Académique Documents

Professionnel Documents

Culture Documents

Pressure Relief Valves

Transféré par

happale20020 évaluation0% ont trouvé ce document utile (0 vote)

113 vues2 pagesPressure relief valves are used to protect equipment from overpressure by quickly opening and closing. They are commonly used in process industries, pressure reducing stations, and turbine bleeder lines where a tight seal is needed to prevent overpressure. The Figure 8292 pressure relief valve design guides the valve disc above and below the seat to ensure accurate closing after relieving pressure and allows installation in any position. As pressure increases beyond the initial relief pressure, the valve's capacity increases until fully opening at a pressure at least 10% higher. Modifications can be made to valves to meet specific application requirements.

Description originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentPressure relief valves are used to protect equipment from overpressure by quickly opening and closing. They are commonly used in process industries, pressure reducing stations, and turbine bleeder lines where a tight seal is needed to prevent overpressure. The Figure 8292 pressure relief valve design guides the valve disc above and below the seat to ensure accurate closing after relieving pressure and allows installation in any position. As pressure increases beyond the initial relief pressure, the valve's capacity increases until fully opening at a pressure at least 10% higher. Modifications can be made to valves to meet specific application requirements.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

113 vues2 pagesPressure Relief Valves

Transféré par

happale2002Pressure relief valves are used to protect equipment from overpressure by quickly opening and closing. They are commonly used in process industries, pressure reducing stations, and turbine bleeder lines where a tight seal is needed to prevent overpressure. The Figure 8292 pressure relief valve design guides the valve disc above and below the seat to ensure accurate closing after relieving pressure and allows installation in any position. As pressure increases beyond the initial relief pressure, the valve's capacity increases until fully opening at a pressure at least 10% higher. Modifications can be made to valves to meet specific application requirements.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Bulletin 8P

Pressure Relief Valves

For applications where a tight seating valve is required to prevent overpressure

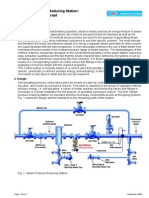

Application Quick-opening, quick-closing valves protect equipment from gas pressure build up or pressure surges. Standard applications involve steam, gases, or liquids where a tight seating valve is required to prevent overpressure. Typical applications are in process industries, pressure reducing stations, and turbine bleeder lines. These valves can also be equipped with a handwheel and screw spindle for either manually opening the disc or to facilitate changing the relief pressure by changing the compression of the spring. In the Figure 8292 Pressure Relief Valve design, the valve disc is guided above and below the seat. This assures accurate seating after relief and enables the valve to be installed in any position - either horizontal or vertical. As shown in Fig. 1 sectional drawing, these valves are designed to relieve increasing capacities with an increase in pressure over and above the initial relief pressure until the maximum capacity is released when the valve is fully open. This pressure increase should not be less than 10% of the initial relief pressure, except on special application. The Figure 8293 Pressure Relief Valve is the same as Figure 8292 except that it is an angle body type. Fig. 8293 valves must be mounted in a horizontal line in an upright position. The Figure 8258 Pressure Relief Valve is designed for conditions too severe for a spring loaded design as the springs get too large. Valves of this design are guided above and below the seat which insures accurate seating after relief. Fig. 8258 Pressure Relief Valve must be mounted in a horizontal line in an upright position. Operation Operation is dependant upon design. Fig. 1 is held in the closed position by an air cylinder acting against the spring. When air pressure is released, the spring opens the valve instantaneously. Similar arrangements provide for quick-closing types. Modifications Valves are designed to meet specific requirements. variations are possible. Many

Fig. 1 Figure 8292 Pressure Relief Valve

Schutte & Koerting 2510 Metropolitan Drive Trevose, PA 19053 USA tel: (215) 639-0900 fax: (215) 639-1597 www.s-k.com sales@s-k.com

Pressure Relief Valves

Bulletin 8P

Fig. 8292 Capacity Curve

If steam is superheated, capacity must be revised upward by multiplying by correction factor before the capacity curves can be used. Spring Loaded Relief Valves. Steam Only - Atmospheric Discharge 10% increase in pressure from initial relief to full open

150

Full Relief Pressure - psig (Valve Wide Open)

125

Co nn 8 ec tio nS

ize

10

100 12

75

14 50

500 400 Superheat F

25

300 200 100 0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 Capacity Correction Factor

25

50

75

100

125

150

175

200

Steam Capacity in Thousands of Lbs. Per Hr.

