo KuželaPas encore d'évaluation

- SCADA and Power System Automation (18GAEE7083)Document18 pagesSCADA and Power System Automation (18GAEE7083)MADHAN KUMAR SPas encore d'évaluation

- Schneider Electric Digital Applications IEC Design GuideDocument268 pagesSchneider Electric Digital Applications IEC Design GuideMichael Parohinog GregasPas encore d'évaluation

- Nmu Siemens Course Detail Guide 2021Document24 pagesNmu Siemens Course Detail Guide 2021Industrial ItPas encore d'évaluation

- Lending OperationsDocument54 pagesLending OperationsFaraz Ahmed FarooqiPas encore d'évaluation

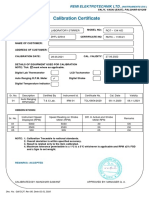

- Calibration CertificateDocument1 pageCalibration CertificateSales GoldClassPas encore d'évaluation

- SCADA in POWER DISTRIBUTION SYSTEMSDocument10 pagesSCADA in POWER DISTRIBUTION SYSTEMSrohinibhaskar0% (1)

- p01 05 Functional Safety v9 Tud 0719 enDocument54 pagesp01 05 Functional Safety v9 Tud 0719 enMetin ErimPas encore d'évaluation

- Substation AutomationDocument5 pagesSubstation AutomationRavi RaikarPas encore d'évaluation

- Wincc FaceplateDocument8 pagesWincc FaceplatevijikeshPas encore d'évaluation

- Spectrum Power 3 Release3.9Document2 pagesSpectrum Power 3 Release3.9Yane HdezPas encore d'évaluation

- Serv1 - 11e - Introduction To Profibus DP and HmiDocument28 pagesServ1 - 11e - Introduction To Profibus DP and HmiAhmed KhairiPas encore d'évaluation

- Siemens SIMATICDocument8 pagesSiemens SIMATICsharib26Pas encore d'évaluation

- Totally Integrated Power ProtectionDocument38 pagesTotally Integrated Power Protectionvthiseas100% (1)

- Digital Substation SolutionsDocument74 pagesDigital Substation SolutionsNelson LozanoPas encore d'évaluation

- IEC61850 SiemensDocument200 pagesIEC61850 SiemensJorge S100% (2)

- Overview of The IEC 61850 StandardsDocument40 pagesOverview of The IEC 61850 Standardswaqasasad408100% (1)

- 3D Photovoltaic Devices Complete Self-Assessment GuideD'Everand3D Photovoltaic Devices Complete Self-Assessment GuidePas encore d'évaluation

- Viceversa Tarot PDF 5Document1 pageViceversa Tarot PDF 5Kimberly Hill100% (1)

- Micro-Grid Modeling and ControlDocument24 pagesMicro-Grid Modeling and Controldebjyoti chatterjeePas encore d'évaluation

- Application Examples Overview enDocument26 pagesApplication Examples Overview enArunagiriPas encore d'évaluation

- IK PI - 2015 Industrial Communication SIMATIC NET PDFDocument1 950 pagesIK PI - 2015 Industrial Communication SIMATIC NET PDFNicuVisanPas encore d'évaluation

- Smart GridDocument11 pagesSmart GridHatem TantawyPas encore d'évaluation

- 1a Function Design Specification - SCADA - Rev ADocument129 pages1a Function Design Specification - SCADA - Rev AVinay GuptaPas encore d'évaluation

- Profinet Step7 v17 Function Manual en-US en-US PDFDocument333 pagesProfinet Step7 v17 Function Manual en-US en-US PDFNam NguyễnPas encore d'évaluation

- Scada SystemDocument9 pagesScada SystemAaqibRPas encore d'évaluation

- Sicam PASDocument16 pagesSicam PASRami El Naqa100% (1)

- Siemens Simatic S 7 300 - 400 - PID Control EnglishDocument42 pagesSiemens Simatic S 7 300 - 400 - PID Control Englishduniaengineering8666100% (15)

- Spectrum Power SiemensDocument8 pagesSpectrum Power SiemensNelson Francisco Marcano AguileraPas encore d'évaluation

- Supervisory Control and Data Acquisition (SCADA)Document16 pagesSupervisory Control and Data Acquisition (SCADA)محمد العراقيPas encore d'évaluation

- CIM Standard OverviewDocument59 pagesCIM Standard Overviewandrescardona1Pas encore d'évaluation

- Clase Tia Portal PLCDocument34 pagesClase Tia Portal PLCHitklerLaynekerSebastian100% (1)

- Smart Grid in TransmissionDocument46 pagesSmart Grid in TransmissionAnil PalamwarPas encore d'évaluation

- SPCDocument149 pagesSPCMatias100% (1)

- Siemens TCP I PcsDocument26 pagesSiemens TCP I PcsChu Quoc ThaiPas encore d'évaluation

- Why Smart Grid Is EssentialDocument7 pagesWhy Smart Grid Is Essentialkaushik4endPas encore d'évaluation

- 11 Training and SupportDocument9 pages11 Training and Supportcarsan87Pas encore d'évaluation

- Siemens CFCDocument20 pagesSiemens CFCscribdkhatnPas encore d'évaluation

- SCADADocument34 pagesSCADADIKSHA81% (31)

