Académique Documents

Professionnel Documents

Culture Documents

Shimano Alivio

Transféré par

Brent MitchellDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Shimano Alivio

Transféré par

Brent MitchellDroits d'auteur :

Formats disponibles

SI-6TD0A-002-00

General Safety Information

WARNING

Maintenance interval depends on the usage and riding circumstances. Clean regularly the chain with an appropriate chaincleaner. Never use alkali based or acid based solvents such as rust cleaners. If those solvent be used chain might break and cause serious injury.

Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose in any way, they may come off the bicycle and serious injury may result. Use the reinforced connecting pin only for connecting the narrow type of chain. There are two different types of reinforced connecting Reinforced Chain Chain tool pins available. Be sure to check the table below before connecting pin selecting which pin to use. 9-speed super narrow If connecting pins other than reinforced connecting chain such as TL-CN32 / TL-CN27 Silver pins are used, or if a reinforced connecting pin or tool 6.5mm CN-7701 / CN-HG93 which is not suitable for the type of chain is used, 8- / 7- / 6-speed narrow sufficient connection force may not be obtained, which chain such as TL-CN32 / TL-CN27 Black could cause the chain to break or fall off. 7.1mm CN-HG50 / CN-HG40 If it is necessary to adjust the length of the chain due Reinforced Connecting Pin to a change in the number of sprocket teeth, make the cut at some other place than the place where the chain has been joined using a reinforced connecting pin or an end pin. The chain will be damaged if it is cut at a place where it has been joined with a reinforced connecting pin or an end pin. Link Pin Check that the tension of the chain is correct and that the chain is not damaged. If the tension is End Pin too weak or the chain is damaged, the chain should be replaced. If this is not done, the chain may break and cause serious injury. Use a front chainwheel which is compatible with 9-speed chains in conjunction with Shimano CN-HG73 and CN-HG53 chains. If a chainwheel for an 8-speed chain or less is used, front chainwheel gear shifting problems may occur, or the chain pins might fall out, causing the chain to break. Obtain and read the service instructions carefully prior to installing the parts. Loose, worn or damaged parts may cause the bicycle to fall over and serious injury may occur as a result. We strongly recommend only using genuine Shimano replacement parts. Obtain and read the service instructions carefully prior to installing the parts. If adjustments are not carried out correctly, the chain may come off and this may cause you to fall off the bicycle which could result in serious injury. Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Cassette sprocket tooth combination

Model number CS-HG50-9 CS-HG30-9 CS-HG61 Group name ar au bg Gears 9 9 9 Tooth combination 11, 12, 14, 16, 18, 21, 24, 28, 32T 11, 13, 15, 17, 20, 23, 26, 30, 34T 11, 12, 13, 14, 16, 18, 21, 24, 28T

Freehub

Model number Gears No. of spoke holes FH-M430 / FH-M435 9 36 / 32

SIS Adjustment

1. Top adjustment

Turn the top adjustment screw to adjust so that the guide pulley is in line with the outer line of the smallest sprocket when looking from the rear.

Outer line of smallest sprocket

5. SIS Adjustment

Operate the shifting lever several times to move the chain to the 2nd sprocket. Then, while pressing the lever just enough to take up the play in the lever, turn the crank arm.

1 2

When shifting to 3rd

When no sound at all is heard

Guide pulley

Gear shifting operation

This release lever is equipped with a 2-way release mechanism which allows release operations to be carried out by either pushing or pulling the lever. Both lever (A) and lever (B) always return to the initial position when they are released after shifting. When operating one of the levers, always be sure to turn the crank arm at the same time.

Top adjustment screw Adjustment bolt

Adjustment bolt

2. Connection and securing of the inner cable

Operate lever (B) 8 or more times to set the lever to the highest position, check on the indicator that the highest position is correct, and then install and adjust the inner cable.

Lever (B)

To shift from a small sprocket to a larger sprocket (Lever A)

To shift one step only, press lever (A) to the (1) position. To shift two steps at one time, press to the (2) position.

Lever (A) initial position

To shift from a large sprocket to a smaller sprocket (Lever B)

Press lever (B) once to shift one step from a larger to a smaller sprocket.

