Académique Documents

Professionnel Documents

Culture Documents

1 PISTA Grit Screw Conveyor

Transféré par

volkandemirmmDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1 PISTA Grit Screw Conveyor

Transféré par

volkandemirmmDroits d'auteur :

Formats disponibles

PISTA Grit Screw Conveyor

The second-stage PISTA Grit Screw Conveyor is designed to work in concert with the complete PISTA Grit Removal System, providing superb dewatering and high retention of fine PISTA Grit Screw Conveyor grit without the burden Introduced: 1989 System Benefit: Lamella plate design of high maintenance. aids in retention of fine Dewatered grit grit while reducing discharges into a turbulence & overflow Upgrade from: Screens container for disposal Sizing: Models 15 & 17 while the flow and residual organics are retuned to the inlet channel prior to the grit chamber, typically 93% of the flow and 95% of the organics.

Key Points

1 Unique Design Elements Retain Ultra-Fine Grit

The PISTA Grit Screw Conveyors separate inlet zone, large Lamella parallel plate section that acts as a high-rate settling device, and double-sided weir trough work in concert to capture silt and and ultra fine grit. The inlet zone facilitates energy dissipation in order to reduce turbulence. This allows easier settling in the plate section while the larger weir trough lowers the carry-over rate.

2 Ideal Upgrade for Screens

Screens are typically maintenance-intensive because of their messy operation. Additionally, they can allow ultra-fine grit to be returned to the flow stream. The PISTA Grit Screw Conveyor greatly reduces maintenance concerns (and mess) while producing dryer grit.

O n l i n e : s m i t h a n d l o v e l e s s . c o m P h o n e : 9 1 3 . 8 8 8 . 5 2 0 1 FA X : 9 1 3 . 8 8 8 . 2 1 7 3

Smith & Loveless Inc. System Innovators for global p umping, water and wastewater treatment

2007 Smith & Loveless Inc. Bulletin 9503-12

The PISTA Grit Screw Conveyor retains ultrafine grit and effectively washes and dewaters it for disposal all in a hassle-free operation. Lamella parallel plates facilitate high rate settling.

Complete Grit Removal, Handling & Dewatering System Flow Scheme

or maximum grit removal, the PISTA Grit Chamber should be complemented with Smith & Loveless PISTA grit handling and dewatering components, which transport, dewater and prepare the grit for final disposal. These components can be retrofitted to increase the efficiency of your grit handling system originally equipped with older components or non-Smith & Loveless accessories. Smith & Loveless commitment to market leadership in grit removal kindles on-going research and development, which leads to continued system and component innovations. See the timeline below of key PISTA design milestones.

PISTA Grit Removal System Components & Scheme

[1]

PISTA Grit Chamber Influent enters flat-floor grit chamber hydraulically guided by coanda ramp, internal baffles and central, low-speed propeller. Forced vortex drives grit particles to center chamber floor and into lower grit hopper while organics and flow continue to plant. PISTA Turbo Grit Pump Top-mounted or remote mounted unit pumps collected grit slurry (kept fluid by the PISTA Grit Fluidizer) to the PISTAs second-stage grit washing and dewatering system while also providing proper head. PISTA Grit Concentrator Specifically engineered for the PISTA system, this abrasion-resistant Ni-Hard unit washes grit further. It positions on the grit discharge line. PISTA Grit Screw Conveyor Grit from the concentrator deposits into the parallel (lamella) plate section of the S&L dewatering screw conveyor, which aids in retaining finer grit and reducing the streams turbulence and overflow rate. Dewatered Grit Discharges from the top of the inclined screw conveyor into a container for disposal. The Flow and any Residual Organics are Returned to the inlet channel prior to the grit chamber, typically 93% of flow and 95% of organics.