062107

ISO 9001:2000 Certified

Schutte & Koerting 2510 Metropolitan Drive Trevose, PA 19053 USA tel: (215) 639-0900 fax: (215) 639-1597 www.s-k.com sales@s-k.com

Vous aimerez peut-être aussi

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Relief Valves: Gases and Gas EquipmentDocument22 pagesRelief Valves: Gases and Gas EquipmentInspection EngineerPas encore d'évaluation

- ! CEB Over Centre Cartridge ValveDocument75 pages! CEB Over Centre Cartridge ValvekmstamimPas encore d'évaluation

- Section 30 - Relief ValvesDocument17 pagesSection 30 - Relief ValveshammamiPas encore d'évaluation

- Understanding Double Seated Shut Off Valves: Tech Tip 12Document4 pagesUnderstanding Double Seated Shut Off Valves: Tech Tip 12AlphaPas encore d'évaluation

- Overcenter ValvesDocument4 pagesOvercenter ValvesAnonymous jSTkQVC27b100% (1)

- Dimensions Specifications: 125 Booster Pump ControlDocument6 pagesDimensions Specifications: 125 Booster Pump ControlDheeraj ThakurPas encore d'évaluation

- Spring Loaded Safety ValvesDocument16 pagesSpring Loaded Safety ValvesUdit Kumar Sarkar0% (1)

- Aeromats Aeropress Aeropress 10s Aerovac GeneralDocument2 pagesAeromats Aeropress Aeropress 10s Aerovac Generalsaket2006Pas encore d'évaluation

- Control Valve - Surge Relief Valve Selection GuideDocument20 pagesControl Valve - Surge Relief Valve Selection GuideSriya PetikiriarachchigePas encore d'évaluation

- Lesson 21 - RP-576 - New2 (8 Q)Document64 pagesLesson 21 - RP-576 - New2 (8 Q)VINOTHKUMARPas encore d'évaluation

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 pagesSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoPas encore d'évaluation

- 0004 Lesson API RP-576Document65 pages0004 Lesson API RP-576tayyab aliPas encore d'évaluation

- Lesson 21 RP-576 New2Document64 pagesLesson 21 RP-576 New2gopu100% (1)

- Installation, Operation and Maintenance Manual For Weight Loaded Fiberglass ValvesDocument17 pagesInstallation, Operation and Maintenance Manual For Weight Loaded Fiberglass ValvesTomas TroncosoPas encore d'évaluation

- Fluid Power Intensifiers Series PC, PD and PS: The Easier, Less Costly Way To Provide High Pressure Hydraulic PowerDocument8 pagesFluid Power Intensifiers Series PC, PD and PS: The Easier, Less Costly Way To Provide High Pressure Hydraulic PowernvkjayanthPas encore d'évaluation

- Compressors Capacity ControlDocument12 pagesCompressors Capacity Controlvalentinlupascu33100% (1)

- Incorporated ValvesDocument7 pagesIncorporated ValvesAlp HaPas encore d'évaluation

- Valvula de Presion y Vacio GROTHDocument16 pagesValvula de Presion y Vacio GROTHSantiago CastañoPas encore d'évaluation

- Hi Pressure Plunger Pump KPDDocument25 pagesHi Pressure Plunger Pump KPDengrtahir100% (1)

- PrdsDocument0 pagePrdssandi1111Pas encore d'évaluation

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 pagesControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımPas encore d'évaluation