Tighten the outer casing adjustment barrel until the chain returns to the 2nd sprocket. (clockwise)

Loosen the outer casing adjustment barrel until the chain touches the 3rd sprocket and makes noise. (counter clockwise)

Best setting

Install the inner hole cover by turning it as shown in the illustration until it stops. Do not turn it any further than this, otherwise it may damage the screw thread.

Feed lever Unit cover

The best setting is when the shifting lever is operated just enough to take up the play and the chain touches the 3rd sprocket and makes noise.

* Return the lever to its original position (the position where the lever is at the 2nd sprocket setting and it has been released) and then turn the crank arm clockwise. If the chain is touching the 3rd sprocket and making noise, turn the outer casing adjustment barrel clockwise slightly to tighten it until the noise stops and the chain runs smoothly.

Lever (B)

2-way release

Inner hole cover

Note

If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts. If the amount of looseness in the links is so great that adjustment is not possible, you should replace the derailleur. You should periodically clean the derailleur and lubricate all moving parts (mechanism and pulleys). If gear shifting adjustment cannot be carried out, check the degree of parallelism at the rear end of the bicycle. Also check if the cable is lubricated and if the outer casing is too long or too short. If you hear abnormal noise as a result of looseness in a pulley, you should replace the pulley. If the wheel becomes stiff and difficult to turn, you should lubricate it with grease. Do not apply any oil to the inside of the hub, otherwise the grease will come out. You should periodically wash the sprockets in a neutral detergent and then lubricate them again. In addition, cleaning the chain with neutral detergent and lubricating it can be a effective way of extending the useful life of the sprockets and the chain. If the chain keeps coming off the sprockets during use, replace the sprockets and the chain. Use a frame with internal cable routing is strongly discouraged as it has tendencies to impair the SIS shifting function due to its high cable resistance. Group marks Always be sure to use the sprocket set bearing the same group marks. Never use in combination with a sprocket bearing a different group mark. Use an outer casing which still has some length to spare even when the handlebars are turned all the way to both sides. Furthermore, check that the shifting lever does not touch the bicycle frame when the handlebars are turned all the way. Grease the inner cable and the inside of the outer casing before use to ensure that they slide properly. For smooth operation, use the specified outer casing and the bottom bracket cable guide. Operation of the levers related to gear shifting should be made only when the front chainwheel is turning. Do not disassemble the indicator and shifting lever unit, as this may damage them or cause mis-operation. Parts are not guaranteed against natural wear or deterioration resulting from normal use. For maximum performance we highly recommend Shimano lubricants and maintenance products For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a professional bicycle dealer.

ag - 18T

ag -15

T

Installation of the rear derailleur

When installing, be careful not to let the B-tension adjustment screw come into contact with the dropout tab, otherwise deformation may result.

Bracket spindle Tightening torque : 8 - 10 Nm {70 - 86 in. lbs.}

Marking Dropout tab 5 mm Allen key B-tension adjustment screw

Operate lever to change gears, and check that no noise occurs in any of the gear positions. For the best SIS performance, periodically lubricate all power-transmission parts.

Inserting the inner cable

Insert the inner cable into the outer casing from the end with the marking on it. Apply grease from the end with the marking in order to maintain cable operating efficiency.

Replacement of the freewheel body

After removing the hub axle, remove the freewheel body fixing bolt (inside the freewheel body), and then replace the freewheel body. Note: Do not attempt to disassemble the freewheel body, because it may result in a malfunction.

Freewheel body Freewheel body fixing bolt

Cutting the outer casing

When cutting the outer casing, cut the opposite end to the end with the marking. After cutting the outer casing, make the end round so that the inside of the hole has a uniform diameter.

Disassembly

ag -1

3T

Installation of the sprockets

For each sprocket, the surface that has the group mark should face outward and be positioned so that the wider part of each sprocket and the A part (where the groove width is wide) of the freewheel body are aligned.

A The groove is wide at

one place only.

ac -14T

Attach the same outer end cap to the cut end of the outer casing. For installation of the sprockets, use the special tool (TL-LR15 / LR10) to tighten the lock ring.

Tightening torque: 30 - 50 Nm {261 - 434 in. lbs.}

Outer end cap

Assembly

Freewheel body washer 10 mm Allen key (TL-WR37)

SH IM

Technical Service Instructions

SI-6TD0A-002

14 T

S

4 0 0 kg /c

Lock ring

In order to realize the best performance, we recommend that the following combination be used.

