Académique Documents

Professionnel Documents

Culture Documents

TDS Korrobond 65

Transféré par

Velina MilevaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TDS Korrobond 65

Transféré par

Velina MilevaDroits d'auteur :

Formats disponibles

Technical Data Sheet

Revision Date: 26.06.08

KORROBOND 65 - EPOXY CRUSHER BACKING

PRODUCT INFORMATION Stock No. 81065P 81065D 81065DH Description Package Size 10kg Kit 200l Crusher Backing 20kg Hardener

Korrobond 65 is a two-component epoxy based backing compound and damping material for stone crushers. It serves as a backing and reinforcing layer between machine parts and as a damper when subjected to impact and shock loads. Very high compressive strength 100% Solids, no solvents, minimum shrinkage Easy to mix and pour - no skilled labour required Long established OEM and after market proven product High impact strength and resilience Ideal for extremely cold environments

Features

PRODUCT DATA Typical Physical Properties Density Compressive Strength Tensile Strength Impact Strength Lap Shear Strength Shore D Hardness Viscosity Curing Shrinkage Pot Life Return to Service Time Mixing Ratio (by volume)

3

1500 kg/m

2

>117.2N/mm (17,000psi) as per ISO 604 >27.6N/mm (4,000psi) as per ASTM 638

2

> 6.5 KJ/m as per ISO 179 > 353.8kg (780lbs) > 80 16000 cps 0.01% 15 minutes (approx.) 8 - 10 hours 7 Resin : 1 Hardener

APPLICATION INFORMATION Application It is recommended that Korrobond 65 is brought to the most suitable working temperature of about 20 C by placing it in a warm room 24 hours prior to use. At lower temperatures the material will be more viscous and at temperatures above 30 C the pot life of the product will be reduced. At temperatures below 5 C and above 40 C casting should not be carried out. Prior to use the respective crusher manufactures instructions should be consulted.

Unit 3 Shipton Way, Express Business Park, Northampton Road Rushden, Northants, NN10 6GL ITW Devcon Industrial Products GmbH, Liebigstrae 21, 24145 KIEL, Deutschland/Germany

Technical Data Sheet

Korrobond 65 Epoxy Crusher Backing

Revision Date: 26.06.08

Mixing

Korrobond 65 is delivered in two components that have a balanced ratio, which should not be altered. Using a suitable mixing tool (e.g. slow running drills with mixing paddle) stir Part A and mix it thoroughly with Part B the curing agent. A uniform colour will be noticed when complete mixing is achieved. Failure to adhere to the correct mixing ratio or poor mixing will result in the compound failing to harden in several areas, thus causing the whole pour to be ruined. Tools used in contact with this product should be cleaned in methylated spirit immediately after use, as Korrobond 65 is difficult to remove once cured. A shelf life of approximately 12 months from date of manufacture can be expected for this product when stored at room temperature (22C) in their original containers. For complete safety and handling information, please refer to the appropriate Material Safety Data Sheets prior to using this product. ITW Korroflex will replace any material found to be defective. As the storage, handling and application of this material is beyond our control we can accept no liability for the results obtained. All information on this data sheet is based on laboratory testing and is not intended for design purposes. ITW Korroflex makes no representations or warranties of any kind concerning this data. For product information visit www.Korroflex.com alternatively for technical assistance please call +44 (0) 870 458 7388 (UK) or +49 431 718830 (Germany).