- Cargador 920 & 930 Sistema HidraulicoDocument19 pagesCargador 920 & 930 Sistema Hidraulicojulio100% (1)

- BOOK 2, CHAPTER 1 - Hydraulic Accumulators (Part 1) - Other Technologies Content From Hydraulics & PneumaticsDocument7 pagesBOOK 2, CHAPTER 1 - Hydraulic Accumulators (Part 1) - Other Technologies Content From Hydraulics & Pneumaticsjanaaidaas1996Pas encore d'évaluation

- Guidelines On The Maintenance of Pressure Relief Valves On Board Gas CarriersDocument17 pagesGuidelines On The Maintenance of Pressure Relief Valves On Board Gas Carriers123habib123fikriPas encore d'évaluation

- t000005801 PDFDocument7 pagest000005801 PDFMohammed Hassan B KorainaPas encore d'évaluation

- Constraints Complicate Centrifugal Compressor Depressurization - Oil & Gas JournalDocument5 pagesConstraints Complicate Centrifugal Compressor Depressurization - Oil & Gas Journalsachin2010Pas encore d'évaluation

- Air Valve BulletinDocument67 pagesAir Valve Bulletinar174_569868987Pas encore d'évaluation

- Pressure Relief ValvesDocument6 pagesPressure Relief ValvesShashank Sudhakar PathakPas encore d'évaluation

- CVS Type 667 Diaphragm Actuator: Instruction ManualDocument8 pagesCVS Type 667 Diaphragm Actuator: Instruction Manualsalmo83:18Pas encore d'évaluation

- Basics of Pressure RegulationDocument18 pagesBasics of Pressure Regulationar174_569868987Pas encore d'évaluation

- E-10 Dual Brake ValvesDocument8 pagesE-10 Dual Brake Valvesjgomez30Pas encore d'évaluation

- Gasliftequipments PDFDocument51 pagesGasliftequipments PDFSufian R EllabbadPas encore d'évaluation

- Antisurge Control SystemDocument10 pagesAntisurge Control Systemlac1981Pas encore d'évaluation

- Emd Mi259Document20 pagesEmd Mi259Mike Finazzi100% (3)

- Pressure Relief ValvesDocument12 pagesPressure Relief ValvesyvhtejaswaroopPas encore d'évaluation

- Om-7 FDocument23 pagesOm-7 FcharlessimoPas encore d'évaluation

- PIlot Operated Safety ValveDocument6 pagesPIlot Operated Safety ValveTrisha SalinasPas encore d'évaluation

- Antisurge Control SystemDocument10 pagesAntisurge Control Systemsopan saPas encore d'évaluation

- LIT1307 Pilot Operated Relief Valves 2020 WebDocument28 pagesLIT1307 Pilot Operated Relief Valves 2020 WebLance Noel SirayPas encore d'évaluation

- 5.plant Layout - Relief SystemDocument7 pages5.plant Layout - Relief Systemhalder_kalyan9216Pas encore d'évaluation

- 205 Drag Valves For Boiler Feedpump RecirculationDocument6 pages205 Drag Valves For Boiler Feedpump Recirculationesakkiraj1590Pas encore d'évaluation

- Sostenedora Presion BERMADDocument6 pagesSostenedora Presion BERMADguzman_10Pas encore d'évaluation

- 고려특수금속 (PSV-FLANGED TYPE) PDFDocument56 pages고려특수금속 (PSV-FLANGED TYPE) PDFStanley PeterPas encore d'évaluation

- Frese OPTIMA Design Guide SEP 12 PDFDocument16 pagesFrese OPTIMA Design Guide SEP 12 PDF윤병택Pas encore d'évaluation

- R431002626 AventicsH 3Controlair®ValveswithRollerDocument2 pagesR431002626 AventicsH 3Controlair®ValveswithRollerHamza ChenakerPas encore d'évaluation

- A t3 Super Choke Operational ManualDocument64 pagesA t3 Super Choke Operational Manualcorsini99986% (7)