Series RAPIDFIRE-Plus Outer casing Rear derailleur Type Freehub Gears Cassette sprocket Chain Bottom bracket guide Alivio SL-M430 SIS-SP40 RD-M430 SGS FH-M430 / FH-M435 9 CS-HG61 / CS-HG50-9 / CS-HG30-9 CN-HG53 SM-SP17 / SM-BT17

14 T

13T

15 T

CS-HG50-9 / CS-HG30-9 (au)

9S

AN JA P

Lock ring

Sprocket spacers

13

T

ar

ba

CS-HG61 (bg)

9S 9S

16T

aQ

AN JA P

12T

Specifications

Lock ring

Rear Derailleur

Model number Type Gears Total capacity Applicable sprocket combination Smallest sprocket Front chainwheel tooth difference RD-M430 SGS 9 45T 11 - 32T, 11 - 34T, 11 - 28T 11T 22T

Chain

Chain length

Add 2 links (with the chain on both the largest sprocket and the largest chainring)

Largest chainring Largest chainring

Installation of the lever

Use a handlebar grip with a maximum outer diameter of 36 mm.

This service instruction explains how to use and maintain the Shimano bicycle parts which have been used on your new bicycle. For any questions regarding your bicycle or other matters which are not related to Shimano parts, please contact the place of purchase or the bicycle manufacturer.

5 mm Allen key

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

* Service Instructions in further languages are available at : http://techdocs.shimano.com

Please note: specifications are subject to change for improvement without notice. (English) Dec. 2009 by Shimano Inc. XBC IZM Printed in Singapore.

Install the shifting lever in a position where it will not obstruct brake operation and gear shifting operation. Do not use in a combination which causes brake operation to be obstructed.

-M

96

11T

-M

96

11T

.S

. PA

T 4268

25

Rear Drive System

CK LO

O AN

HYPERGL I DE - C

Wide part

Tightening torque: 35 - 50 Nm {305 - 434 in. lbs.}

To replace the sprockets, use the special tool (TL-LR15 / LR10) and TL-SR21 to remove the lock ring.

Connect the cable to the rear derailleur and, after taking up the initial slack in the cable, re-secure to the rear derailleur as shown in the illustration.

Note: Be sure that the cable is securely in the groove.

Replacement of the indicator

Disassembly and reassembly should only be carried out when replacing the indicator.

Groove

CS-HG50-9 / CS-HG30-9 (ar)

IM

A NO

HYP

ER

G

DE L I

- C

J AP

Pull Tightening torque : 5 - 7 Nm {44 - 60 in. lbs.}

Lock ring

1. Remove the two indicator set screws which are securing the

indicator.

Tightening torque : 0.3 - 0.5 Nm {3 - 4 in. lbs.}

AN

2. Remove the indicator unit as 3. Low adjustment

TL-LR15/LR10

30T

Indicator set screws

shown in the illustration.

Tool (TL-SR21)

Disassembly

P ER G L I D E HY

as

11T

Turn the low adjustment screw so that the guide pulley moves to a position directly in line with the largest sprocket.

3. Operate lever (B) at least eight

times to set the lever to the highest position.

Indicator

34T

17T 23T 20T 26T

au

as

au

as

au

CS

asap

ap ap as as as ap as

Lever (B) Largest sprocket Guide pulley

1 2 1

Low adjustment screw

11

T

aQ

ar

P ER G L I D E HY

CS

ba

4. How to use the B-tension adjustment screw

Mount the chain on the smallest chainring and the largest sprocket, and turn the crank arm backward. Then turn the B-tension adjustment screw to adjust the guide pulley as close to the sprocket as possible but not so close that it touches. Next, set the chain to the smallest sprocket and repeat the above to make sure that the pulley does not touch the sprocket.

Largest sprocket Smallest sprocket

4. After checking that the indicator needle is at the left edge, install

the indicator from directly above.

5. Check the operation of the indicator. If it does not operate

correctly, re-install the indicator while taking particular note of steps 3. to 4. Do not disassemble the indicator and shifting lever unit, as this may damage them or cause mis-operation.

