Académique Documents

Professionnel Documents

Culture Documents

Chemical Storage Guide

Transféré par

ipliprensDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chemical Storage Guide

Transféré par

ipliprensDroits d'auteur :

Formats disponibles

Safe Storage of Chemicals

Proper storage of chemicals within a laboratory is a difficult and continuing problem. Some experts have stated that the majority of laboratory accidents are related to improper storage of chemicals. The overall purpose is to maintain control over the chemicals so that they can be safely stored and retrieved. Since it is almost inevitable that a bottle will fall and hit other bottles, chemicals should be arranged so that no adverse reaction occurs between the chemicals. Many chemicals have special storage requirements with temperature, time, or security restrictions. Many practical problems arise because of the number of separations that would be desirable. Chemicals should not be stored alphabetically. Acetic acid and acetlehyde could be adjacent members on a shelf and are an incompatible pair. It is also a good idea to separate liquids from solids because chemicals must come into contact to react and this is avoided by having liquids and solids separated. The general approach is to separate all the chemicals into compatible groups. Then separate each group from the other groups by a barrier. While this is a good idea, most facilities do not have the space for such a system. However, the use of secondary containment, such as plastic bins, can maximize the space allowed for chemical storage. In summary, proper storage must address flammables, unstable materials (including those that can form explosive peroxides), reactives and vapors from highly toxic materials. This can be achieved by arranging the materials to provide separation based on their chemical properties. See the various literature resources and the MSDSs for determining the characteristics of a compound. The following groups should be separated: 1. Acids and bases - Acids should be further separated into inorganic acids and organic acids. 2. Oxidizing agents from reducing agents 3. Potentially explosive materials 4. Water reactive materials 5. Pyrophoric chemicals 6. Peroxide forming materials - these must be properly managed and disposed of within recommended time periods 7. Materials which can react with themselves (Polymerization for example) 8. Incompatible chemicals 9. Chemicals showing hazards such as flammability, reproductive toxicity, or suspect and confirmed carcinogens A specific storage arrangement, based on hazard and compatibility, is shown below: 1. General procedures: a) Perchloric acid is separated from all other substances b) Concentrated nitric acid is separated from all other substances c) Highly toxic and carcinogenic chemicals are stored in ventilated safety storage cabinets d) Inorganic and organic acids are stored separately e) Bases are stored separately f) Explosives or potential explosives are separated

g) Inorganic and organic flammables are separated. In addition, organic flammables are further separated into two classes based on compatibility h) Oxidizing and reducing agents are separated i) Other chemicals can generally be grouped together (but compatibility must be considered). 2. The separations, either by distance or physcial barriers, should be enough to prevent the mixing of two incompatibles if a container is dropped and breaks a second container. Ideally the separation would also reduce the amount of materials that could become involved in a fire. Some laboratories have found fiber glass trays useful for limited separation and containment. 3. Extremely toxic (and/or carcinogenic) or dangerous materials should be double containerized and carried back and forth from the storage cabinet to the hood in an unbreakable outer container. 4. Cabinets for flammables and corrosives make ideal storage cabinets. However, depending on the quantity and variety of chemicals, the cost may be high. These cabinets can be conveniently vented to the outside so that toxic vapors do not enter the laboratory. A ventilation rate of approximately 8 -15 cfm is usually adequate. Several cabinet manufacturers make smaller stackable units. Each cabinet should have a spill containment reservoir in the bottom. The Flinn Chemical Catalog Reference Manual suggests organic and inorganic groupings which are further sorted into compatible families. The compatible families suggested are: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Inorganic Metals, hydrides Halides, sulfates, sulfites, thiosulfates, phosphates, halogens Amides, nitrates (except ammonium nitrate), nitrites, azides, nitric acid Hydroxides, oxides, silicates, carbonates, carbon Sulfides, selenides, phosphides, carbides, nitrides Chlorates, perchlorates, perchloric acid, chlorites, hypochlorites, peroxides, hydrogen peroxide Arsenates, cyanides, cyanates Borates, chromates, manganates, permanganates Acids (except nitric) Sulfur, phosphorus, arsenic, phosphorus pentoxide Organic Acids, anhydrides, peracids Alcohols, glycols, amines, amides, imines, imides Hydrocarbons, esters, aldehydes Ethers, ketones, ketenes, halogenated hydrocarbons, ethylene oxide Epoxy compounds, isocyanates Peroxides, hydroperoxides, azides Sulfides, polysulfides, sulfoxides, nitriles Phenols, cresols

