Académique Documents

Professionnel Documents

Culture Documents

Deep Blue Pump Co Brochure 2010

Transféré par

khorzooCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Deep Blue Pump Co Brochure 2010

Transféré par

khorzooDroits d'auteur :

Formats disponibles

ROTTERDAM DUBAI DALIAN

DEEP BLUE PUMP COMPANY, THE COMPANY ENGAGED IN THE MANUFACTURING OF INTERNATIONAL HIGH QUALITY CENTRIFUGAL PUMPS TO MEET ALL REQUIREMENTS (DIN, ANSI, API STANDARDS)

WATER PUMPS

MINING PUMPS

CHEMICAL PUMPS

PETRO-CHEMICAL PUMPS

PUMPING TECHNOLOGY

DEEP BLUE PUMP CO. A company will become strong competitive with advanced technology in the Market. We paid extensive attention on research and exploitation of technology from the first start. At the same time, we also concentrated on establishment of technology innovation and environmental issues to promote exploitation of our products and markets. We are a multi location pump company engaged in the manufacture of a diverse range of international quality pumps. We have closely understood and succesfully met the pumping requirements of the global industry. -

MANAGEMENT AND CULTURE Deep Blue Pump Co. is a Dutch pump manufacturer with its offices and assembly shop located in the heart of the logistic centre of The Netherlands, Rotterdam Europoort. Deep Blue Pump Co. products are being used worldwide in a vast variety of industrial markets such as refineries, offshore, water and chemical. Deep Blue Pump Co. provides European quality backed up by reliable warranties and after sales service. Objective Diversification: Serve Oil & Gas Production Off Shore, Chemical Refining, Coal Chemical, Nuclear Power, and water Market Differentiation: Products differentiation based on market position Globalization: World class R&D ,Production, Service and Management Competitive Advantage: Be market leader in our top 4 served industry Grow with Global supplier and Global customer To become top 20 (petro) chemical pump producer in the world Mission Continuously carry out technology and management innovation to provide customer with best products and service, build Deep Blue Pump Co. into a world class firm with sustainable growth capability, thus achieve higher return for our shareholders, customers ,employees and society Vision To become the most valuable chemical equipment supplier in the world.

Customer: Customer always right, our mission is to satisfy customer demand Employee: Employee is the most valuable asset of the company, the driving force of our growth. The accomplishment of our goal fully rely on the great efforts of employees, we respect every input and suggestions from employees Integrity: We treat our customer, employee ,supplier and share holder with integrity ,dignity and respect, we act on our words with honor Quality: Relentless pursuit of perfection is our working principle Innovation: Our name may stay the same, everything else need to be adapted to external market environment Speed: Speed to the market to obtain competitive advantage, high speed in technology adoption, production and service Management: Simple and Efficient Work Flow Management is our core management principle Supplier: Supplier is the most important part in our market value chain, we build strategic partnership with each of them Corp De Spirit and Mutual Trust. We cherish cooperation, mutual trust and responsibility within our organization, we also

encourage individual creativity, encourage our employee to achieve their personal goal as well as collective goal. Topmanagement shall carry great responsibility and integrity, embrace the continuous learning attitude, build constructive relationship, be communicative and bring the best out of peers and subordinates.

Customer Leadership Mutual Support Supplier Management

Employee Integrity

Value System

Quality Innovation

Speed

PRODUCTION CAPACITY Casting Area of structure: 7,200m2 Equipment: 7 sets medium-frequency induction furnace of 250~3000Kg. Capacity: 2000 ton/year Single piece weight: 12 ton Casting material: more than 40 kinds of nickel-base alloy, duplex SS and Austenitic SS, according to GB and ASTM standard Machining Area of structure: 9,500m2 Equipment: 206 sets of lathe, miller, planer, grinder, borer, driller and reamer, including imported machining center, NC multiple driller, NC boring-milling machine Capacity parameter: turning diameter4.0m, turning length10m, grinding length4.0m, milling dimension 2.5X5.0m, boring dimension 2.5X2.5m Assembly and testing Standard pump workshop: Area of structure: 8,500m2, elevating capacity 10 ton, 250KW automatic enclosed testing bench. Special pump workshop: Area of structure: 7,000m2, elevating capacity 50 ton, 3000KW automatic open testing bench. Nuclear pump workshop: Area of structure: 3,000m2, elevating capacity 5 ton, with A grade water treatment system. Production management Advanced group technology organizing production Overall using ERP production resource management system

