Académique Documents

Professionnel Documents

Culture Documents

Chapter 2

Transféré par

Girma FikreDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Chapter 2

Transféré par

Girma FikreDroits d'auteur :

Formats disponibles

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

1

Chapter Two: Limit State Design

1.1 Introduction

The objective of limit state design is to achieve acceptable probabilities that the structure

being designed will not become unfit for its intended purpose during its expected life. When a

structure or structural element becomes unfit for its intended use, it is said to have reached a

limit state. The limit states for reinforced concrete structures can be divided into three basic

groups:

1. Ultimate limit states

2. Serviceability limit states

3. Special limit states

Ultimate limit States

These involve a structural collapse of part or all of the structure. Such a limit state should have

a very low probability of occurrence since it may lead to loss of life and major financial losses.

The major ultimate limit states are:

a) Loss of equilibrium of a part or all of the structure when considered as a rigid body.

Such a failure would generally involve tipping or sliding of the entire structure and would

occur if the reactions necessary for equilibrium could not be developed.

b) Rupture of critical parts of the structure, leading to partial or complete collapse. It

includes flexural failures, shear failures, direct compression or tension failures and so

on. The majority of this course deals with this limit state.

c) Progressive collapse: In some cases a minor localized failure may cause adjacent

members to be overloaded and fail, until the entire structure has collapsed. Since such

failures frequently occur during construction, the designer should be aware of

construction loads and procedures.

d) Formotion of plastic mechanism: A mechanism is formed when the reinforcement yields

to form plastic hinges at enough sections to make the structure unstable.

e) Instability due to deformations of the structure: This type of failure involves buckling

due to gravity load effects.

f) Fatigue: Fracture of members due to repeated stress cycles may cause collapse of part

or all of a structure. Although, fatigue failure results from repeated application of

service loads, this has been listed as an ultimate limit state as it leads to a structural

collapse.

Serviceability limit states

These involve disruption of the functional use of the structures but not collapse. Since there is

less danger of loss of life, a higher probability of occurrence can generally be tolerated than in

the case of an ultimate limit states. The major serviceability limit states include:

a) Excessive deflections for normal service: Excessive deflections may cause machinery

to malfunction, may be visually unacceptable, and may lead to damage to nonstructural

elements or to changes in the distribution of forces. A minimum depth is recommended

for the control of deflection.

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

2

b) Excessive crack width: Although reinforced concrete must crack before the

reinforcement can act, it is possible to detail the reinforcement to minimize the crack

widths. Excessive crack widths lead to leakage through the cracks, corrosion of the

reinforcement, and gradual deterioration of the concrete. In addition, wide cracks may

be unsightly. Special detailing is required in structures that must be watertight.

c) Undesirable vibrations: Vertical vibrations of floors or bridges and lateral and torsional

vibrations of tall buildings may disturb the user.

Special limit states

a) Damages or collapses in extreme earthquakes

b) Structural effects of fire, explosions, or vehicular collisions

c) Structural effects of corrosion or deterioration, particularly when exposed to deicing

compounds.

Limit State design Procedure

During design it is necessary to identify whether the ULS or SLS is the conical limit state for a

particular structure and base the design on this. Checks are then made to ensure that all other

relevant limit states are satisfied by the results produced.

Generally, in the design of reinforced concrete members (except in special cases such as water

retaining structures), it is usual to first ensure that the ULS is not exceeded (by applying factor

of safeties) and then to check that the relevant SLSs are satisfied.

General Design Equation

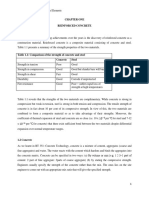

Consider the RC simply supported beam shown below. The applied loads cause bending moments,

which are directly obtained from the loads using the law of statics. The bending moments, shear

force, axial force, torsion, deflection, etc. are referred to as load effects.

w

Design actions

Design action effects

(B.M.D)

Fig. 2.1 Action and action effects

Fig. 2.2 shows flexural stresses acting on a beam cross-section and the internal couple resulted

from their resultants. The compressive and tensile stresses can be replaced by their resultants,

C and T, as shown below. The resulting couple is said to be an internal resisting moment. The

internal resisting moments when the cross section fails is referred to as the moment capacity or

moment resistance. The word resistance can also be used to describe shear resistance or axial

load resistance. The beam shown in Fig. will safely support the loads if at every section the

resistance of the member exceeds the effects of the loads.