Cleaning of tools Shelf life & Storage Precaution

Warranty

Disclaimer

Unit 3 Shipton Way, Express Business Park, Northampton Road Rushden, Northants, NN10 6GL ITW Devcon Industrial Products GmbH, Liebigstrae 21, 24145 KIEL, Deutschland/Germany

Vous aimerez peut-être aussi

- Loctite 592™: % of Initial Strength Environment °C 720 HDocument2 pagesLoctite 592™: % of Initial Strength Environment °C 720 HAndy ChongPas encore d'évaluation

- Protective Coating-3Document0 pageProtective Coating-3Sivaratnam NavatharanPas encore d'évaluation

- Date Sheet For PaintingDocument5 pagesDate Sheet For PaintingAws MohamedPas encore d'évaluation

- Optitemp HT 2 EP: DescriptionDocument2 pagesOptitemp HT 2 EP: DescriptionWirawan Adi Setya RPas encore d'évaluation

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013Pas encore d'évaluation

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYPas encore d'évaluation

- Epirez 733 Ultra High Build Epoxy CoatingDocument3 pagesEpirez 733 Ultra High Build Epoxy CoatingRai Hasnain Ahmad DahaPas encore d'évaluation

- Intertherm 838Document4 pagesIntertherm 838Ashta VakrPas encore d'évaluation

- Interbond 600Document4 pagesInterbond 600Trịnh Minh KhoaPas encore d'évaluation

- 4011 TDDocument2 pages4011 TDFernando HalaburaPas encore d'évaluation

- Product Description Sheet Hysol® Product 9460F: Industrial Products, August 2001Document2 pagesProduct Description Sheet Hysol® Product 9460F: Industrial Products, August 2001engpontelliPas encore d'évaluation

- 2 Ton Epoxy TDSDocument2 pages2 Ton Epoxy TDSFrichsGabinoCondoriMonzonPas encore d'évaluation

- Interzone 485Document4 pagesInterzone 485Sinan A AzizPas encore d'évaluation

- Intergard 475HS: Primed SurfacesDocument3 pagesIntergard 475HS: Primed SurfaceskareemPas encore d'évaluation

- Liquid Slilcone Rubber For Mould Making Tse 3455tDocument4 pagesLiquid Slilcone Rubber For Mould Making Tse 3455tsumit1022Pas encore d'évaluation

- Loctite 648: Technical Data SheetDocument3 pagesLoctite 648: Technical Data SheetRuiPas encore d'évaluation

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781Pas encore d'évaluation

- Energrease HTG 2 PDFDocument2 pagesEnergrease HTG 2 PDFLê Duy PhongPas encore d'évaluation

- Jotafloor SL UniversalDocument4 pagesJotafloor SL UniversalSlamat Parulian SimamoraPas encore d'évaluation

- Penguard Tie CoatDocument4 pagesPenguard Tie CoatajuhaseenPas encore d'évaluation

- Jotafloor SL UniversalDocument6 pagesJotafloor SL UniversalrogandatambunanPas encore d'évaluation

- Interprime 160Document0 pageInterprime 160Mehman NasibovPas encore d'évaluation

- Vinyl Ester-Glass Flake PaintDocument4 pagesVinyl Ester-Glass Flake PaintSimbu ArasanPas encore d'évaluation

- Intergard 251 Tech Data SheetDocument0 pageIntergard 251 Tech Data SheetL Mahender ReddyPas encore d'évaluation

- 8810Document2 pages8810Sikander Aleem100% (1)

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaPas encore d'évaluation

- Interbond 600 PDFDocument4 pagesInterbond 600 PDFTrịnh Minh KhoaPas encore d'évaluation

- HysolDocument2 pagesHysoljorgequijanoPas encore d'évaluation

- Korethan H.B. UH279 (Two-Component) : Physical PropertiesDocument2 pagesKorethan H.B. UH279 (Two-Component) : Physical PropertiesTrịnh Minh KhoaPas encore d'évaluation

- Physical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRDocument1 pagePhysical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRAlberto GutierrezPas encore d'évaluation

- Carbocoat 8215 PDS 6-10Document2 pagesCarbocoat 8215 PDS 6-10Mayur PatelPas encore d'évaluation

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data Sheetajuhaseen100% (1)

- Intergard 415Document4 pagesIntergard 415Hugo GLPas encore d'évaluation

- Loctite 324™: Technical Data SheetDocument3 pagesLoctite 324™: Technical Data SheetUgan Git PadayacheePas encore d'évaluation

