Académique Documents

Professionnel Documents

Culture Documents

ColdWAR January 2008 Large Tonnage Process Cooling

Transféré par

Fred SmifCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ColdWAR January 2008 Large Tonnage Process Cooling

Transféré par

Fred SmifDroits d'auteur :

Formats disponibles

January 2008

A collection of short pointed topical papers.

ir Condi er its A Wheth

r Refri tioning o

geration

Large Tonnage Process Cooling

py, but ing a co nthly are view If you e the mo to receiv y, e-mail uld like tl wo .R. direc Cold W.A er.com D@park list. WarSV g Cold ur mailin to join o

by: Garth Denison Senior Application Engineer

The Sporlan Division of Parker Hannifin assumes no obligation or liability for any advice furnished or for any results obtained with respect to this information. All such advice is given and accepted at users risk. This disclosure of information herein is not a license to operate under, or a recommendation to infringe any patent of Sporlan Division of Parker Hannifin or others. Registered trademark of Sporlan Division of Parker Hannifin, Washington, MO 63090 USA Copyright 2003 by Sporlan Division of Parker Hannifin, Washington, MO 63090 USA

57

This document may be copied and distributed for educational purposes only. Cold W.A.R. Issue 057

Cold W.A.R. Issue 57 - Page 2

Single Temperature Level

Compact Arrangement With Water Cooled Condensing

Condenser

Compressor

Economizer

Cooler

Motorized Butter y Damper / Temperature Controller

This refrigeration cycle is commonly used when all process loads require approximately the same temperature level. With a standard centrifugal refrigerating machine a two stage compressor can produce temperatures in the range of plus 20F, three stages of around minus 10F, and four stages down to approximately minus 40F to 50F. Between stages, economizers may be added to reduce horsepower requirements by improving cycle efciency. In this cycle arrangement, the standard process centrifugal machine operates on a balanced refrigerant charge and thus does not require an operating receiver.

Education is Just the Beginning

Cold W.A.R. Issue 57 - Page 3

Single Temperature Level

Remote Cooler With Water Cooled Condensing

Separator Remote Cooler

Condenser

Receiver

Compressor

Closed Economizer

Motorized Butter y Damper / Temperature Controller

There are times when the refrigerating machine must be located remotely from the process refrigeration requirement. Normally this would be handled by cooling a brine and circulating it to the process heat exchanger. Sometimes it can be handled by adding a closed economizer to the refrigeration system. This sub-cools the high pressure condensed refrigerant enabling it to be transferred by its own pressure to a remotely located evaporator. A separator should be added on the suction line to prevent liquid from being carried over to the compressor during start up or large uctuations in load.

Education is Just the Beginning

Cold W.A.R. Issue 57 - Page 4

Single Temperature Level (Low)

Compact Arrangement with Water Cooled Condensing

Condenser Compressor Compressor

Economizer

Intercooler Float Brine Cooler

Motorized Butter y Damper / Temperature Controller

The operating simplicity and reliability of this cycle make it especially suitable for low temperature applications. Temperatures as low as minus 125F suction can be obtained by cascading two centrifugal refrigerating machines. The inter-cooler condenses refrigerant from the low stage machine. Since two standard machines are used, each operating on a balanced refrigerant charge, no operating receivers or level controls are needed. Different refrigerants may be used in each machine, depending upon process temperature level requirements.

Education is Just the Beginning

Cold W.A.R. Issue 57 - Page 5

Single Temperature Level

Separate Components With Air Cooled Condensing

Compressor

Air Cooled Condenser

Float

Cooler

Economizer / Receiver

Motorized Butter y Damper / Temperature Controller

When water for condensing is scarce, restricted, or of poor quality, air cooled condensers for process heat rejection can be used. Air cooled condensing may be applied with any of the commonly used refrigerants such as R-123, R-134a and R-404A. The choice of refrigerants generally depends upon the process load and temperature levels. Normally, this arrangement of separated components requires the addition of a refrigerant storage tank and a liquid level controller on the cooler. The refrigerant receiver may be utilized as an economizer during operation.

Education is Just the Beginning

Cold W.A.R. Issue 57 - Page 6

Dual Temperature Levels

Separate Components With Water Cooled Condensing

Condenser

Compressor

Float

Cooler #1

Cooler #2

Economizer / Receiver

Motorized Butter y Damper / Temperature Controller

Where more than one temperature level is required in a process refrigeration cycle, the centrifugal machine may serve several coolers, each equipped with independent controllers. With this arrangement, an operating receiver and refrigerant level controls are required. The receiver also serves as an economizer during operation and for the refrigerant storage on shut down. On multi-temperature applications, the effects of varying loads and operating periods should be given consideration to determine if the process requirements can be handled by a single machine more effectively than by two.