QUALITY CONTROL: Quality assurance system ISO9001 certification, all the process of designing and development, fabrication, sales and service will be accordance with the ISO certification, to permit the high efficiency of production business, and high quality performance. Quality target Will be the cooperative associate for all the clients, with advanced technology, high quality products, and perfect service. Inspection and testing equipment Dynamic balance equipment Type: YYW160, YYQ-5, HM60V Precision: ISO 1940 G1.0 Balance weight: 800Kg Balance speed: 6000r/min Physical and chemical testing equipment PMI Hydraulic universal test machine Impact tester Durometer Stress failure machine Vibration failure machine NDT equipment Supersonic flaw detecting machine Radiographic flaw detecting machine Magnetometer Infrared Hardness Tester X-ray film machine Static hydraulic pressure equipment. More than 10 sets static hydraulic Pressure equipment Testing pressure will achieve to 60MPa Measuring tool Various types of gauge calibration, chock gauge, external cylindrical gauge, and etc, more than 500 sets high precision measuring tools.

SALES AND SERVICE Service system Sub service company can afford the technical support and operation and maintenance service. With the perfect spare parts supply system, we can give the clients convenient service for spare parts. Furthermore, our service engineer will inspect the clients jobsite. Service promise No matter whats kinds of problem in jobsite, we promise to start our jobsite service within 24 hours, with the principle of settling down the trouble. Within warranty, we will be response for maintenance and change the equipment. After warranty, we will submit the service for life, without any service fees.

APPLICATION Product model More than 40 series and 100 types, and the construction cover all the API 610 pumps. Terminal parameters Max. flow: 20000m3/h Max. head: 3500m Max. speed: 22700r/min Max. tem: 450 Max. pressure: 42MPa Design standard API, ISO, ANSI, DIN, GB and other standards. Application field Our products is widely used in petrochemical, chemical, fertilizer, steel, coking, coal chemical, food, electrical power, car, metal, pulp, mine smelt, city water supply, oil field and nuclear inductry.

TECHNOLOGY DEVELOPMENT Personnel structure More than 60 technicians, 9 high-grade engineers, 32 engineers, 19 other technicians. Working content New products design New technic innovation New technology institute New material research Client technical support Personnel training Three-dimensional analog flow field analysis Hardness analysis calculation Design methods AUTOCAD, MDS2002 CAPP UG CFD ANSYS PUMPCAD

Technical cooperation Good relationship with local pump scientific research unit and academy, which can promote our technology. Development orientation We invest 3% of turnover per year for technology research to promote the technical content of products, which can bring us to the advanced level in the world. At present, our products is towards high tem, high pressure, low temperature, high efficiency, high NPSH performance, wear-less, high security, large sized, complete sets.

WATERFLO WF General Purpose pump Series acc.to the. DIN24255 standards Design specification: DIN 24255 Capacity 2~900m3/h Head ~140m T ~+105C Pressure ~1.6Mpa; Applicable Cooling water Water supply/distribution. Fire protection, drainage, Irrigation. General industrial services. Summarize Horizontal, single stage, single suction, radial split, foot support volute pump. high interchangeability. high reliability, high efficiency.

SPLITFLO RE heavy duty horizontal split-case pump Capacity 18.000m3/h Head ~200m T ~105 celcius, Pressure ~2.5MPa Applicable Liquid transportation for water works air-conditioning, irrigation, drainage pump stationfire-fighting system, ship-building and so on. Summarize single stage, double suction, split volute casing, horizontal heavy duty centrifugal pumps with closed impeller, and the axial force balanced by balancing hole. Kinds of seal type can be fitted. Back pull designing is easy for maintenance. High interchangeability with low operation cost.

TURBINEFLO Series vertical turbine pump Capacity 8~60.000m3/h Head ~90m T ~+60~ Pressure ~1.5MPa Applicable fields of public work, steel and iron metallurgy, chemistry, paper-making, tapping water service, power station and irrigation and water conservancy, etc. Summarize Single / multistage closed or semi-open adjustable impeller. Surface or underground discharge head, shaft and bearings combinations promote long life with options of open or enclosed line shaft construction.

PROFLO PF Series chemical process pump Design specification ANSI B73.1M Capacity PROFLO ~1400m3/h, Head PF ~223 m. T -40~+371 Celcius. Pressure ~2.5Mpa. Applicable Chemical, oil, refining, paper making, refine sugar, pharmacy, power station, steel making, tank car delivery, oil residue transferring. Summarize PF is the standard chemical pump. SP is standard chemical self-priming pump. Single stage, single suction, overhung. Back open impeller, high efficiency, stable operation. External shaft adjustment construction.