Suggested Shelf Storage Patterns* A. Inorganic (*Bottom shelf is #1 & top shelf is #5) 1. Acids, except nitric, should be stored in an acid cabinet, separate from other inorganic chemicals. Store nitric acid away from other acids unless the acid cabinet provides a separate compartment for nitric. 2. Cabinet No. 1 - bottom shelf, No. 1, has hydroxides, oxides, silicates, carbonates and carbon. Shelf No. 2 - metals and hydrides (store away from water); store flammable solids in separate cabinet. Shelf No. 3 - amides, nitrates (not ammonium nitrate), nitrites, azides; store ammonium nitrate away from all other substances (isolate it). Shelf No. 4 - halides, sulfates, sulfites, thiosulfates, phosphates, halogens and acetates. Shelf No. 5 - top shelf, has sulfur, arsenic, phosphorus, and phosphorus pentoxide. 3. Cabinet No. 2 - bottom shelf, No.1 - miscellaneous. Shelf No. 2 - chlorates, perchlorates, chlorites, perchloric acid, peroxides, hypochlorites, and hydrogen peroxide. Shelf No. 3 - borates, chromates, manganates, and permanganates. Shelf No. 4. - sulfides, phosphides, carbides, and nitrides. Shelf No. 5 - top shelf - has arsenates, cyanides, and cyanates - store away from water). Organic (*Bottom shelf is #1 & top shelf is #5) Store severe poisons in poisons cabinet. Store flammables in a dedicated cabinet: bottom shelf No. 1 - ethers and ketones; shelf No. 2 - hydrocarbons, esters, etc.; top shelf - has alcohols and glycols.

B.

1. Cabinet No. 1 - bottom shelf - No. 1 - sulfides and polysulfides. Shelf No. 2 has epoxy compounds and isocyanates. Shelf No. 3 - ethers, ketones, ketenes, halogenated hydrocarbons, and ethylene oxide (store flammables in a dedicated cabinet). Shelf No. 4 - hydrocarbons, esters, aldehydes (store flammables in a dedicated cabinet). Top shelf - No. 5 - has alcohols, glycols, amines, amides, and imines (store flammables in a dedicated cabinet). 2. Cabinet No. 2 - bottom shelf - No. 1, and shelf 2 - miscellaneous. Shelf No. 3 - acids, anhydrides, and peracids (store certain organic acids in acid cabinet). Shelf No. 4 - has peroxides, azides, and hydroperoxides). Top shelf - no. 5 - phenol and cresols. Avoid using the floor for storage if possible. Hazards Due to Chemical Reactions (Incompatibles) Generation of Heat - e.g. acid and water Fire - e.g. hydrogen sulfide and calcium hypochlorite Explosion - e.g. picric acid and sodium hydroxide Toxic gas or vapor production - e.g. sulfuric acid and plastic Flammable gas or vapor production - e.g. acid and metal Formation of a substance with greater toxicity than reactants - e.g. chlorine and ammonia Formation of shock or friction-sensitive compounds Pressurization of closed vessels - fire extinguisher Solubilization of toxic substances - e.g. hydrochloric acid and chromium Dispersal of toxic dusts and mists Violent polymerization - e.g. ammonia and acrylonitrile

Flammables Many organics are flammable and should be treated accordingly. When flammable materials are used, care should be taken to avoid a flammable or explosive mixture with air. A general rule is that controls should be in place (or quantities limited) so that the concentration of a flammable will not exceed 25% of the lower explosive limit (please refer to NFPA 45, Fire Protection for Laboratories Using Chemicals, for the quantities of flammables allowed in the laboratory and storage requirements). A list of selected flammable limits is shown below. If it is necessary to have the concentration of a flammable in the explosive range, all sources of ignition must be excluded. Explosive Limits of Hazardous Materials Compound Acetone Acetylene Ammonia, anhydrous Benzene Carbon Monoxide Gasoline Cyclohexane Toluene Vinyl chloride p-xylene LEL% 2.15 2.50 16 1.30 12.4 1.4 1.3 1.2 3.6 1.0 UEL% 13 100 25 7.1 74 7.6 8.4 7.1 33 6.0 Flashpoint (oF) -4 Gas Gas 12 Gas -45 -4 40 Gas 90 Vapor Density 2.0 0.9 0.6 7.8 1.0 3-4 3.0 3.1 2.2 3.7