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

3

Stresses

C

T

Internal couple

Fig. 2.2 Internal resisting moment

Accordingly, the structure or structural elements shall be verified by the following equations.

Verifications of Static Equilibrium and Strength, Ultimate Limit State

1) When considering a limit state of static equilibrium or of gross displacement of the

structure as a rigid body, it shall be verified that:

E

d,dst

s E

d,stb

where E

d,dst

is the design value of the effect of destabilizing actions;

E

d,stb

is the design value of the effect of stabilizing actions.

2) When considering a limit state of rupture or excessive deformation of a section, member

or connection it shall be verified that:

E

d

s R

d

Where E

d

is the design value of the effect of actions such as internal force, moment or

a vector representing several internal forces or moments;

R

d

is the corresponding design resistance, associating all structural properties

with the respective design values.

Verification of Serviceability, Serviceability Limit States

It shall be verified that:

E

d

s C

d

Where C

d

is a nominal value or a function of certain design properties of materials related to

the design effects of actions considered; and

Ed is the design value of the action effect (e.g. displacement, acceleration), determined

on the basis of one of the combinations defined for serviceability.

Characteristic Strengths and Loads

The characteristic strength of a material may be defined as the strength that is normally

expected to be exceeded and may be defined statistically as (based on the assumption that, for a

given material the distribution of strengths follows normal distribution curve):

f

k

=f

m

- k

1

o

Where: f

k

= characteristic strength (expected to be exceeded)

f

m

= mean strength

o = standard deviation,

(

(

|

.

|

\

|

=

=

n

i

i

n x x

1

2

/ o

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

4

- k

1

= a factor which ensures that the probability of the characteristic strength is not

being exceeded is small (K1 = 1 is to ensure that not more than 5% (1 in 20) of the

test results will give a strength less than the characteristic value) (see Fig.).

The characteristic load may be defined as the load which is not likely to be exceeded during

the useful life of the structure and can be expressed as:

F

k

= F

m

+ k

2

o

Where: F

k

= characteristic load (not likely to be exceeded)

F

m

= mean Load

o = standard deviation,

K

2

= a factor which ensures that the probability of the characteristic load being

exceeded is small (may be k

1

= 1.64) (see Fig. 2.3).

1.64o

1.64o

F

r

e

q

u

e

n

c

y

Effect of Load

Strength of Materials

F

m

F

k

f

k

f

m

Fig. 2.3 Determination of characteristic Parameters

For the case so far, material specifications and safety provisions are listed in the respective

national building codes. For instance consider the following in accordance with Ethiopian

Standards.

Characteristic Strengths of Materials, EBSC 2

Grades of concrete:

Concrete of a given strength is identified by its grade. Concrete is on tests of 150mm cubes at

the edge of 28 days in terms of its characteristic compressive strength (the strength below

which 5% of all possible strength measurements may be expected to fall) and this depends on

the classification of the concrete works and its intended use (see Table 2.1).

Table 2.1 Grades of concrete

Class Permissible grades of concrete

I C5 C15 C20 C25 C30 C40 C50 C60

II C5 C15 C20

Grade C5 shall be used as lean concrete

The numbers in the grade designation denote the specified characteristic compressive strength

in MPa (N/mm

2

).

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

5

Cylindrical or cubical specimens of other sizes may also be used with conversion factors

determined from a comprehensive series of tests. In the absence of such tests, the conversion

factors given in Table may be applied to obtain the equivalent characteristic strength on the

basis of 150 mm cubes.

The characteristic cylinder compressive strength f

ck

are also given for the different grades of

concrete (see Table 2.3).

Table 2.2 Conversion factors for strength

Size and Type of Test Specimen Conversion Factor

Cube (200mm) 1.05

Cylinder(150mm diameter 300mm

height)

1.25

Table 2.3 Grades of concrete and characteristic cylinder compressive strength f

ck

Grades of concrete

C15 C20 C25 C30 C40 C50 C60

f

ck

12 16 20 24 32 40 48

The characteristic tensile strength of concrete may be determined from the characteristic

cylinder compressive strength by:

f

ctk

= 0.21f

ck

2/3

The characteristic strength f

yk

of steel is defined as the 5% fractile of the proof stress f

y

or

o.2 % offset strength, denoted as f

0.2

.