PROFLO ANS series chemical process pump Design specification B73.1M Capacity ~2000m3/h, 2~250m3/h Head ~250 m, ~150 m T -40~+260 Pressure ~2.5Mpa, ANSZ ~2.0 Mpa Applicable Chemical, oil, refining, paper making, refine sugar, pharmacy, power-station, steel making, tank car delivery, oil residue transferring. Summarize ANS is chemical process pump ANSZ is chemical process self-priming pump. Single stage, single suction, overhung. Back open impeller, high efficiency, stable operation. External shaft adjustment construction.

ISOFLO series chemical process pump Design specification ISO2858 Capacity 2~2000m3/h Head ~160m T -40~+260 Pressure 2.5Mpa Applicable Chemical, petrochemical, steel making, power station, pulp, pharmacy, foodstuff, refine sugar. Summarize Horizontal, single stage, overhung, single suction, foot support, closed impeller. Standard seal chamber applicable for kinds seal plan. Oil lubrication controlled by oil cup. As shaft is not wetted part, the working time can be enlarged. Back pull structure, easy for maintenance.

ISOFLO SP series self priming chemical process pump Design specification ISO 2858 Capacity 6~200m3/h Head ~125m T -80~+240 Pressure~1.6MPa Applicable Tank pump drainage, tank car lading, sewage drainage, ship water supply and drainage. Summarize Single stage, single suction, overhung, radial split foot support volute pump. External mixing type construction, high efficiency, starting without filling pump, good self priming performance. Closed impeller, axial force balanced by vane. Various kinds of seal types can be fitted. Back pull designingis easy for maintenance.

ELBOWFLO series chemical axial flow pump Design specification ISO2858 Capacity 460~11000m3/h Head 2.4~8m T 0~+180 Pressure 0.6 Mpa. Applicable Large capacity and low head condition in making salt or making alkaline circle system especially. Summarize Horizontal, single stage, single suction, overhung axial flow pump. Simple structure and high dependability. Casing is 90angle branch or volute structure. Suction and discharge position is top/end, also can be designed according to the requirements of client. Packing and double seal can be fitted.

SOLIDFLO series chemical mixed flow pump Design specification ISO2858 Capacity ~7000m3/h Head ~25m T-20~+180 Pressure 0.6Mpa Applicable Forced circulation, water treatment circulation, seawater breed aquatics, city gas project. Summarize. Single stage, single suction, overhung mixed flow pump. Semi-open impeller, axial force balanced by balancing hole. Each kinds of seal type can be fitted. High efficiency, low energy cost, open valve starting. As the large overflowing cross section, non blinding.

HTFLO series petrochemical processpump (OH1) Design specification API610 (th7) Capacity 2~2600m3/h Head ~240m T -80~+450~ Pressure ~2.5MPa Applicable Refinery, Petrochemical, chemical, low temp, power station, environment protection, offshore platform. Summarize Closed or semi-open impeller for ESH, as well as open impeller for ESHK. Horizontal, single suction, single stage, radial split, foot support volute pump. For closed and semi-open impeller, axial force will be balanced by balancing hole and wear rings. For open impeller, axial force will be balanced by vane.

APIFLO EGS-L series vertical high speed pump (OH6) Design specification API610 Capacity 2~90m3/h Head ~1500m Pressure ~15Mpa T -130~+260 Speed ~22470r/min. Applicable Petrochemical, refining, power station, inorganic chemistry, paper making,environment protect. Summarize Gear up, single stage, single suction. Simple construction, smart axial dimension. The rigidity and intensity will assure the stable operation. Vertical mounted with small space. Gear box made from high strength aluminum alloy, with cooling performance.

APIFLO EGS-W Series horizontal high speed pump Design specification API610 Capacity 2~90m3/h Head ~1500m Pressure ~25Mpa T -130~+340 Speed ~22470r/min. Applicable Petrochemical, refining, power station, inorganic chemistry, paper making, environment protect. Summarize Gear up, single stage, single suction. Simple construction, smart axial dimension. The rigidity and intensity will assure the stable operation. Horizontal mounted, gear box made from spheroidal graphite iron. Very limited and interchangeable parts, easy for maintenance.

PROFLO ANSG series chemical process in-line pump Design specification ANSI B73.1M Capacity 2~250m3/h Head ~150 m T -40~+150 Pressure ~2.0 Mpa Applicable Petrochemical, paper making, oil, chemical, pipeline booster, water supply and sewerage. Summarize Single stage, single suction, inline pump. Inlet and outlet is horizontal concentric. Pump and motor connected with spacer coupling, which is easy for maintenance. Back open impeller, high efficiency, stable performance. External axial adjustment construction.