- Breather ValvesDocument3 pagesBreather Valves@@ng100% (1)

- Installation Procedure - 1200ADocument18 pagesInstallation Procedure - 1200AHarshkumar PatelPas encore d'évaluation

- Tanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFDocument24 pagesTanque Presurizado de Acero Pro-Source Plus - Manual Del Propietario - 1000000173 - 2010 - PENTAIR WATER PDFpevarePas encore d'évaluation

- Plant Layout (Relief Valve)Document10 pagesPlant Layout (Relief Valve)Mee WinPas encore d'évaluation

- Performance and Dimension RCS OLD MANUAL 8INCH2.PDF NewDocument16 pagesPerformance and Dimension RCS OLD MANUAL 8INCH2.PDF NewJorge A VilalPas encore d'évaluation

- HTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P23Document11 pagesHTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P23jorsuePas encore d'évaluation

- Ejector Working PrincipleDocument11 pagesEjector Working Principleanuram66100% (3)

- Safety Valve LaserDocument15 pagesSafety Valve Lasersajjad_naghdi241Pas encore d'évaluation

- Valve Actuator Torque CurvesDocument4 pagesValve Actuator Torque CurvesyogitatanavadePas encore d'évaluation

- Rtaa SB 4 - 10011991Document6 pagesRtaa SB 4 - 10011991alcomech100% (3)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- NIOEC Vendor List Based On ManufacturersDocument234 pagesNIOEC Vendor List Based On Manufacturershappale2002Pas encore d'évaluation

- Mist EliminatorDocument4 pagesMist Eliminatorhappale2002Pas encore d'évaluation

- Spec524rev4coating Threaded Fasterners 1124440653Document4 pagesSpec524rev4coating Threaded Fasterners 1124440653happale2002Pas encore d'évaluation

- SP-1200 Procurement Specification For Pipeline Check ValvesDocument25 pagesSP-1200 Procurement Specification For Pipeline Check Valveshappale2002Pas encore d'évaluation

- SP-1136 Cathodic Protection DrawingsDocument4 pagesSP-1136 Cathodic Protection Drawingshappale2002Pas encore d'évaluation

- Specification For Cathodic Protection DesignDocument39 pagesSpecification For Cathodic Protection Designhezron7771% (7)

- SP 1190 Desing - For - Sour - Service - SpecificationDocument15 pagesSP 1190 Desing - For - Sour - Service - Specificationhappale2002100% (1)

- Valve Selection Guide: 2/2 Way SolenoidsDocument4 pagesValve Selection Guide: 2/2 Way Solenoidshappale2002Pas encore d'évaluation

- SP 1032 Specification - For - The - Design - of - Pipeline - Block - ValvDocument17 pagesSP 1032 Specification - For - The - Design - of - Pipeline - Block - Valvhappale2002100% (1)

- GU-379 Pipeline Emergency Repair ManualDocument76 pagesGU-379 Pipeline Emergency Repair Manualhappale2002Pas encore d'évaluation

- GU-379 Pipeline Emergency Repair ManualDocument76 pagesGU-379 Pipeline Emergency Repair Manualhappale2002Pas encore d'évaluation

- GU-504 Gas Flotation Tank Systems Rev2 Old PDFDocument37 pagesGU-504 Gas Flotation Tank Systems Rev2 Old PDFhappale2002Pas encore d'évaluation

- PR-1272 Standard Welding PQRs For On-Plot PipingDocument10 pagesPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002Pas encore d'évaluation

- Chlorination of Cooling Water Systems PDFDocument4 pagesChlorination of Cooling Water Systems PDFhappale2002Pas encore d'évaluation

- Quality and Productivity Improvement - Total Improvement Management PDFDocument20 pagesQuality and Productivity Improvement - Total Improvement Management PDFhappale2002Pas encore d'évaluation

- Hazop Example PDFDocument2 pagesHazop Example PDFhappale200286% (7)