[2]

Unparalleled Innovation For 30+ Years

1973 - PISTA Grit Removal System (270) 1974 - PISTA Grit Screw Conveyor 1981 - 50 MGD PISTA Grit Chamber 1982 - PISTA Grit Turbo Grit Pump (4) 1982 - 175 GPM PISTA Grit Concentrator 1984 - 70 MGD PISTA Grit Chamber 1988 - 360 PISTA In-Line Design 1988 - 250 GPM PISTA Grit Concentrator 1989 - Parallel Plate PISTA Grit Screw Conveyor 1992 - PISTA Grit Fluidizer 1992 - 4 PISTA Grit Turbo Grit Pump 1998 - 6 PISTA Grit Turbo Grit Pump 1998 - 500 GPM PISTA Grit Concentrator 1999 - 100 MGD PISTA Grit Chamber 2004 - PISTA Grit Flow Control Baffle 2006 - PISTA Grit Stick Deflector [6] [5] [4] [3]

O n l i n e : s m i t h a n d l o v e l e s s . c o m P h o n e : 9 1 3 . 8 8 8 . 5 2 0 1 FA X : 9 1 3 . 8 8 8 . 2 1 7 3

Smith & Loveless Inc. System Innovators for global p umping, water and wastewater treatment

Vous aimerez peut-être aussi

- Brewing Technology From BriggsDocument14 pagesBrewing Technology From BriggsDuy NguyenPas encore d'évaluation

- Huber - Folleto - Deshidratador - RoS 3QDocument4 pagesHuber - Folleto - Deshidratador - RoS 3Qenzo_kcrs2787109Pas encore d'évaluation

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Drilling Fluids Processing HandbookD'EverandDrilling Fluids Processing HandbookÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Pista Grit Removal SystemDocument2 pagesPista Grit Removal Systemnermeen ahmedPas encore d'évaluation

- VERTI-G Cuttings DryerDocument4 pagesVERTI-G Cuttings DryerLoganBohannon100% (1)

- Milnor 48040F7J SpecificationsDocument4 pagesMilnor 48040F7J Specificationsmairimsp2003Pas encore d'évaluation

- DB DISA FLEX LowresDocument8 pagesDB DISA FLEX LowresdfeltrinpPas encore d'évaluation

- Ts SandMediaFilterDocument2 pagesTs SandMediaFiltermohammudaphPas encore d'évaluation

- Lakeside Wastewater Treatment Capability BrochureDocument16 pagesLakeside Wastewater Treatment Capability BrochurePromagEnviro.comPas encore d'évaluation

- Cosechadora Serie 7000Document20 pagesCosechadora Serie 7000Secreto SecretosPas encore d'évaluation

- Flygt Centrifugal Grinder Pump (893772)Document8 pagesFlygt Centrifugal Grinder Pump (893772)sarajevobih100% (1)

- EZstrip Cake Pump - 0Document8 pagesEZstrip Cake Pump - 0MoynomanPas encore d'évaluation

- Pelletizing Disc: The Haver Screening Group - A Member of The Haver GroupDocument8 pagesPelletizing Disc: The Haver Screening Group - A Member of The Haver GroupRebecca Francis100% (1)

- Pivot Master Floating Roof Drain SystemDocument8 pagesPivot Master Floating Roof Drain Systemnaveenbaskaran1989Pas encore d'évaluation

- Rotary Kilns For Cement PlantsDocument10 pagesRotary Kilns For Cement PlantsMehtab AhmedPas encore d'évaluation

- Alfa Laval As H Belt Press g3Document2 pagesAlfa Laval As H Belt Press g3MAPas encore d'évaluation

- DeepConeThickeners BrochureDocument4 pagesDeepConeThickeners BrochureustavPas encore d'évaluation

- Planta Compacta Camiones AtmosfericosDocument4 pagesPlanta Compacta Camiones AtmosfericosAlbert quilcaPas encore d'évaluation

- Evolution V-Backed Pump Intake Screen BrochureDocument4 pagesEvolution V-Backed Pump Intake Screen BrochureEvolution Oil ToolsPas encore d'évaluation

- Xylem Flygt Slurry Pumps Product BrochureDocument12 pagesXylem Flygt Slurry Pumps Product BrochureFrank Vega OrtegaPas encore d'évaluation

- Demister Pads/ Mist EliminatorsDocument14 pagesDemister Pads/ Mist Eliminatorsaagarwal30Pas encore d'évaluation

- Pannevis Brochure FinalDocument20 pagesPannevis Brochure FinalAnonymous XFK4lezBvPas encore d'évaluation

- Noggerath Combi Anlagen eDocument4 pagesNoggerath Combi Anlagen eAngele IvanovskiPas encore d'évaluation

- Understanding Grit Removal - 2Document4 pagesUnderstanding Grit Removal - 2mariuspiPas encore d'évaluation

- Finepac Sand-Jet Systems: Specialised Internals For Protection Against CloggingDocument2 pagesFinepac Sand-Jet Systems: Specialised Internals For Protection Against CloggingAnonymous bHh1L1Pas encore d'évaluation