- Thermaline 450 PDFDocument2 pagesThermaline 450 PDFNageswara Rao BavisettyPas encore d'évaluation

- Epirez 733Document3 pagesEpirez 733Andy AcousticPas encore d'évaluation

- Intergard 986Document4 pagesIntergard 986Ashta VakrPas encore d'évaluation

- High Build Protective Coating: Technical DataDocument2 pagesHigh Build Protective Coating: Technical Dataafic219473Pas encore d'évaluation

- Araldite 2010Document6 pagesAraldite 2010nrd9771Pas encore d'évaluation

- Lo-Frick L300 (Two-Component) : Physical PropertiesDocument2 pagesLo-Frick L300 (Two-Component) : Physical PropertiesTrịnh Minh KhoaPas encore d'évaluation

- Loctite 242: Product Description TechnologyDocument3 pagesLoctite 242: Product Description TechnologyRuiPas encore d'évaluation

- Betaforce ™ 2850S: Technical DatasheetDocument3 pagesBetaforce ™ 2850S: Technical Datasheetenrico_andreoli88Pas encore d'évaluation

- Product Data: Redux HP655Document6 pagesProduct Data: Redux HP655ja_mufc_scribdPas encore d'évaluation

- 186 Soldering Flux: Mildly Activated Rosin Liquid FluxDocument4 pages186 Soldering Flux: Mildly Activated Rosin Liquid FluxAmirPas encore d'évaluation

- Xylar Data SheetDocument3 pagesXylar Data Sheetsarath6725Pas encore d'évaluation

- Loctite 567 Thread Sealant Data SheetDocument3 pagesLoctite 567 Thread Sealant Data SheetJoseph BernardPas encore d'évaluation

- Araldite 2022Document6 pagesAraldite 20228612106535Pas encore d'évaluation

- Loctite 262: Product Description TechnologyDocument3 pagesLoctite 262: Product Description TechnologyrajaramPas encore d'évaluation

- Amercoat 471 Application May 08Document2 pagesAmercoat 471 Application May 08Biju_PottayilPas encore d'évaluation

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukPas encore d'évaluation

- Primastic UniversalDocument5 pagesPrimastic UniversalaleventPas encore d'évaluation

- HYSOL® FP4323 (ES4323) : Technical Data SheetDocument2 pagesHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemPas encore d'évaluation

- Resist 65: Technical Data SheetDocument5 pagesResist 65: Technical Data Sheetchristian210789Pas encore d'évaluation

- Formula 150 Primer (MILDTL-24441)Document4 pagesFormula 150 Primer (MILDTL-24441)Trịnh Minh KhoaPas encore d'évaluation

- Polyclad 975 H PDSDocument2 pagesPolyclad 975 H PDSLinnie McleodPas encore d'évaluation

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryD'EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryPas encore d'évaluation

- Bottles, Preforms and Closures: A Design Guide for PET PackagingD'EverandBottles, Preforms and Closures: A Design Guide for PET PackagingÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- GRP and Buildings: A Design Guide for Architects and EngineersD'EverandGRP and Buildings: A Design Guide for Architects and EngineersPas encore d'évaluation

- Pocket Guide to Preventing Process Plant Materials Mix-upsD'EverandPocket Guide to Preventing Process Plant Materials Mix-upsPas encore d'évaluation

- Introduction to Petroleum Process SafetyD'EverandIntroduction to Petroleum Process SafetyÉvaluation : 3 sur 5 étoiles3/5 (2)

- Leaflet English ILMEG Products ABDocument4 pagesLeaflet English ILMEG Products ABVelina MilevaPas encore d'évaluation

- Brand Oe. Part No. Model: Original Equipment Numbers vs. Kojen ModelDocument24 pagesBrand Oe. Part No. Model: Original Equipment Numbers vs. Kojen ModelVelina MilevaPas encore d'évaluation

