Académique Documents

Professionnel Documents

Culture Documents

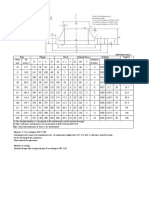

Metric Hex Bolts ISO 4014

Transféré par

sroenschCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metric Hex Bolts ISO 4014

Transféré par

sroenschDroits d'auteur :

Formats disponibles

Cap Screws & Bolts

U H E T

METRIC

R F

Hex Bolts Grade-A & B

L

ISO 4014 F G K

METRIC - HEX H EAD B OLTS, PRODUCT GRADE A

R W T U E H Head Height Max 1.225 1.525 1.825 2.125 2.925 3.65 4.15 5.45 6.58 7.68 8.98 10.18 12.715 15.215 Min 0.975 1.275 1.575 1.875 2.675 3.35 3.85 5.15 6.22 7.32 8.62 9.82 12.285 14.785 Under- Washer Fillet Nominal Thread Threaded Length Washer Face Transition head Face Thickness Size Pitch Diameter Fillet Diameter

L <= 125 L>125mm mm <=200mm

Width WrenchWidth Across Across ing Flats Corners Height Max 3.2 4 5 5.5 7 8 10 13 16** 18** 21** 24 30 36 Min 3.02 3.82 4.82 5.32 6.78 7.78 9.78 12.73 15.73 17.73 20.67 23.67 29.67 35.38 Min 3.41 4.32 5.45 6.01 7.66 8.79 11.05 14.38 17.77 20.03 23.36 26.75 33.53 39.98 Min 0.68 0.89 1.1 1.31 1.87 2.35 2.7 3.61 4.35 5.12 6.03 6.87 8.6 10.35

Max 0.25 0.25 0.25 0.4 0.4 0.5 0.5 0.6 0.6 0.6 0.6 0.8 0.8 0.8

Min 0.1 0.1 0.1 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.15 0.2 0.2 0.2

Max 2 2.6 3.1 3.6 4.7 5.7 6.8 9.2 11.2 13.7 15.7 17.7 22.4 26.4

Max 0.6 0.8 1 1 1.2 1.2 1.4 2 2 3 3 3 4 4

Min 2.27 3.07 4.07 4.57 5.88 6.88 8.88 11.63 14.63 16.63 19.37 22.49 28.19 33.61

M1.6 M2 M2.5 M3 M4 M5 M6 M8 M10 M12 M14 M16 M20 M24

0.35 0.4 0.45 0.5 0.7 0.8 1 1.25 1.5 1.75 2 2 2.5 3

9 10 11 12 14 16 18 22 26 30 34 38 46 54

40 44 52 60 73*

Tolerance on Length

12-16mm: 0.35

20-30mm: 0.42 90-120: 0.7

35-50mm: 0.5

55-80mm: 0.6

130-150mm: 0.8

*For nominal lengths over 200mm. **DIN 931 spec for maximum width across flats on these three diameters are 17, 19 & 22 mm, respectively.

METRIC - HEX HEAD B OLTS, PRODUCT GRADE B

R W T U E Washer Face Diameter Min 22 27.7 33.25 42.75 51.11 59.95 69.45 78.66 88.16 H Head Height Max 10.29 12.85 15.35 19.12 22.92 26.42 30.42 35.5 40.5 Min 9.71 12.15 14.65 18.28 22.08 25.58 29.58 34.5 39.5 F G UnderFillet Nominal Thread Threaded Length Washer Face Transition head Thickness Diameter Size Pitch Fillet

L>125mm <=200mm L>200 mm

ISO 4014 K

Width WrenchWidth Across ing Across Flats Corners Height Max 24 30 36 46 55 65 75 85 95 Min 23.16 29.16 35 45 53.8 63.1 73.1 82.8 92.8 Min 26.17 32.95 39.55 50.85 60.79 71.3 82.6 93.56 104.86 Min 6.8 8.51 10.26 12.8 15.46 17.91 20.71 24.15 27.65