Characteristic Values of Actions, EBSC 1

The characteristic value of an action is its main representative value. Characteristic value of

actions F

K

shall be specified: as a mean value, an upper or lower value, or a nominal value (when

statistical distribution is not known).

The characteristic value of a permanent action shall be determined as follows:

a) if the variability of G is small, one single value GK may be used

b) if the variability of G is not small, two values have to be used; an upper value G

K,sup

and a

lower value G

K,inf

In most cases the variability of G can be assumed to be small if G does not vary significantly

during the design working life of the structure and its coefficient of variation is not greater

than 0.1. However in such cases when the structure is very sensitive to variations in G (e.g. some

types of prestressed concrete structures), two values have to be used even if the coefficient of

variation is small.

The following may be assumed in most cases:

a) Gk is the mean value

b) G

kinf

is the 0.5 fractile, and G

ksup

is the 0.95 fractile of the statistical; distribution for G

which may be assumed to be Gaussian.

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

6

The self-weight of the structure can, in most cases, be represented by a single characteristic

value and be calculated on the basis of the nominal dimensions and mean unit masses

For variable actions the characteristic value (Q

k

) corresponds to either:

a) an upper value with an intended probability of not being exceeded or a lower value with

an intended probability of not falling below, during some reference period;

b) a nominal value which may be specified in cases where a statistical distribution is not

known.

For accidental actions the representative value is generally a characteristic value A

k

corresponding to a specified value.

Values of A

Ed

for seismic actions are given in EBCS 8.

Other Representative Values of Variable and Accidental Actions

The most common cases the other representative values of a variable action are:

a) The combination value generally represented as a product:

o

Q

k

. Combination values are

associated with the use of combinations of actions, to take account of a reduced probability

of simultaneous occurrence of the most unfavourable values of several independent actions.

b) The frequent value generally represented as a product:

1

Q

k

. The frequent value is

determined such that the frequency with which it is exceeded is limited to a given value.

Unless other values are specified the part may be chosen to be 0.05 or the frequency to be

300 per year for ordinary buildings.

c) The quasi-permanent value generally represented as a product:

2

Q

k

. The quasi-permanent

value is so determined that the total time, within a chosen period of time, during which it is

exceeded is a considerable part of the chosen period of time. The quasi-permanent value

may also be determined as the value averaged over the chosen period of time.

These representative values and the characteristic value are used to define the design values of

the actions and the combinations of actions. The combination values are used for the verification

of ultimate limit states and irreversible serviceability limit states. The frequent values and

quasi-permanent values are used for the verification of ultimate limit states involving accidental

actions and for the verification of reversible serviceability limit states. The quasi-permanent

values are also used for the calculation of long term effects of serviceability limit states.

Partial Safety Factors

To safe guard the structure against unforeseen effects LSD make use of partial safety factors

for all the uncertainties and variables originating from different causes.

Partial Safety Factors for Materials (

m

)

The value of partial safety factor for material strength should account for the following

parameter:

- Possibility of deviation of the strength of material

- Deviation of the sectional dimensions

- Accuracy of the calculation procedure

- Risk to life and economic consequences

There fore, in LSD the basic or characteristics strength of a material is modified by a partial

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

7

safety factor to give the design strength.

Hence the design strength of a material is given by:

f

d

= f

k

/

m

where f

k

= characteristic strength of materials, (f

ck

for concrete, f

yk

for reinforcing steel)

f

d

= design strength for ULS (f

cd

or f

yd

)

Accordingly, the design strengths as per EBCS 2 are as follows:

Concrete in compression: f

cd

= (0.85f

ck

)

/

c

Concrete in tension: f

ctd

=f

ctk

/

c

Steel (in tension and compression):f

yd

= f

yk

/

s

Where

c

and

s

are partial safety factors of concrete and steel respectively and are given below

(EBCS 2).

Table 2.4 Partial safety factors for materials

Design situation

Class I works Class II works

Concrete,

c

Reinforcing steel,

s

Concrete,

c

Reinforcing steel,

s

Persistent and Transient

1.50 1.15 1.65 1.20

Accidental 1.30 1.00 1.45 1.10

The value of

m

in serviceability limit states may be taken as 1.0 for both steel and concrete.

Note: Persistent situation corresponding to normal conditions of use of structure

Transient situations, such as those, for example during construction or repair

Accidental situations, which refer to exceptional conditions applicable to the structure

or to its exposure, e.g. to fire, explosion, impact

Partial Safety Factors for Loads (

f

)

In practice the applied loads may be greater than the characteristic load for any of the

following reasons:

- In accurate assessment of the effect of loading (calculation errors).