- SeriesDocument4 pagesSeriesteguheafPas encore d'évaluation

- Matec Catalog Technical PDFDocument21 pagesMatec Catalog Technical PDFMa. Cristina EspinosaPas encore d'évaluation

- 06c Mudsystems 100513092031 Phpapp01Document18 pages06c Mudsystems 100513092031 Phpapp01FabianBauerPas encore d'évaluation

- Big Pack Baler LeafletDocument40 pagesBig Pack Baler LeafletemmanolanPas encore d'évaluation

- Vortex Grit RemoverDocument4 pagesVortex Grit RemoverIsmael KhalilPas encore d'évaluation

- RHINO Borehole EnlargementDocument8 pagesRHINO Borehole EnlargementLoganBohannonPas encore d'évaluation

- H 05893Document4 pagesH 05893gplese0Pas encore d'évaluation

- Roto Rainer 2011Document8 pagesRoto Rainer 2011sunilbholPas encore d'évaluation

- Section2 Downhole Tool SystemsDocument38 pagesSection2 Downhole Tool SystemsHeru Hardanto SPas encore d'évaluation

- Hayward Pro Series Side Mount BrochureDocument2 pagesHayward Pro Series Side Mount BrochureEng Mostafa ElsayedPas encore d'évaluation

- Sepax SeparatorDocument6 pagesSepax SeparatorMahaveer SinghPas encore d'évaluation

- Jay R Smith Grease InterceptorsDocument6 pagesJay R Smith Grease InterceptorsonspsnonsPas encore d'évaluation

- Plug and Retainer Kit: Setting New Standards For Inflatable PackersDocument2 pagesPlug and Retainer Kit: Setting New Standards For Inflatable Packerseduardo_ricaldiPas encore d'évaluation

- Noggerath Multi Drum HRS eDocument2 pagesNoggerath Multi Drum HRS emainoPas encore d'évaluation

- SPX-Plenty Mixer PDFDocument24 pagesSPX-Plenty Mixer PDFkingathur26681100% (1)

- KREBS gravelMAX Dredge Slurry Pump BrochureDocument8 pagesKREBS gravelMAX Dredge Slurry Pump BrochureTobias De SomerPas encore d'évaluation

- Agri ManualDocument34 pagesAgri ManualLu1sFeRPas encore d'évaluation

- Proseries: The Clear Choice in Sand FiltrationDocument2 pagesProseries: The Clear Choice in Sand FiltrationAndrea Devky KresnaPas encore d'évaluation

- Rieter Roving Frame f19 f39 3265 v21 v21 enDocument2 pagesRieter Roving Frame f19 f39 3265 v21 v21 enSudheer Singh chauhanPas encore d'évaluation

- 2 Mixer FlygtDocument8 pages2 Mixer FlygtHugo Miño Carrasco100% (1)

- Truck-Mounted Concrete Pump With 4-Section Placing BoomDocument6 pagesTruck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuPas encore d'évaluation

- VP - ScrewPress Optimization - 21 - BDI - VP1464 - enDocument28 pagesVP - ScrewPress Optimization - 21 - BDI - VP1464 - enCaio NunesPas encore d'évaluation

- Flygt Jet MixerDocument8 pagesFlygt Jet Mixerfaizfrasat123100% (1)

- Remedial Tools HandbookDocument250 pagesRemedial Tools Handbookjdmacbook100% (5)

- LYNX 40 Drilling Mud DecanterDocument2 pagesLYNX 40 Drilling Mud DecanterPierluigi Ciampiconi0% (1)

- Folleto Filtro Cristal Flo 2 PentairDocument2 pagesFolleto Filtro Cristal Flo 2 PentairJOSE ALBERTO AMAYA SAUCEDOPas encore d'évaluation

- Vortex Grit Chamber - BrochureDocument3 pagesVortex Grit Chamber - BrochureLTE002Pas encore d'évaluation

- Mifab Interceptor PDFDocument8 pagesMifab Interceptor PDFBashir SaadehPas encore d'évaluation

- High-Throughput Dewatering and Cake Washing: SeparationDocument12 pagesHigh-Throughput Dewatering and Cake Washing: SeparationMichel M.Pas encore d'évaluation