Max 0.8 0.8 0.8 0.8 0.8 1 1 1 1

Min 0.2 0.2 0.2 0.2 0.2 0.3 0.3 0.3 0.3

Max 17.7 22.4 26.4 33.4 39.4 45.6 52.6 63 71

Max 3 4 4 6 6 8 10 12 13

M16 M20 M24 M30 M36 M42 M48 M56 M64

2 2.5 3 3.5 4 4.5 5 5.5 6

44 52 60 72 84 96 108 -

73 85 97 109 121 137 153

Tolerance on Length

110-120mm: 1.75

130-180mm: 2.0

200-240mm: 2.3

260-300mm: 2.6

320-400mm: 2.85

420-500mm: 3.15

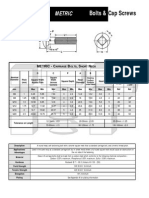

Hex Bolts Class 8.8 & 10.9

METRIC

Bolts & Cap Screws

8.8

8.8

CLASS 8.8 BOLTS

A hex bolt with metric thread pitch made from medium carbon steel and heat-treated. Grade-A bolts are the preferred style for most applications. Grade-B bolts have looser tolerances and can be manufactured in a cold or hot-forging process. Has greater tensile strength than Class 4.6, 4.8 and 5.8 bolts. Class 8.8 bolts can be made from a carbon steel with additives (such as Boron, Manganese or Chromium) which conforms to the following chemical composition-- Carbon: 0.15-0.40%; Phosphorus: 0.035% maximum; Sulfur: 0.035% maximum. In case of plain carbon boron alloyed steel with a carbon content of less than 0.25% (ladle analysis), the minimum Manganese content shall be 0.6% Class 8.8 bolts can be made from a carbon steel which conforms to the following chemical composition-- Carbon: 0.25-0.55%; Phosphorus: 0.035% maximum; Sulfur: 0.035% maximum.

Description Applications/ Advantages

Material

Heat Treatment Core Hardness Surface Hardness Proof Load Tensile Strength Elongation Plating

Class 8.8 bolts shall be heat treated by quenching in a liquid medium from above the transformation temperature and reheating to a tempering temperature of 425C. For diameters less than or equal to 16mm: Rockwell C22 - 32 (Vickers HV 250 - 320) For diameters greater than 16mm: Rockwell C23 - 34 (Vickers HV 255 - 335) Shall not be more than 30 Vickers points above the measured core hardness on the product For diameters less than or equal to 16mm: 640 N/mm2 minimum For diameters greater than 16mm: 660 N/mm2 minimum For diameters less than or equal to 16mm: 800 N/mm2 minimum For diameters greater than 16mm: 830 N/mm2 minimum 12% minimum See Appendix-A for plating information

10.9 10.9

CLASS 10.9 BOLTS

A bolt with metric thread pitch made from medium carbon alloy steel and heat-treated. Grade-A bolts are the preferred style for most applications. Grade-B bolts have looser tolerances and can be manufactured in a cold or hot-forging process. Has greater tensile strength than Class 8.8 bolts; is most comparable but not exactly equivalent to U.S. Grade 8 cap screws. Class 10.9 bolts can be made from a carbon steel which conforms to the following chemical composition-- Carbon: 0.25-0.55%; Phosphorus: 0.035% maximum; Sulfur: 0.035% maximum. Class 10.9 bolts can be made from a low carbon martensite steel with additives (such as Boron, Manganese or Chromium) which conforms to the following chemical composition-- Carbon: 0.20-0.55%; Phosphorus: 0.035% maximum; Sulfur: 0.035% maximum. In case of plain carbon boron alloyed steel with a carbon content 0f less than 0.25% (ladle analysis), the minimum Manganese content shall be 0.7% Class 10.9 bolts can be made from an alloy steel which conforms to the following chemical composition-Carbon: 0.20-0.55%; Phosphorus: 0.035% maximum; Sulfur: 0.035% maximum; and shall contain one or more of the following elements: Chromium, Nickel, Molybdenum or Vanadium

Description Applications/ Advantages

Material

Heat Treatment Core Hardness Surface Hardness Proof Load Tensile Strength Elongation Plating

Class 10.9 bolts shall be heat treated by quenching in oil from above the transformation temperature and reheating to a tempering temperature of 425C. Rockwell C32 - 39 (Vickers HV 320 - 380) Shall not be more than 30 Vickers points above the measured core hardness on the product 940 N/mm2 minimum 1040 N/mm2 minimum 9% minimum See Appendix-A for plating information

Vous aimerez peut-être aussi

- Lister Hr3 ManualDocument119 pagesLister Hr3 ManualRichard Gomez Cueva100% (2)

- C79 Service Kits and Parts List: CAP179 - C79 Aug 2017 - Rev ADocument32 pagesC79 Service Kits and Parts List: CAP179 - C79 Aug 2017 - Rev Arobert100% (2)

- Bs-3692 Iso Metric Precision Hexagon Bolts, Screws, and NutsDocument34 pagesBs-3692 Iso Metric Precision Hexagon Bolts, Screws, and NutsUmesh ChamaraPas encore d'évaluation