- Constructional inaccuracies (member sizes and building dimensions)

- Adverse modification of load effect in design assumption

- Change of load due to level of usage

- Unforeseen stress redistribution

To allow for these, the respective characteristic loads are multiplied by a partial safety factors

to give the ultimate design load appropriate to the limit being considered.

The design load is given by:

F

d

=

f

F

k

Where

f

is the partial safety factors for the action considered

F

k

is the characteristic load

The ultimate design load acting on a member will be the summation of the relevant characteristic

load combination multiplied by their respective partial safety factors.

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

8

Combination of Actions, ULS

For each critical load case, the design values of the effects of actions (Ed) should be

determined by combining the values of actions which occur simultaneously, as follows:

(a) Persistent and transient situations: Design value of the permanent actions together with

the design values of the dominant variable actions and the combination design values of

other actions. Symbolically, it may be represented as follows:

{ }

>

+ + =

1 i

, , i Q, 1 , Q,1 , j G, d

S S

i k i o k j k

Q Q G

(b) Accidental situations: Design values of permanent actions together with the frequent

value of the dominant variable action and the quasi-permanent values of other variable

actions and the design value of one accidental action. Symbolically, it may be represented

as follows:

{ }

>

+ + + =

1 i

, , 2 1 , ,1 1 d , j GA, d

A S S

i k i k j k

Q Q G

(c) Seismic situations: Characteristic values of the permanent actions together with the

quasi-permanent values of the variable actions and the design value of the seismic

actions. Symbolically, it may be represented as follows:

{ }

>

+ + =

1 i

, , 2 Ed , j GA, d

A S S

i k i j k

Q G

Where: G

k, j

= is the characteristic value of permanent action

Q

k, 1

is the characteristic value of the variable action

Q

k, i

is the characteristic value of the other variable actions

A

d

is the design value (specified value) of the accidental action

A

Ed

is the design value of the seismic action

G, j

is the partial safety factors for permanent action j

GA, j

is as

G, j

, but for accidental design situations

Q, i

= is the partial safety factor for variable action i

0

,

1

,

2

are combination coefficients (see Table)

Combination for static equilibrium may be taken as:

Sd = S(0.9G

1

1.1 G

2

1.6 Q

1

)

Where: G1 is the permanent stabilizing action

G2 is the permanent non-stabilizing action

Q1 is the variable non-stabilizing action

- When the dominant action is not obvious, each variable action should be considered in

turn as the dominant action.

- In the relevant load cases, those permanent actions that increase the effect of the

variable actions (i.e. produce unfavourable effects) shall be represented by their

upper design values, those that decrease the effect of the variable actions (i.e.

produce favourable effects) by their lower design values (see EBCS 1).

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

9

- Where the result of verification may be very sensitive to variations of the magnitude

of a permanent action from place to place in the structure, the unfavourable and the

favourable parts of this action shall be considered as individual actions. This applies

in particular to the verification of static equilibrium.

- Combinations for accidental design situations either involve an explicit accidental

action A (e.g. fire or impact) or refer to a situation after an accidental event (A = 0).

Unless specified otherwise,

GA

= 1 may be used.

- For building structures, the partial safety factors for ultimate limit states in the

persistent, transient and accidental design situations are given in the following Table.

Table 2.5 Partial safety factors: Ultimate Limit States for Buildings

Case Action

Symb

ol

Design

Situation

P/T A

Case A

Loss of Static equilibrium

Permanent actions: self weight of structural and

non-structural components, permanent actions

caused by ground, ground water and free water

- unfavourable

- favorable

Variable actions

- unfavourable

Accidental actions

Gsup

Ginf

Q

A

1.10

0.90

1.60

1.00

1.00

1.00

1.00

Case B

Failure of structure or

structural elements, including

those of the footing, piles,

basement walls etc., governed by

strength of structural materials

Permanent actions (see above)

- unfavourable

- favorable

Variable actions

- unfavourable

Accidental actions

Gsup

Ginf

Q

A

1.30

1.00

1.60

1.00

1.00

1.00

1.00

Case C

Failure in the ground

Permanent actions (see above)

- unfavourable

- favorable

Variable actions

- unfavourable

Accidental actions

Gsup

Ginf

Q

A

1.00

1.00

1.30

1.00

1.00

1.00

1.00

P: persistent situation T: Transient situation A: Accidental situation

1) The design should be verified for each A, B and C separately as relevant.