2 2

1 1 1

Tightening torque : 5 Nm {44 in. lbs.}

B-tension adjustment screw

Vous aimerez peut-être aussi

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsD'EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsÉvaluation : 5 sur 5 étoiles5/5 (1)

- rd-m592 2Document1 pagerd-m592 2faizgpPas encore d'évaluation

- SI 5VV0B en v1 m56577569830604982Document1 pageSI 5VV0B en v1 m56577569830604982iodinPas encore d'évaluation

- SI 6PZRA 003 ENG - v1 - m56577569830677284Document1 pageSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5Pas encore d'évaluation

- DL RD m760 2 PDFDocument1 pageDL RD m760 2 PDFtudor-72Pas encore d'évaluation

- Shimano XTDocument1 pageShimano XTVennia PapadipoulouPas encore d'évaluation

- Shimano Tourney Rear and Knob AdjustmentDocument1 pageShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetPas encore d'évaluation

- SI 6VJRA 001 00 Eng - v1 - m56577569830769083Document1 pageSI 6VJRA 001 00 Eng - v1 - m56577569830769083chandlerPas encore d'évaluation

- Manuale Cambio ShimanoDocument1 pageManuale Cambio ShimanoPaola CapassoPas encore d'évaluation

- ShimanoDocument1 pageShimanoProto Popescu VictorPas encore d'évaluation

- Shimano Ultegra 6700 Shifters Double Owners ManualDocument2 pagesShimano Ultegra 6700 Shifters Double Owners ManualTimPas encore d'évaluation

- Shimano 105 5700 Rear Derailleur Installation ManualDocument2 pagesShimano 105 5700 Rear Derailleur Installation ManualjjjPas encore d'évaluation

- SI-5TK0D-En v1 m56577569830603908Document1 pageSI-5TK0D-En v1 m56577569830603908dcduquPas encore d'évaluation

- Si F570CDocument1 pageSi F570CmegclayPas encore d'évaluation

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverDocument3 pagesFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5Pas encore d'évaluation

- Alivio Front Drive SI-6KFFA - v1 - m56577569830565035Document1 pageAlivio Front Drive SI-6KFFA - v1 - m56577569830565035setze16setze16Pas encore d'évaluation

- Shimano XTR M980 Shift Lever Set ManualDocument4 pagesShimano XTR M980 Shift Lever Set ManualNick SpeisPas encore d'évaluation

- Disc BrakeDocument1 pageDisc BrakepahelwanPas encore d'évaluation

- 6jr0a enDocument0 page6jr0a enBilly GeorgiouPas encore d'évaluation

- SH Cset m151 Front Chainwheel FC-M151Document2 pagesSH Cset m151 Front Chainwheel FC-M151Ingrid VantaPas encore d'évaluation

- MTB Technology: FRONT CHAINWHEEL: InstallationDocument4 pagesMTB Technology: FRONT CHAINWHEEL: InstallationRoy Chung Qi Huan100% (1)

- Shimano Tiagra 4600Document1 pageShimano Tiagra 4600Florian JurinPas encore d'évaluation

- Moulton TSR APB SuspensionDocument5 pagesMoulton TSR APB SuspensionteuapPas encore d'évaluation

- DM FD0001 00 EngDocument29 pagesDM FD0001 00 EngpietouPas encore d'évaluation

- Hoist Drum Brake Maintenance: Inspection, Adjustment, Testing and ReplacementDocument6 pagesHoist Drum Brake Maintenance: Inspection, Adjustment, Testing and ReplacementDaniel TostaPas encore d'évaluation

- Inter BrakeDocument1 pageInter BrakedovlikusPas encore d'évaluation

- Awc Src3 Manual. 1Document5 pagesAwc Src3 Manual. 1ghionoiucPas encore d'évaluation

- SR Suntour XC Pro Forks Instructions ManualDocument8 pagesSR Suntour XC Pro Forks Instructions Manual110972ryanPas encore d'évaluation

- DM FC0003 03 EngDocument15 pagesDM FC0003 03 EngJosko SpehPas encore d'évaluation

- Sturmey Archer Hub TechnicalDocument8 pagesSturmey Archer Hub TechnicalbobnunleyPas encore d'évaluation