APIFLO P series Petrochemical Process Pump (OH2) Design specification: API610 Capacity 2~2600m3/h Head ~240m T -80~+450 Pressure EAP ~5.0Mpa; EAPG ~10.0Mpa Applicable: Refinery Petrochemical, chemical, environment protection, low temp, coal, power station, pulp, platform, seawater desalt Summarize: Horizontal, single stage, single suction, radial split, centre-line support volute pump. Volute pump with horizontal single stage, single suction, radial split with centre-line support. interchangeability. high reliability, high efficiency.

APIFLO LF series low flow chemical process pump (OH2) Design specification API610 Capacity 0.4~15m3/h Head ~125m T -80~+450 Pressure ~2.5MPa Applicable chemical, Petrochemical, refining, power station, paper making, medicine, foodstuff, refine sugar. Summarize Single stage, single suction, overhung, radial split, centre-line support volute pump. Closed impeller, which can be designed into semi-open impeller, and the axial force balanced by balancing hole. Kinds of seal type can be fitted. Back pull designing is easy for maintenance. High interchangeability with low operation cost. Oil lubrication controlled by oil cup.

MAGFLO MDP Series magnetic drive pump (OH1/OH2) Design specification API685 Capacity 2~1200m3/h Head ~190m T -80~+350 Pressure ~4.0Mpa Power ~315KW. Applicable Refining, Petrochemical, environment protection, pharmacy, bio engineering, printing and dyeing. Summarize Horizontal, single stage, single suction, radial split. 100% non-leakage, for handling flammable, strongly corrosion and toxic liquid. The designing of flushing, lubrication and cooling device are fully comply with API685 1st revision, which can make internal flushing, external flushing, cooling, filtrate, pressure monitoring.

APIFLO MK series Horizontal Split Multistage Pump (BB3) Design specification API610 Capacity ~800 m3/h Head 140~1000 m T 0~+120 Pressure ~15 MPa Applicable boiler feeding water, offshore platform, Petrochemical, chemical, power station. Summarize Horizontal Split, volute multistage pump. Impeller symmetry distribution, separately orientation for each stage, fully balancing axial force with stable operation. Horizontal split, easy for maintenance. Ring elastic seal fitted between stages, as well as skin gasket between casings.

APIFLO M series Self balanced Horizontal Multistage Pump (BB4) Design specification API610 Capacity ~800 m3/h Head ~2800 m T -80~+450 Pressure ~28 MPa Applicable Petrochemical, chemical, boiler feeding water, seawater, descaling pump, high pressure buck water pump. Summarize Ring section pump multistage pump single casing for MK Series double casings for MKA Series. Long working period, as impeller symmetry distribution and axial force auto balanced. As no balancing system, the fluid with solid particle can be pumped. High reliable operation, as the rigidity shaft.

APIFLO MR / DR Series radiation feed pump (BB4/BB5) Design specification API610 Capacity ~400 m3/h Head ~1000 m T ~+450 Pressure ~15 MPa. Applicable Petrochemical, chemical, coking stoker feed pump, and other working conditions with high temp. and impurity. Summarize Horizontal and ring section pump multistage pump. Single casing for MR Series, double casing for DR Series. Rigidity rotor is high reliable, which can be emergency starting at normal heat impact. Axial force is balanced by balancing system, as well as remnants axial force withstanded by thrust bearing.

VERTIFLO LYA Series long shaft submerged pump Design specification ISO2858 Capacity 2~900m3/h Head 5~135m T -20~+125 Pressure 1.6Mpa Pump length ~7018mm. Applicable Sewage water treatment, cement mill, power station, petrochemical. Summarize Single stage single suction vertical long shaft submerged pump. Reliable connecting shaft, special balancing chamber with high reliability, which can enlarge the maintenance period. Packing seal with self flushing or external flushing, applicable for transferring clean liquid or with some particle.

VERTIFLO LG Series high temperature submerged pump Design specification ISO2858 Capacity 2~400m3/h Head 5~100m T ~+500 Pressure 1.6Mpa Pump length ~5632mm. Applicable chemical, oil industry, refining, iron &steel, power station. Summarize Vertical, single stage, single suction, axial split volute pump. Three kinds of construction. LG for low melting point, the liquid will be concretionary after stop, such as asphaltum; LGJ jacket pump for low melting point, the liquid will be concretionary after stop very soon, such as sulphur.