Selection and Use of Refrigerators A. Ordinary Refrigerators Not designed for chemical storage. Hot surfaces (light bulb), possibly sparking switches, heating tapes, drains used for the water to run out, and potential ignition sources from the motor. 1. Not for storage of flammable materials 2. Motor produces sparks outside storage area 3. Not for use in hazarous environment B. Refrigerators for Flammable Materials Designed for storing flammables. magnetic door seals (to avoid pressure buildup). No sparks or hot surfaces inside. The motor and motor controls may generate sparks. 1. For use in ordinary laboratory 2. No sparks or hot surfaces, but motor produces sparks outside storage area 3. Not for use in hazardous environments C. Explosion-Proof Refrigerators This provides a safe spark free interior and can be used in a hazardous envirnment (Class I, Division I & II Group C and D applications). 1. For storage of flammables 2. Uses magnetic door latches and produces no sparks, has no hot surfaces 3. For use in hazardous environments

Control of Vapors Within a Refrigerator In spite of the lower temperatures, the odors tend to accumulate in a refrigerator of freezer and are then released into the laboratory and become another source of exposure. It is possible to ventilate a refrigerator by installing a slot hood along the edges of the door. The door is opened only a couple of inches and held there a few minutes. The slot ventilation causes the air to sweep through the refrigerator and out the ventilation system. This system has some disadvantages: Moisture condenses on the cold surfaces of the contents of the refrigerator There is always that annoying 5 minute wait

Another method which is very satisfactory for reducing the vapors of pesticides and many solvents is to place a tray of activated charcoal in the refrigerator. The charcoal should be handled in the hood because of the dust but it effectively controls many vapors. Vented Fire Cabinets Fire safety cabinets are required by regulation to be vented in many localities. The ventilation rate specified in the manual is 5-20 CFM provided by a roof mounted motor. The inlet should have a spark arrestor. However the NFTA has not taken a position on the venting of the fire safety cabinets. The cabinets were designed to protect the contents of the cabinet from fire and were not designed as storage cabinets. The concern is whether forced venting affects the fire rating.

A Second Suggested Shelf Pattern for Chemical Storage I have used the following chart to label shelves in my stockroons. The system is pretty straightforward, and after everyone gets used to it I find it works very well. Within each category, chemicals ARE stored alphabetically (and this tends to please the old-timers). But the categories are arranged by compatibility and reactivity. What I have always done is create a pretty chart (I no longer have the original from Flinn) and then make multiple copies. I post a few in convenient locations around the stockroom so that folks can refer to it to find things. I also cut out the labels and place the appropriate one on each shelf so that folks can find the correct category easily. It has worked well for me. I hope you find the same true for you. Todd Woerner woerner@acpub.duke.edu The following shelf pattern segregates chemicals first into organic and inorganic. Chemical organization then follows compatibility groupings within the major organic/inorganic headings. Finally, those chemicals appearing at the top of the chart are less reactive and therefore can be stored higher off the ground, while those nearest the bottom of the chart are more reactive and should be stored closer to the floor to reduce the chance of breakage if dropped from the shelf. Organic #2: Alcohols, Glycols Inorganic #10: Sulfur, Phosphorus, Arsenic, Phosphorus pentoxide Organic #3: Hydrocarbons, Esters Inorganic #2: Halides, Sulfates, Sulfites, Thiosulfates, Phosphates Organic #4: Ethers, Ketones Inorganic #3: Amides, Nitrates, Nitrites Organic #5: Epoxy compounds, Isocyanates Inorganic #1: Metals and Hydrides (No Water!) Organic #7: Sulfides, Polysulfides Inorganic #4: Hydroxides, Oxides, Silicates Organic #8: Phenol, Cresols Inorganic #7: Arsenates, Cyanide (above acids) Organic #6: Peroxides, Azides Inorganic #5: Sulfides, Selenides, Phosphides, Carbides, Nitrides Organic #1: Acids, Anhydrides, Peracids Inorganic #8: Borates, Chromates, Manganates, Permanganates 2nd shelf: Miscellaneous Inorganic #6: Chlorates, Perchlorates, Chlorites, Perchloric acid, Peroxides Bottom shelf: Miscellaneous (Nitric Acid) Inorganic #9: Acids (not nitric)

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Bitumen Safety CodeDocument69 pagesBitumen Safety CodeVictor Eugen100% (2)