- BGP PDFDocument100 pagesBGP PDFJeya ChandranPas encore d'évaluation

- Asugal Albi 4540Document2 pagesAsugal Albi 4540dyetex100% (1)

- BIO122 - CHAPTER 7 Part 1Document53 pagesBIO122 - CHAPTER 7 Part 1lili100% (1)

- Vacon NX, Non-Regenerative Front End FI9 UD01217B PDFDocument48 pagesVacon NX, Non-Regenerative Front End FI9 UD01217B PDFSilvian IonescuPas encore d'évaluation

- SQL TestDocument10 pagesSQL TestGautam KatlaPas encore d'évaluation

- Konsep Negara Hukum Dalam Perspektif Hukum IslamDocument11 pagesKonsep Negara Hukum Dalam Perspektif Hukum IslamSiti MasitohPas encore d'évaluation

- Operation ManagementDocument4 pagesOperation ManagementHananiya GizawPas encore d'évaluation

- Ce Project 1Document7 pagesCe Project 1emmaPas encore d'évaluation

- Project Synopsis On LAN ConnectionDocument15 pagesProject Synopsis On LAN ConnectionডৰাজবংশীPas encore d'évaluation

- WDP Process Diagrams v1Document6 pagesWDP Process Diagrams v1Ryan HengPas encore d'évaluation

- INA Over Drive Pulley SystemDocument1 pageINA Over Drive Pulley SystemDaniel JulianPas encore d'évaluation

- Assignment 1 - Vertical Alignment - SolutionsDocument6 pagesAssignment 1 - Vertical Alignment - SolutionsArmando Ramirez100% (1)

- EUCLIDDocument3 pagesEUCLIDNandini MouryaPas encore d'évaluation

- History of JavaDocument3 pagesHistory of JavaKyra ParaisoPas encore d'évaluation

- Tournament Rules and MechanicsDocument2 pagesTournament Rules and MechanicsMarkAllenPascualPas encore d'évaluation

- RESUME1Document2 pagesRESUME1sagar09100% (5)

- Ccie R&s Expanded-BlueprintDocument12 pagesCcie R&s Expanded-BlueprintAftab AlamPas encore d'évaluation

- Projected Costs of Generating Electricity (EGC) 2005Document233 pagesProjected Costs of Generating Electricity (EGC) 2005susantojdPas encore d'évaluation

- Asian Paints Final v1Document20 pagesAsian Paints Final v1Mukul MundlePas encore d'évaluation

- 3 - Risk Opportunity RegisterDocument4 pages3 - Risk Opportunity RegisterArmando CorboPas encore d'évaluation

- Debate Lesson PlanDocument3 pagesDebate Lesson Planapi-280689729Pas encore d'évaluation

- Decision Tree AlgorithmDocument22 pagesDecision Tree Algorithmvani_V_prakashPas encore d'évaluation

- ModelsimDocument47 pagesModelsimKishor KumarPas encore d'évaluation

- Historical Roots of The "Whitening" of BrazilDocument23 pagesHistorical Roots of The "Whitening" of BrazilFernandoMascarenhasPas encore d'évaluation

- IJISRT23JUL645Document11 pagesIJISRT23JUL645International Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- GSM BSC6000 Performance StatisticsDocument72 pagesGSM BSC6000 Performance StatisticsAli AlshwalPas encore d'évaluation

- Perbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota MalangDocument11 pagesPerbandingan Implementasi Smart City Di Indonesia: Studi Kasus: Perbandingan Smart People Di Kota Surabaya Dan Kota Malanglely ersilyaPas encore d'évaluation

- Project 4 Close TestDocument7 pagesProject 4 Close TestErika MolnarPas encore d'évaluation

- Leadership Nursing and Patient SafetyDocument172 pagesLeadership Nursing and Patient SafetyRolena Johnette B. PiñeroPas encore d'évaluation

- CBLM - Interpreting Technical DrawingDocument18 pagesCBLM - Interpreting Technical DrawingGlenn F. Salandanan89% (45)