APIFLO LC series vertical Tank Pump (VS4) Design specification API610 Capacity 2~250m3/h Head ~150m T -20~+250 Pressure 4.0Mpa Pump length ~3535mm. Applicable Petrochemical, chemical, foodstuff, pharmacy, medical, textile, tank and storage. Summarize Single stage, single suction, vertical, volute pump. Rigidity shaft designing. Kinds of mechanical seal can be fitted to assure the safe operation. Pairs of bearing withstand residual axial force and rotor weight. Oil lubrication. Air cooling is applicable for bearing housing, as cooling can be fitted on bearing housing.

APIFLO V series Vertical can pump Design specification API610 Capacity ~800m3/h Head ~800m T -80~+150 Pressure 10.0Mpa Pump length ~2635mm. Applicable Refining, low temp, offshore platform, liquid ammonia, condensation, liquid gas. Summarize Multistage, ring section, vertical construction. First impeller is high NPSH performance. Axial force will be balanced by balance disc. Casing withstand the suction pressure. Pump length will be confirmed according to the NPSHa. It also can be used as multistage submerged pump. Cartridge mechanical seal, as well as dry gas seal.

GLOBAL COVERAGE

YOUR DEEP BLUE PUMP CO AGENT

Headquarters Seggelant Noord 11 3237 MG, Vierpolders The Netherlands T. +31 (0) 181-473872 F. +31 (0) 84-7562066 E. info@deepbluepumps.com W. www.deepbluepumps.com

United Arab Emirates office RAK Free Trade Zone (BC-4) Ras Al Khaimah PO Box 10559 E. uae.sales@deepbluepumps.com

Vous aimerez peut-être aussi

- Winston Engineering CompanyDocument10 pagesWinston Engineering Companylimcsiang99Pas encore d'évaluation

- 001 Manual Data Sheet PipaDocument3 pages001 Manual Data Sheet Pipawahyu hutamaPas encore d'évaluation

- Goulds PumpsDocument44 pagesGoulds PumpscridavarPas encore d'évaluation

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartDocument1 pageMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanPas encore d'évaluation

- List of Machines in Mechanical WorkshopDocument3 pagesList of Machines in Mechanical WorkshopHamza Nouman100% (1)

- Hydro Test Procedure For y Type StrainerDocument8 pagesHydro Test Procedure For y Type StrainernarendraPas encore d'évaluation

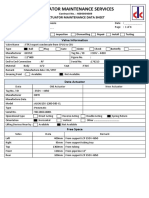

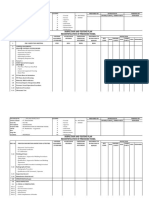

- Actuator Maintenance ServicesDocument7 pagesActuator Maintenance ServicesKevin MuhalingPas encore d'évaluation

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Document1 pageCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaPas encore d'évaluation

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- Jsa For Roof Air LiftDocument2 pagesJsa For Roof Air LiftKoshy ThankachenPas encore d'évaluation

- Standard U BoltDocument4 pagesStandard U BoltSyifa Alfi HabibiPas encore d'évaluation

- Central Processing Facility (CPF) : Inlet ManifoldDocument1 pageCentral Processing Facility (CPF) : Inlet Manifoldfathi100% (1)

- Pressure Vessel Inspection PlanDocument8 pagesPressure Vessel Inspection Plansuratno 25100% (1)

- Is Iso 8573 1 2001Document8 pagesIs Iso 8573 1 2001herrerafaridPas encore d'évaluation

- Elbow Trimming ProcedureDocument5 pagesElbow Trimming ProcedureMechanical Static WRKPas encore d'évaluation

- GT Tray Tower1 PDFDocument12 pagesGT Tray Tower1 PDFJose Christian Viladegut GuzmanPas encore d'évaluation

- Boroscope InspectiónDocument14 pagesBoroscope InspectiónXiomara Hurtado FloresPas encore d'évaluation

- ChecklistDocument2 pagesChecklistdassayevPas encore d'évaluation

- RBR Ball ValveDocument16 pagesRBR Ball Valveeka pramudia santosoPas encore d'évaluation

- AMC-SCHOU Cylindrical Grinders ProfileDocument28 pagesAMC-SCHOU Cylindrical Grinders Profilem_najmanPas encore d'évaluation

- Minimum Length and Spacing For Welded Nozzles PDFDocument7 pagesMinimum Length and Spacing For Welded Nozzles PDFSoniPas encore d'évaluation

- Actuator Maintenance ServicesDocument7 pagesActuator Maintenance ServicesKevin MuhalingPas encore d'évaluation

- Hydraulic Torque WrenchDocument16 pagesHydraulic Torque WrenchMr. S.L. AdvaniPas encore d'évaluation