Education is Just the Beginning

Cold W.A.R. Issue 57 - Page 7

Dual Temperature Levels

Separated Components With Booster Compressor, Water Cooled Condensing

Condenser

Condenser Compressor Receiver

Economizer

Reciprocating Compressor

High Temp. Cooler Low Temp. Cooler

Motorized Butter y Damper / Temperature Controller

In vapor condensing, such as chlorine, the process stream is usually handled at two different temperature levels, requiring a high and a low stage system. Refrigeration for the high stage or major part of the load is usually handled by a standard centrifugal machine for temperatures down to approximately 0F. At this level, tail gas is reduced to a much lower temperature for maximum recovery. Here a reciprocating system may be used to handle the relatively smaller refrigeration load. Different refrigerants may be used, and refrigerant from the high stage machine is used in the condenser of the low stage.

Education is Just the Beginning

Cold W.A.R. Issue 57 - Page 8

Dual Temperature Levels

Compact Arrangement With Water Cooled Condensing

Condenser Compressor

Economizer

Cooler #2

Cooler #1 Receiver

Motorized Butter y Damper / Temperature Controller

This scheme illustrates the possibility of obtaining two considerably different temperature levels for refrigeration duty utilizing only one standard multi-stage centrifugal compressor. For example, with this arrangement the cooler of the centrifugal machine may be chilling water to plus 40F, and a separate or remote cooler may be chilling brine to minus 20F. Each cooler has its own temperature controller. This system utilizes an operating receiver in the refrigerant circuit to accommodate uctuating loads in the two coolers, and it is also used to store refrigerant on shut down.

Education is Just the Beginning

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Carpentry and Joinery 1 (3rd Edition - 2001)Document317 pagesCarpentry and Joinery 1 (3rd Edition - 2001)slartibartfPas encore d'évaluation

- Australian Fish and Seafood Cookbook - John Susman PDFDocument855 pagesAustralian Fish and Seafood Cookbook - John Susman PDFFred Smif100% (4)

- Rational Psychrometric Formulae:Paper - Wikisource, The Free Online LibraryDocument21 pagesRational Psychrometric Formulae:Paper - Wikisource, The Free Online LibraryFred SmifPas encore d'évaluation

- Leather Carving 101 PDFDocument5 pagesLeather Carving 101 PDFFred Smif100% (1)

- Chandler Condensing UnitsDocument40 pagesChandler Condensing UnitsFred SmifPas encore d'évaluation

- Biden To Take Poor Kids Free School Lunches If Their School Doesn't Let Boys in To Girl's BathroomsDocument16 pagesBiden To Take Poor Kids Free School Lunches If Their School Doesn't Let Boys in To Girl's BathroomsFred SmifPas encore d'évaluation

- Blackstar Id Series High HandbookDocument57 pagesBlackstar Id Series High HandbookFred SmifPas encore d'évaluation

- UNEnv ASHRAE Fact Sheet On Refrigerant Designation and Safety Classification 2017 English1Document4 pagesUNEnv ASHRAE Fact Sheet On Refrigerant Designation and Safety Classification 2017 English1Fred SmifPas encore d'évaluation

- Petopia: The Big List of Pet SkillsDocument14 pagesPetopia: The Big List of Pet SkillsFred SmifPas encore d'évaluation

- ColdWAR March 2007 Multi ReceiversDocument4 pagesColdWAR March 2007 Multi ReceiversFred SmifPas encore d'évaluation

- Dee Song TabDocument3 pagesDee Song TabFred SmifPas encore d'évaluation

- ColdWAR January 2009 Electrical SafetyDocument2 pagesColdWAR January 2009 Electrical SafetyFred SmifPas encore d'évaluation

- True :dixell TS InstructionsDocument4 pagesTrue :dixell TS InstructionsFred Smif100% (1)

- System Charging ManualDocument32 pagesSystem Charging ManualFred SmifPas encore d'évaluation

- The Chemistry of Water: 2.1. Water As A SolventDocument6 pagesThe Chemistry of Water: 2.1. Water As A SolventEva MoonPas encore d'évaluation

- Chemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus) Chemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus)Document20 pagesChemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus) Chemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus)Laura FidarovaPas encore d'évaluation