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekPas encore d'évaluation

- Bolting Information Pertaining To ASTM A193Document25 pagesBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Iso 10511 Nut Dimensions - RefDocument2 pagesIso 10511 Nut Dimensions - Refkumarkk1969Pas encore d'évaluation

- Din 267-3 - 08.83Document2 pagesDin 267-3 - 08.83gkhnPas encore d'évaluation

- 1DIN 6921-10.9 Hex Flange Bo.Document2 pages1DIN 6921-10.9 Hex Flange Bo.Sunil BaliPas encore d'évaluation

- Bolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDocument2 pagesBolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDeepakGawasPas encore d'évaluation

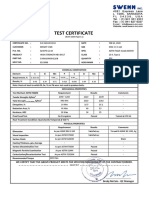

- Test Certificate: (BS EN 10204 Type 3.1)Document1 pageTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarPas encore d'évaluation

- Tightening Torques PDFDocument1 pageTightening Torques PDFlaweencePas encore d'évaluation

- 12 Point Flange ScrewsDocument1 page12 Point Flange ScrewsstugwynnePas encore d'évaluation

- Asme B18.16.6Document1 pageAsme B18.16.6Mario FonsecaPas encore d'évaluation

- Iso 7380Document1 pageIso 7380MarioPas encore d'évaluation

- Merkblatt DVS 1617Document5 pagesMerkblatt DVS 1617ryo_brawoPas encore d'évaluation

- L9 Fastening System PDFDocument6 pagesL9 Fastening System PDFMarcel BaquePas encore d'évaluation

- Din 976-1 1995Document6 pagesDin 976-1 1995Charmaine DrafkePas encore d'évaluation

- DIN ISO 3302-1: Nominal Dimension Class M1 Class M2 Class M3 Class M4Document1 pageDIN ISO 3302-1: Nominal Dimension Class M1 Class M2 Class M3 Class M4Augusto PeinadoPas encore d'évaluation

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDFrancisco RojasPas encore d'évaluation

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDocument1 page024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaPas encore d'évaluation

- Din 434Document1 pageDin 434RaduZapciroiuPas encore d'évaluation

- Metric Heavy Hex Nut DimensionsDocument3 pagesMetric Heavy Hex Nut DimensionsSenthillkumar BalasubramaniamPas encore d'évaluation

- Astm A194Document11 pagesAstm A194Jarek CieslakPas encore d'évaluation

- Techincal Data For PCD Dia & Torque ChartDocument1 pageTechincal Data For PCD Dia & Torque ChartTuff quality100% (1)

- DuraSquirt RCSC 2.12.5Document6 pagesDuraSquirt RCSC 2.12.5rob westoverPas encore d'évaluation

- Tightening TorqueDocument2 pagesTightening TorqueMehul BansalPas encore d'évaluation

- Screw, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDocument1 pageScrew, DIN 7500TX 7500CE DIN 7500-1, Thread Forming Screw, Metric, TorxDerekPas encore d'évaluation

- Din 6798 ADocument3 pagesDin 6798 ADuong BachPas encore d'évaluation

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFLiu YangtzePas encore d'évaluation

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinPas encore d'évaluation

- Astm A31 (1995)Document4 pagesAstm A31 (1995)gsb2100% (1)

- Fittings Din11852 Din11850Document14 pagesFittings Din11852 Din11850dingobk1Pas encore d'évaluation

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoPas encore d'évaluation

- ISO 14583-01 - Hexalobular Socket Pan Head ScrewsDocument8 pagesISO 14583-01 - Hexalobular Socket Pan Head ScrewsGuillermo TorresPas encore d'évaluation

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönPas encore d'évaluation

- Conical Seat Spherical Washer Is 4297Document6 pagesConical Seat Spherical Washer Is 4297Rajasekaran Murugan0% (1)

- DIN 934 NutsDocument1 pageDIN 934 NutsleroniusPas encore d'évaluation

- 803 Aluminum Alloys For Chill Casting and Low Pressure CastingDocument4 pages803 Aluminum Alloys For Chill Casting and Low Pressure Castingketan1965Pas encore d'évaluation

- Steel Standards PDFDocument50 pagesSteel Standards PDFstallone21Pas encore d'évaluation

- Unsintered Polytetrafluoroethylene (PTFE) Extruded Film or TapeDocument4 pagesUnsintered Polytetrafluoroethylene (PTFE) Extruded Film or TapeShiv PandeyPas encore d'évaluation

- ISO Tolerances For FastenersDocument2 pagesISO Tolerances For Fastenersganeshl08Pas encore d'évaluation