2) In this verification the characteristic value of the unfavourable part of the permanent action is multiplied by

the factor 1.1 and the favorable part by the factor 0.9. More refined rules are given in EBCS 3 and EBCS 4.

3) In this verification the characteristic values of all permanent actions from one source are multiplied by 1.3 if

the total resulting action effect is unfavourable and by 1.0 if the total resulting action effect is favourable.

4) In cases when the limit state is very sensitive to variation of permanent actions, the upper and lower

characteristic values of these actions should be taken.

5) For cases B and C the design ground properties may be different, see EBCS 7.

6) Instead of using G (1.30) and Q = (1.60) for lateral earth pressure actions the design ground properties may be

introduced in accordance with EBCS 7 and a model factor sd is applied.

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

10

Table 2.6 factors for buildings

The simplified load combination for building structures for the persistent and transient

situations can be taken as follows:

a) Design situations with only one variable action Q

kl

>

+

1

kl

1.6Q

j

kj Gj

G

b) Design situations with two or more variable actions Q

k,i

> >

+

1 1 i

ki

Q 1.35

j

kj Gj

G

Combination of Actions, SLS

The combination of actions to be considered for serviceability limit states depends on the

nature of the effect of actions being checked, e.g. irreversible, reversible or long term. Three

combinations of actions for serviceability limit states are defined symbolically by the following

expressions:

a) Characteristic (rare) combination

{ }

>

+ + =

1 i

, , 1 , , d

S S

i k i o k j k

Q Q G

b) Frequent combination

{ }

>

+ + =

1 i

, , 2 1 , ,1 1 , d

S S

i k i k j k

Q Q G

c) Quasi-permanent combination

{ }

>

+ =

1 i

, , 2 , d

S S

i k i j k

Q G

Chapter Two: Limit State Design

Reinforced Concrete I Yibeltal Temesgen

11

Note: - For serviceability limit state, the partial factors (serviceability)

G

and

Q

are taken as

1.0 except where specified otherwise.

- The notation is as given in the previous section.

For building structures the characteristic (rare) combination may be simplified to the following

expressions, which may also be used as a substitute for the frequent combination.

c) Design situations with only one variable action Q

kl

>

+

1

kl

Q

j

kj

G

d) Design situations with two or more variable actions, Q

ki

> >

+

1 1 i

ki

Q 0.9

j

kj

G

Where simplified prescriptive rules are given for serviceability limit states, detailed calculations

using combinations of actions are not required.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Lecture StaticsDocument213 pagesLecture StaticsGirma FikrePas encore d'évaluation

- Chapter 2Document20 pagesChapter 2Girma FikrePas encore d'évaluation

- 05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesDocument14 pages05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesGirma FikrePas encore d'évaluation

- Surveying by Dr. RamachandraDocument338 pagesSurveying by Dr. Ramachandravrsec-rao84% (19)

- Chapter7 Rock Mechanics InteractionsDocument7 pagesChapter7 Rock Mechanics InteractionsGirma FikrePas encore d'évaluation

- Chapter One Stress and Strain: 1.1. Mechanical Properties of MaterialsDocument12 pagesChapter One Stress and Strain: 1.1. Mechanical Properties of MaterialsGirma FikrePas encore d'évaluation

- Chapter 7Document11 pagesChapter 7Girma FikrePas encore d'évaluation

- Assignment-1 On Sheet Pile Walls & Braced Cuts: (Submission Date: 27-03-2011)Document1 pageAssignment-1 On Sheet Pile Walls & Braced Cuts: (Submission Date: 27-03-2011)Girma FikrePas encore d'évaluation

- Chapter 3Document35 pagesChapter 3Girma Fikre100% (1)

- Intro GeoDocument48 pagesIntro GeoGirma FikrePas encore d'évaluation

- Assignment-2 On Pile Foundations: SubmissionDocument1 pageAssignment-2 On Pile Foundations: SubmissionGirma FikrePas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Earthquak e Hazards: Prepared by Mariel Manansala / GAS2Document11 pagesEarthquak e Hazards: Prepared by Mariel Manansala / GAS2Ronelyn EsmeraldaPas encore d'évaluation