- Change Procedure of Hub BearingsDocument4 pagesChange Procedure of Hub BearingsRadu DumbravaPas encore d'évaluation

- SI F920A ShimanoDocument7 pagesSI F920A ShimanoolligesPas encore d'évaluation

- 2 Gear LinkageGolf Mk1Document46 pages2 Gear LinkageGolf Mk1SteggosPas encore d'évaluation

- Alfa Alfasud 1.3 PDFDocument50 pagesAlfa Alfasud 1.3 PDFnubercard6111100% (1)

- Steering Axle: Safety Precautions Maintenance and RepairDocument9 pagesSteering Axle: Safety Precautions Maintenance and RepairPhilip Peter HanssenPas encore d'évaluation

- Fitting Instructions For RTC3176 Adjuster Shoes Drum Brake LAnd Rover SeriesDocument2 pagesFitting Instructions For RTC3176 Adjuster Shoes Drum Brake LAnd Rover SeriesALP1981100% (1)

- CB E110 enDocument1 pageCB E110 enandPas encore d'évaluation

- ProLIGHT 2000 Maintenance ManualDocument19 pagesProLIGHT 2000 Maintenance ManualmegclayPas encore d'évaluation

- Traxxas Revo Slipper RebuildDocument1 pageTraxxas Revo Slipper RebuildbernadysrosePas encore d'évaluation

- Avid User Manual Bb7Document2 pagesAvid User Manual Bb7Elizabeth Soares BournePas encore d'évaluation

- SI-0087A-001-ENG - v1 - m56577569830657743 Technical Service InstructionsDocument1 pageSI-0087A-001-ENG - v1 - m56577569830657743 Technical Service InstructionsIngrid VantaPas encore d'évaluation

- ATV Clutch Setups V6.7Document16 pagesATV Clutch Setups V6.7Luis BaracchiPas encore d'évaluation

- WJ 3 Inch Lift InstallDocument3 pagesWJ 3 Inch Lift InstallGuillePas encore d'évaluation

- Shimano WH R 600Document1 pageShimano WH R 600AHSetiawanPas encore d'évaluation

- Shimano Brake ManualDocument1 pageShimano Brake ManualscozansPas encore d'évaluation

- MitzuDocument2 pagesMitzuLuis Fabio Aguilar MontoyaPas encore d'évaluation

- Sequential Shifter Fitting Instructions v2 A4Document17 pagesSequential Shifter Fitting Instructions v2 A4Ufix FabricationPas encore d'évaluation

- 01 Rock Shox Judy Owners ManualDocument7 pages01 Rock Shox Judy Owners ManualakjasonPas encore d'évaluation

- 2012 GTR ManualDocument21 pages2012 GTR ManualAkrae Acr0% (1)

- Startrac Spinner Chain MaintenanceDocument5 pagesStartrac Spinner Chain Maintenanceu795992Pas encore d'évaluation

- Joplin Instructions SeatpostDocument2 pagesJoplin Instructions Seatpostlaboratorio_iessigloxxiPas encore d'évaluation

- Enfield Bullet Workshop Manual 2000 2 PDFDocument53 pagesEnfield Bullet Workshop Manual 2000 2 PDFsivakumar natarajanPas encore d'évaluation

- Track Chain Removal and AssemblyDocument12 pagesTrack Chain Removal and AssemblyAaron MulengaPas encore d'évaluation

- VDL Service ManualDocument13 pagesVDL Service ManualSergio Martín BrionesPas encore d'évaluation

- DM Cn0001 00 Eng (Cadena)Document8 pagesDM Cn0001 00 Eng (Cadena)Mauricio Isaias LargaespadaPas encore d'évaluation

- Shimano Inter-M BR-IM31-R Brakes Service InstructionsDocument1 pageShimano Inter-M BR-IM31-R Brakes Service InstructionsJon_Bramley_3524Pas encore d'évaluation

- EN Pilot-XPDocument6 pagesEN Pilot-XProssandcoPas encore d'évaluation

- SI 3TF0A 001 00 Eng - v1 - m56577569830732611Document1 pageSI 3TF0A 001 00 Eng - v1 - m56577569830732611Yutt WattPas encore d'évaluation

- Manual Mantenimiento Mission 40Document8 pagesManual Mantenimiento Mission 40Daygor Martinez SabucoPas encore d'évaluation