- Siemens BookDocument6 pagesSiemens BookSakib KaldanePas encore d'évaluation

- WCP Faceplates Valve enDocument75 pagesWCP Faceplates Valve enchupoPas encore d'évaluation

- SeminarDocument23 pagesSeminaraartitomar47_8332176Pas encore d'évaluation

- ETAP RT vs. Power SCADADocument7 pagesETAP RT vs. Power SCADANghĩa HữuPas encore d'évaluation

- SystemConfiguratorHelp enDocument206 pagesSystemConfiguratorHelp enLuis FernandoPas encore d'évaluation

- Power Management Using PLC and ScadaDocument8 pagesPower Management Using PLC and Scadaanon_735401345Pas encore d'évaluation

- PV Visualization With WinCCDocument6 pagesPV Visualization With WinCCvoltus88Pas encore d'évaluation

- Etrax Rail SolutionDocument8 pagesEtrax Rail Solutionpimpowimpi4667Pas encore d'évaluation

- Head End System For Meter Data AcquisitionDocument8 pagesHead End System For Meter Data Acquisitionermanos3Pas encore d'évaluation

- Catálogo Sicam Pas enDocument16 pagesCatálogo Sicam Pas enAlejandro Soto AltamiranoPas encore d'évaluation

- Sicam 230 Brochure enDocument8 pagesSicam 230 Brochure enLuis Enrique PariapazaPas encore d'évaluation

- Brochure Pss Sincal en s4Document6 pagesBrochure Pss Sincal en s4Jorge CáceresPas encore d'évaluation

- 01 IK IESYS e Communications OverviewDocument12 pages01 IK IESYS e Communications OverviewHernando AlborPas encore d'évaluation

- Comm Processors For S7Document24 pagesComm Processors For S7catalinccPas encore d'évaluation

- PACiS Subsation AutomationDocument12 pagesPACiS Subsation Automationanon_205398010Pas encore d'évaluation

- Heavy LiftDocument4 pagesHeavy Liftmaersk01Pas encore d'évaluation

- How Yaffs WorksDocument25 pagesHow Yaffs WorkseemkutayPas encore d'évaluation

- Ajp Project (1) MergedDocument22 pagesAjp Project (1) MergedRohit GhoshtekarPas encore d'évaluation

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiPas encore d'évaluation

- Building New Boxes WorkbookDocument8 pagesBuilding New Boxes Workbookakhileshkm786Pas encore d'évaluation

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZDocument3 pagesMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezPas encore d'évaluation

- Research Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNADocument10 pagesResearch Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAAnonymous cgcKzFtXPas encore d'évaluation

- SME-Additional Matter As Per Latest Syllabus Implementation WorkshopDocument14 pagesSME-Additional Matter As Per Latest Syllabus Implementation WorkshopAvijeet BanerjeePas encore d'évaluation

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationDocument27 pagesAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfPas encore d'évaluation

- 4 Bar LinkDocument4 pages4 Bar LinkConstance Lynn'da GPas encore d'évaluation

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 page18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaPas encore d'évaluation

- Ikea AnalysisDocument33 pagesIkea AnalysisVinod BridglalsinghPas encore d'évaluation

- Ludwig Van Beethoven: Für EliseDocument4 pagesLudwig Van Beethoven: Für Eliseelio torrezPas encore d'évaluation

- Rating SheetDocument3 pagesRating SheetShirwin OliverioPas encore d'évaluation

- Section 8 Illustrations and Parts List: Sullair CorporationDocument1 pageSection 8 Illustrations and Parts List: Sullair CorporationBisma MasoodPas encore d'évaluation

- Ss 7 Unit 2 and 3 French and British in North AmericaDocument147 pagesSs 7 Unit 2 and 3 French and British in North Americaapi-530453982Pas encore d'évaluation

- Vinera Ewc1201Document16 pagesVinera Ewc1201josue1965Pas encore d'évaluation

- Maths PDFDocument3 pagesMaths PDFChristina HemsworthPas encore d'évaluation

- Proceedings of SpieDocument7 pagesProceedings of SpieNintoku82Pas encore d'évaluation

- How To Control A DC Motor With An ArduinoDocument7 pagesHow To Control A DC Motor With An Arduinothatchaphan norkhamPas encore d'évaluation

- CI Principles of EconomicsDocument833 pagesCI Principles of EconomicsJamiePas encore d'évaluation

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunPas encore d'évaluation

- SILABO 29-MT247-Sensors-and-Signal-ConditioningDocument2 pagesSILABO 29-MT247-Sensors-and-Signal-ConditioningDiego CastilloPas encore d'évaluation

- Brand Positioning of PepsiCoDocument9 pagesBrand Positioning of PepsiCoAbhishek DhawanPas encore d'évaluation

- Vangood Quotation - Refrigerator Part - 2023.3.2Document5 pagesVangood Quotation - Refrigerator Part - 2023.3.2Enmanuel Jossue Artigas VillaPas encore d'évaluation

- Kaitlyn LabrecqueDocument15 pagesKaitlyn LabrecqueAmanda SimpsonPas encore d'évaluation