- Stainless Steel Metric Bolts, Screws, and Studs: Standard Specification ForDocument9 pagesStainless Steel Metric Bolts, Screws, and Studs: Standard Specification ForaryopnPas encore d'évaluation

- Oread 8.8 Metric Bolt Torque Table 2018Document1 pageOread 8.8 Metric Bolt Torque Table 2018Athul T.NPas encore d'évaluation

- Cmpl-Bolt and Torque Specifications UsDocument3 pagesCmpl-Bolt and Torque Specifications UsYanina CamonesPas encore d'évaluation

- (JISF) : Japanes E IndustrialDocument19 pages(JISF) : Japanes E IndustrialTrịnh Thanh TùngPas encore d'évaluation

- Procedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Document14 pagesProcedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Sayed Diab AlsayedPas encore d'évaluation

- ASTM Bolts Grade MarkDocument8 pagesASTM Bolts Grade MarkpouyaPas encore d'évaluation

- Hex Bolts Grade A B Metric PDFDocument2 pagesHex Bolts Grade A B Metric PDFRAMAKRISHNAN RPas encore d'évaluation

- Metric Carriage ShortneckDocument1 pageMetric Carriage ShortneckStefan StereaPas encore d'évaluation

- John Crane 502Document6 pagesJohn Crane 502Eh OngPas encore d'évaluation

- AEGNEP Compressed AirDocument42 pagesAEGNEP Compressed AirDavid HayesPas encore d'évaluation

- Next Generation: Ultragrip Reducing CouplingsDocument1 pageNext Generation: Ultragrip Reducing CouplingsblindjaxxPas encore d'évaluation

- PC WireDocument7 pagesPC Wirejupe01Pas encore d'évaluation

- Roll PinsDocument8 pagesRoll Pinshemanth337Pas encore d'évaluation

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryPas encore d'évaluation

- Userguide For SSDocument26 pagesUserguide For SSehsan4uPas encore d'évaluation

- Heavy Hex NutsDocument3 pagesHeavy Hex NutsAhmadreza AminianPas encore d'évaluation

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081Pas encore d'évaluation

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoPas encore d'évaluation

- CapScrewA325 A490Document2 pagesCapScrewA325 A490sergiosilvahPas encore d'évaluation

- Eurosurv 27 26 1Document6 pagesEurosurv 27 26 1sroenschPas encore d'évaluation

- Nasa STD 5001a Approved 2008-08-05Document20 pagesNasa STD 5001a Approved 2008-08-05sroenschPas encore d'évaluation

- Roensch - The Finite Element MethodDocument8 pagesRoensch - The Finite Element MethodsroenschPas encore d'évaluation

- Ansibifma x5 12011 Office ChairsDocument4 pagesAnsibifma x5 12011 Office ChairssroenschPas encore d'évaluation

- ANSYS Hyperelastic MaterialsDocument188 pagesANSYS Hyperelastic MaterialssroenschPas encore d'évaluation

- Purdue ME 452 Machine Design II Hw5csol - sp12Document9 pagesPurdue ME 452 Machine Design II Hw5csol - sp12sroenschPas encore d'évaluation

- Roensch - The Finite Element MethodDocument8 pagesRoensch - The Finite Element MethodsroenschPas encore d'évaluation

- Wilson Clough FEM HistoryDocument35 pagesWilson Clough FEM Historygene_sparcPas encore d'évaluation

- Holo-Krome Catalog March 2016Document40 pagesHolo-Krome Catalog March 2016sroenschPas encore d'évaluation

- Esdep Lecture Note (Wg12)Document43 pagesEsdep Lecture Note (Wg12)sroenschPas encore d'évaluation

- Roensch - The Finite Element Method - A Four-Article SeriesDocument8 pagesRoensch - The Finite Element Method - A Four-Article SeriessroenschPas encore d'évaluation

- BIFMA Chair Standards PDFDocument2 pagesBIFMA Chair Standards PDFsroenschPas encore d'évaluation

- NIST - US Furniture Compliance RequirementsDocument29 pagesNIST - US Furniture Compliance RequirementssroenschPas encore d'évaluation

- Kerr Lakeside Socket Head ProductsDocument11 pagesKerr Lakeside Socket Head Productssroensch100% (1)

- Chapter 1 - S10Document44 pagesChapter 1 - S10Amanda SmithPas encore d'évaluation

- Fatigue of Bolts in Aircraft Applications PDFDocument58 pagesFatigue of Bolts in Aircraft Applications PDFsroenschPas encore d'évaluation