- Material Balances Design Project Production of Phthalic Anhydride From O-XyleneDocument40 pagesMaterial Balances Design Project Production of Phthalic Anhydride From O-XylenemoheedPas encore d'évaluation

- Databook Ch2-Ammonia PDFDocument32 pagesDatabook Ch2-Ammonia PDFjmjaravPas encore d'évaluation

- Esl TR 93 04 07Document16 pagesEsl TR 93 04 07ipliprensPas encore d'évaluation

- Subcontractor Safety Work BookDocument7 pagesSubcontractor Safety Work BookipliprensPas encore d'évaluation

- Alcohol&AlarmsreportDocument73 pagesAlcohol&AlarmsreportipliprensPas encore d'évaluation

- Contractor Safety Man May2011Document161 pagesContractor Safety Man May2011ipliprensPas encore d'évaluation

- Special Safety Practices For CSL2Document1 pageSpecial Safety Practices For CSL2ipliprensPas encore d'évaluation

- Implementing and Effective Safety ProgramDocument79 pagesImplementing and Effective Safety ProgramipliprensPas encore d'évaluation

- Wooliams PresentationDocument46 pagesWooliams PresentationipliprensPas encore d'évaluation

- Control Banding B NaumannDocument11 pagesControl Banding B NaumannipliprensPas encore d'évaluation

- Guidance Sheet 1 - Chemical StorageDocument6 pagesGuidance Sheet 1 - Chemical StorageipliprensPas encore d'évaluation

- Occupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationDocument26 pagesOccupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationipliprensPas encore d'évaluation

- Chemical Hygiene Plan 2Document43 pagesChemical Hygiene Plan 2ipliprensPas encore d'évaluation

- BP Modeling 508Document12 pagesBP Modeling 508ipliprensPas encore d'évaluation

- Chemical Laboratory UnitDocument13 pagesChemical Laboratory Unitipliprens0% (1)

- Fume Hood - VentilationDocument24 pagesFume Hood - VentilationAaron AngPas encore d'évaluation

- Laboratory Handbook WorkSafeBCDocument88 pagesLaboratory Handbook WorkSafeBCkanakarao1Pas encore d'évaluation

- Lab HoodDocument26 pagesLab Hoodipliprens100% (1)

- M602 SyllabusDocument4 pagesM602 SyllabusipliprensPas encore d'évaluation

- AIHce Pharma Forum Quality Risk-MaPP Implications - EditedDocument28 pagesAIHce Pharma Forum Quality Risk-MaPP Implications - EditedipliprensPas encore d'évaluation

- Chemical Laboratory UnitDocument13 pagesChemical Laboratory Unitipliprens0% (1)

- Z9.5 - 2003 Laboratory Ventilation: - Format - 2 Columns - Shall vs. Should - Explanatory LettersDocument16 pagesZ9.5 - 2003 Laboratory Ventilation: - Format - 2 Columns - Shall vs. Should - Explanatory LettersipliprensPas encore d'évaluation

- Safety Standards For Electronic ProductsDocument9 pagesSafety Standards For Electronic ProductsBurhan AhmadPas encore d'évaluation

- FinalLabDesign4 09Document20 pagesFinalLabDesign4 09ipliprens100% (1)

- Electrical Safety Testing Reference GuideDocument58 pagesElectrical Safety Testing Reference GuideNora FizaPas encore d'évaluation

- Chemical Hygiene Plan 2Document43 pagesChemical Hygiene Plan 2ipliprensPas encore d'évaluation

- Lab Safety ManagementDocument35 pagesLab Safety ManagementipliprensPas encore d'évaluation

- Developing Process Safety Indicators A Step-By-step Guide For Chemical And, 2010-03-19Document59 pagesDeveloping Process Safety Indicators A Step-By-step Guide For Chemical And, 2010-03-19jeremyg998Pas encore d'évaluation

- RespiratorDocument25 pagesRespiratoripliprensPas encore d'évaluation

- Emergency Lighting Design GuideDocument5 pagesEmergency Lighting Design GuideipliprensPas encore d'évaluation

- Lab HoodDocument26 pagesLab Hoodipliprens100% (1)

- Hazardous Area ClassificationDocument4 pagesHazardous Area ClassificationmkkamarajPas encore d'évaluation

- Divinylbenzene Storage, Handling and SafetyDocument19 pagesDivinylbenzene Storage, Handling and SafetyMehul DeshpandePas encore d'évaluation