- Prob Set 10Document5 pagesProb Set 10Payal SPas encore d'évaluation

- Pretreatment Training-EngDocument62 pagesPretreatment Training-EngNethaji Mett100% (1)

- 10 1016@j Mineng 2020 106456Document10 pages10 1016@j Mineng 2020 106456faouzi rachidPas encore d'évaluation

- N. Sabila, P. M.Mwangi, P. Kareru and G. Thiong'o Department Chemistry, Jomo Kenyatta University of Agriculture and Technology, Nairobi, KenyaDocument8 pagesN. Sabila, P. M.Mwangi, P. Kareru and G. Thiong'o Department Chemistry, Jomo Kenyatta University of Agriculture and Technology, Nairobi, KenyaAli DandamunPas encore d'évaluation

- Sample Paper HMT EME504Document1 pageSample Paper HMT EME504manidev25% (4)

- CSEC Physics June 2014 P2Document19 pagesCSEC Physics June 2014 P2Kriston KhanPas encore d'évaluation

- To Determine % Purity of The Given Sample of Mefenamic Acid by Titrimetric Method. Chemicals RequiredDocument4 pagesTo Determine % Purity of The Given Sample of Mefenamic Acid by Titrimetric Method. Chemicals RequiredjerritPas encore d'évaluation

- Design Rules For Steam Condensate SystemsDocument87 pagesDesign Rules For Steam Condensate SystemsAnonymous gr5Pr9AV100% (1)

- Internal Energy of An Ideal GasDocument15 pagesInternal Energy of An Ideal GasMD Al Fahad NirobPas encore d'évaluation

- Experiment 5 Chem 26.1Document2 pagesExperiment 5 Chem 26.1Collin Reyes HuelgasPas encore d'évaluation

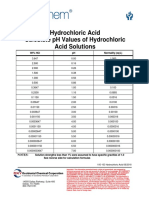

- Tech-Calculated PH Values HCLDocument3 pagesTech-Calculated PH Values HCLNurlaila Ela IlaPas encore d'évaluation

- Mechanical Engineering Objective Mcqs With AnswersDocument2 pagesMechanical Engineering Objective Mcqs With AnswersAdnan MaharPas encore d'évaluation

- Fiber Optic Chemical Sensors Biosensors PDFDocument2 pagesFiber Optic Chemical Sensors Biosensors PDFKatreenaPas encore d'évaluation

- XR-EBSD 203110007 13thfebDocument12 pagesXR-EBSD 203110007 13thfebVikram ChavanPas encore d'évaluation

- MCB 307 - 1Document15 pagesMCB 307 - 1marvelloussamuel771Pas encore d'évaluation

- Sas7 STM-005Document6 pagesSas7 STM-005mayasPas encore d'évaluation

- Fig.5.5 (A) - P-V Diagram of Modified Rankine CycleDocument3 pagesFig.5.5 (A) - P-V Diagram of Modified Rankine Cycleapi-3830954Pas encore d'évaluation

- MI - 1748 Rev FDocument21 pagesMI - 1748 Rev FSudarshan Dhumal100% (2)

- Tugas Teknik Reaksi Kimia Lanjut EXAMPLE 10.2 & PROBLEM 10.3Document13 pagesTugas Teknik Reaksi Kimia Lanjut EXAMPLE 10.2 & PROBLEM 10.3Andre Fahriz Perdana HarahapPas encore d'évaluation

- Isolobal AnalogyDocument4 pagesIsolobal Analogyindu priyaPas encore d'évaluation

- Gelation Properties of Flaxseed GumDocument9 pagesGelation Properties of Flaxseed GumAntares1973Pas encore d'évaluation

- Laboratory Manual: Bacis Physical ChemistryDocument30 pagesLaboratory Manual: Bacis Physical ChemistryNurul SafwahPas encore d'évaluation

- Carbon Nanotube: Properties and ApplicationsDocument22 pagesCarbon Nanotube: Properties and ApplicationsmanuPas encore d'évaluation

- ElectrochemistryDocument93 pagesElectrochemistrySrinivasanPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological Universityvifaket581Pas encore d'évaluation

- PDF Q0 8 Final EIM 7 8 Module 8Document14 pagesPDF Q0 8 Final EIM 7 8 Module 8Joy Cabug LemosneroPas encore d'évaluation

- Daftar PustakaDocument3 pagesDaftar PustakaNicodemus Sigit SutantoPas encore d'évaluation

- STD 113Document44 pagesSTD 113Arun KumarPas encore d'évaluation