- Quicklub Lubrication Systems: SSV Divider ValvesDocument4 pagesQuicklub Lubrication Systems: SSV Divider ValvesVelina MilevaPas encore d'évaluation

- Lagan Group Duleek Quarry enDocument5 pagesLagan Group Duleek Quarry enVelina MilevaPas encore d'évaluation

- Bds en Iso 8469 2013Document20 pagesBds en Iso 8469 2013Velina MilevaPas encore d'évaluation

- CAN Troubleshooting Sheet v3Document1 pageCAN Troubleshooting Sheet v3Velina MilevaPas encore d'évaluation

- 519379-Design A 100A Active Load To PDFDocument7 pages519379-Design A 100A Active Load To PDFVelina MilevaPas encore d'évaluation

- Performance Prediction Cf128G: Male Rotor Tip Speed in M/sDocument4 pagesPerformance Prediction Cf128G: Male Rotor Tip Speed in M/sVelina MilevaPas encore d'évaluation

- Effective Use of Water in A System For Water Driven Hammer DrillingDocument10 pagesEffective Use of Water in A System For Water Driven Hammer DrillingVelina MilevaPas encore d'évaluation

- MatexDocument2 pagesMatexVelina MilevaPas encore d'évaluation

- Technical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureDocument1 pageTechnical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureVelina MilevaPas encore d'évaluation

- Super TacDocument2 pagesSuper TacVelina MilevaPas encore d'évaluation

- AWS A10.1M-2007 Calibration and Performance Testing of Secondary Current Sensing Coils and Weld PDFDocument56 pagesAWS A10.1M-2007 Calibration and Performance Testing of Secondary Current Sensing Coils and Weld PDFVelina MilevaPas encore d'évaluation

- Level Ton ReportDocument72 pagesLevel Ton ReportVelina MilevaPas encore d'évaluation

- The Chemistry of Soap BubblesDocument15 pagesThe Chemistry of Soap BubblesGenesisCuervoCoronadoPas encore d'évaluation

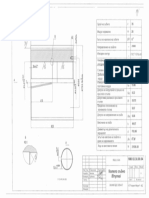

- Chertezh Zubna VtulkaDocument1 pageChertezh Zubna VtulkaVelina MilevaPas encore d'évaluation

- Coriolis ReportDocument51 pagesCoriolis ReportVelina MilevaPas encore d'évaluation

- FINAL REPORT Coastal Markets PDFDocument58 pagesFINAL REPORT Coastal Markets PDFVelina MilevaPas encore d'évaluation

- Blasting Plan TrenchDocument16 pagesBlasting Plan TrenchVelina Mileva100% (1)

- Laboratory Tests For The Drillability of Rock: Goodrich Test: Sievers J-ValueDocument2 pagesLaboratory Tests For The Drillability of Rock: Goodrich Test: Sievers J-ValueVelina MilevaPas encore d'évaluation

- The Influence of Wood Moisture Content On The Process of Circular Rip-Sawing. Part I: Power Requirements and Specific Cutting ForcesDocument15 pagesThe Influence of Wood Moisture Content On The Process of Circular Rip-Sawing. Part I: Power Requirements and Specific Cutting ForcesVelina MilevaPas encore d'évaluation

- Laboratory Tests For The Abrasiveness of Rock 20120516154148Document4 pagesLaboratory Tests For The Abrasiveness of Rock 20120516154148Velina MilevaPas encore d'évaluation

- J1587 IntroductionDocument7 pagesJ1587 IntroductionVelina MilevaPas encore d'évaluation

- Cambridge IGCSE Paper 2Document4 pagesCambridge IGCSE Paper 2irajooo epik zizterPas encore d'évaluation

- Purpose in LifeDocument1 pagePurpose in Lifeaashish95100% (1)

- Plastics and Polymer EngineeringDocument4 pagesPlastics and Polymer Engineeringsuranjana26Pas encore d'évaluation