- JIG (English)Document22 pagesJIG (English)keenis herreraPas encore d'évaluation

- Fluxi 2000 TZ EN-03 - 18Document4 pagesFluxi 2000 TZ EN-03 - 18Praveen KumarPas encore d'évaluation

- Pump Performance Test ProcedureDocument11 pagesPump Performance Test ProcedureAryaPas encore d'évaluation

- Actuation Product Catalogue - OneSteelDocument65 pagesActuation Product Catalogue - OneSteelJOHN100% (1)

- Vessel DesignDocument14 pagesVessel DesignElia MekdadPas encore d'évaluation

- Cameron Ball ValvesDocument31 pagesCameron Ball ValvesJosé Roberto Alejo MirandaPas encore d'évaluation

- AutoPIPE QuickStart - Model Modification - WorkbookDocument63 pagesAutoPIPE QuickStart - Model Modification - WorkbookJames100% (1)

- Hose Reels SriDocument10 pagesHose Reels SriAakashSrivastavaPas encore d'évaluation

- Install, operate and maintain microfinish ball valvesDocument14 pagesInstall, operate and maintain microfinish ball valvesrajputashiPas encore d'évaluation

- Mechanical Datasheet - Wellhead Compressor PackageDocument12 pagesMechanical Datasheet - Wellhead Compressor PackageRokan Pipeline100% (1)

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Document9 pagesJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshPas encore d'évaluation

- Pertamina EP Cepu 2022 Procurement ListDocument2 pagesPertamina EP Cepu 2022 Procurement Listmarketing kinaryaPas encore d'évaluation

- Fan Merk Kruger Model APMDocument4 pagesFan Merk Kruger Model APMKarin Aca OviPas encore d'évaluation

- Coal crushing plant 750 tph performance test recordsDocument2 pagesCoal crushing plant 750 tph performance test recordsariyanagung29Pas encore d'évaluation

- Atbq1714 Measurement I: Piling WorksDocument24 pagesAtbq1714 Measurement I: Piling WorksJIE YI CHENPas encore d'évaluation

- Pump Sizing Fire Hydrant MojoDocument2 pagesPump Sizing Fire Hydrant MojoAnonymous 6S9tcbhPas encore d'évaluation

- Backup Wrench ManualDocument8 pagesBackup Wrench ManualHarold AnilloPas encore d'évaluation

- Ebara Pumps Catalog DVS CatalogueDocument30 pagesEbara Pumps Catalog DVS CataloguePutry Tria ChristyPas encore d'évaluation

- Pump and vacuum pump offer from PT Sumber Waja AbadiDocument2 pagesPump and vacuum pump offer from PT Sumber Waja Abadicia sin kwangPas encore d'évaluation

- Guidelines For Specification of Generating EquipmentDocument81 pagesGuidelines For Specification of Generating Equipmentcrowjik5672100% (1)

- Vortex FlowmeterDocument5 pagesVortex FlowmeterAsthy FaridaPas encore d'évaluation

- Waukesha Knock Index Power CurveDocument1 pageWaukesha Knock Index Power CurveparathasiPas encore d'évaluation

- Rotating Equipment Engineer ResumeDocument3 pagesRotating Equipment Engineer Resumesuba ananth100% (1)

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDocument42 pagesPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplPas encore d'évaluation

- 1847 A Duplex Piston Pump Mud PumpDocument2 pages1847 A Duplex Piston Pump Mud PumpÆmanuel J SilvaPas encore d'évaluation

- XBD SlowDocument11 pagesXBD SlowabsahkahPas encore d'évaluation

- Roof Air Rising of An Ammonia Storage Tank at KPICDocument12 pagesRoof Air Rising of An Ammonia Storage Tank at KPICHgagselim Selim100% (1)

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaPas encore d'évaluation

- Smith Meter VDR Vertical Deaerator SpecificationsDocument8 pagesSmith Meter VDR Vertical Deaerator SpecificationsClarkFedele27Pas encore d'évaluation

- AJAX Brochure PDFDocument8 pagesAJAX Brochure PDFupper20cPas encore d'évaluation

- EBARA Catalogue Fire PumpDocument14 pagesEBARA Catalogue Fire PumpVanja Ivkovic100% (2)

- Safety in Oil Movement & Storage Operations: Reliance JamnagarDocument55 pagesSafety in Oil Movement & Storage Operations: Reliance JamnagarVELPas encore d'évaluation

- MiniElcor EngDocument131 pagesMiniElcor Engroberto casca0% (1)