- Cleaves - Properties of High Purity IronDocument32 pagesCleaves - Properties of High Purity IronsroenschPas encore d'évaluation

- Product Data Sheet: Socket Head Cap ScrewsDocument2 pagesProduct Data Sheet: Socket Head Cap ScrewssroenschPas encore d'évaluation

- Torque Data ChartDocument2 pagesTorque Data ChartAscenderBSP100% (1)

- NIST - US Furniture Compliance RequirementsDocument29 pagesNIST - US Furniture Compliance RequirementssroenschPas encore d'évaluation

- Torque Data ChartDocument2 pagesTorque Data ChartAscenderBSP100% (1)

- Roensch - The Finite Element Method - A Four-Article SeriesDocument8 pagesRoensch - The Finite Element Method - A Four-Article SeriessroenschPas encore d'évaluation

- The Finite Element MethodDocument8 pagesThe Finite Element MethodsroenschPas encore d'évaluation

- Tutorial Chapter 2Document5 pagesTutorial Chapter 2Naasir SheekeyePas encore d'évaluation

- Acceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderDocument2 pagesAcceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderAnushka SharmaPas encore d'évaluation

- Product Management PRELIM EXAMDocument24 pagesProduct Management PRELIM EXAMAlyssa mariePas encore d'évaluation

- HP RT3000 G2 Toronto UPS SpecsDocument13 pagesHP RT3000 G2 Toronto UPS SpecsJokBalingitPas encore d'évaluation

- Thermo 5th Chap17 P096Document19 pagesThermo 5th Chap17 P096UTA - Std - Elvin ChantrePas encore d'évaluation

- Healing GardensDocument7 pagesHealing GardensElvaPas encore d'évaluation

- Please Complete The Information Requested Below: COMPANY NAME: X2 Logics Staffing Solution, IncDocument2 pagesPlease Complete The Information Requested Below: COMPANY NAME: X2 Logics Staffing Solution, Incwasim riyazPas encore d'évaluation

- Sony HCD Dx8Document66 pagesSony HCD Dx8videoson100% (1)

- GS at CPP HuyHoang CodeDocument285 pagesGS at CPP HuyHoang CodeTran Bach DangPas encore d'évaluation

- Pre-Placement Training Program: Sample Profiling (All About You)Document2 pagesPre-Placement Training Program: Sample Profiling (All About You)RISHAV RAJ GUPTAPas encore d'évaluation

- Reemergent Scientism, Postmodernism, and Dialogue Across DifferencesDocument7 pagesReemergent Scientism, Postmodernism, and Dialogue Across DifferencesJose Luis Ramos CañonPas encore d'évaluation

- Precast Concrete ConstructionDocument37 pagesPrecast Concrete ConstructionRuta Parekh100% (1)

- 01-Toy Product DesignDocument54 pages01-Toy Product DesignJuanPas encore d'évaluation

- Wind Load On StructuesDocument14 pagesWind Load On StructuesNasri Ahmed mohammedPas encore d'évaluation

- 1 Conformity Asch StudyDocument31 pages1 Conformity Asch StudyjasbruPas encore d'évaluation

- An Automated Test and Measurement System For Calibration of Industrial FlowmetersDocument2 pagesAn Automated Test and Measurement System For Calibration of Industrial FlowmetersfredpintoPas encore d'évaluation

- Ballsim DirectDocument58 pagesBallsim DirectDiego GaliciaPas encore d'évaluation

- Proc.-02 GTAW - PAWDocument37 pagesProc.-02 GTAW - PAWRaghu vamshiPas encore d'évaluation

- Pascal LawDocument17 pagesPascal LawJasmandeep brarPas encore d'évaluation

- Balanced Cable Measurement Using The 4-Port ENADocument9 pagesBalanced Cable Measurement Using The 4-Port ENAA. VillaPas encore d'évaluation

- Oracle CRM On DemandDocument2 pagesOracle CRM On Demandajazahmednet3946Pas encore d'évaluation

- 1xEV RF Optimization Guidelines R24Document83 pages1xEV RF Optimization Guidelines R24lady_sPas encore d'évaluation

- Ass AsDocument2 pagesAss AsMukesh BishtPas encore d'évaluation

- ECM 206 Site VisitDocument36 pagesECM 206 Site VisitAZUAN BIN AHMAD FAUZI100% (2)

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112Rupendra palPas encore d'évaluation

- ApolloBVM PDFDocument41 pagesApolloBVM PDFShiva KumarPas encore d'évaluation