- Someone Who Believes in YouDocument1 pageSomeone Who Believes in YouMANOLO C. LUCENECIOPas encore d'évaluation

- Elements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesDocument8 pagesElements of Romanticism in The Poetry of W. B. Yeats: Romantic InfluencesSadman Shaid SaadPas encore d'évaluation

- Impact of Retrofitting Existing Combined Heat and Power Plant With Polygeneration of Biomethane PDFDocument16 pagesImpact of Retrofitting Existing Combined Heat and Power Plant With Polygeneration of Biomethane PDFAwais Salman0% (1)

- Sony Cdm82a 82b Cmt-hpx11d Hcd-hpx11d Mechanical OperationDocument12 pagesSony Cdm82a 82b Cmt-hpx11d Hcd-hpx11d Mechanical OperationDanPas encore d'évaluation

- Extract From The Painted Door' by Sinclair RossDocument2 pagesExtract From The Painted Door' by Sinclair RosssajifisaPas encore d'évaluation

- EXP4 The Diels Alder ReactionsDocument3 pagesEXP4 The Diels Alder ReactionsLaura GuidoPas encore d'évaluation

- Reviews: The Global Epidemiology of HypertensionDocument15 pagesReviews: The Global Epidemiology of Hypertensionrifa iPas encore d'évaluation

- Industrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsDocument5 pagesIndustrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsMuhammad HaziqPas encore d'évaluation

- De Vault 1996Document22 pagesDe Vault 1996Harumi OOPas encore d'évaluation

- Presentation On 4G TechnologyDocument23 pagesPresentation On 4G TechnologyFresh EpicPas encore d'évaluation

- PPT DIARHEA IN CHILDRENDocument31 pagesPPT DIARHEA IN CHILDRENRifka AnisaPas encore d'évaluation

- Electricity NotesDocument35 pagesElectricity Notesapi-277818647Pas encore d'évaluation

- AssessmentDocument3 pagesAssessmentpalflaxPas encore d'évaluation

- Clevo W940tu Service ManualDocument93 pagesClevo W940tu Service ManualBruno PaezPas encore d'évaluation

- Piriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar KusumaDocument6 pagesPiriformis Syndrome: Hardi Adiyatma, Shahdevi Nandar Kusumaismael wandikboPas encore d'évaluation

- Sika - Bitumen: Bitumen Emulsion Waterproof & Protective CoatingDocument3 pagesSika - Bitumen: Bitumen Emulsion Waterproof & Protective Coatingdinu69inPas encore d'évaluation

- Significance of GodboleDocument5 pagesSignificance of GodbolehickeyvPas encore d'évaluation

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaPas encore d'évaluation

- Recipes From The Perfect Scoop by David LebovitzDocument10 pagesRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)

- CapstoneDocument23 pagesCapstoneA - CAYAGA, Kirby, C 12 - HermonPas encore d'évaluation

- Math AA SL P 1 Marks SchemeDocument6 pagesMath AA SL P 1 Marks SchemeMrin GhoshPas encore d'évaluation

- Week 1 - NATURE AND SCOPE OF ETHICSDocument12 pagesWeek 1 - NATURE AND SCOPE OF ETHICSRegielyn CapitaniaPas encore d'évaluation

- Liver: Anatomy & FunctionsDocument18 pagesLiver: Anatomy & FunctionsDR NARENDRAPas encore d'évaluation

- 外贸专业术语Document13 pages外贸专业术语邱建华Pas encore d'évaluation

- Ficha Tecnica-Skyjack SJ3219 8mtDocument2 pagesFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALPas encore d'évaluation

- Syllabus Unit Iv Unit Commitment and Economic DispatchDocument23 pagesSyllabus Unit Iv Unit Commitment and Economic DispatchBALAKRISHNANPas encore d'évaluation

- Parts Catalogue of Foton: (TC2A504-034K)Document132 pagesParts Catalogue of Foton: (TC2A504-034K)МаксимPas encore d'évaluation