- International Journal of Fatigue: SciencedirectDocument21 pagesInternational Journal of Fatigue: SciencedirectolavusPas encore d'évaluation

- LAb 2Document33 pagesLAb 2Casey JacksonPas encore d'évaluation

- 33 - India - Connecting Rod AnalisysDocument7 pages33 - India - Connecting Rod AnalisysBima SorayaPas encore d'évaluation

- We Design ReportDocument45 pagesWe Design Reportorode franklynPas encore d'évaluation

- Chapter2 - 3 - 3D Stiffness and Compliance MatricesDocument43 pagesChapter2 - 3 - 3D Stiffness and Compliance MatricesRobby GunadiPas encore d'évaluation

- Sect Prop XyDocument3 pagesSect Prop Xyপ্রিয়দীপ প্রিয়ম100% (1)

- Earthquake Resistance of Buildings With A First Soft StoreyDocument9 pagesEarthquake Resistance of Buildings With A First Soft StoreyZobair RabbaniPas encore d'évaluation

- MOM II - Module 1Document10 pagesMOM II - Module 1Wolf LordPas encore d'évaluation

- Shallows FoundationDocument10 pagesShallows FoundationMaria VencentciaPas encore d'évaluation

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping ForceALP69Pas encore d'évaluation

- G12EXAMDocument3 pagesG12EXAMKa KlasmeytPas encore d'évaluation

- Source: Deped Science 8 Teacher'S Guide P.80Document2 pagesSource: Deped Science 8 Teacher'S Guide P.80Dabe Genesis Ligalig100% (1)

- Oedemeter Consolidation TestDocument24 pagesOedemeter Consolidation Testyashas sPas encore d'évaluation

- Chapter8 Column DesignDocument58 pagesChapter8 Column DesignKaren Lovedorial75% (4)

- Quiz 1lecture Ce3Document46 pagesQuiz 1lecture Ce3FELICITY MONTEFALCOPas encore d'évaluation

- Reinforced Concrete Design by Professor Anthony Kwame DansoDocument131 pagesReinforced Concrete Design by Professor Anthony Kwame DansoBadu Evans NyiayePas encore d'évaluation

- Chapter 12 PDFDocument17 pagesChapter 12 PDFAdolfo ElizondoPas encore d'évaluation

- Ce Review Nov 2021 PI Description: Min MaxDocument9 pagesCe Review Nov 2021 PI Description: Min MaxJoseph LantoPas encore d'évaluation

- Soil Stress Total Stress, Pore Pressure, U Effective Stress, 'Document7 pagesSoil Stress Total Stress, Pore Pressure, U Effective Stress, 'Nala A.Pas encore d'évaluation

- 01 - Soporte Principal - Ipt Stress Analysis Report 21-1-2024Document57 pages01 - Soporte Principal - Ipt Stress Analysis Report 21-1-2024David MF CocPas encore d'évaluation

- Timoshenko BeamsDocument3 pagesTimoshenko BeamsCristina VlaicuPas encore d'évaluation

- Deformation Due To PrestressingDocument6 pagesDeformation Due To PrestressingBodhi RudraPas encore d'évaluation

- Geodesic Analysis SampleDocument22 pagesGeodesic Analysis SampleSeaShell_6Pas encore d'évaluation

- Castiglianos Theorem of Least Work or Castiglianos Principle of Minimum Strain EnergyDocument98 pagesCastiglianos Theorem of Least Work or Castiglianos Principle of Minimum Strain EnergyAa AaPas encore d'évaluation

- Tdas PPTDocument41 pagesTdas PPTamin peyvandPas encore d'évaluation

- Design of A Bevel Gear National InstitutDocument13 pagesDesign of A Bevel Gear National InstitutGauravPas encore d'évaluation

- Wrinkling and Local Instabilities: Pling and The Intracell Buckling or Dimpling. This Chapter Presents The MeDocument25 pagesWrinkling and Local Instabilities: Pling and The Intracell Buckling or Dimpling. This Chapter Presents The MechacrdPas encore d'évaluation

- Mathcad - Case-1 (40 Od) InstallDocument4 pagesMathcad - Case-1 (40 Od) InstallAdvisPas encore d'évaluation

- Lecture 11.4 - Mohr-Coulomb Criterion IDocument9 pagesLecture 11.4 - Mohr-Coulomb Criterion Iabubaker ahmedPas encore d'évaluation