- Product Range: Pump PerformanceDocument32 pagesProduct Range: Pump PerformanceFlorin StarpituPas encore d'évaluation

- BPC Summer Training OverviewDocument21 pagesBPC Summer Training OverviewAmit PandeyPas encore d'évaluation

- Uhde LDPEDocument11 pagesUhde LDPEmirakel000100% (2)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsD'EverandModeling, Control, and Optimization of Natural Gas Processing PlantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- IPS-e-ce-210, Structural Steel StandardDocument20 pagesIPS-e-ce-210, Structural Steel StandardkhorzooPas encore d'évaluation

- E PR 460Document37 pagesE PR 460khorzooPas encore d'évaluation

- Chapter 7: Design and Operation of Steam-Assisted FlaresDocument44 pagesChapter 7: Design and Operation of Steam-Assisted FlaresBre WirabumiPas encore d'évaluation

- Chapter 7: Design and Operation of Steam-Assisted FlaresDocument44 pagesChapter 7: Design and Operation of Steam-Assisted FlaresBre WirabumiPas encore d'évaluation

- Sp-47-27 (Fire Fighting Equipment and Facilities)Document17 pagesSp-47-27 (Fire Fighting Equipment and Facilities)khorzooPas encore d'évaluation

- Corrosion Characteristics of Aluminum Alloy in Bio-Ethanol Blended Gasoline FuelDocument7 pagesCorrosion Characteristics of Aluminum Alloy in Bio-Ethanol Blended Gasoline FuelkhorzooPas encore d'évaluation

- BP Code GS146-1Document33 pagesBP Code GS146-1khorzooPas encore d'évaluation

- Asme B16.47 PDFDocument25 pagesAsme B16.47 PDFkta_87Pas encore d'évaluation

- Att2 Baretti InternalsDocument36 pagesAtt2 Baretti InternalsAli MetinPas encore d'évaluation

- AMISTCO tower trays guide to sieve, valve, bubble cap & dual flow designsDocument8 pagesAMISTCO tower trays guide to sieve, valve, bubble cap & dual flow designsAnonymous QM0NLqZOPas encore d'évaluation

- BP Code GS146-1Document33 pagesBP Code GS146-1khorzooPas encore d'évaluation

- مقايسه حد پذيرش عيوب براساس استانداردها PDFDocument1 pageمقايسه حد پذيرش عيوب براساس استانداردها PDFeghashangzadehPas encore d'évaluation

- The Oil and Gas Global Salary Guide 2011Document32 pagesThe Oil and Gas Global Salary Guide 2011khorzooPas encore d'évaluation

- Fuel EthanolDocument41 pagesFuel EthanolkhorzooPas encore d'évaluation

- Ground Flare Systems GuideDocument12 pagesGround Flare Systems GuidezopitaPas encore d'évaluation

- Flare Gase Recovery SystemsDocument16 pagesFlare Gase Recovery SystemskhorzooPas encore d'évaluation

- Enclosed Flare Incineration System - Brochure (May 2012)Document10 pagesEnclosed Flare Incineration System - Brochure (May 2012)Chris van der ZandePas encore d'évaluation

- ARAMCO Material SpecificationDocument21 pagesARAMCO Material Specificationkhorzoo83% (6)

- Types TanksDocument17 pagesTypes TanksCarlos Augusto FerreiraPas encore d'évaluation

- Elevated FlareDocument16 pagesElevated FlareDeepak SreekumarPas encore d'évaluation

- Design LNG Storage TanksDocument6 pagesDesign LNG Storage TanksYetkin Erdoğan100% (1)

- Heat Radiation From FlaresDocument90 pagesHeat Radiation From FlaresAman Goel100% (3)

- ABS-Automatic or Remote Control and Monitoring Systems For Vessels in PortDocument10 pagesABS-Automatic or Remote Control and Monitoring Systems For Vessels in PortkhorzooPas encore d'évaluation

- Chapter 7: Design and Operation of Steam-Assisted FlaresDocument44 pagesChapter 7: Design and Operation of Steam-Assisted FlaresBre WirabumiPas encore d'évaluation

- NEMA SM-23 - Steam Turbine For Mechanical Drive SystemDocument62 pagesNEMA SM-23 - Steam Turbine For Mechanical Drive SystemkhorzooPas encore d'évaluation

- Vertical Vessel Design LessonsDocument43 pagesVertical Vessel Design Lessonskhorzoo100% (1)

- Methanol Storage TankDocument7 pagesMethanol Storage Tankkhorzoo100% (1)

- Welding and Inspection of PipingDocument20 pagesWelding and Inspection of PipingMohammed Najim89% (9)