- Pivot Master Floating Roof Drain System PDFDocument4 pagesPivot Master Floating Roof Drain System PDFsusansuePas encore d'évaluation

- Completion Tools CatalogDocument118 pagesCompletion Tools CatalogPavaniimc Mc100% (1)

- AutoJet Brochure CurrentDocument4 pagesAutoJet Brochure CurrentmenriquepcPas encore d'évaluation

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- S211-7-2020 Operator's Manual (English) PDFDocument119 pagesS211-7-2020 Operator's Manual (English) PDFDiego Castañeda SantaPas encore d'évaluation

- Cs6212 Programming and Data Structures Laboratory I Laboratory ManualDocument28 pagesCs6212 Programming and Data Structures Laboratory I Laboratory Manualprasath_676303Pas encore d'évaluation

- WISKA Cable Glands and Junction Boxes English PDFDocument216 pagesWISKA Cable Glands and Junction Boxes English PDFtony6868Pas encore d'évaluation

- CrcwikiDocument8 pagesCrcwikiPratik MahajanPas encore d'évaluation

- High Precision Ball Berings GMNDocument72 pagesHigh Precision Ball Berings GMNSilvio Busdraghi AmorosoPas encore d'évaluation

- WPH02 01 Que 20160120Document24 pagesWPH02 01 Que 20160120Omar HashemPas encore d'évaluation

- SR en 10025-04Document8 pagesSR en 10025-04pukla100% (2)

- CPAR Summary - WK 144Document6 pagesCPAR Summary - WK 144NagarajPas encore d'évaluation

- PMAC720Document3 pagesPMAC720felipePas encore d'évaluation

- HART Tech Short FormDocument9 pagesHART Tech Short FormJediael JuniorPas encore d'évaluation

- Materials Science and Engineering.: Session 9 - The Eutectic Phase DiagramsDocument34 pagesMaterials Science and Engineering.: Session 9 - The Eutectic Phase DiagramsfiestapaganaPas encore d'évaluation

- The Centaur Upper Stage Vehicle HistoryDocument12 pagesThe Centaur Upper Stage Vehicle HistoryjuniormirandaPas encore d'évaluation

- Parking BrakeDocument16 pagesParking BrakeDat100% (1)

- Poster Flender Com1 PDFDocument1 pagePoster Flender Com1 PDFvijaykumarnPas encore d'évaluation

- Icom en YcivDocument124 pagesIcom en YcivDavid Lemos SanchezPas encore d'évaluation

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006Pas encore d'évaluation

- How To Solve Turtle Logo QuestionsDocument13 pagesHow To Solve Turtle Logo QuestionsSadman SameerPas encore d'évaluation

- ESDR4Document4 pagesESDR4Eddy Skb0% (1)

- Durability of Clay BricksDocument18 pagesDurability of Clay BricksEmmanuel okelloPas encore d'évaluation

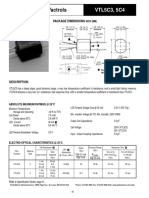

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 pagesLow Cost Axial Vactrols: VTL5C3, 5C4sillyPas encore d'évaluation

- Parts Catalog: MF9280Cdn/9220Cdn/9170/ 9150/9130/8450 SeriesDocument94 pagesParts Catalog: MF9280Cdn/9220Cdn/9170/ 9150/9130/8450 SeriesAdorjan Sandor ZoltanPas encore d'évaluation

- Bulk CollectDocument5 pagesBulk CollectAbhishekPas encore d'évaluation

- Microsoft SQL Server 2005 Express Edition &Document95 pagesMicrosoft SQL Server 2005 Express Edition &lgmep350Pas encore d'évaluation

- ADPDocument165 pagesADPmohhizbarPas encore d'évaluation

- Air Compressor Anatomy 101Document20 pagesAir Compressor Anatomy 101Rahul ChandrawarPas encore d'évaluation

- Application of Neutralization TitrationsDocument21 pagesApplication of Neutralization TitrationsAsuncion Thea50% (2)

- General Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptDocument3 pagesGeneral Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptNatasha de SilvaPas encore d'évaluation

- CV PDFDocument4 pagesCV PDFSIVA0% (1)

- Internal Arc IEC 61641 - EN - V07Document24 pagesInternal Arc IEC 61641 - EN - V07arkupi100% (1)

- AISC Properties ViewerDocument3 pagesAISC Properties ViewerrubenPas encore d'évaluation