- CSC:361-Software Engineering: Semester: Fall2020Document39 pagesCSC:361-Software Engineering: Semester: Fall2020hamsfayyazPas encore d'évaluation

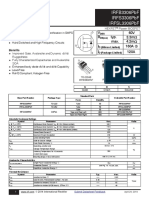

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 pagesIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligPas encore d'évaluation

- Chord Tone Improvisation Part IDocument38 pagesChord Tone Improvisation Part I2018 01097Pas encore d'évaluation

- The Number MysteriesDocument3 pagesThe Number Mysterieskothari080903Pas encore d'évaluation

- Anue 3500 Qrs - 0Document2 pagesAnue 3500 Qrs - 0ullascsPas encore d'évaluation

- Redox TitrationDocument5 pagesRedox TitrationchristinaPas encore d'évaluation

- Watchgas AirWatch MK1.0 Vs MK1.2Document9 pagesWatchgas AirWatch MK1.0 Vs MK1.2elliotmoralesPas encore d'évaluation

- CH 1 Optical Fiber Introduction - 2Document18 pagesCH 1 Optical Fiber Introduction - 2Krishna Prasad PheluPas encore d'évaluation

- Therapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Document11 pagesTherapeutic EffectsofWhole-BodyDevices Applying Pulsed Electromagnetic Fields (PEMF)Jeroan MonteiroPas encore d'évaluation

- PRD Doc Pro 3201-00001 Sen Ain V31Document10 pagesPRD Doc Pro 3201-00001 Sen Ain V31rudybestyjPas encore d'évaluation

- Pile FoundationDocument38 pagesPile FoundationChowdhury PriodeepPas encore d'évaluation

- Data Mining ConceptsDocument175 pagesData Mining ConceptsNikolya SmirnoffPas encore d'évaluation

- 02 WholeDocument344 pages02 WholeedithgclemonsPas encore d'évaluation

- Orthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Document30 pagesOrthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Uma MageshwariPas encore d'évaluation

- Notes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFDocument9 pagesNotes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFRahul ChauhanPas encore d'évaluation

- Air Movements 06-26-2019 - Full ScoreDocument5 pagesAir Movements 06-26-2019 - Full ScoreMichael CrawfordPas encore d'évaluation

- Data and Specifications: HMR Regulated MotorsDocument21 pagesData and Specifications: HMR Regulated MotorsBeniamin KowollPas encore d'évaluation

- Class - B Complementary Symmetry Power AmplifierDocument3 pagesClass - B Complementary Symmetry Power AmplifierAnonymous SH0A20Pas encore d'évaluation

- Cópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersDocument6 pagesCópia de Teste Excel - Intermediário (5166) .XLS: BIM Technology For EngineersFernanda AzevedoPas encore d'évaluation

- Cep MPDocument1 pageCep MPAzmat HabeebPas encore d'évaluation

- Student - The Passive Voice Without AnswersDocument5 pagesStudent - The Passive Voice Without AnswersMichellePas encore d'évaluation

- Exploring Music ContentsDocument370 pagesExploring Music ContentsRoby SamboraPas encore d'évaluation

- DCM-I&II Lab Equipments ListDocument2 pagesDCM-I&II Lab Equipments ListPrashant ChinamalliPas encore d'évaluation

- 1400 CFM TDocument3 pages1400 CFM TmahmadwasiPas encore d'évaluation

- The Library of Babel - WikipediaDocument35 pagesThe Library of Babel - WikipediaNeethu JosephPas encore d'évaluation

- Dual Inverter Gate: Features DescriptionDocument19 pagesDual Inverter Gate: Features DescriptionYaju JotosPas encore d'évaluation

- The SphereDocument9 pagesThe SpherePast Buanget100% (1)

- Tech Specs - TC 5540 PDFDocument2 pagesTech Specs - TC 5540 PDFziaarkiplanPas encore d'évaluation

- Icf 7 Module First YearDocument180 pagesIcf 7 Module First YearMarvin PanlilioPas encore d'évaluation

- Entropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6Document14 pagesEntropy and The Second Law of Thermodynamics Disorder and The Unavailability of Energy 6HarishChoudharyPas encore d'évaluation