- S-001 - E4 NORSOK Technical IntegrityDocument72 pagesS-001 - E4 NORSOK Technical IntegrityKris TrezegoalPas encore d'évaluation

- Organizaational ChangeDocument94 pagesOrganizaational ChangeAravind Kumar KotamsettyPas encore d'évaluation

- Turbopump Shaft NasaDocument136 pagesTurbopump Shaft NasacarlfelipePas encore d'évaluation

- Reactivity Series Worksheet - 8B and 8CDocument6 pagesReactivity Series Worksheet - 8B and 8CHighlightPas encore d'évaluation

- Lab Technician Interview QuestionsDocument3 pagesLab Technician Interview QuestionsCandra AprizalPas encore d'évaluation

- What Is WeldingDocument4 pagesWhat Is WeldingAnonymous hBBam1nPas encore d'évaluation

- Product Catalogue WEBDocument48 pagesProduct Catalogue WEBSidy Semba DagnogoPas encore d'évaluation

- Cooling Towers: Key Design Factors and Operation PrinciplesDocument8 pagesCooling Towers: Key Design Factors and Operation PrinciplesMade PutraPas encore d'évaluation

- Coating Procedure - Shuqaiq Desalination PJT - Rev.2Document19 pagesCoating Procedure - Shuqaiq Desalination PJT - Rev.2ABAID ULLAHPas encore d'évaluation

- Glass Making TheoryDocument14 pagesGlass Making TheorySK SHAHNAWAZPas encore d'évaluation

- Gen Chem 2 DAILY LESSON LOGDocument8 pagesGen Chem 2 DAILY LESSON LOGMaricriz Bioco100% (1)

- Carbon Activado CabotDocument13 pagesCarbon Activado CabotGuillermo PpdPas encore d'évaluation

- In The Name of GodDocument34 pagesIn The Name of GodFariha NormanPas encore d'évaluation

- Chemistry TextDocument45 pagesChemistry Textariel yana morgaPas encore d'évaluation

- Molecular Orbital Theory Multiple Choice QuestionsDocument3 pagesMolecular Orbital Theory Multiple Choice QuestionsRasel Islam100% (3)

- Noble Gases 20 Aug 2022Document2 pagesNoble Gases 20 Aug 2022PLABAN DASPas encore d'évaluation

- E53-07 (Reapproved 2013) PDFDocument4 pagesE53-07 (Reapproved 2013) PDFearth metallurgical services pvt.ltd.Pas encore d'évaluation

- Using psychrometric charts to analyze HVAC systemsDocument18 pagesUsing psychrometric charts to analyze HVAC systemsRockydel MontesPas encore d'évaluation

- Cap TradeDocument8 pagesCap TradeEkopribadiPas encore d'évaluation

- Chapter Wise QuestionsDocument6 pagesChapter Wise QuestionsDr. B. Sree Giri Prasad100% (2)

- Types of SewerDocument14 pagesTypes of SewerAmbalal DhongadiPas encore d'évaluation

- Pipes, Tubes, Fittings, FlangesDocument121 pagesPipes, Tubes, Fittings, FlangesCarl Jones100% (2)

- Partial replacement of discarded rubber tyres with coarse aggregate in concreteDocument18 pagesPartial replacement of discarded rubber tyres with coarse aggregate in concretePrasanna Gayathri VinnakotaPas encore d'évaluation

- Cells and BatteriesDocument3 pagesCells and BatteriesmelissaPas encore d'évaluation

- Micropitting Can Lead To Macro ProblemsDocument2 pagesMicropitting Can Lead To Macro ProblemsAnonymous alQXB11EgQPas encore d'évaluation

- MSDS Mindray M-30 LyseDocument2 pagesMSDS Mindray M-30 LyseSandra HubayaPas encore d'évaluation

- Opioid Adjuvant in NeuraxialDocument10 pagesOpioid Adjuvant in NeuraxialiswanlatifPas encore d'évaluation

- Astm c1161 13Document19 pagesAstm c1161 13Taiana BonadioPas encore d'évaluation

- Finish Powerball (1999)Document4 pagesFinish Powerball (1999)Jim SmithPas encore d'évaluation

- Capillary Viscometer Calculations for Newtonian & Non-Newtonian FluidsDocument2 pagesCapillary Viscometer Calculations for Newtonian & Non-Newtonian Fluidsgrovestreet1Pas encore d'évaluation

- Building electricity vocabularyDocument9 pagesBuilding electricity vocabularyChan PhakkdeyPas encore d'évaluation