- ATEX Hazardous Location GuideDocument59 pagesATEX Hazardous Location GuidedinoPas encore d'évaluation

- Section 1 Product Identification: Material Safety Data SheetDocument3 pagesSection 1 Product Identification: Material Safety Data SheetPutri MasyitahPas encore d'évaluation

- T 1566Document5 pagesT 1566Erwin Mauricio Alarcon PradenasPas encore d'évaluation

- Authorised Gas Tester PDFDocument32 pagesAuthorised Gas Tester PDFTrainer 1 TVSPas encore d'évaluation

- 1to10Document83 pages1to10jamjam75Pas encore d'évaluation

- Phenoline 1205: Selection & Specification DataDocument4 pagesPhenoline 1205: Selection & Specification DataRicardo CarvalhoPas encore d'évaluation

- Pressure Relief, Flares, Flame Arrestors PDFDocument15 pagesPressure Relief, Flares, Flame Arrestors PDFRenanPas encore d'évaluation

- ADI-146 Rhodimet at 88 (en-CA)Document9 pagesADI-146 Rhodimet at 88 (en-CA)Give UpPas encore d'évaluation

- Safety Data Sheet: Chemical Name Cas # Percent Classification NoteDocument7 pagesSafety Data Sheet: Chemical Name Cas # Percent Classification NotesharathPas encore d'évaluation

- Jet Fuel ProductionDocument101 pagesJet Fuel Productionshezistic pRoPas encore d'évaluation

- Plantaren 2000 MSDSDocument6 pagesPlantaren 2000 MSDSHusley MoralesPas encore d'évaluation

- Safety Data Sheet: ARDROX 800/3 AerosolDocument9 pagesSafety Data Sheet: ARDROX 800/3 AerosolantonioPas encore d'évaluation

- ArsonDocument59 pagesArsonKaizen McrayPas encore d'évaluation

- Chapter 06Document5 pagesChapter 06김순혁Pas encore d'évaluation

- SH 5107 Dilution Ventilation 2021 - LumiNUS (Update Slide 75)Document103 pagesSH 5107 Dilution Ventilation 2021 - LumiNUS (Update Slide 75)Shuyuan LuPas encore d'évaluation

- Crowl - Understanding ExplosionsDocument6 pagesCrowl - Understanding ExplosionsJosé De Jesús Ibarra SánchezPas encore d'évaluation

- Chico A Sealing Compound/Chico A3/ Chico A4/ Chico A05/Chico A200/ Chico A19Px/Chico A39PxDocument10 pagesChico A Sealing Compound/Chico A3/ Chico A4/ Chico A05/Chico A200/ Chico A19Px/Chico A39PxSupervisor HSEQ RotativosPas encore d'évaluation

- Code of Practice For Minimum Fire Service Installation and Equipment and Inspection, Testing and Maintenance of Installations and Equipment 2012 PDFDocument187 pagesCode of Practice For Minimum Fire Service Installation and Equipment and Inspection, Testing and Maintenance of Installations and Equipment 2012 PDFmisslady100% (1)

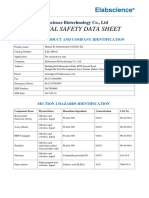

- E EL H0102 Elabscience MSDSDocument10 pagesE EL H0102 Elabscience MSDSTaufiq GemawanPas encore d'évaluation

- MSDS For GasolineDocument8 pagesMSDS For GasolineSandra Acevedo ValdiviaPas encore d'évaluation

- Tanker Familiarization CourseDocument135 pagesTanker Familiarization CoursePavlin Koev100% (2)

- Microsoft Word - SDS R290Document7 pagesMicrosoft Word - SDS R290AchmadAscarPas encore d'évaluation

- Manual X Stream 11th Ed Rosemount en 71924Document436 pagesManual X Stream 11th Ed Rosemount en 71924Duverli Andree Culquicondor RuizPas encore d'évaluation

- Technomelt Supra Ts-100 MsdsDocument5 pagesTechnomelt Supra Ts-100 Msdsariel delgadoPas encore d'évaluation

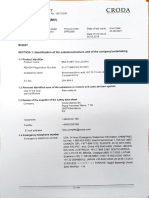

- Multiwet SO-LQ. CRODA. MSDSDocument14 pagesMultiwet SO-LQ. CRODA. MSDSsumeshPas encore d'évaluation